mount lcd panel in pelican case quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Model SRD-VR-185 LCD monitor is a true daylight readable high brightness NEMA 4 (IP65) rated product and utilizes the latest 18.5” 1920 x 1080 resolution TFT Flat Panels. AbraxSys has added a versatile Analog-Digital interface board, backlight inverter and OSD controls. All elements, including a toughened glass protective screen have been packaged in a compact, rugged metal housing. The result is a flexible Display Head, ready for integration as part of any system; as an analog monitor, or a touchscreen driven human-machine interface.

This industrial grade Sunlight Readable NEMA 4 IP65 LCD TFT monitor is designed for use throughout a wide range of harsh outdoor applications. These rugged daytime viewable LCD displays are rigorously tested to ensure compliance with various industry standards and are engineered to withstand the effects of severe environments such as water, dust and dirt intrusion. These products perform well beyond ordinary ‘commercial’ type monitors. AbraxSys" high bright Sunlight Readable LCDs are ideal for use in any high ambient light condition, and will give you the intensity and brilliance your application requires..

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Merchandise returns must be shipped, pre-paid, at the customer’s expense. All returned items must be in "as-new" condition, in their original packaging, with all accessories enclosed. The original packing slip must be included and the Return Merchandise Authorization (RMA) number must be visible on the outside of the shipping package. To obtain a RMA number, call our customer service department at 888.515.5255. You must be able to provide the following information: the quantity and item number of the product to be returned, the date of purchase, the invoice number, and the cost of the item. Discrepancies or missing information may result in delays or refusal of your refund. Merchandise returned to Cases By Source, Inc. without a RMA number will not be accepted. The issuance of a RMA number does not guarantee that a credit will be issued.

If part of a product becomes defective, the entire item must be returned for credit or replacement within 10 days of the invoice date. A packing slip—with the item number(s) and a description of the defect—must be included in the package. At its discretion, Cases by Source, Inc. will repair or replace defective goods. Please Note: Following repair or replacement, defective goods will be returned to customers in the same box in which they were received by Cases By Source, Inc.

All merchandise returns—defective or otherwise—are subject to thorough inspection by a Cases By Source, Inc. representative. Merchandise credits are issued at the company’s discretion, based on the aforementioned requirements and instructions. A $25.00 re-boxing fee will be charged for credited products not returned in the original manufacturer"s packaging.

Please allow 2-4 weeks for refunds to be processed and credited to your account. If your order was charged to a credit card, we will need your card number to process the refund (Orders placed online do not provide full disclosure of the card information.)

All products come with the manufacturer’s warranty against material and manufacturing defects. This warranty specifically excludes misuse, abuse, and normal expected wear and tear. Wheels are not covered by this warranty.

At our discretion, Cases By Source, Inc. retains the right to repair, replace, or issue credit for products covered by this warranty. Custom product warranties are considered on a case-by-case basis, but must be agreed upon in writing in advance. Products found to be defective more than 30 days after shipment from Cases By Source, Inc. should be returned to us at the customer’s expense. Products found to be defective upon receipt (within 30 days of the invoice date) are to be returned by the most cost-effective method at Cases By Source, Inc.’s expense. Before products are returned, a Return Merchandise Authorization (RMA) must be obtained. See “Returns and Exchanges” section for information about obtaining a RMA.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

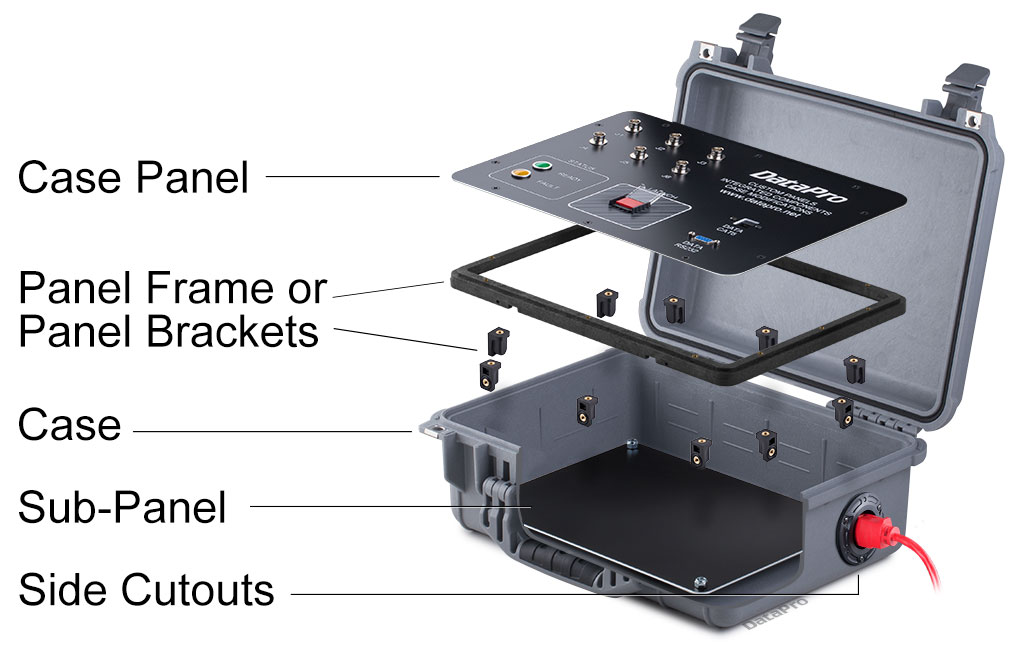

Many Pelican™ cases can be adapted for use with electronic interface panels by using a Panel Frame (Pelican™ Protector Case™) or Bezel Kit (Pelican™ Storm Case™) accessory. Mount most interface panels (customer supplied) flush with the rim of the Pelican™ Protector Case™ or desired area in a Pelican™ Storm Case™, and your technology is ready to go.

A polymer o-ring seals the panel so the base of the case remains watertight, even with the lid open. The mounting bracket, fasteners and o-ring are included in the Panel Frame Kit.

My latest project is an Xbox 360 stuffed inside of a Pelican 1490 case. The intention here to create a “tough” portable Xbox 360 that can be transported with ease.

This unit was built because I’ve had a lot of requests for game consoles that could be used overseas by our servicemen and women and I thought it’d be interesting to take a crack at the concept. It was not built on consignment, a rarity for me these days, so it is up for grabs. I’m also interested the larger-scale possibilities of this kind of project if anyone has any ideas/money.

The idea for this unit was inspired by Clint Green’s cases that I saw last May in D.C., you can check out his site at www.greenbarron.com/armoredgaming.

Here’s the briefcase at the beginning of the project. We tried a couple different sizes, this is the slightly smaller one. The first and most basic idea was to NOT drill holes through the surfaces of the case itself so it remains watertight/proof/whatever they claim it is.

Inside the top half behind the screen. The LCD’s internals are mounted to the inside of the via a wooden frame (hey, it was the right thickness) and… wait for it… INDUSTRIAL STRENGTH VELCRO! No, really! It’s actually called “self-lock mushroom head” as it adheres to itself.

The white plastic on the sides is the mounting frame that Velcros (now a verb) to the inside of the lid. I had to figure out the inner curvature and was only about 30% off for a change!

Velcro is applied in small bits to the sanded inside surface of the case and then matching Velcro, mounted to a frame on either side of the LCD, latches onto that. So basically the LCD and metal frame Velcro into place, which sounds cheesy but this mushroom head stuff is reallytough. It’s quite a chore pulling the screen back out again to make changes, but possible. I actually used less Velcro than originally planned because it was too difficult to pull out originally, and I always build things in such a way they can be taken apart. (despite what my hot-glue obsession might make you think)

With the screen portion done I tested the basic idea of fitting a 360 inside the bottom of the unit. Seems to fit. The LCD is a newer version of the kind I’ve been using in my last few Xbox 360 laptops, it’s still a Gateway but now the resolution is slightly higher.

The next step was to take the XBox apart further and see how best to mount the DVD drive and power supply. This configuration looks like it will work, and have some extra “cord room” under the DVD drive itself.

To keep all of the components inside the case the DVD drive needed to be modified. This was done by disabling the tray eject mechanism, designing a PS1-style disc lid and finally installing new limit switches to detect the position of the new door (open or closed).

My old Shawn Mullins CD is the sacrificial lamb for this first reworked DVD drive tests – my apologies to the person who bought it for me back in the day.

Here is the disc holding magnet, built into a new aluminum ring retainer. I had to make all this stuff quite accurate since the Xbox spins the DVD at approximately 75% the speed of light. This is actually the first time I’ve reworked a drive in such a way since the infamous MGDpc.

In the end it worked out OK – there was a bit of scraping, but this was solved by putting some .020″ spacers on either side the disc on top of the white frame.

I tried to motorize the lid but I was unable to. Thus the disc must be changed with the Xbox powered off. This is unfortunate, but since I consider this unit a proof-of-concept prototype I’ll let it go for now. “Next time, baby!”, to quote Terrence Howard’s rather-ironic statement in Iron Man.

Here is the Xbox 360 motherboard used with this project. Since I’ve been working on this for a few months this is still the older Falcon board. I thought about using one of my Jaspers but the mods on the Falcon DVD had already been done and as many of you know the DVD drive is keyed to the motherboard so I can’t mix and match.

Anyway, having a bit of room to work with, I slapped a bunch of copper plating on top of the GPU, as well as some just above the heatpipe, a heat sink on that, and a 50x50x10mm fan on the GPU’s external radiator.

Two main fans blow air across the GPU and CPU in place of the stock fans. (I don’t know why I always replace the fans since they’re one of the more expensive parts to re-buy) The basic idea is to get the hot air out of the case, blow it across and then up.

Installing the parts in the bottom half of the case. The super-Velcro was used again, in fact, I made damn sure I had all the connections done to the motherboard that I needed because I’m not sure it actually could be removed without damage. Seriously, buy some of it, it’s awesome.

The bottom frame getting attached to the internals. Kind of looks like a mess, but the only things interconnected are SATA DVD, DVD power, AC power plug, Speaker out, HDMI out, Speaker In, Speaker Amp power, USB port, Ring of Light/Death, Ethernet and SATA hard drive. OK I guess that is a lot, but really, didn’t seem that bad to me.

To all aspiring modders – buy and use a lot of headers and receptacles. It takes longer and costs more than just wiring crap together, but when you have to pull a project apart for the zillionth time while troubleshooting you’ll thank yourself.

…but hey, there’s an Ethernet port finally! Don’t know why I didn’t do these before, the jack costs a whopping 2 bucks at Menards. This unit does not have a Wi-Fi module at present.

End view of the unit opened. All of the components in the lower half are flush with the surface so the unit can actually close

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey