tft display interface with 8051 brands

The display is a critical component in every project, impacting the case, firmware, electrical design, user interface, and even battery life. For these reasons, and because it is the most visible component of your product, it must be approved by the mechanical design team, management and marketing.Before these teams can approve, they need to see it in action. But it can take days or weeks to connect a display to your platform, initialize it and build a code library able to create believable demonstrations. Meanwhile, the whole project is on hold.Our 8051 development kit / demonstration board can solve this problem. Use it to get the display seen, demonstrated and approved for your project.

ER-DBTM080-2 is a microcontroller 8051(80C51) demonstration and development kit for ER-TFTM080-2 product that is 8 inch tft lcd display with RA8875 controller board.The kit includes MCU board controlled by STC12LE5A60S2,ISP(In System Programming) with USB port and cable to customize the demonstration that includes your own bitmap images,personalized fonts,symbols,icons and burn sketches,microSD card that is written graphic and text into it,the power adaptor,the adaptor board with various pitch dimension used to connect MCU board and display.Optional for 8080 8/16-bit,6800 8/16-bit parallel interface and I2C,3-wire,4-wire serial interface.

The display is a critical component in every project, impacting the case, firmware, electrical design, user interface, and even battery life. For these reasons, and because it is the most visible component of your product, it must be approved by the mechanical design team, management and marketing.Before these teams can approve, they need to see it in action. But it can take days or weeks to connect a display to your platform, initialize it and build a code library able to create believable demonstrations. Meanwhile, the whole project is on hold.Our 8051 development kit / demonstration board can solve this problem. Use it to get the display seen, demonstrated and approved for your project.

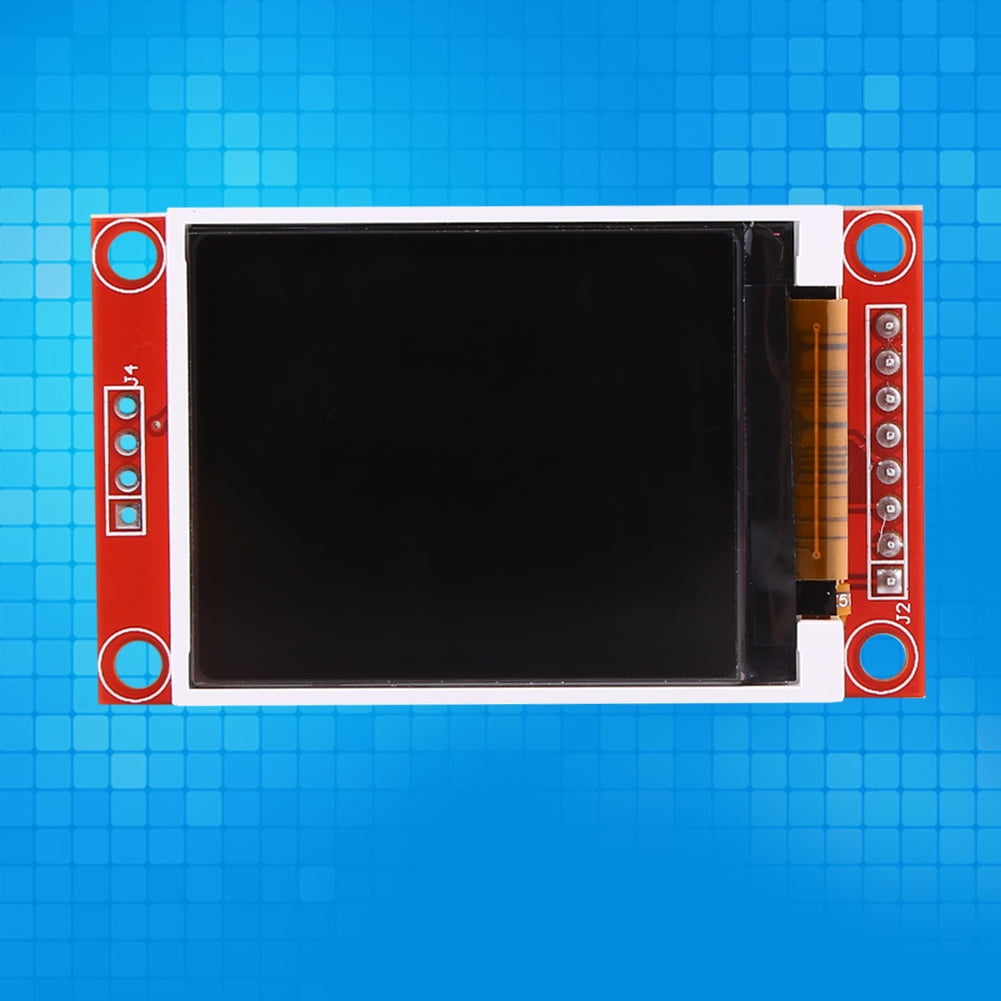

ER-DBT028-4 is a microcontroller 8051(80C51) demonstration and development kit for 2.8 inch tft lcd display with ILI9341 controller.The kit includes MCU board controlled by STC12LE5A60S2,ISP(In System Programming) with USB port and cable to customize the demonstration that includes your own bitmap images,personalized fonts,symbols,icons and burn sketches,microSD card that is written graphic and text into it,the power adaptor,the adaptor board with various pitch dimension used to connect MCU board and display.Optional for 8080 8-bit,8080 16-bit parallel interface and 3-wire,4-wire serial interface.

A display interface that is common for TFT displays is the combination of the 3-wire Serial Peripheral Interface (SPI) and the 16/18/24-bit RGB parallel interface. The two interfaces are used in a sequence to communicate data to the display. This note will discuss how to set up a display using the 3-wire SPI+24-bit RGB parallel interface.

The 3-wire Serial Peripheral Interface (SPI) and the 16/18/24-bit RGB parallel interface are used in a sequence to communicate data to the display. The SPI interface is first used to initialize the display parameters through command registers. Once initialized, the display can receive data over the RGB parallel interface at a higher speed. This data can be sent in segments of 16, 18 or 24-bit lengths depending on what is specified by the SPI initialization commands.

The display used in this application note is a 3” TFT with 854x480 pixels. This display has high resolution and high color which requires a faster interface so the pixel clock can maintain a 60Hz frame rate. The part number for this display is E30RA-FW400-N. Details of this display are described below.

The display is connected to a graphics controller over a 24 parallel data bus and the display’s signaling pins. A graphics controller is used in addition to a microcontroller to provide the high-speed clock signal required to support this resolution and color depth. The connections to the graphics controller in the following table can be changed to connect to a single microcontroller, if the device has RGB parallel dedicated pins. The minimum requirement of RAM reserved for the frame buffer is calculated as (480 pixels x 854 pixels x 24bits/pp) 1.23 MB which will need to be provided by the microcontroller, graphics controller or external memory.

There are 45 pins that are required to be connected to the graphics controller. This includes the 3-wire SPI interface pins and the 24-bit parallel RGB data pins. This display is operated at a low voltage of 3.3V which can be provided by the microcontroller. The display has an additional feature of IPS view, and a bright backlight operated at 19.2V. The backlight voltage will need to be provided externally to the display. Below are the pin functions and connections between the display and the controller.

The serial interface clock is run at a lower frequency of 2Mhz. This frequency was chosen to maintain signal integrity and can be changed to any value between 1-15Mhz for this controller. At higher frequencies, noise can become a factor and create errors when sending commands and data. Since the SPI interface is only used to send 8-bit commands to initialize the display, it does not require a high frequency clock. This makes it possible for a basic microcontroller to provide these signals without the use of the graphics controller.

The DCLK signal is determined by the resolution, porch settings of the HSYNC and VSYNC signals and the frame rate of the display. The frame rate is standard at 60Hz, which is the minimum frequency to maintain an image. The timing parameters of the HSYNC and VSYNC signals are specified by the controller. Below are the timing parameters specified in the ST7701S datasheet and the displays datasheet.

The total HSYNC period for this display is calculated as the total time in DCLKs for one line, including the time where the pixels are not active. In this example, this value is calculated to be 480+50+10+2=542 DCLKs. The total VSYNC period for one frame of pixels to be displayed is calculated in the number of lines. The total time it takes for one frame of pixels is 854+30+10+2=896 lines.

The dot clock (DCLK) signal is determined by these two totals and the frame rate in order to maintain the image at 60Hz. The calculation of the DCLK signal is as follows: 542 x 896 x 60 = 29Mhz. This is a high clock speed for the RGB interface. The maximum clock speed for the RGB parallel interface with this controller is 33MHz. Certain steps should be taken to reduce noise on this signal to ensure reliability of the data transmitted.

The 3-wire SPI interface is used to send 8-bit commands and data to initialize the display. Each of these commands can be found in the specification sheet for the display’s embedded controller IC ST7701S. These commands specify the selection of color format, resolution, timing parameters and power control. There are a few ways to send these commands to the display.

Most microcontrollers offer dedicated SPI interface pins for the SPI protocol. There are many code repositories available for the SPI interface so there are many options for sending these commands and data. In this application, the SCL clock signal is set at 2MHz. This lower frequency was chosen over a maximum frequency of 15MHz to ensure proper signal timing and to avoid noise. Since the SPI interface is used for a brief initialization period, high speed is not required.

Another way is to use any digital pins available and “bit-bang” the information. This is when the clock and data pins are signaled on and off in the right sequence to communicate the data. This is done when there are not specific SPI pins available. This is common with the 8051 microcontrollers where most ARM and AVR microcontrollers have an SPI interface. This option has the benefit of control over whether the data is set at the rising or falling edge of the clock signal. This can be different for each display that uses the SPI interface for initialization, so it is important to confirm in the data sheet.

SPI initialization commands for the 24-bit parallel RGB interface can be found here. These commands set many functions of the display such as: timing constraints for the RGB interface, color depth, resolution, and voltage control.

This application uses a graphics controller to increase the clock speed and provide memory. If the microcontroller is providing the RGB function to the display, then this step can be skipped. The graphics controller used in this application is SSD1963. This graphics controller provides the memory for the frame buffer of the display. The DCLK signal is also generated by this controller to an RGB PLL setting of 29MHz.

The RGB interface pins are connected to the graphics controller in parallel. This application uses the 24-bit interface so all 24 data bus pins must be connected to the controller. The HSYNC, VSYNC, DE and DCLK pins are also connected to this controller. The graphics controller is controlled by commands over a 16-bit parallel MCU interface. These pins will need to be connected to the microcontroller to send the initialization commands as well as the data that will be projected on the display.

The initialization of the graphics controller will specify the desired DCLK speed that is needed for the RGB interface. These commands are sent by the microcontroller in sequences of 8-bits. Because the commands are 8-bits, it is possible to send the data over an 8-bit parallel interface. The commands that are used to initialize the graphics controller are reviewed in the data sheet of the IC SSD1963. The commands that were used to initialize the graphics controller can be found here.

The RGB interface can now be used to transmit data to the display. The serial interface no longer needs to be used after initialization is complete. Now the 24 RGB data pins will send the 24-bits of RGB data per clock cycle. The data in this example is processed at 24bpp. This means that each pixel will have 24-bits of information for the color depth and that the display is capable of 24 million different color variations.

A brief example of how to display colors on the display will be reviewed. Displaying colors onto the screen requires sending 24-bit color data to each of the visible pixels in the display area. This can be done by writing to each location in RAM where every pixel is stored and telling it which color you have selected. This application can be used to portray bitmap pictures through the same process.

The example used to write to RAM stored on the SSD1963 controller can be found here. This process is done using the command “memory write” (0x2c) of the graphics controller for each of the pixels on the display. The colors can be sent in 6-digit, 24-bit sequences and decoded or as three 8-bit sequences representing one for each of the red, green, and blue components of the color. Below the color will be sent as components of the RGB color in three steps on eight bits to the graphics controller. The image above shows how the 24-bit data is sent to the graphics controller in sequences of 16-bits.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

This lovely little display breakout is the best way to add a small, colorful, and bright display to any project. Since the 2.0-inch SPI TFT LCD Color Screen Module display uses 4-wire SPI to communicate and has its own pixel-addressable frame buffer, it can be used with every kind of microcontroller. Even a very small one with low memory and few pins available. The 2.0″ display has 176×220 color pixels. Unlike the low-cost “Nokia 6110” and similar LCD displays, which are CSTN type and thus have poor color and slow refresh, this display is a true TFT! The TFT driver (ILI9225) can display full 18-bit color (262,144 shades!). And the LCD will always come with the same driver chip so there are no worries that your code will not work from one to the other. The breakout has the TFT display soldered on (it uses a delicate flex-circuit connector) as well as an ultra-low-dropout 3.3V regulator and a 3/5V level shifter so you can use it with 3.3V or 5V power and logic. We also had a little space so we placed a microSD card holder so you can easily load full color bitmaps from a FAT16/FAT32 formatted microSD card.

ST cooperates with Riverdi because we believe that such partnership brings value to our joint customers. On top of this, we also discovered that we shared some business visions about how to make it easier and faster to go from the initial stages of designing a product embedding a graphical user interface to a production ready product. The conclusion was that combining the STM32 High performance microcontrollers, with the free STM32 graphics toolchain and Riverdi displays + PCB and then merge all of this into a board support package ready to run TouchGFX, would be a compelling offering.

Designing and developing a product with an embedded user interface (GUI), can be complex, as it involves many building block and disciplines, which all requires expert knowledge. Riverdi offer is covering a lot of them, allowing the customer to focus on the most important part of the development, the GUI Application itself. And remember that this is the face of your product. Choosing such solution, the customer does not need to worry about sourcing components like the display, microcontrollers, memory, etc. or even writing low-level drivers, development the board support package or porting TouchGFX. Its all ready done. What makes cooperation with Riverdi unique is that Riverdi has been able to drive a 1280*800 display resolution in high colors, with a STM32H7 microcontroller and a TouchGFX application showing a smart home UI. This shows that Riverdi is well aware of how to exploit all the capabilities of the STM32 Graphics offering combining hardware and software in a unique solution. From the first business meetings, it was clear that we shared visions of the market for embedded GUIs. And Riverdi proved that they can go from an idea and concept to actual working hardware, very fast.

I have a small 3.5 in TFT LCD display from a Chinese manufacturer. It doesn"t have an integrated LCD controller. The documentation claims it is a "16 bit RGB/parallel interface" and it uses a Renesas R61581B0 driver chip.

These types of displays are very common and cheap. They sell for less than $15 a pop on Alibaba.com, but I don"t really have a high esteem for these manufacturers since they do not provide any good / consistent documentation, and their English is riddled with mistakes! But I did get the display, and the product looks and feels like it will do the job!

My question now is, how do I get started ? I have looked on the internet and cannot find a good starting point. I have a 32MHz microcontroller in mind, but I am stumped on how to interface it with the LCD.

Most display projects online that I"ve seen assume that the LCD module comes with an integrated controller , so the MCU"s job becomes pretty simple.. Provide image updates when necessary, and the controller will do the job of refreshing the LCD module at the required 60hz (or so)

This LCD module that I have has raw data lanes that I need to drive myself at 60hz. Are there any good documents on how to interface an MCU directly with such an LCD module?

I"ll be happy with any info that points me in the right direction, whether it be an answer on stackexchange or a reference to any good documentation online.

Searching for the best TFT LCD module manufacturers in India? Well, that is admittedly a daunting task. With the growing number of TFT LCD display suppliers and manufacturers, it’s truly hard to pick which ones are reputable and which ones are not.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

There is also a downloadable design software called STONE Designer. This is a completely free GUI design software you can use to create responsive digital module-ready user interfaces.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and a consumer’s mindset.

Hence, we’ve rounded up 7 famous and reputable Indian LCD module manufacturers. These companies all produce quality display and screen-related products such as:

Videocon Industries Ltd is a well-known Indian manufacturer of TFT display modules, color TVs, home appliances, and consumer electronics. Videocon is a large company based in Mumbai, India.

The company takes pride in being India’s pioneer in color TV production and retail. Before the advent of the TFT display module, Videocon has been the world’s third-largest picture tube (CRT) manufacturer.

Videocon is popular for its high-quality products. Videocon manufactures an LCD display screen for LCD TV sets. A lot of Indians trust Videocon’s television sets.

Videocon assembles and manufactures their TFT LCD module products in world-class factories. The company’s main factories are in India. However, they also have manufacturing plants in Mainland China, Mexico, Poland, and Italy.

All of Videocon’s TFT LCD display products passed strict quality control checks. Testing is done throughout the entire manufacturing and assembly process. Furthermore, quality checks are done from the raw materials phase until the products’ release.

Videocon’s TFT display screens and TVs are affordable of good quality. The company knows how to manufacture quality TV sets at pocket-friendly prices since it is a pioneer in the Indian color TV industry.

Videocon’s mobile phone range is equipped with the latest touch LCD display technology. Smartphones are assembled in the company’s TFT touch screen factory. Hence, customers are ensured of high-performance mobile phones with a crisp touch screen LCD display.

To sum it up, Videocon Industries Limited is a strong TFT LCD display manufacturer. The company’s quality manufacturing plants, good end-products, and affordable prices make it among the famous TF LCD manufacturers in India.

Teronix is an Indian electronics company based in New Delhi. It specializes in TV sets with LED and LCD screen module technology. The company also offers a range of smart mobiles and power banks.

The company’s products are all high-quality and durable. Teronix sees to it that its range of smart LCD and LED TVs, along with their other products, reach their customers in good condition, and perform at their best all the time.

Teronix knows that good quality LCD module and other electronic parts are the cores of high-performance products. Hence, their assembly and product research units are stocked with the latest technology to produce the best possible products. Furthermore, Teronix’s research and assembly hubs are strategically located in Delhi.

Special teams are assigned to run quality control tests for all of Teronix’s products. Tests are done before and after launch to ensure that their LED TV range and power banks are all working well with no defects. Also, Teronix has a minimum quality test duration of 3 years.

The company started manufacturing televisions and telecom equipment in the 1980s. BPL joined forces with Japanese company Sanyo in 2006 to strengthen BPL’s consumer electronics brand, including TF-LCD display products and color televisions. The joint venture ended in 2007, leaving BPL to focus on its healthcare equipment sector.

1. BPL takes pride in its superior-quality television sets. The TVs are made with combinations of TFT-LCD display and LED output. The products are manufactured by third-party TFT LCD suppliers. Then, the TV parts are assembled at a plant in Baddi, Himachal Pradesh.

2. BPL also takes the lead when it comes to medical display equipment. BPL uses different combinations of TFT display, VGA output, LED, and touch LCD display to manufacture the following devices:

3. The company upholds strict quality standards in all TFT LCD display products. This is achieved through quality tests at all stages of production and assembly. Even the third-party suppliers providing the raw materials for TFT-LCD modules are required to run through tests to ensure quality.

In a nutshell, BPL continues to be an industry leader in India’s consumer electronics and medical equipment industries. BPL provides households and health facilities with top-notch TFT-LCD display module sets used in televisions and health monitoring equipment. And in recent years, BPL has clearly shown no signs of slowing down.

Dixon Technologies Limited is a long-standing company providing consumer electronics, LED and LCD TVs, light fixtures, appliances, mobile phones, and CCTV systems. The company was founded in 1993 with its current headquarters in New Delhi and Uttar Pradesh.

Dixon’s creed is providing consumers with world-class products at affordable prices. Consequently, the company is among the top TFT LCD manufacturers in India because:

Dixon is proud to create its products in local factories. For instance, the company has an LCD display module factoryin Tirupati, Andhra Pradesh. Furthermore, the company also operates three facilities in Uttarakhand and three more in Noida, Uttar Pradesh.

Reasonable prices also make Dixon’s LCD module products and TVs appealing to the public. Couple that with features that are on par with the world’s best TV sets. Dixon believes that quality shouldn’t be sacrificed at the expense of affordability.

In conclusion, Dixon Technologies (India) Limited is among India’s famous TFT LCD manufacturers simply because it provides original, feature-packed, high-quality, and pocket-friendly products to both tech companies and end-consumers.

Oriole Electronics is an electronics company based in Mumbai. It was established in 1972 and is among the famous long-standing TFT LCD manufacturers in India.

Oriole’s strongest quality lies in its extensive experience in the TFT LCD and electronics industry. The company’s experience puts them at an edge against many younger industry competitors. All these thanks to several insights and expertise the company collected since 1972.

Furthermore, Oriole is dedicated to meeting its client’s needs as much as it can. The company partners with its customers throughout the product cycle, making sure that client inputs are incorporated into the products’ final design and functionality. This type of customer partnership uniquely reflects Oriole’s commitment to creating products that truly meet its customers’ various needs.

Another Oriole advantage is its in-house Research and Development team. Oriole’s R&D team conceptualizes products for its customers. They also formulate quality control guidelines that are strictly implemented during the production and testing phases. All these things are done to ensure the highest quality of Oriole’s TFT, LCD modules, and other product ranges.

Speaking of quality, Oriole is also ISO 9001:2008 certified. This credential ultimately proves the company’s utmost dedication to quality processes. Also, this ensures consistent operations of Oriole’s TFT LCD display factory network throughout India.

To wrap it all up, Oriole Electronics is indeed a quality display module manufacturer in India. Superior quality products, customized services, and affordable rates – all of these are testaments to Oriole’s good reputation.

RandServ proudly provides and even encourages custom manufacturing services. The company responds to unique client needs by creating LCD display modules and designs according to customer requirements. RandServ lets clients specify custom shapes, display sizes, and interactive touch support integration.

Another good point of RandServ is its superior-quality product range. The company may be new to the industry, but its products are made with world-class technology and attention to detail. RandServ’s electronic, TFT, LCD, and LED technologies make their end-products among the most long-lasting and robust electronic/digital products in the Indian market today.

In conclusion, RandServ Systems deserves a spot in our 7 famous TFT LCD manufacturers list mainly because of three things – cutting-edge LCD and digital products, customized client services, and high regard for ethical business practices.

Royal Display India is a reputable TFT display supplier and manufacturer based in Mumbai. Royal Display is relatively new, being in the business since 2003. But the company didn’t let their newness stop them from growing into a successful LCD display supplier and manufacturer.

A major factor that Royal Display holds in regard is value for money. The company keeps this in mind when creating and supplying display modules to their clients. Furthermore, Royal Display firmly believes that people need not shell out several bucks to get world-class quality products.

Another considerable advantage of Royal Display is its spacious manufacturing and warehousing units. Both are located in Maharashtra. The manufacturing unit boasts of specialized techniques used to produce modules for TFT, LCD, and OLED. Meanwhile, the warehouse unit is large enough to accommodate bulk orders from clients.

To wind this up, Royal Display is a young yet quality manufacturer for LCD modules and other related display screens in India. The company continues to grow with its plethora of quality display products coupled with many satisfied clients.

To conclude this post, we’ve rounded up 7 Famous TFT LCD Manufacturers in India. Some of them are industry pioneers, while some are novices. However, we’re sure all these reputable companies will be a good source of products for all your display module needs.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

SainSmart 3.2" TFT LCD Displayis a LCD touch screen module. It has 40pins interface and SD card and Flash reader design. It is a powerful and mutilfunctional module for your project.The Screen include a controller SSD1289, it"s a support 8/16bit data interface , easy to drive by many MCU like STM32 ,AVR and 8051. It is designed with a touch controller in it . The touch IC is ADS7843 , and touch interface is included in the 40 pins breakout. It is the version of product only with touch screen and touch controller.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey