tft lcd pcb connection made in china

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

The famous china LCD display manufacturers. It is the world’s leading semiconductor display technology, products, and services provider. Products are widely used in mobile phones, tablets, laptops, monitors, televisions, cars, digital information displays, and other display fields.

Focus on the development and production of china HMI (Intelligent TFT LCD Module) LCD display manufacturers, production, and sales of LCD display modules for 16 years. The company master TFT LCD technology and software system. The main products are industrial electronic series, advanced series, and civil and commercial series. Application scenarios include automation systems, medical beauty equipment, vending machines, smart lockers, energy, and power equipment (refueling machines, charging piles), elevators, smart homes, and offices, measuring instruments, public transportation, etc.

Mainly committed to the r&d, production, and sales of TFT-LCD/stn-LCD /OLED display modules, it is a modern high-tech enterprise that provides a full range of product LCD module technology and manufacturing support services for TCL group member enterprises and international electronic enterprises.

Set an LCD display module (LCM), capacitive touch screen (CTP), fully integrated touch display module (TDM), LCD thin technology development, production, and service in one national high-tech company.

Domestic size of the top four small and medium-sized flat panel display manufacturers. The products cover medium and small-size TFT-LCD display modules and high-precision miniature cameras, which have been widely used in the fields of smartphones, medical treatment, and industrial display.

The LCD business division is specialized in the r&d, production, and sales of the LCD display (LCD) and LCD module (LCM) series of products. It has ten semi-automatic COG production lines, 1.5KK of monthly COG products, covering COG, TAB, COB, and other LCD module products, TFT, CSTN, and other color LCD display products, and OLED display products. touch screen manufacturers.

Byd IT products and business mainly include the establishment of rechargeable batteries, plastic parts, metal parts, hardware, and electronic products, mobile phone keys, microelectronics, LCD display module, optoelectronic products, flexible circuit board, chargers, connectors, uninterruptible power supply, dc power supply, solar energy products, mobile phone decoration, mobile phones ODM, mobile phone test, assembly operations, laptop, ODM, manufacturing, testing and assembly operations, etc.

Star source products cover backlight, LCD, optical diaphragm, etc., widely used in LCD modules, photo frames, tablets, portable, instruments, and meters.

The company has long invested in the research and development of the TFT-lcm LCD module, focusing on consumer products and industrial control products. Currently, 3.5-11.6 inch modules are available, among which 4.0, 4.3, 5, 6, and 10.1-inch products have reached the leading level in the industry. Products are mainly used in vehicles, mobile TV, PMP, DVD, EPC, security, and industrial control products.

Professional development, design, production, and sales of LCD display module (LCM), products cover COB, TAB, COG, and other LCD module products, TFT, CSTN, and other color LCD display products, as well as OLED display products. Products are widely used in mobile phones, communications, digital products, household appliances, industrial control, instrumentation, vehicle display, color screen display, and other fields.

Mainly engaged in research and development, manufacturing, and sales of the LCD display and LCD display module. Products are widely used in all kinds of electronic products and equipment HMI interface, such as medical equipment, instruments and meters, audio, household appliances, telephone and clocks, game machines, and other different types and use.

Focusing on the LCD module industry, is a collection of research and development, manufacturing, sales as one of the high-tech enterprises. TFT module size from 1.44 to 7 inches, product specifications cover QVGA, WVGA, qHD, HD, etc., the market prospects are broad.

The display manufacturers company mainly researches and develops the LCD display, charger, battery, and other products of mobile communication mobile phone, telephone, MP3, and other high-tech products.

The company integrates research and development, design, production, sales, and service into one, and provides comprehensive touch and display integrated solutions for the complete machine touch screen manufacturer of smartphones, specializing in the development and manufacture of Sensor sensors, capacitive touch screens (GFF/OGS/GG), small and medium-sized LCD (TN/HTN/STN/CSTN/TFT) and corresponding modules and glass cover plate products. The company’s products are widely used in communication terminals (smartphone, tablet computer, etc.), household appliances, car electronics, digital products, and other industries, exported to Europe and America, Japan and South Korea, Singapore, and other countries.

Mainly produces medium and small-size LCD display module (LCM), multi-point capacitive touch screen (CTP), and other high-tech products. At present, more than 1000 models of 1.2-12.1 inch products have been developed. Products are widely used in mobile phones, GPS, mobile TV, tablet computers, digital photo frames, e-books, and other consumer electronics.

It is a professional development and production of small and medium-sized flat panel display upstream materials manufacturers. The company’s main products include LCD display panels, color filter, ITO conductive glass (CF), TFT LCD panel, and capacitive touch screen with multi-touch control functions (sensor and the final module), can provide complete medium and small size flat-panel display device using the solution of raw materials, product specifications varieties complete, widely used in 10.4 inches below the smartphone, tablet, PMP, digital camera, digital camera, GPS and other products of the display panel.

Now it is divided into mobile phone business division: the main products are (2.8-6) inch and the LCD screen and capacitive screen all fit together.MID tablet computer and ultrabook computer division: the main production product size is (7-15) inch capacitive touch screen.

Committed to 3.5~4.3 inches, 5 inches, 5.88 inches, 6.2 inches, 7.0 inches, 8.0 inches, 9.7 inches, 10.1 inches, 12.1 inches medium size FOG, backlight process production, products should be widely used in high-end communication phones, tablets, notebook computers, car TV, navigator, and other display products. automotive LCD display touch screen manufacturers.

The company has an injection molding business division, SMT business division, FPC business division, backlight business division, irrigation crystal business division, TFT module business division, SIN module business division, products involving touch screen, LCD display module, backlight, black and white screen, flexible circuit board.

Engaged in the laptop, tablet, smartphone, computer high-performance board card, LCD module, and other electronic products research and development, production, and sales of high-tech private enterprises.

Is a professional engaged in LCD display module, electronic components, production, design, research and development, sales as one of the high-tech enterprises. Products are widely used in mobile phones, game consoles, PDA, portable DVDs, video phones, intercom doorbells, car video, industrial control medical, and other fields.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Are you bogged down by unreliable PCB manufacturers, who are cheap but not dependable? Then stop right there! Switch to PCBMay, because we have the right options for all your LCD PCB needs.Count on our strict and safe PCB manufacturing process

We are a company that values honest communication Anytime, 24/7, you can contact us if you have questions about your circuit board. We have people on hand to answer inquiries about your LCD PCB.

For example, you need EMS PCB manufacturing help, or you need Backdrill PCB services done for your LCB PCB. With engineering and other technical-related questions, we’ll get back to you in one to two hours. For sales matters, we can give a quick quote in a matter of minutes.

Rest assured that we strictly follow international rules on environment management. We also execute professionalism by upholding IS0 9000:2015 guidelines. As a result, you are treated to comprehensive customer care and customer relationship building. We don’t just see to your LCD PCB needs, we will take care of our partnership.

For large orders, we can provide a free sample as well as a soldering sample. We want to make you feel sure that we got your LCD PCB specs precisely right.

Are you looking to manufacture LCD monitors? Then you need LCD PCBs to power and control your LCDs, because circuit boards are essential in your electronic device.

Before beginning the manufacture of LCD PCBs, you need to know a lot of facts about the LCD PCBs boards. Info about the manufacturing process, material selections, types of boards, and manufacturer are key factors you need to know.

We will discuss and answer several questions about LCD PCBs in this FAQ article. Go through the entire article to get basic facts about LCD PCB monitor PCB boards.

LCD is an abbreviation for Liquid Crystal Display. Pictures are produced when various electrical voltages are applied to a display device. A display device is an electronic display device that creates images.

The LCD is usually thought of as a collection of diodes. The pictures are produced by the diodes using small cells and ionized gasses. Aside from that, the LCD is based on the light modulation characteristic, which is a mechanism for transmitting and receiving signals via light.

On the other hand, theprinted circuit board (PCB) is the controller board of any electronic device. A Printed Circuit Board (PCB) comprises many components and conductive lines that are hidden from view from the end-user.

So a PCB that is utilized for controlling LCD screens is referred to as the LCD PCB. LCD PCBs are made of different materials such as FR4, Polyamide, and Teflon among others.

To make an LCD PCB, you need to follow specific design procedures. There are a lot of things to consider. For starters, the LCD PCB design begins with drawing the schematic. Here is a further step-by-step design procedure of LCD PCB production.

The first step to designing an LCD PCB is to start with a schematic. First, you need to draw a schematic of your LCD PCB. You can say the schematic is your circuit’s blueprint.

The schematic will show the components you will use for your PCB. Also, it directs how you will connect the components and the relationship between the group of components.

After creating the schematic, you have to create a blank LCD PCB layout on your computer design tool. Now, import the schematic of the LCD PCB to the blank layout by schematic capture tool.

Determine the stack-up of your LCD PCB with multilayers. You can set any number for the PCB layers you want. You can use the layer stack-up manager to define and design the layers.

After finalizing the PCB layout and layers, you must print the PCB layout on the PCB board. For printing the layout of your LCD PCB, you can use 3D or laser printing. Etch the conductive traces to ensure the electric current flows to the components.

After finishing the successful printing of your LCD PCB, it is time to assemble the PCB. You can use an automated process or manually arrange and place them on your PCB board.

There are three types of component mount technology available you can use. They are through-hole technology, surface mount, and press-fit PCB technology.

Your PCB is ready for trace routing when you complete the component placement. Connect the components where needed. Ensure the correct routing so that the board can function correctly.

Single-sided PCBs are the most common type of PCBs. Primarily, a single conductive layer features the single-sided PCB. You will see all components on one side. The entire etched section is on the other side of the PCB.

As the name describes, the two-sided or double-sided PCB has two conductive layers. You can connect the two conductive layers by drilled holes. These holes are called vias.

Multilayer PCBs are PCBs that have at least three conductive layers. The layers are stacked up in multiple layers. Primarily, adhesive and high pressure attach sandwich-fashion conductive layers to form a multilayer PCB.

The rigid PCB is so strong that you can not twist or bend the board. Rigid PCBs are made of rigid PCB substrates such as FR4, aluminum, and etc. Rigid PCBs are generally multilayer PCBs.

As the name describes, the flexible PCBs are made of flex materials that you can bend and fold. Generally, polyimide, Teflon, PEEK, or other transparent conductive polyester films make flexible PCBs.

Rigid-flex PCBs are a combination of rigid and flexible PCBs. The flexible part of the rigid-flex PCB is used for connecting narrower parts of the rigid boards.

The most popular of application is the LCD TV PCB board. These are used for high contrast television monitors. LCD is a cheaper alternative to plasma monitors.

When soldering the base metal of LCD PCB boards together, you may find that the solder does not adhere properly. When the melted solder fails to form a connection, this is referred to as a non-wetting defect of the printed circuit boards.

As a result, the solder materials do not conform to the requirement to attach to the PCB pads firmly. The boards’ surface materials are revealed due to the non-wetting flaw. Furthermore, the non-wetting issue contributes to the inability to create holes in the boards.

You may follow the following steps to fix the non-wetting defects on your LCD PCBs:Take proper action to prevent oxidation. Oxidation is one of the biggest causes of non-wetting defects.

Polyamide, commonly known as polyimide, is a PCB board material used to fabricate flexible printed circuit boards. Polyamide is made from a variety of materials, including silk and wool. It is widely utilized in the mass fabrication of LCD PCBs.

Filled Polyamide:To make filled polyamide, the materials polyamide and filler must be combined. Polyamide aids in becoming thermally stable, and the filler aids in the reduction of polymer contraction of the PCB.

Because of its flexibility and strength, there is a massive demand for polyamide in the PCB industry. Another point to consider, the use of suitable substrates in the right place is why this material is widely sought after.

The following are some significant advantages that polyamide has:The most common reason to use polyamide is its suberb flexibility. It is mainly used to produce flexible, rigid-flex LCD PCBs.

The LCD controller board is the board that regulates the LCD’s functions. The controller board creates video signals and connects them to various video sources. Then the board creates the visibility of the videos on the LCD when they are connected.

The following are some excellent features of LCD controller boards:The LCD controller boards are capable of displaying images in ultra-high resolution. The resolution may be as high as 3840 x 2160 pixels per point.

Impedance in LCD PCBs measures opposition to electrical flow, which is something measured in ohms. This measurement is vital for the operation of the circuits in high frequency.

Meanwhile, impedance matching is the arrangement for the maximum power transmission and minimum signal interference through the conductive traces of the PCBs.

Suppose you did not design the conductive traces with proper design rules. Then, the impedance for the traces will be mismatched. Due to this, your PCB traces will not behave normally.

The mismatch in environment and design will lead your PCBs to have signal interference. Also, you will likely experience inefficient power transmission. On the other hand, the controlled or matched impedance helps traces to pass signals without a hitch.

The PCB layer stack-up is the process of placing the copper layers and insulating layers one on top of the other. This facilitates you to design and implement many conductive layers of the LCD PCBs in a single PCB.

Multilayer stack-up is the central theme of the multilayer PCBs. Multilayer stack up provides you with the following advantages:Multilayer stack-up reduces noise, crosstalk, and radiation.

Mainly, vias provide conductive paths to the layer to layer in a multilayer PCB. These conductive paths ensure the electrical and thermal energy of the different layers.

Testing is among the most essential steps in manufacturing PCBs. Employ proper testing to ensure the required design facts for your LCD PCBs. The following are the most robust testing methods you can use for testing LCD PCBs.

ICT is the most common type of PCB testing. It is also known as a bed of nails testing. The ICT powers up and actuate every circuit on the board. The probes used in the ICT testing create a specific pressure range on the circuits.

In AOI, you have to use two 3D or one 2D camera to take photos of every board detail. Then, you need to compare the photos to the schematic of the LCD PCB. The PCB is okay if the comparison verifies that the board and the schematic are the same.

You cannot expect that your LCD PCB will last forever. But, that does not mean you cannot extend the lifespan of your PCBs. If you follow the following tips, you can extend the life cycle of your PCB significantly.

Temperature is a vital fact in electronics. High heat or excessive heat can harm your LCD PCBs in many ways. You need to monitor your LCD PCBs’ temperature else, the following harm can occur to your PCB:

Finding a reliable manufacturer for LCD PCBs is crucial. A highly skilled and experienced manufacturer can provide you with the best quality products. To find out the best PCB manufacturer, you should check the following criteria:The manufacturer should have intensive experience in the PCB industry.

As An LCD PCB enthusiast, you need proper knowledge about this type of PCB. We hope that this guide reconciled you with the type of information you need. Already, you might sense that a highly experienced manufacturer can help you produce high-quality PCBs for your business.

You may choose us, PCBMay, as your PCB manufacturer. We are a highly professional LCD PCB manufacturer in China. We have been successfully manufacturing all sorts of high-end PCBs for an extended period. You can contact us today to get the best quote for your LCD PCBs.

In ruling NY N320557 (August 4, 2021), Customs and Border Protection (CBP) discussed the country of origin of five Thin Film Transistor – Liquid Crystal Display (TFT-LCD) modules. All five modules are virtually identical in composition, as they are all composed of a TFT-LCD cell, polarizers, a backlight, a driver and control printed circuit board (PCB), and a flexible PCB for connection. TFT display technology allows for the construction of high-resolution LCD displays, and the modules – once completed – can be incorporated into a variety of consumers display applications.

The manufacturing process for the five modules is also identical. The process begins in Japan where the TFT-LCD cell is manufactured. The TFT is created by depositing transistors onto a substrate through chemical vapor deposition, while the color filter is manufactured by building a color matrix on a glass substrate. The creation process of the cells is then completed when a layer of liquid crystal is deposited between the color filter and TFT as the two part are bonded together, creating a sheet of TFT-LCD cells. As next steps, the sheet of cells is delivered to China to be cut into individual cells. The cut-up cells are then bonded to the printed circuit board assembly (PCBA) – which contains the driver and control circuity – before the polarizers, backlight, and flexible connection PCBA are attached.

CBP also established that “substantial transformation” takes place when a particular product “emerges from a process with a new name, character or use different from that possessed by the article prior to processing.” The agency explained that the completed TFT-LCD cell is what imparts the essential function of the module and that the manufacturing process in Japan is what renders the end-use of the product. Despite the assembly that took place in China, the process did not substantially transform the cell into a new and different article. As such, CBP determined that the country of origin of the five modules is Japan.

TFT LCD display is an ESD susceptible part within an electronic device. Electrostatic Discharge (ESD) is the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown.

We have this power grid device manufacture in Eastern China, who picks Topway as the TFT LCD display supplier for new circuit breaker project. The new circuit breaker"s TFT LCD screen is LMT035DNJFWD-NNA with resistive touch screen.

For a new electrical circuit breaker, certification process is very stringent. One day, the client asked Topway for on-site support. Their new circuit breaker fails ESD Class 3 (4KV~8KV discharge) test. During the test, LCD screen turns dark and becomes unresponsive. Disconnect then re-connect power supply is the only way to bring TFT LCD display back online.

Based on customer"s feed back and on-site analyzing, Kenny narrows down the culprit to radiated noise. Two modification suggestions are discussed with client"s engineers: Increase grounding contact area of TFT LCD metal frame to product PCB; Enlarge "floating" gap between circuit breaker housing and TFT touch screen.

TFT LCD display is vulnerable to EMI & ESD, especially with built-in touch screen. Checkout this post about LCD & EMI. As for ESD, TFT LCD display is mounted flush on an equipment façade. A discharge can reach the edge of the LCD frame, not fully released by product housing.

Making things complicated, the LCD frame is often connected to product PCB"s signal Gnd. Thus, the full discharge current can flow to equipment board. The solutions depend on finished product, conductive or non-conductive housing.

The TFT LCD display is sacrificed as entry point for ESD. Use a shielded flat cable, connect LCD frame to PCB ground; Increase insulation gap(float) between product housing and LCD display module.

eDP (embedded DisplayPort) cables are beginning to supersede LVDS as the cable assembly of choice for connecting driver boards to TFT displays. They use the same digital signal processing protocol as DisplayPort cables, but in a smaller physical connector.

Often manufactured from micro-coax cable, eDP cable assemblies require fewer connections than LVDS. They also offer all power, data and control signals through one single assembly. Where LVDS assemblies could require 18 signal wires, a comparative eDP cable would use only five.

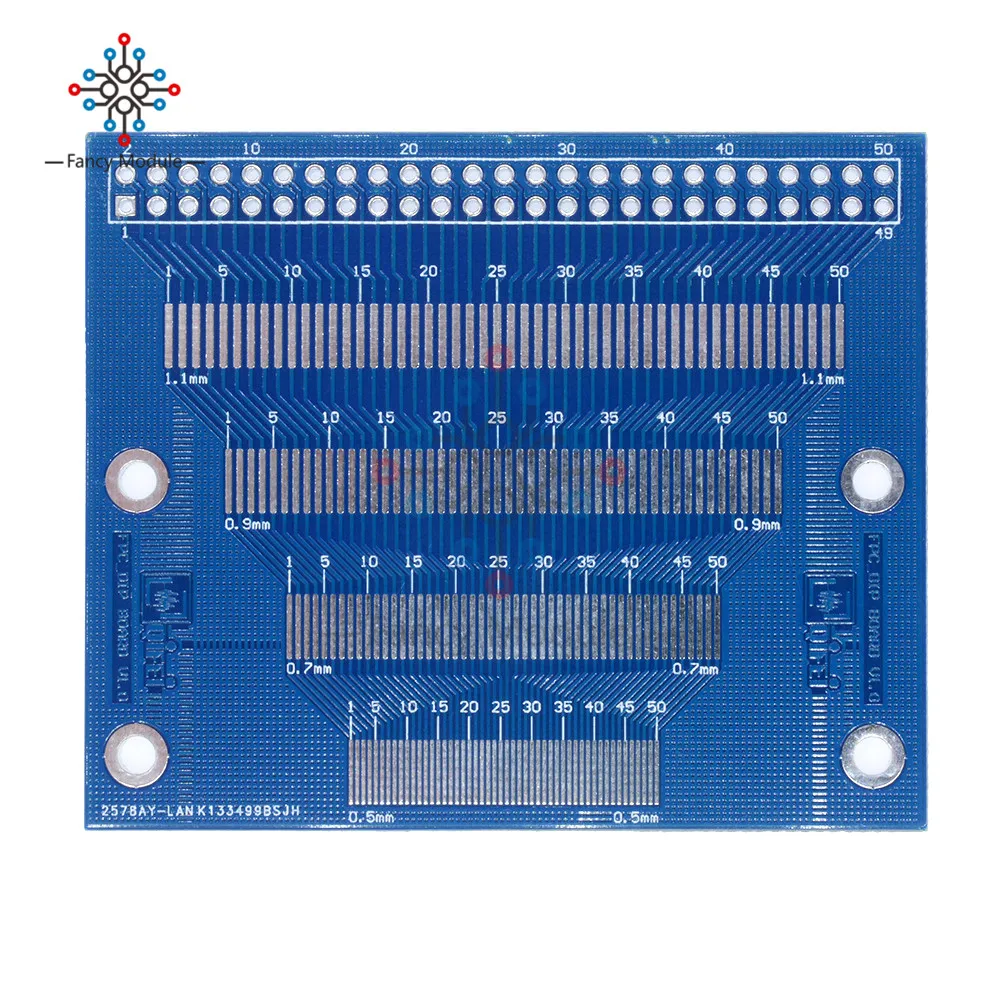

WO1602I3 and WO1602I5 are two models of 16 characters by 2 lines of COG LCD P/N WO1602I with PCB board on module. WO1602I3 and WO1602I5 are built in with ST7032i IC; it supports I2C interface. The advantage of WO1602I3/WO1602I5 is having circuit layout on PCB board and with screw holes which make modules can be fixed on customers’ applications easily. Also, there are three kinds of connector pitch sizes of 2.54mm (default), 1.0mm and 0.5mm for options.

The supply voltage for logic (VDD) of WO1602I3 is 3.3V; as to the WO1602I5 is 5V, 1/16 duty circle, 1/5 bias. The module can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃. WO1602I3 and WO1602I5 are available in FSTN positive Transflective LCD and with White LED backlight; please contact us if you need different types of LCDs or LED combinations.

WO12864K and WO12864K1 models are monochrome COG graphic LCD modules made of 128x64 dot matrix format. WO12864K/WO12864K1 COG Module is built in with ST7565 IC, it supports 8-bit 6800, 8-bit 8080 parallel and 4-wire serial SPI interface, power supply voltage 3V, VOP 9.5V, 1/65 duty. The WO12864K item is adopted ST7565V IC which is built-in with negative voltage, as to the WO12864K1 item is adopted ST7565P IC which is built- in with positive voltage.

This module can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃. WO12864K/K1 are available in STN Negative, Blue Transmissive LCD and with White LED backlight. Please contact us if you need different types of LCDs or LED combinations.

WO128128A2 model is a round COG LCD display WO128128A model with a PCB board on module. This Round STN COG module is built in with ST75161 IC; it supports 8080 parallel (default), 6800 parallel, 3-wire and 4-wire serial SPI, I2C interface, power supply voltage 3V, 1/136 driving duty, 1/12 BIAS. The advantage of WO128128A2 is having circuit layout on PCB board and with screw holes which make modules can be fixed on customers’ applications easily. Also, there are three kinds of connector pitch sizes of 2.54mm (default), 1.0mm and 0.5mm for options. WO128128A2 also have VDD 5V power supply voltage for optional.

The supply voltage for logic of WO128128A2 is 2.7V to 3.3V, typical value 3V. This module can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃. WO128128A2 is available in FSTN positive LCD type with white LED backlight. Please contact us if you need different types of LCDs or LED combinations.

WO240128B2 model is a COG LCD display WO240128B model with a PCB board on module, which is made of 240x128 dots. WO240128B2 is built in with ST7586S controller IC; it supports 6800 8-bit (default), 8080 8-bit parallel and serial SPI interface, power supply voltage 3.3V, 1/128 duty, 1/12 Bias. The advantage of WO240128B2 is having circuit layout on PCB board and with screw holes which make modules can be fixed on customers’ applications easily. Also, there are three kinds of connector pitch sizes of 2.54mm (default), 1.0mm and 0.5mm for options. WO240128B2 also have VDD 5V power supply voltage for optional.

This WO240128B2 module can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃. The WO240128B2 is available for FSTN positive Transflective with white LED backlight. Please contact us if you need different types of LCDs or LED combinations.

WO256128A2 model is a COG LCD display WO256128A model featured with a PCB board on module which is made of 256x128 dots, diagonal size 2.9 inch. WO256128A2 is built in with ST75256 controller IC, it supports 8080 8-bit parallel (default), 6800 8-bit and 4-wire serial SPI and I2C interface, power supply voltage 3.3V, 1/128 duty, 1/12 Bias. The advantage of WO256128A2 is having circuit layout on PCB board and with screw holes which make modules can be fixed on customers’ applications easily. Also, there are three kinds of connector pitch sizes of 2.54mm (default), 1.0mm and 0.5mm for options. WO256128A2 also have VDD 5V power supply voltage for optional.

WO256128A2 module can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃. The WO256128A2 is available for FSTN positive Transflective with white LED backlight. Please contact us if you need different types of LCDs or LED combinations.

Printed Circuit Board (PCB) are used in almost all kinds of electronic equipment. They are the supporter of electrical connections for electronic components. Read more for a brief introduction on PCB technology. Learn More.

The creation of high-speed digital is increasingly important. Designers use a series of material parameters such as the dissipation factor (Df) and the dielectric constant (Dk) to determine the suitability of high-speed PCB materials. Learn More.

This article aims to introduce the different types of materials used in the printed circuit board(PCB) substrates. The commonly used substrates include the organic substrate(FR-4), ceramic substrate, and metal substrate. Learn More.

This article aims to introduce the working principles of laser drilling in PCB. It also covers four laser drilling methods: single pulse, percussion, trepanning and helical drilling. Learn More.

This article aims to provide guidelines for both Radio frequency(RF) and microwave printed circuit board design. RF PCB is operating above 100MHz, while microwave PCB is operating above 2GHz. Learn More.

The prepreg acts as an insulator, bonding cores and copper foil together to make a strong PCB. This article briefly introduces what prepreg is and the differences between prepreg and core. Learn More.

Back drilling is used to remove conductive via stubs of the copper barrel in the through-hole in printed circuit boards (PCB). The stub can result in serious signal integrity problems in the high-speed design. Learn More.

PCB designs begins when a electronic engineer chooses the components required to perform the functions of the end product and then determines the best way to connect those components electrically. The design gives the manufacturer a lot of information including the PCB dimension, hole sizes and positions, and overall mechanical definition; it may also incorporate notes referring type of material, specifications, UL requirements, solder mask, and test requirements. Learn More.

The double-sided PCB (or 2-layer PCB) is the printed circuit board with copper coated on both sides, top and bottom. There is an insulating layer in the middle. To use circuits on both sides, there must be a proper circuit connection between the two sides. The “bridges” between such circuits are call vias. A via is a small hole on the PCB board coated with metal, which can be connected with circuits on both sides. Learn More.

As shown in fig. 1, a composite display integrating a TFT module and a VA liquid crystal panel includes a VA-type LCD panel 1, a TFT liquid crystal panel 4, a left LED backlight 6, and a right LED backlight 7, wherein the TFT liquid crystal panel 4 is attached to a central area below the VA-type LCD panel 1; the left LED backlight 6 and the right LED backlight 7 are attached to the left side and the right side below the VA type LCD screen 1.

The utility model also comprises a PCB circuit board 12, the PCB circuit board 12 is fixed below the TFT LCD screen 4 and the left LED backlight and the right LED backlight 6 and 7; the PCB 12 is attached to the VA mode LCD 1 and the TFT module 4 on the PCB 12 by means of the high viscosity foam 11 attached to the periphery of the PCB.

As shown in fig. 2, the circuit structure on the PCB circuit board 12 includes: the main control MCU is connected with a VA-LCD driving chip, a left LED backlight driving circuit and a right LED backlight driving circuit which are connected with ports of the main control MCU.

As shown in fig. 1-2, the VA LCD panel 1 is provided with a left FPC2 and a right FPC3, and the ports of the VA-LCD driver chip are respectively connected to the left FPC2 of the VA LCD panel through the left FPC socket of the VA-LCD and connected to the right FPC3 of the VA LCD panel through the right FPC socket of the VA-LCD.

And a driving IC is bound on the TFT liquid crystal screen 4, and a TFT-LED backlight 8 is also arranged at the bottom of the TFT liquid crystal screen 4.

The circuit structure on the PCB 12 further comprises a TFT LED backlight driving circuit, and a port of the main control MCU is directly connected with an FPC jack of the TFT liquid crystal screen and is connected to a driving IC of the TFT liquid crystal screen through the jack; the LED backlight driving circuit of the TFT has one end connected to the power supply and the other end connected to the FPC jack of the TFT LCD, and is connected to the TFT-LED backlight 8 of the TFT LCD via the FPC5 of the TFT LCD and the jack.

VA type LCD screen 1 is dot matrix LCD screen, the utility model discloses a circuit structure on PCB circuit board 12 still includes VA-LCD line drive enable circuit and VA-LCD row drive enable circuit that is connected with master control MCU, VA-LCD line drive enable circuit and VA-LCD row drive enable circuit are respectively through the left FPC of VA-LCD left side FPC socket connection VA type LCD screen, through the right FPC of VA-LCD right side FPC socket connection VA type LCD screen, line drive and row drive are used for the line and the display control who arranges to dot matrix type LCD screen-VA type LCD screen 1.

Like fig. 3-10, for in fig. 2 the utility model discloses an actual design of each chip and circuit of PCB circuit board, in fig. 3, main control MCU adopts STM32 singlechip, 32 bit ARM microcontroller, Cortex-M3 kernel, the highest operating frequency 72 MHz. And FLASH and SRAM are built in. The support sets are ADC, SPI, USB, I2C and UART, and their connection relationships with other chips and circuits are described in the foregoing description of fig. 2, and the port numbers of STM32 correspond to the interconnection port numbers of other chips one to one, which can be recognized by those skilled in the art and will not be described in detail.

In fig. 4, the VA-LCD driving chip of the present embodiment is ST7072LQFP80, and P32-P35 are ports connected to the main control MCU through I2C, corresponding to fig. 3. SEG0-SEG33 are port numbers corresponding to port numbers on the VA-LCD left FPC jack of fig. 8 and the 9VA-LCD right FPC jack of fig. 8, respectively.

Fig. 5-6 show the driving circuits of the left LED backlight 6, the right LED backlight 7 and the TFT-LED backlight 8, which are all driving circuits formed by transistors (Q3 drives the TFT-LED backlight 8, Q4 drives the left LED backlight 6, Q5 drives the right LED backlight 7), the power supply terminal VCC3.3V is connected to the base of the transistor, the backlight power output terminal VLEDK3(2, 1) is connected to the collector of the transistor, the emitter of the transistor is grounded, and the backlight power supply is connected between VCC3.3V and VLEDK3(2, 1).

Fig. 7 shows a VA-LCD row driving enable circuit and a VA-LCD column driving enable circuit of this embodiment, which are formed by transistors (Q1 and Q2 drive rows and columns, respectively), the base control terminals P15 and P16 of the transistors are connected to the master MCU port, and the collector output terminals TCOM and TSEG are connected to the VA-LCD left FPC socket of fig. 8 and 9 and the VA-LCD right FPC socket of fig. 9, respectively.

The FPC jack of the TFT liquid crystal panel of fig. 10 has a driving port VLEDK1 for the TFT-LED backlight in addition to a connection port to the main control MCU.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey