lcd panel manufacturing india brands

Searching for the best TFT LCD module manufacturers in India? Well, that is admittedly a daunting task. With the growing number of TFT LCD display suppliers and manufacturers, it’s truly hard to pick which ones are reputable and which ones are not.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and a consumer’s mindset.

Hence, we’ve rounded up 7 famous and reputable Indian LCD module manufacturers. These companies all produce quality display and screen-related products such as:

Videocon Industries Ltd is a well-known Indian manufacturer of TFT display modules, color TVs, home appliances, and consumer electronics. Videocon is a large company based in Mumbai, India.

Videocon has several manufacturing plants across different countries. It also boasts of several brands under its name, including Videocon Telecom, DigiWorld, Next, and Planet M.

The company takes pride in being India’s pioneer in color TV production and retail. Before the advent of the TFT display module, Videocon has been the world’s third-largest picture tube (CRT) manufacturer.

Videocon is popular for its high-quality products. Videocon manufactures an LCD display screen for LCD TV sets. A lot of Indians trust Videocon’s television sets.

Videocon assembles and manufactures their TFT LCD module products in world-class factories. The company’s main factories are in India. However, they also have manufacturing plants in Mainland China, Mexico, Poland, and Italy.

All of Videocon’s TFT LCD display products passed strict quality control checks. Testing is done throughout the entire manufacturing and assembly process. Furthermore, quality checks are done from the raw materials phase until the products’ release.

Videocon’s TFT display screens and TVs are affordable of good quality. The company knows how to manufacture quality TV sets at pocket-friendly prices since it is a pioneer in the Indian color TV industry.

Videocon’s mobile phone range is equipped with the latest touch LCD display technology. Smartphones are assembled in the company’s TFT touch screen factory. Hence, customers are ensured of high-performance mobile phones with a crisp touch screen LCD display.

To sum it up, Videocon Industries Limited is a strong TFT LCD display manufacturer. The company’s quality manufacturing plants, good end-products, and affordable prices make it among the famous TF LCD manufacturers in India.

Teronix is an Indian electronics company based in New Delhi. It specializes in TV sets with LED and LCD screen module technology. The company also offers a range of smart mobiles and power banks.

Teronix has been in the electronics industry since 2017. But the company has proven that it has what it takes to be a reputable LCD manufacturer in India. Teronix has risen to popularity among Indian consumers because of the following qualities:

The company’s products are all high-quality and durable. Teronix sees to it that its range of smart LCD and LED TVs, along with their other products, reach their customers in good condition, and perform at their best all the time.

Teronix knows that good quality LCD module and other electronic parts are the cores of high-performance products. Hence, their assembly and product research units are stocked with the latest technology to produce the best possible products. Furthermore, Teronix’s research and assembly hubs are strategically located in Delhi.

BPL Limited is a recognized Indian leader in health care equipment and consumer electronics. The Bangalore-based company operates business groups which include:

The company started manufacturing televisions and telecom equipment in the 1980s. BPL joined forces with Japanese company Sanyo in 2006 to strengthen BPL’s consumer electronics brand, including TF-LCD display products and color televisions. The joint venture ended in 2007, leaving BPL to focus on its healthcare equipment sector.

1. BPL takes pride in its superior-quality television sets. The TVs are made with combinations of TFT-LCD display and LED output. The products are manufactured by third-party TFT LCD suppliers. Then, the TV parts are assembled at a plant in Baddi, Himachal Pradesh.

2. BPL also takes the lead when it comes to medical display equipment. BPL uses different combinations of TFT display, VGA output, LED, and touch LCD display to manufacture the following devices:

3. The company upholds strict quality standards in all TFT LCD display products. This is achieved through quality tests at all stages of production and assembly. Even the third-party suppliers providing the raw materials for TFT-LCD modules are required to run through tests to ensure quality.

In a nutshell, BPL continues to be an industry leader in India’s consumer electronics and medical equipment industries. BPL provides households and health facilities with top-notch TFT-LCD display module sets used in televisions and health monitoring equipment. And in recent years, BPL has clearly shown no signs of slowing down.

Dixon Technologies Limited is a long-standing company providing consumer electronics, LED and LCD TVs, light fixtures, appliances, mobile phones, and CCTV systems. The company was founded in 1993 with its current headquarters in New Delhi and Uttar Pradesh.

Dixon’s creed is providing consumers with world-class products at affordable prices. Consequently, the company is among the top TFT LCD manufacturers in India because:

Dixon is proud to create its products in local factories. For instance, the company has an LCD display module factoryin Tirupati, Andhra Pradesh. Furthermore, the company also operates three facilities in Uttarakhand and three more in Noida, Uttar Pradesh.

Reasonable prices also make Dixon’s LCD module products and TVs appealing to the public. Couple that with features that are on par with the world’s best TV sets. Dixon believes that quality shouldn’t be sacrificed at the expense of affordability.

In conclusion, Dixon Technologies (India) Limited is among India’s famous TFT LCD manufacturers simply because it provides original, feature-packed, high-quality, and pocket-friendly products to both tech companies and end-consumers.

Oriole Electronics is an electronics company based in Mumbai. It was established in 1972 and is among the famous long-standing TFT LCD manufacturers in India.

Oriole’s strongest quality lies in its extensive experience in the TFT LCD and electronics industry. The company’s experience puts them at an edge against many younger industry competitors. All these thanks to several insights and expertise the company collected since 1972.

Another Oriole advantage is its in-house Research and Development team. Oriole’s R&D team conceptualizes products for its customers. They also formulate quality control guidelines that are strictly implemented during the production and testing phases. All these things are done to ensure the highest quality of Oriole’s TFT, LCD modules, and other product ranges.

Speaking of quality, Oriole is also ISO 9001:2008 certified. This credential ultimately proves the company’s utmost dedication to quality processes. Also, this ensures consistent operations of Oriole’s TFT LCD display factory network throughout India.

To wrap it all up, Oriole Electronics is indeed a quality display module manufacturer in India. Superior quality products, customized services, and affordable rates – all of these are testaments to Oriole’s good reputation.

RandServ proudly provides and even encourages custom manufacturing services. The company responds to unique client needs by creating LCD display modules and designs according to customer requirements. RandServ lets clients specify custom shapes, display sizes, and interactive touch support integration.

Another good point of RandServ is its superior-quality product range. The company may be new to the industry, but its products are made with world-class technology and attention to detail. RandServ’s electronic, TFT, LCD, and LED technologies make their end-products among the most long-lasting and robust electronic/digital products in the Indian market today.

Businesses across several industries tend to neglect ethical business practices. But not RandServ. The company takes pride in its clean business practices and integrity. Commitment to ethical standards enabled RandServ to steadily grow as a reputable LCD screen manufacturer.

In conclusion, RandServ Systems deserves a spot in our 7 famous TFT LCD manufacturers list mainly because of three things – cutting-edge LCD and digital products, customized client services, and high regard for ethical business practices.

Royal Display India is a reputable TFT display supplier and manufacturer based in Mumbai. Royal Display is relatively new, being in the business since 2003. But the company didn’t let their newness stop them from growing into a successful LCD display supplier and manufacturer.

Another considerable advantage of Royal Display is its spacious manufacturing and warehousing units. Both are located in Maharashtra. The manufacturing unit boasts of specialized techniques used to produce modules for TFT, LCD, and OLED. Meanwhile, the warehouse unit is large enough to accommodate bulk orders from clients.

To wind this up, Royal Display is a young yet quality manufacturer for LCD modules and other related display screens in India. The company continues to grow with its plethora of quality display products coupled with many satisfied clients.

To conclude, Teronix is a young but reputable and promising LCD manufacturer in India. Lots of satisfied customers flock to them because of their dedication to high-quality products and top-notch manufacturing technologies.

To conclude this post, we’ve rounded up 7 Famous TFT LCD Manufacturers in India. Some of them are industry pioneers, while some are novices. However, we’re sure all these reputable companies will be a good source of products for all your display module needs.

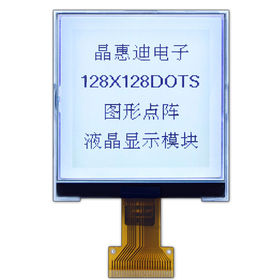

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystalsread more...

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

ROYAL DISPLAY was established in the year 2003 in Mumbai, India with a single goal of bringing the best technology in Display-world to its customers. Back then, Display industry in India was still very new and LCD was a thing of fancy. Royal display began operations with an aim to distribute LCD displays to all prospective industries. In the initial stages, while in 2003, all our displays were sourced from Tiawan and we managed to set up an efficient supply chain for display from Taiwan in to India. This not only leveraged us the first-movers advantage but also put us on top of a very fast growing customer base in India A further expansion of customer base in year 2007, we have started TFT,, Touch screen and OLED marketing and started direct dialogue with most manufacturers in Korea & Taiwan making it possible for us to buy from origin. This was our answer to customers on quality-assurance. From supplying LCD Modules to public phone Manufacturer back in year 2003 to selling Displays for Military applications, Medical & Industrial Application, Royal Display has come a long way in defining and redefining values for its products to customers in India. We enjoy a niche customer segment in all industry verticals due to the technical expertise we acquired in all these years. Our focus still remains to be `Bringing the best display technology? to our customer. However a newer multi-dimensional approach has carved a way out for us in this world of stiff competition. At Royal Display, all are commitments are abiding and we take pride in delivering our best when it matters most.

Our commitment towards successfully catering to the requirements of market for LCD display has motivated us to consistently engaged in trading comprehensive range of these products. This range comprises of technically advanced LCD modules such as RS232 interface colour TFT, SPI interface colour TFT, and many more. Adding to this, this range also encompasses various OLED display TFT display open frames form 5.6” to 10.4” with A/D card and many more which are widely appreciated for a number of in-built high quality facilities. We also offer wide range of Touch screens in various technology which are absolutely latest of its kind in domestic market. Apart from these, we also now offering Tablet PC, MID(Mobile internet Device), Panel PC and Projected Capacitive Touch screen

Further, we are also engaged in manufacturing superior range of customized lift LCDs that have large number of quality features. The entire range of our products is acknowledged for entailing different advanced qualitative features; some of which include:

Understanding the value for money and time of clients, we always emphasize on sourcing our entire range of LCD display products strictly from reliable vendors who already have recognized place in their domain of expertise. In addition to this, we take care of the needs of market and clients along with upcoming trends at the time of market survey and bargaining with vendors that enable us to be updated in terms of technically advanced Display products for mobile, computer and other electronic items.

Our technically advanced products have varied applications in a large number of industries that successfully cater to specific requirements of their user. Some of the significant industries in which our LCD display products are proficiently utilized entail:

Over the years of our operation, we have garnered a viable team of industry experts who have extensive experience in their domain of activity. This team forms the backbone of our organization capitalizing on which we have made inroads in trading business and gained a position of repute across the Indian market as a dependable trader, distributor and marketer. Our team comprises of:

Each of the team members is filled with true team spirit that consistently motivate them to proceed in right way with right efforts to achieve aims and goals of our organization. Procurement specialists and distribution experts work in close coordination in order to source the most reliable product from the premises of vendor. They are proficiently supported by our marketing experts and market analysts who provide them significant information on latest market developments in terms of trends, requirements and demands for LCD display products. This helps our procurement expert to draw effective strategy for approaching the most suitable vendor and initiating discussions on procurement issues.

Further, our business managers are innovative and quite capable to manage entire business procedure and in maintaining appropriate balance among various team members. They guide marketing expert & analysts on various issues involved in marketing and gathering requisite information on analyzing market for LCD display units that are demanded in a host of industries. Moreover, we undertake in-house training session for our team members that help them to upgrade their skills.

Further, we have made appropriate arrangements for packaging of these products which are a significant stage of our activity. In order to package each of the LCD display product, we utilize sturdy & dependable material that ensure safety of these products during the process of transit. Adding to this, we undertake customized packaging which is guided by details of packaging as per the specifications provided by our clients.

V5 semiconductors can meet the demands of Character, OLED, TFT, COG, Graphic LCD, Control Board, and AD Board of various sizes that will be needed for use and development of new technologies and progress of existing industries.

A few India-based enterprises have decided or plan to set up display panel plants in India, but this is unlikely to have substantially impact on the existing global display supply chain in the foreseeable future, as the total panel production capacity in India will be much smaller than that in China, South Korea, Taiwan and Japan.

Under the Indian government"s Production Linked Incentive (PLI) scheme, Elest, a subsidiary of India-based Rajesh Exports - which is among the globally top-500 enterprises - will invest INR240 billion (US$3.01 billion) to set up a 6G AMOLED plant in Telangana State, central India, to produce smartphone, tablet and notebook applications.

India-based oil, gas and metal producer Vedanta has acquired Japan-based LCD glass substrate maker AvanStrate and applied to the India government for setting up a 8.6G TFT-LCD plant in India. Vedanta in February 2022 signed an MoU with Taiwan-based Foxconn Electronics to establish a joint-venture maker of semiconductors. As Taiwan-based LCD panel maker Innolux is AvanStrate"s client and has a 8.6G LCD plant in southern Taiwan, Vedanta could cooperate with Innolux via AvanStrate.

With subsidies under India government"s PLI scheme and UP Electronics Manufacturing Policy 2017 set by the state government of Uttar Pradesh, northern India, Samsung Display (SDC) invested US$654 million to set up a panel module factory in the state and started production in April 2021.

Samsung Electronics, SDC"s parent company, has cumulatively invested over US$1.1 billion in India and has been shifting production lines from China and Vietnam to India. The company has set up two large production bases and five R&D bases in India.

According to DIGITIMES Research, Samsung Electronics" factories in India produced about 60 million smartphones in 2021 and are expected to produce 93 million in 2022 and 108 million in 2026, with the proportion of total smartphone output from India to rise from 20% in 2020 to 29% in 2026.

Although Samsung is expanding its production in India, clustering and production of its South Korea-based supply chain makers in India are currently much smaller than those in Vietnam.

China-based panel maker China Star Optoelectronics Technology (CSOT) has invested INR18.3 billion to set up a factory to produce 5- to 65-inch LCD modules in Andhra Pradseh, southeastern India. With annual production capacity of 8.0 million LCD modules, the factory is intended to mainly support TCL, CSOT"s parent company, to sell LCD TVs in the India market. TCL expects to sell 10 million LCD TVs for a market share of 7% in India in 2022. TCL currently ranks fourth in the India TV market and aims to surpass Sony, ranking third with a market share of 12% at present, by the end of 2022.

Taiwan-based LCD panel maker AU Optronics (AUO) has evaluated the feasibility of investing in India. There are problems concerning culture and government efficiency in India, AUO chairman Paul Peng has said.

Some cities in India are ambitious to create manufacturing hubs through developing industrial districts of which some have development potential and are likely to replace some locations in China, Peng noted. However, India is impossible to completely replace China in terms of investment in manufacturing, Peng indicated.

Besides, infrastructure in India and Vietnam is insufficient and, in the case of Vietnam, surging investment has sharply shored up factory land prices and this will affect foreign enterprises" willingness to invest, Peng said. In fact, it is very difficult for Thailand, Indonesia and even Taiwan to completely replace China in manufacturing, Peng noted.

There are many factors that need to be considered in setting up overseas factories, including ecosystem support, infrastructure and local talent, Peng said. India is not ideal in terms of these three factors, and exiting panel makers are quite unlikely to set up panel lines in India for the time being, Peng noted.

China-based panel makers had kept expanding production capacities for nearly 10 years and, as a result they together occupied over 60% of global production capacity for LCD panels as of 2021, followed by Taiwanese makers with 20%, South Korean ones with 10% and Japanese ones with 6%.

Since major Chinese makers are still expanding LCD panel production capacities, China"s combined share of global total will reach 70% in the mid- to long-term.

In view of diminishing competitiveness in LCD, SDC terminated LCD panel production in June 2022 and has shifted focus to AMOLED. Taiwanese LCD panel makers are expected to benefit from SDC"s exit but are still far less competitive against Chinese fellow makers in production capacity. Therefore, they have chosen not to expand production capacities and have focused on high value-added LCD panels.

The government on Saturday revealed that it has received proposals from five companies to set up semiconductor and display manufacturing facilities in India with an investment of $20.5 billion -- around 1.53 lakh crores (

The recently announced Vedanta-Foxconn joint venture, IGSS Ventures and ISMC have proposed to set up semiconductor manufacturing facilities with an investment of $13.6 billion, while also seeking the support of $5.6 billion from the government under the Rs 76,000 crore Semicon India Programme.

Moreover, Vedanta has teamed up with another company dubbed Elest for setting up display manufacturing facilities. They"ve submitted applications for setting up display fab projects with an investment of $6.7 billion while seeking financial support of around $2.7 billion from the government.

All the aforementioned applications have been acknowledged by India Semiconductor Mission which was set up as an independent institution to take the Semicon India program further. ISM will also be responsible to coordinate with companies while also reaching out to state governments to offer access to infrastructure.

Manufacturing and Service Providing a Broad Range of PCB Assembly, LED Strips, Circuit Board, LED Bulb PCB, Touch Switch and Soldering Services. ...More

LED Display, Outdoor And Indoor Video Wall, Digital Signage, Bank Displays, Electronic Displays, Large Format Display, Car Parking Guidance Systems, Touch Screen Panels, Make Your Car Products ...More

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

MUMBAI: Vedanta Group"s owner Anil Agarwal is setting up the country’s first LCD panel manufacturing plant in Maharashtra with an investment of $10 billion ( Rs 68,000 crore).

The investment is through a new company called Twinstar Display Technologies, which is promoted by holding company Volcano Investments, chairman Agarwal said in an exclusive interview with ET. The metals tycoon is set to sign a memorandum of understanding with Maharashtra government on the first day of "Make in India" week.

"All over the world you see Made in China electronics, but India can also manufacture its own electronics," Agarwal said. "We worked with the government and agreed this project has to be aMade in India product." Agarwal said the company will endeavour to make India a significant export hub of display units with the setting up of the unit, known as Panel FAB. India’s LCD market is entirely import-dependent.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

According to a news release from the Ministry of Electronics and IT, Vedanta Foxconn joint venture, IGSS Ventures, and ISMC plan to invest $13.6 billion in electronic chip manufacturing plants and have requested $5.6 billion in funding from the Centre under the Rs76,000 crore Semicon India Programme.

According to a news release from the Ministry of Electronics and IT, Vedanta Foxconn joint venture, IGSS Ventures, and ISMC plan to invest $13.6 billion in electronic chip manufacturing plants and have requested $5.6 billion in funding from the Centre under the Rs76,000 crore Semicon India Programme.

"Despite aggressive timelines for submission of applications in this greenfield segment of semiconductor and display manufacturing, the scheme has elicited good response."

According to the statement, Vedanta and Elest have sought approvals for setting up generation-8.6 TFT LCD display fab as well as 6th generation display FAB for the manufacture of AMOLED display panels that are used in smartphones.

The India Semiconductor Mission (ISM), which was established as an autonomous agency to drive the Semicon India initiative, has granted recognition to the applicants under the semiconductor and display fab programmes.

The Indian semiconductor market was worth $15 billion in 2020, according to the government, and is expected to reach $63 billion by 2026. The display panel industry in India is predicted to be worth roughly $7 billion and is expected to reach $15 billion by 2025.

Officials claimed the government was in negotiations with industry giants including Intel, Samsung, Global Foundries, and Taiwan Semiconductor Manufacturing Company about applying for the plan and investing in India.

According to a news release from the Ministry of Electronics and IT, Vedanta Foxconn joint venture, IGSS Ventures, and ISMC plan to invest $13.6 billion in electronic chip manufacturing plants and have requested $5.6 billion in funding from the Centre under the Rs76,000 crore Semicon India Programme.

According to a news release from the Ministry of Electronics and IT, Vedanta Foxconn joint venture, IGSS Ventures, and ISMC plan to invest $13.6 billion in electronic chip manufacturing plants and have requested $5.6 billion in funding from the Centre under the Rs76,000 crore Semicon India Programme.

https://techgig.com/generateHttpWebService-v2.php?tgtype=SAVE_NEWS_READ_LOGS&news_id=89726237&news_title=5 Companies that are ready to open chip and display manufacturing plants in India&news_sec=Technology&tags=india,

&news_url=https://content.techgig.com/5-companies-that-are-ready-to-open-chip-and-display-manufacturing-plants-in-india/articleshow/89726237.cms&ppuserinfo=

Ösel is one of the few original equipment manufacturers (OEMs) of LED signage display systems in India. We manufacture the full range of LED display panel systems including all the major components at our ultra-modern plant in Greater Noida, in Delhi NCR. We also offer, off-the-rack, integration-ready and bespoke HD LED display solutions. The LED display solutions we offer, are designed for indoor, outdoor and semi-outdoor settings that essentially covers all the major locations of LED display panel systems. The material used to manufacture Ösel are robust and durable even in the most challenging environments. Ösel assures you the highest levels of customer care and project management services.

With the discerning consumer no longer being impressed by a bunch of television sets stacked together in a grid, LED video walls have grown in popularity in the past few years. Unlike LCD TVs and their thick bezels, LED display walls come with seamless splicing and the ability to showcase high-resolution visual content as if it were being played on a single screen. Know more…

Ösel is a sought-after LED display solution because of its price advantage and quality. Ösel has full-fledged manufacturing facilities in India, allowing it the cost advantage, which it passes on to the buyer.

The retail sector in India is going through a fresh period of growth. But even as retail spaces mushroom throughout the country, not all are able to operate successfully.

Doordarshan is the national broadcaster of India with a countrywide network of studios and with headquarters at Mandi House in New Delhi. Doordarshan have been using a few rented video walls in its studios at the Mandi House headquarters and a few other locations across the country.

This company manufactures the full range of LED display panel systems including all the major components at its ultra-modern plant in Greater Noida, Uttar Pradesh.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey