transparent touch screen monitor for sale price

[av_row row_style=” av_uid=’av-18boerj’][av_cell col_style=” av_uid=’av-15psztb’]Screen size[/av_cell][av_cell col_style=” av_uid=’av-14hfcdr’]10 inch to 86 inch[/av_cell][/av_row]

[av_row row_style=” av_uid=’av-x8yudb’][av_cell col_style=” av_uid=’av-wy6gvz’]Touch screen[/av_cell][av_cell col_style=” av_uid=’av-33v9sf’]Optional[/av_cell][/av_row]

It’s a kind of computer display monitor which you can see through it when it’s working. It has several names, such as transparent screen, see through monitor and so on.

The transparent monitor is made by the transparent LCD screen. If you want to see through it when it’s working, there is an essential condition. That is the monitor needs to work with the bright white backlight. If there is not the backlight, the screen would be dark and you can see nothing from it.

The transparent monitor is widely used in many applications, such as vending machine, retail windows, LCD display box, video wall and many more. It has lots of custom parameters, such as the size, resolution, function and so on. Plenty of applications use such monitor with the touch screen.

The transparent monitor has many details that you need to pay attention to, for example the size, resolution, touch screen and so on. If you want to buy such product, what you need most is to find a professional supplier. The professional supplier can provide the prefect transparent monitors with the best quality and pretty price.

The size of commonly used transparent monitor can be from 10” to 110”. Full sizes of monitors can meet your any applications. There are some special monitors in the market, such as the stretched bar. It’s a kind of bar type monitor. If you need the bar type transparent monitor, such as 1/2 32”, please feel free to contact us first.

The resolution is also an important factor when you prepare to buy the transparent monitor. The commonly used resolution is 1920×1080( FHD ). However the resolution is always related to the screen size. For example, the commonly used resolution of 15” monitor is 1024 x 768, but the commonly used resolution of 15.4” monitor is 1920×1080.

Some clients told us that they needed some 24” transparent monitors to replace their common desktop computer monitors. Some other clients told us their applications need to use 17” transparent monitors and the users could see each other from both sides of the monitor screen.

The sizes of LCD monitors can be from 10” to 110”, so you have full freedom to select the right size of such transparent monitor for your application. However, as we mentioned at the beginning of the article, it need to work with the backlight system.

The backlight is the most confusing and easily overlooked point. Plenty of clients don’t know that transparent monitor needs the backlight. Many clients tell us that they need a 15 inch see through monitor to replace the monitor of their laptop. In fact, it’s impossible, unless it’s OLED screen. However, there isn’t 15” OLED screen which is transparent in the market.

The backlight is essential when the transparent monitor is working. If not, the whole monitor screen would be dark and you can see nothing. The backlight is placed in the back of the screen. It can be at the top or at the bottom. It can also be on 4 sides. The only condition is that it needs to be bright enough and the color temperature of the light should to be about 6000K (pure white).

Control board: it’s essential for the monitor. It’s used to connect the computer and drive the screen. It has many interfaces, such as HDMI, VGA ,DVI and others. The computer monitor is not the only function of transparent monitor. Use different control board, the functions would also different. For details, please read the chapter 8.

Enclosure : for most of the monitors, the enclosures are essential, especially for the big size monitors. They are used to hold the screens and protect them in the process of moving and using.

Touch screen: it’s optional. Many clients need the touch screen function, but others don’t need. The most commonly used touch screens are the capacitive touch screen and IR touch screen. For the details, please read the next chapter.

Glass: it’s used to protect the monitor screen. The glasses are installed on one surface or both surfaces of the screen. The monitor screen is very easy to be damaged, caused by the thickness is just 1.4mm. The commonly used glass is the tempered glass which the thickness is from 4mm to 6mm.

[av_heading heading=’Chapter 7: Touch screen’ tag=’h2′ link_apply=” link=’manually,http://’ link_target=” style=” size=” subheading_active=” subheading_size=’15’ margin=” margin_sync=’true’ padding=’10’ color=” custom_font=” av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” av_uid=’av-kmyag72w’ custom_class=” admin_preview_bg=”][/av_heading]

Although the touch screen is optional, lots of transparent monitors are used with the touch screens. The monitor with touch screen is interactive. The customers can use their fingers to tell the machines what they want to do next. For the transparent monitor, there are two kinds of commonly used touch screens. They are capacitive touch screen and infrared touch screen.

The capacitive touch screen is transparent and frameless. The thickness is just about 2 mm. The IR touch screen has the frame, but the quality is more stable for large size and its price is better than the capacitive touch screen.

For small size transparent monitor, you can use either of them. For middle size monitor and large size monitor, the IR touch screen is more popular. We recommend to use the IR touch screen, because it’s strong and easy to be installed.

[av_image src=’https://gecey.com/wp-content/uploads/2020/04/Capacitive-touch-screen-300×242.png’ attachment=’7320′ attachment_size=’medium’ align=’center’ styling=” hover=” link=” target=” caption=” font_size=” appearance=” overlay_opacity=’0.4′ overlay_color=’#000000′ overlay_text_color=’#ffffff’ copyright=” animation=’no-animation’ av_uid=’av-4kob7cv’ custom_class=” admin_preview_bg=”][/av_image]

[av_image src=’https://gecey.com/wp-content/uploads/2020/04/IR-touch-screen-300×242.png’ attachment=’7321′ attachment_size=’medium’ align=’center’ styling=” hover=” link=” target=” caption=” font_size=” appearance=” overlay_opacity=’0.4′ overlay_color=’#000000′ overlay_text_color=’#ffffff’ copyright=” animation=’no-animation’ av_uid=’av-4kob7cv’ custom_class=” admin_preview_bg=”][/av_image]

The control board is essential for the transparent monitor. According to the function, the controllers can be divided into two types. The first type is widely used in various computer monitors. Its function is very simple. It just can be connected to the computer and drive the screen to display the videos, pictures and others.

Fist of all, as we have mentioned at the beginning of the article, you need to provide the backlight for the transparent monitor. Usually, the clients buy the transparent monitors from us, then install them to their machines or equipments. Their machines can provide the backlight for the monitor.

This is a very interesting question. Plenty of clients think that they can see through the transparent monitor from both sides. However, it’s not the truth. You can just see through it from the front of the screen and it’s impossible from the back. This is one of the disadvantages of such product.

The display box is used to show the best products. The customers can see through the monitor to take a close look at the attractive products and read the detail introductions on screen. The box can just use a transparent monitor on one side, or two monitors which are back to back on two sides, or on all four sides.

Vending machine is one of the most popular applications. Plenty of clients buy the transparent monitors and the IR touch screens to make the doors of the machines. The clients can see the products through the door and select what they want to purchase.

The touch screen is very convenient for them to choose the drinks, foods and others. Vending machine is very common in our daily life. You can see them in the parks, super markets, hotels and other places.

The video wall is consisted of several pieces of transparent monitors. People can not only look at the exhibits, but also read the introductions of them.

Science fiction has always served as a window into a potential future, namely in the way of technology. But what was once regulated to episodes of Star Trek is quickly becoming the stuff of reality. Many fixtures of these kinds of shows and books have begun to inspire real-life counterparts, including - but not limited to - touchscreen technology.

One only has to look at how far cell phones have come since their inception. Physical keyboards, like those from BlackBerry, gave people about as much of a solution as is possible for those who found themselves doing more on the devices as they became more advanced. Where tactile options came up short, touchscreens graciously stepped up to bat, providing a much fuller experience. This kind of functionality then spread to tablets, which are considered by many to be rivals of laptops and even standard PCs.

While there are still some things that are best done on a desktop computer, that does not change the fact that many users find themselves longing for the same abilities on their PCs afforded by many of their mobile devices. This is what helped breed the touchscreen monitor market, which has many viable options for people seeking the best of both worlds. With stronger computing power and a finer ability to control actions occurring in the screen, users can get more work done in new and exciting ways.

Traditionally, computer mice are what have allowed us to "touch" in a virtual context, but touchscreen monitors are changing all that. It might be said that the reason that mice were used in the first place was because the technology had not evolved to a responsive enough level to enable that natural solution. Now that people have the touchscreen technology, they want it everywhere.

If one thing is for certain, it is that the burgeoning adoption of touchscreen technology is no fad. Proliferation has already come too far to turn back now, and computer manufacturers are taking notice. Everyone is trying to get a piece of the action, including ELO Touch Solutions, Laiputuo Electronics, Planar, HP, 3M, Touch Systems, ViewSonic, Dell and ACER as well. Getting into the touchscreen monitor game is a no-brainer for the companies involved in this generation of computing. With so many different applications made for touchscreen monitors, options exist for all sorts of interested parties.

Touchscreen monitors are becoming the new standard in both private and enterprise settings. Here are some of the ways they can be leveraged effectively for business: touchscreen monitors for workstations, touchscreen monitors for hospitals, and touchscreen monitors for POS systems.

Newegg offers a large selection of touchscreen monitors which vary according to the type from 5-wire Resistive touchscreen monitors, and Accu Touch touchscreen monitors, to Capacitive touchscreen monitors, and more. Newegg’s wide selections will definitely meet your needs.

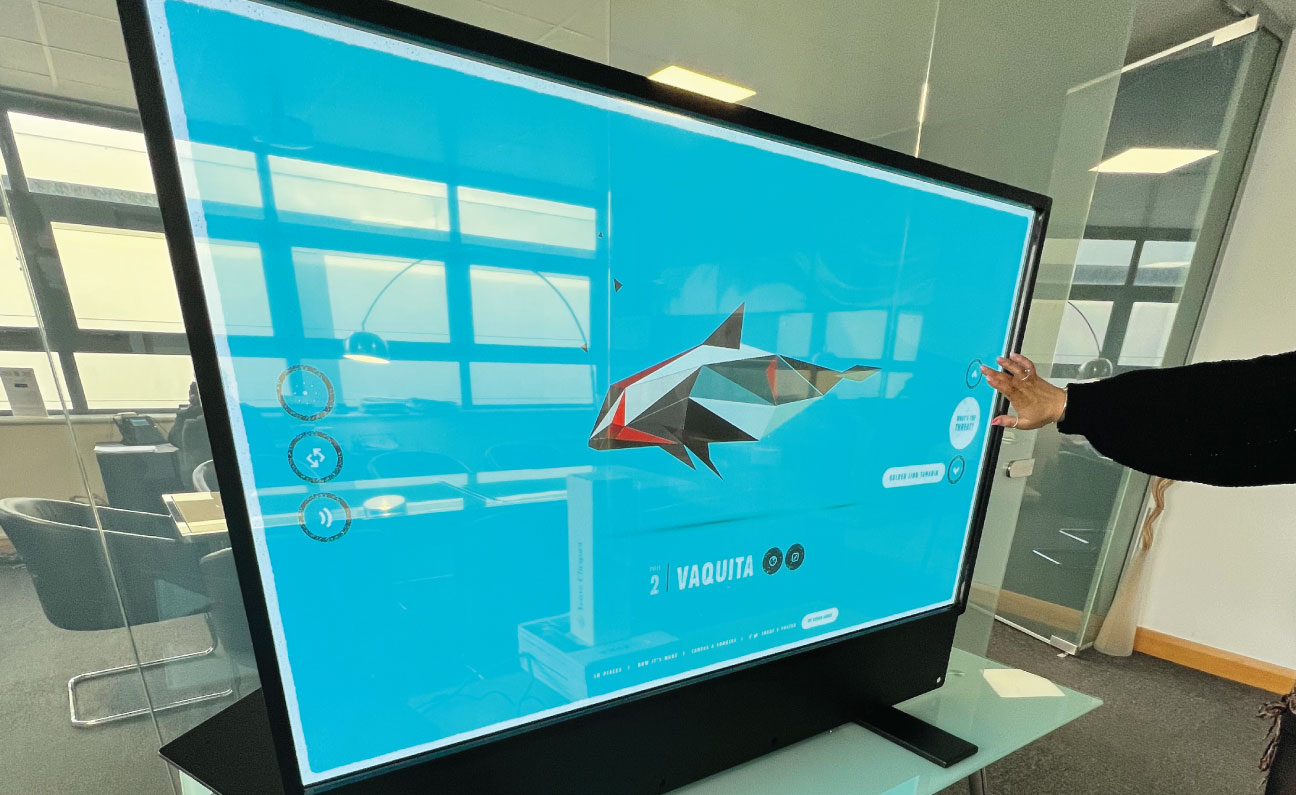

Transparent Touch Screens combine our Transparent LCD Displays along with a Touch Screen Overlay to create a screen with a difference. Transparent touch screens bring two innovative technologies together to create a cutting edge display that is hard to ignore. At its heart, the Transparent LCD screen delivers HD or 4K images (depending on screen size) just like a standard digital signage display whereas the IR or PCAP touch overlay provides a seamless multi-touch experience.

If you’re looking for a compelling and engaging solution that goes beyond the traditional touch display, a transparent touch screen is the answer. The key difference being that the display provides transparency – white content appears transparent and black content appears opaque while the full range of colours in between have semi-transparent properties that can be used to great creative effect with the content you design.

Transparent Touch Screens are often integrated into POP and POS displays for retail applications or in custom display cases for Museum, Exhibitions and Events. Display case housings are not always required however, as we’ve seen our Transparent LCD Touch Screens installed for Nike, instead using a high brightness LED light panel to support the content on screen rendering any additional surround unnecessary. This offers the potential to create modern, minimalist touchscreens and interactive totems designed for the future of user experience.

Farnborough Airshow is the world’s premier commercial and military trade event. Ouno’s brief was to present GKN’s innovative technologies in a standout way that builds on the established trade show format. Pro Display supplied its 65-inch multi-touch transparent LCD screen to live event specialists Ouno Creative. The holographic-effect interactive display showcases the latest jet engine products from Ouno’s client, GKN Aerospace

As with all LCD displays, colour is displayed using Red, Green and Blue pixels which are combined to display the final colour on screen. White content is displayed using an LED backlight behind the LCD display however with Transparent LCD technology, the backlight is removed which results in white content appearing transparent.

Add to that our Infrared or PCAP touch technology to allow viewers or presenters to interact with your content, and the result is a transparent touch screen that will attract, engage and entertain your audience like no other display solution!

We also offer alternative transparent touch screen technology including our Clearview Rear Projection Interactive Touch Foils, a transparent rear projection foil with through glass touch capabilities and our Interactive Transparent OLED, a high end transparent touch display with no requirement for backlighting and stunning HD 1080p image reproduction. We also offer an interactive switchable glass projection screen where the glass can be switched from frosted to clear on demand, giving touch screen glass a whole new meaning!

Our Transparent Touch Screens use IR (infrared) touch technology as standard to create interactive transparent displays. Infrared technology utilises an invisible grid system of light across the screen and as the screen is touched the grid is broken, therefore registering the touch on the screen.

Our standard Transparent Touch Screen Solution is our Interactive Transparent LCD, which requires backlighting and housing, with options for 4K UHD image resolution.

We can also offer our 55″ Transparent OLED screen with multi touch capabilities, providing a HD 1080p image with no backlighting or housing necessary.

For projection applications, our Clearview Interactive Projection Touch Foil can be applied to windows to create interactive window displays using through glass touch. For a more versatile screen solution our Interactive Switchable Glass Screens provide a HD/4K image canvas when turned off and a holo effect image when switched to clear.

Choosing the right Transparent Touch Screen is influenced by the screen size, lighting conditions and how you would like to use the screen. If the screen will be used as a product reveal, then our Transparent LCD’s or Smart Glass Touch Screens could be the ideal solution while our Transparent OLED’s are a popular choice which don’t require housing or a backlight.

If you’re creating an interactive window, our Clearview Rear Projection Touch Screen Foil is ideal, allowing customers to interact with the display while still allowing visibility into the store.

Transparent Touch Screens are a great way to combine physical and digital displays without one distracting from the other. They enable in-depth, layered displays that are more likely to leave lasting impressions on your audience.

Yes, our Transparent OLED’s can be made interactive. Our Interactive TOLEDs use infrared technology to offer captivating multi-touch displays that are perfect for museums, live events, conferences and much more.

We manufacture in Britain and ship worldwide – if you need further information, a pricing quote, or want to discuss ideas for using our Transparent Touch Screens click the link below to contact us, email us via info@prodisplay.com or call us on +44 (0)1226 361 306.

LCD Transparent Displays, transparent screens, transparent monitors, see through screens, transparent touch screen technology, and kits from CDS as we have our own range of transparent screens / displays and transparent video screens manufactured for us, and as we control the manufacturing, we can not only offer more sizes than anyone else in the world, but also guarantee stable supply, long term availability LCDs with amazing quality. We have replaced the Samsung Transparent Displays / see through Displays and LG Transparent OLEDs that are no longer available!

CDS has increased the use of these see through screens / see through displays / see through computer screens / clear monitors across the world including touchscreen computer screens combined with the transparent LCD touch screens and Transparent OLED displays.

A touchscreen or touch screen is the assembly of both an input ("touch panel") and output ("display") device. The touch panel is normally layered on the top of an electronic visual display of an information processing system. The display is often an LCD, AMOLED or OLED display while the system is usually use in laptop, tablet, or smartphone. A user can give input or control the information processing system through simple or multi-touch gestures by touching the screen with a special stylus or one or more fingers.zooming to increase the text size.

The touchscreen enables the user to interact directly with what is displayed, rather than using a mouse, touchpad, or other such devices (other than a stylus, which is optional for most modern touchscreens).

Touchscreens are common in devices such as game consoles, personal computers, electronic voting machines, and point-of-sale (POS) systems. They can also be attached to computers or, as terminals, to networks. They play a prominent role in the design of digital appliances such as personal digital assistants (PDAs) and some e-readers. Touchscreens are also important in educational settings such as classrooms or on college campuses.

The popularity of smartphones, tablets, and many types of information appliances is driving the demand and acceptance of common touchscreens for portable and functional electronics. Touchscreens are found in the medical field, heavy industry, automated teller machines (ATMs), and kiosks such as museum displays or room automation, where keyboard and mouse systems do not allow a suitably intuitive, rapid, or accurate interaction by the user with the display"s content.

Historically, the touchscreen sensor and its accompanying controller-based firmware have been made available by a wide array of after-market system integrators, and not by display, chip, or motherboard manufacturers. Display manufacturers and chip manufacturers have acknowledged the trend toward acceptance of touchscreens as a user interface component and have begun to integrate touchscreens into the fundamental design of their products.

The prototypeCERNFrank Beck, a British electronics engineer, for the control room of CERN"s accelerator SPS (Super Proton Synchrotron). This was a further development of the self-capacitance screen (right), also developed by Stumpe at CERN

One predecessor of the modern touch screen includes stylus based systems. In 1946, a patent was filed by Philco Company for a stylus designed for sports telecasting which, when placed against an intermediate cathode ray tube display (CRT) would amplify and add to the original signal. Effectively, this was used for temporarily drawing arrows or circles onto a live television broadcast, as described in US 2487641A, Denk, William E, "Electronic pointer for television images", issued 1949-11-08. Later inventions built upon this system to free telewriting styli from their mechanical bindings. By transcribing what a user draws onto a computer, it could be saved for future use. See US 3089918A, Graham, Robert E, "Telewriting apparatus", issued 1963-05-14.

The first version of a touchscreen which operated independently of the light produced from the screen was patented by AT&T Corporation US 3016421A, Harmon, Leon D, "Electrographic transmitter", issued 1962-01-09. This touchscreen utilized a matrix of collimated lights shining orthogonally across the touch surface. When a beam is interrupted by a stylus, the photodetectors which no longer are receiving a signal can be used to determine where the interruption is. Later iterations of matrix based touchscreens built upon this by adding more emitters and detectors to improve resolution, pulsing emitters to improve optical signal to noise ratio, and a nonorthogonal matrix to remove shadow readings when using multi-touch.

The first finger driven touch screen was developed by Eric Johnson, of the Royal Radar Establishment located in Malvern, England, who described his work on capacitive touchscreens in a short article published in 1965Frank Beck and Bent Stumpe, engineers from CERN (European Organization for Nuclear Research), developed a transparent touchscreen in the early 1970s,In the mid-1960s, another precursor of touchscreens, an ultrasonic-curtain-based pointing device in front of a terminal display, had been developed by a team around Rainer Mallebrein[de] at Telefunken Konstanz for an air traffic control system.Einrichtung" ("touch input facility") for the SIG 50 terminal utilizing a conductively coated glass screen in front of the display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreenMagnavox Plato IV Student Terminal and thousands were built for this purpose. These touchscreens had a crossed array of 16×16 infrared position sensors, each composed of an LED on one edge of the screen and a matched phototransistor on the other edge, all mounted in front of a monochrome plasma display panel. This arrangement could sense any fingertip-sized opaque object in close proximity to the screen. A similar touchscreen was used on the HP-150 starting in 1983. The HP 150 was one of the world"s earliest commercial touchscreen computers.infrared transmitters and receivers around the bezel of a 9-inch Sony cathode ray tube (CRT).

In 1977, an American company, Elographics – in partnership with Siemens – began work on developing a transparent implementation of an existing opaque touchpad technology, U.S. patent No. 3,911,215, October 7, 1975, which had been developed by Elographics" founder George Samuel Hurst.World"s Fair at Knoxville in 1982.

In 1984, Fujitsu released a touch pad for the Micro 16 to accommodate the complexity of kanji characters, which were stored as tiled graphics.Sega released the Terebi Oekaki, also known as the Sega Graphic Board, for the SG-1000 video game console and SC-3000 home computer. It consisted of a plastic pen and a plastic board with a transparent window where pen presses are detected. It was used primarily with a drawing software application.

Touch-sensitive control-display units (CDUs) were evaluated for commercial aircraft flight decks in the early 1980s. Initial research showed that a touch interface would reduce pilot workload as the crew could then select waypoints, functions and actions, rather than be "head down" typing latitudes, longitudes, and waypoint codes on a keyboard. An effective integration of this technology was aimed at helping flight crews maintain a high level of situational awareness of all major aspects of the vehicle operations including the flight path, the functioning of various aircraft systems, and moment-to-moment human interactions.

In the early 1980s, General Motors tasked its Delco Electronics division with a project aimed at replacing an automobile"s non-essential functions (i.e. other than throttle, transmission, braking, and steering) from mechanical or electro-mechanical systems with solid state alternatives wherever possible. The finished device was dubbed the ECC for "Electronic Control Center", a digital computer and software control system hardwired to various peripheral sensors, servos, solenoids, antenna and a monochrome CRT touchscreen that functioned both as display and sole method of input.stereo, fan, heater and air conditioner controls and displays, and was capable of providing very detailed and specific information about the vehicle"s cumulative and current operating status in real time. The ECC was standard equipment on the 1985–1989 Buick Riviera and later the 1988–1989 Buick Reatta, but was unpopular with consumers—partly due to the technophobia of some traditional Buick customers, but mostly because of costly technical problems suffered by the ECC"s touchscreen which would render climate control or stereo operation impossible.

Multi-touch technology began in 1982, when the University of Toronto"s Input Research Group developed the first human-input multi-touch system, using a frosted-glass panel with a camera placed behind the glass. In 1985, the University of Toronto group, including Bill Buxton, developed a multi-touch tablet that used capacitance rather than bulky camera-based optical sensing systems (see History of multi-touch).

The first commercially available graphical point-of-sale (POS) software was demonstrated on the 16-bit Atari 520ST color computer. It featured a color touchscreen widget-driven interface.COMDEX expo in 1986.

In 1987, Casio launched the Casio PB-1000 pocket computer with a touchscreen consisting of a 4×4 matrix, resulting in 16 touch areas in its small LCD graphic screen.

Touchscreens had a bad reputation of being imprecise until 1988. Most user-interface books would state that touchscreen selections were limited to targets larger than the average finger. At the time, selections were done in such a way that a target was selected as soon as the finger came over it, and the corresponding action was performed immediately. Errors were common, due to parallax or calibration problems, leading to user frustration. "Lift-off strategy"University of Maryland Human–Computer Interaction Lab (HCIL). As users touch the screen, feedback is provided as to what will be selected: users can adjust the position of the finger, and the action takes place only when the finger is lifted off the screen. This allowed the selection of small targets, down to a single pixel on a 640×480 Video Graphics Array (VGA) screen (a standard of that time).

Sears et al. (1990)human–computer interaction of the time, describing gestures such as rotating knobs, adjusting sliders, and swiping the screen to activate a switch (or a U-shaped gesture for a toggle switch). The HCIL team developed and studied small touchscreen keyboards (including a study that showed users could type at 25 wpm on a touchscreen keyboard), aiding their introduction on mobile devices. They also designed and implemented multi-touch gestures such as selecting a range of a line, connecting objects, and a "tap-click" gesture to select while maintaining location with another finger.

In 1990, HCIL demonstrated a touchscreen slider,lock screen patent litigation between Apple and other touchscreen mobile phone vendors (in relation to

An early attempt at a handheld game console with touchscreen controls was Sega"s intended successor to the Game Gear, though the device was ultimately shelved and never released due to the expensive cost of touchscreen technology in the early 1990s.

Touchscreens would not be popularly used for video games until the release of the Nintendo DS in 2004.Apple Watch being released with a force-sensitive display in April 2015.

In 2007, 93% of touchscreens shipped were resistive and only 4% were projected capacitance. In 2013, 3% of touchscreens shipped were resistive and 90% were projected capacitance.

A resistive touchscreen panel comprises several thin layers, the most important of which are two transparent electrically resistive layers facing each other with a thin gap between. The top layer (that which is touched) has a coating on the underside surface; just beneath it is a similar resistive layer on top of its substrate. One layer has conductive connections along its sides, the other along top and bottom. A voltage is applied to one layer and sensed by the other. When an object, such as a fingertip or stylus tip, presses down onto the outer surface, the two layers touch to become connected at that point.voltage dividers, one axis at a time. By rapidly switching between each layer, the position of pressure on the screen can be detected.

Resistive touch is used in restaurants, factories and hospitals due to its high tolerance for liquids and contaminants. A major benefit of resistive-touch technology is its low cost. Additionally, as only sufficient pressure is necessary for the touch to be sensed, they may be used with gloves on, or by using anything rigid as a finger substitute. Disadvantages include the need to press down, and a risk of damage by sharp objects. Resistive touchscreens also suffer from poorer contrast, due to having additional reflections (i.e. glare) from the layers of material placed over the screen.3DS family, and the Wii U GamePad.

Surface acoustic wave (SAW) technology uses ultrasonic waves that pass over the touchscreen panel. When the panel is touched, a portion of the wave is absorbed. The change in ultrasonic waves is processed by the controller to determine the position of the touch event. Surface acoustic wave touchscreen panels can be damaged by outside elements. Contaminants on the surface can also interfere with the functionality of the touchscreen.

The Casio TC500 Capacitive touch sensor watch from 1983, with angled light exposing the touch sensor pads and traces etched onto the top watch glass surface.

A capacitive touchscreen panel consists of an insulator, such as glass, coated with a transparent conductor, such as indium tin oxide (ITO).electrostatic field, measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing. Touchscreens that use silver instead of ITO exist, as ITO causes several environmental problems due to the use of indium.complementary metal-oxide-semiconductor (CMOS) application-specific integrated circuit (ASIC) chip, which in turn usually sends the signals to a CMOS digital signal processor (DSP) for processing.

Unlike a resistive touchscreen, some capacitive touchscreens cannot be used to detect a finger through electrically insulating material, such as gloves. This disadvantage especially affects usability in consumer electronics, such as touch tablet PCs and capacitive smartphones in cold weather when people may be wearing gloves. It can be overcome with a special capacitive stylus, or a special-application glove with an embroidered patch of conductive thread allowing electrical contact with the user"s fingertip.

A low-quality switching-mode power supply unit with an accordingly unstable, noisy voltage may temporarily interfere with the precision, accuracy and sensitivity of capacitive touch screens.

Some capacitive display manufacturers continue to develop thinner and more accurate touchscreens. Those for mobile devices are now being produced with "in-cell" technology, such as in Samsung"s Super AMOLED screens, that eliminates a layer by building the capacitors inside the display itself. This type of touchscreen reduces the visible distance between the user"s finger and what the user is touching on the screen, reducing the thickness and weight of the display, which is desirable in smartphones.

In this basic technology, only one side of the insulator is coated with a conductive layer. A small voltage is applied to the layer, resulting in a uniform electrostatic field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. The sensor"s controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel. As it has no moving parts, it is moderately durable but has limited resolution, is prone to false signals from parasitic capacitive coupling, and needs calibration during manufacture. It is therefore most often used in simple applications such as industrial controls and kiosks.

This diagram shows how eight inputs to a lattice touchscreen or keypad creates 28 unique intersections, as opposed to 16 intersections created using a standard x/y multiplexed touchscreen .

Projected capacitive touch (PCT; also PCAP) technology is a variant of capacitive touch technology but where sensitivity to touch, accuracy, resolution and speed of touch have been greatly improved by the use of a simple form of

Some modern PCT touch screens are composed of thousands of discrete keys,etching a single conductive layer to form a grid pattern of electrodes, by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid, or by forming an x/y grid of fine, insulation coated wires in a single layer . The number of fingers that can be detected simultaneously is determined by the number of cross-over points (x * y) . However, the number of cross-over points can be almost doubled by using a diagonal lattice layout, where, instead of x elements only ever crossing y elements, each conductive element crosses every other element .

In some designs, voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. This is measurable as a change in capacitance. If a finger bridges the gap between two of the "tracks", the charge field is further interrupted and detected by the controller. The capacitance can be changed and measured at every individual point on the grid. This system is able to accurately track touches.

Unlike traditional capacitive touch technology, it is possible for a PCT system to sense a passive stylus or gloved finger. However, moisture on the surface of the panel, high humidity, or collected dust can interfere with performance.

These environmental factors, however, are not a problem with "fine wire" based touchscreens due to the fact that wire based touchscreens have a much lower "parasitic" capacitance, and there is greater distance between neighbouring conductors.

This is a common PCT approach, which makes use of the fact that most conductive objects are able to hold a charge if they are very close together. In mutual capacitive sensors, a capacitor is inherently formed by the row trace and column trace at each intersection of the grid. A 16×14 array, for example, would have 224 independent capacitors. A voltage is applied to the rows or columns. Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field, which in turn reduces the mutual capacitance. The capacitance change at every individual point on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers, palms or styli can be accurately tracked at the same time.

Self-capacitive touch screen layers are used on mobile phones such as the Sony Xperia Sola,Samsung Galaxy S4, Galaxy Note 3, Galaxy S5, and Galaxy Alpha.

Self capacitance is far more sensitive than mutual capacitance and is mainly used for single touch, simple gesturing and proximity sensing where the finger does not even have to touch the glass surface.

Capacitive touchscreens do not necessarily need to be operated by a finger, but until recently the special styli required could be quite expensive to purchase. The cost of this technology has fallen greatly in recent years and capacitive styli are now widely available for a nominal charge, and often given away free with mobile accessories. These consist of an electrically conductive shaft with a soft conductive rubber tip, thereby resistively connecting the fingers to the tip of the stylus.

Infrared sensors mounted around the display watch for a user"s touchscreen input on this PLATO V terminal in 1981. The monochromatic plasma display"s characteristic orange glow is illustrated.

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any opaque object including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and POS systems that cannot rely on a conductor (such as a bare finger) to activate the touchscreen. Unlike capacitive touchscreens, infrared touchscreens do not require any patterning on the glass which increases durability and optical clarity of the overall system. Infrared touchscreens are sensitive to dirt and dust that can interfere with the infrared beams, and suffer from parallax in curved surfaces and accidental press when the user hovers a finger over the screen while searching for the item to be selected.

A translucent acrylic sheet is used as a rear-projection screen to display information. The edges of the acrylic sheet are illuminated by infrared LEDs, and infrared cameras are focused on the back of the sheet. Objects placed on the sheet are detectable by the cameras. When the sheet is touched by the user, frustrated total internal reflection results in leakage of infrared light which peaks at the points of maximum pressure, indicating the user"s touch location. Microsoft"s PixelSense tablets use this technology.

Optical touchscreens are a relatively modern development in touchscreen technology, in which two or more image sensors (such as CMOS sensors) are placed around the edges (mostly the corners) of the screen. Infrared backlights are placed in the sensor"s field of view on the opposite side of the screen. A touch blocks some lights from the sensors, and the location and size of the touching object can be calculated (see visual hull). This technology is growing in popularity due to its scalability, versatility, and affordability for larger touchscreens.

Introduced in 2002 by 3M, this system detects a touch by using sensors to measure the piezoelectricity in the glass. Complex algorithms interpret this information and provide the actual location of the touch.

The key to this technology is that a touch at any one position on the surface generates a sound wave in the substrate which then produces a unique combined signal as measured by three or more tiny transducers attached to the edges of the touchscreen. The digitized signal is compared to a list corresponding to every position on the surface, determining the touch location. A moving touch is tracked by rapid repetition of this process. Extraneous and ambient sounds are ignored since they do not match any stored sound profile. The technology differs from other sound-based technologies by using a simple look-up method rather than expensive signal-processing hardware. As with the dispersive signal technology system, a motionless finger cannot be detected after the initial touch. However, for the same reason, the touch recognition is not disrupted by any resting objects. The technology was created by SoundTouch Ltd in the early 2000s, as described by the patent family EP1852772, and introduced to the market by Tyco International"s Elo division in 2006 as Acoustic Pulse Recognition.

There are several principal ways to build a touchscreen. The key goals are to recognize one or more fingers touching a display, to interpret the command that this represents, and to communicate the command to the appropriate application.

Dispersive-signal technology measures the piezoelectric effect—the voltage generated when mechanical force is applied to a material—that occurs chemically when a strengthened glass substrate is touched.

There are two infrared-based approaches. In one, an array of sensors detects a finger touching or almost touching the display, thereby interrupting infrared light beams projected over the screen. In the other, bottom-mounted infrared cameras record heat from screen touches.

The development of multi-touch screens facilitated the tracking of more than one finger on the screen; thus, operations that require more than one finger are possible. These devices also allow multiple users to interact with the touchscreen simultaneously.

With the growing use of touchscreens, the cost of touchscreen technology is routinely absorbed into the products that incorporate it and is nearly eliminated. Touchscreen technology has demonstrated reliability and is found in airplanes, automobiles, gaming consoles, machine control systems, appliances, and handheld display devices including cellphones; the touchscreen market for mobile devices was projected to produce US$5 billion by 2009.

The ability to accurately point on the screen itself is also advancing with the emerging graphics tablet-screen hybrids. Polyvinylidene fluoride (PVFD) plays a major role in this innovation due its high piezoelectric properties, which allow the tablet to sense pressure, making such things as digital painting behave more like paper and pencil.

TapSense, announced in October 2011, allows touchscreens to distinguish what part of the hand was used for input, such as the fingertip, knuckle and fingernail. This could be used in a variety of ways, for example, to copy and paste, to capitalize letters, to activate different drawing modes, etc.

For touchscreens to be effective input devices, users must be able to accurately select targets and avoid accidental selection of adjacent targets. The design of touchscreen interfaces should reflect technical capabilities of the system, ergonomics, cognitive psychology and human physiology.

Guidelines for touchscreen designs were first developed in the 2020s, based on early research and actual use of older systems, typically using infrared grids—which were highly dependent on the size of the user"s fingers. These guidelines are less relevant for the bulk of modern touch devices which use capacitive or resistive touch technology.

Much more important is the accuracy humans have in selecting targets with their finger or a pen stylus. The accuracy of user selection varies by position on the screen: users are most accurate at the center, less so at the left and right edges, and least accurate at the top edge and especially the bottom edge. The R95 accuracy (required radius for 95% target accuracy) varies from 7 mm (0.28 in) in the center to 12 mm (0.47 in) in the lower corners.

This user inaccuracy is a result of parallax, visual acuity and the speed of the feedback loop between the eyes and fingers. The precision of the human finger alone is much, much higher than this, so when assistive technologies are provided—such as on-screen magnifiers—users can move their finger (once in contact with the screen) with precision as small as 0.1 mm (0.004 in).

Users of handheld and portable touchscreen devices hold them in a variety of ways, and routinely change their method of holding and selection to suit the position and type of input. There are four basic types of handheld interaction:

Touchscreens are often used with haptic response systems. A common example of this technology is the vibratory feedback provided when a button on the touchscreen is tapped. Haptics are used to improve the user"s experience with touchscreens by providing simulated tactile feedback, and can be designed to react immediately, partly countering on-screen response latency. Research from the University of Glasgow (Brewster, Chohan, and Brown, 2007; and more recently Hogan) demonstrates that touchscreen users reduce input errors (by 20%), increase input speed (by 20%), and lower their cognitive load (by 40%) when touchscreens are combined with haptics or tactile feedback. On top of this, a study conducted in 2013 by Boston College explored the effects that touchscreens haptic stimulation had on triggering psychological ownership of a product. Their research concluded that a touchscreens ability to incorporate high amounts of haptic involvement resulted in customers feeling more endowment to the products they were designing or buying. The study also reported that consumers using a touchscreen were willing to accept a higher price point for the items they were purchasing.

Unsupported touchscreens are still fairly common in applications such as ATMs and data kiosks, but are not an issue as the typical user only engages for brief and widely spaced periods.

Touchscreens can suffer from the problem of fingerprints on the display. This can be mitigated by the use of materials with optical coatings designed to reduce the visible effects of fingerprint oils. Most modern smartphones have oleophobic coatings, which lessen the amount of oil residue. Another option is to install a matte-finish anti-glare screen protector, which creates a slightly roughened surface that does not easily retain smudges.

Touchscreens do not work most of the time when the user wears gloves. The thickness of the glove and the material they are made of play a significant role on that and the ability of a touchscreen to pick up a touch.

Walker, Geoff (August 2012). "A review of technologies for sensing contact location on the surface of a display: Review of touch technologies". Journal of the Society for Information Display. 20 (8): 413–440. doi:10.1002/jsid.100. S2CID 40545665.

"The first capacitative touch screens at CERN". CERN Courrier. 31 March 2010. Archived from the original on 4 September 2010. Retrieved 2010-05-25. Cite journal requires |journal= (help)

Johnson, E.A. (1965). "Touch Display - A novel input/output device for computers". Electronics Letters. 1 (8): 219–220. Bibcode:1965ElL.....1..219J. doi:10.1049/el:19650200.

Stumpe, Bent; Sutton, Christine (1 June 2010). "CERN touch screen". Symmetry Magazine. A joint Fermilab/SLAC publication. Archived from the original on 2016-11-16. Retrieved 16 November 2016.

Biferno, M.A., Stanley, D.L. (1983). The Touch-Sensitive Control/Display Unit: A promising Computer Interface. Technical Paper 831532, Aerospace Congress & Exposition, Long Beach, CA: Society of Automotive Engineers.

Potter, R.; Weldon, L.; Shneiderman, B. (1988). "Improving the accuracy of touch screens: an experimental evaluation of three strategies". Proceedings of the SIGCHI conference on Human factors in computing systems - CHI "88. Proc. of the Conference on Human Factors in Computing Systems, CHI "88. Washington, DC. pp. 27–32. doi:10.1145/57167.57171. ISBN 0201142376. Archived from the original on 2015-12-08.

Sears, Andrew; Plaisant, Catherine; Shneiderman, Ben (June 1990). "A new era for high-precision touchscreens". In Hartson, R.; Hix, D. (eds.). Advances in Human-Computer Interaction. Vol. 3. Ablex (1992). ISBN 978-0-89391-751-7. Archived from the original on October 9, 2014.

Apple touch-screen patent war comes to the UK (2011). Event occurs at 1:24 min in video. Archived from the original on 8 December 2015. Retrieved 3 December 2015.

Hong, Chan-Hwa; Shin, Jae-Heon; Ju, Byeong-Kwon; Kim, Kyung-Hyun; Park, Nae-Man; Kim, Bo-Sul; Cheong, Woo-Seok (1 November 2013). "Index-Matched Indium Tin Oxide Electrodes for Capacitive Touch Screen Panel Applications". Journal of Nanoscience and Nanotechnology. 13 (11): 7756–7759. doi:10.1166/jnn.2013.7814. PMID 24245328. S2CID 24281861.

Kent, Joel (May 2010). "Touchscreen technology basics & a new development". CMOS Emerging Technologies Conference. CMOS Emerging Technologies Research. 6: 1–13. ISBN 9781927500057.

Ganapati, Priya (5 March 2010). "Finger Fail: Why Most Touchscreens Miss the Point". Archived from the original on 2014-05-11. Retrieved 9 November 2019.

Beyers, Tim (2008-02-13). "Innovation Series: Touchscreen Technology". The Motley Fool. Archived from the original on 2009-03-24. Retrieved 2009-03-16.

"Acoustic Pulse Recognition Touchscreens" (PDF). Elo Touch Systems. 2006: 3. Archived (PDF) from the original on 2011-09-05. Retrieved 2011-09-27. Cite journal requires |journal= (help)

Hoober, Steven (2013-11-11). "Design for Fingers and Thumbs Instead of Touch". UXmatters. Archived from the original on 2014-08-26. Retrieved 2014-08-24.

Henze, Niels; Rukzio, Enrico; Boll, Susanne (2011). "100,000,000 Taps: Analysis and Improvement of Touch Performance in the Large". Proceedings of the 13th International Conference on Human Computer Interaction with Mobile Devices and Services. New York.

Lee, Seungyons; Zhai, Shumin (2009). "The Performance of Touch Screen Soft Buttons". Proceedings of the SIGCHI Conference on Human Factors in Computing Systems. New York: 309. doi:10.1145/1518701.1518750. ISBN 9781605582467. S2CID 2468830.

Bérard, François (2012). "Measuring the Linear and Rotational User Precision in Touch Pointing". Proceedings of the 2012 ACM International Conference on Interactive Tabletops and Surfaces. New York: 183. doi:10.1145/2396636.2396664. ISBN 9781450312097. S2CID 15765730.

Hoober, Steven (2014-09-02). "Insights on Switching, Centering, and Gestures for Touchscreens". UXmatters. Archived from the original on 2014-09-06. Retrieved 2014-08-24.

Brasel, S. Adam; Gips, James (2014). "Tablets, touchscreens, and touchpads: How varying touch interfaces trigger psychological ownership and endowment". Journal of Consumer Psychology. 24 (2): 226–233. doi:10.1016/j.jcps.2013.10.003.

Zhu, Ying; Meyer, Jeffrey (September 2017). "Getting in touch with your thinking style: How touchscreens influence purchase". Journal of Retailing and Consumer Services. 38: 51–58. doi:10.1016/j.jretconser.2017.05.006.

"A RESTAURANT THAT LETS GUESTS PLACE ORDERS VIA A TOUCHSCREEN TABLE (Touche is said to be the first touchscreen restaurant in India and fifth in the world)". India Business Insight. 31 August 2011. Gale A269135159.

Sears, A.; Plaisant, C. & Shneiderman, B. (1992). "A new era for high precision touchscreens". In Hartson, R. & Hix, D. (eds.). Advances in Human-Computer Interaction. Vol. 3. Ablex, NJ. pp. 1–33.

Sears, Andrew; Shneiderman, Ben (April 1991). "High precision touchscreens: design strategies and comparisons with a mouse". International Journal of Man-Machine Studies. 34 (4): 593–613. doi:10.1016/0020-7373(91)90037-8. hdl:

Why have we included LCDs as a transparent display when, at first glance, they’re not truly transparent? In fact, we’re only able to see the information on our monitors, such as laptops, with the introduction of a backlight and a reflector shield.

LCDs are also one of the most popular screens on the market and this rise occurred early in the 21st century when liquid-crystal-display sets rocketed in popularity. In 2007, LCDs eclipsed sales of competing technologies like plasma, cathode ray tube, and rear-projection TVs.

This means they’re thinner and lighter and have higher levels of brightness which is why they’re used to create displays in smartphones, tablets, computer/laptop monitors and portable games consoles.

The organic materials used in OLEDs are affected by the environment, they’re sensitive to moisture and screen discoloration occurs if subjected to direct sunlight and heat

However, due to the limitation of monochromatic images, transparent electroluminescent displays shouldn’t be used as entertainment screens in vehicles - they should be used to display only the most critical information in the eye-line of the driver without distractions.

The LG Information Display website utilizes responsive design to provide convenient experience that conforms to your devices screen size. In order to get the best possible experience our LG Information Display website please follow below instructions.If you’re using Internet Explorer 8 or earlier, you will need to use an alternate browser such as Firefox or Chrome or upgrade to a newer version of internet Explorer (IE9 or greater).If you’re using Internet Explorer 9 and higher, turn off your Internet Explorer browser’s “Compatibility View settings” by following steps below:

Transparent LCD Screens Panels are the latest innovation in LCD technology. These transparent screen are providing a range of new opportunities in retail, marketing, or entertainment displays. With the new transparent LCD display technology, you will be able not only to promote products and show information on a screen, but also being able to see through it.

The transparent screen or transparent monitor, is a see-through display that let the user to see what is shown on the transparent LCD panel while still being able to see the product or items inside the display with the transparent screen.

USB, HDMI & VGA connections are included in the package of transparent screen which allows you to connect a media player, PC or laptop to it. Transparent LCD screens are made to use a video content that shows or hide the physical objects behind the screen. It can be used as a Transparent Display showcase to use in shops or exhibitions or even as a Transparent Screen Fridge or Cooler.

Transparent touch screen technology can be combined with the transparent LCD screens opening a whole new way for retail displays, booths and they are especially useful when it comes to product launches and promotions.

Transparent LCD technology requires a separate backlight, usually achieved by building the screen into the front of an enclosed cabinet containing strong white LED lighting. The screen is around 15% transparent, so the lighting inside the cabinet needs to be around 6-7 times brighter than the light on the viewing side.

Retail windows, interactive booths, digital signage, events & exhibitions, display cases, interactive games, vending machines, drinks coolers… the uses for transparent touch screens are limited only by your creativity.

Screen Solutions offers complete solutions for transparent displays including standard and custom display cases. SSI has designed and built transparent displays for companies like Chrysler, Lockheed Martin, Mazda and many others over the last 15 years.

Standard Sizes start as small as 10″ and can get as big as 86″ Diagonal as seen in the video to your left. These complete displays include transparent panel, lighting, glass, display case and even a touch screen if you want.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey