reduce glare on camera lcd screen supplier

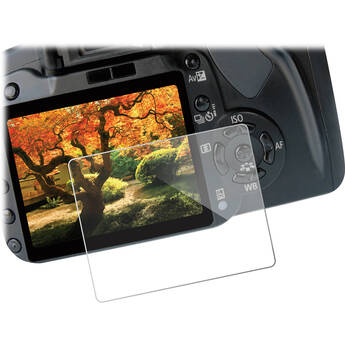

{"smallUrl":"https:\/\/www.wikihow.com\/images\/thumb\/0\/08\/See-the-Screen-of-a-Digital-Camera-when-the-Sunlight-Makes-a-Glare-Step-1.jpg\/v4-460px-See-the-Screen-of-a-Digital-Camera-when-the-Sunlight-Makes-a-Glare-Step-1.jpg","bigUrl":"\/images\/thumb\/0\/08\/See-the-Screen-of-a-Digital-Camera-when-the-Sunlight-Makes-a-Glare-Step-1.jpg\/aid1290876-v4-728px-See-the-Screen-of-a-Digital-Camera-when-the-Sunlight-Makes-a-Glare-Step-1.jpg","smallWidth":460,"smallHeight":308,"bigWidth":728,"bigHeight":487,"licensing":"

License: Creative Commons<\/a>

\n<\/p>

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey