lcd panel pinouts diagram brands

This is a page where you can find common laptop/desktop LCD panel pinouts and see if your laptop screen"s pinout matches any one of them (it likely does!).

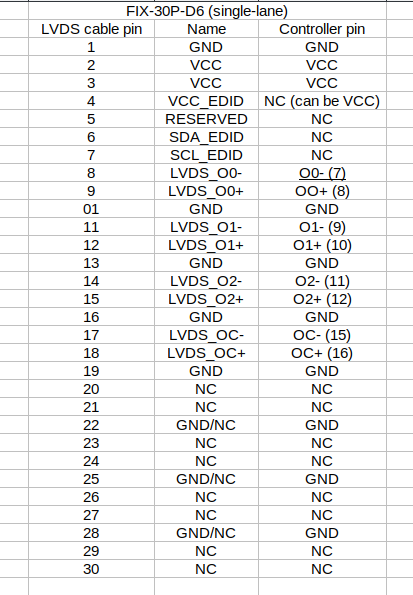

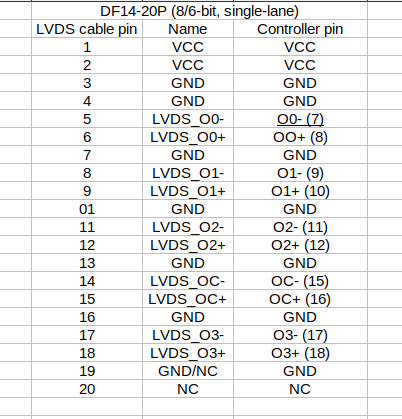

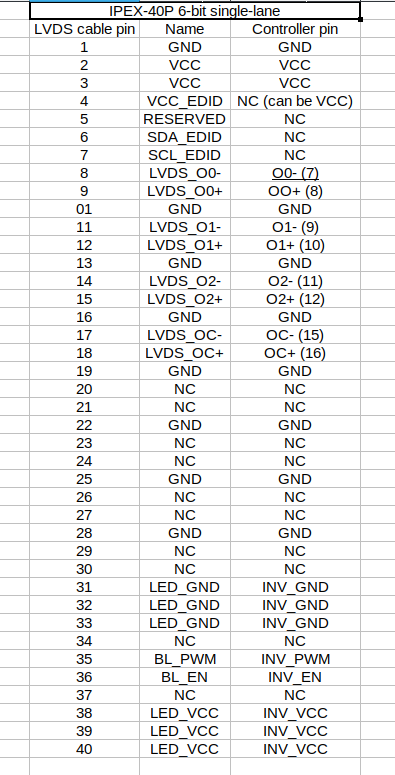

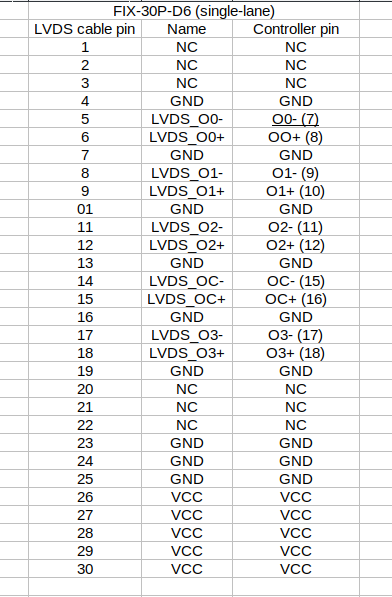

This is a very common pinout for higher-resolution CCFL displays. If you have a 1440x900, 1400x1050 or 1680x1050 panel, it"s likely using this pinout.

This is a pinout for desktop LCD monitor screens - laptop panels do not use this pinout (if there are some, let me know). If you"re ordering a MT6820 (MT561) board, it will arrive with a cable that has this specific pinout and is therefore incompatible with laptop screens - as you"re likely here to reuse a laptop screen, you will want to either rewire the cable you get, or order a suitable cable (for either A or B pinout, whichever you need) from the beginning.

This is a pinout that"s, apparently, specific to a select range of 18.5" 1366x768 displays used in desktop LCD monitors. It"s not compatible with either A, B or C pinouts, and requires a specifically wired cable.

In some datasheets, the pinout will list extra pins - one before and one after the main pins, both would be described something like "shield GND". So, for a FI-X 30-pin connector, you might find a pinout in your datasheet that lists 32 pins instead of 30. These two pins are not "real" connector pins and you shouldn"t worry about them - they"re pins that the manufacturer decided to mention for some reason, but they"re not relevant when you are actually connecting to the panel.

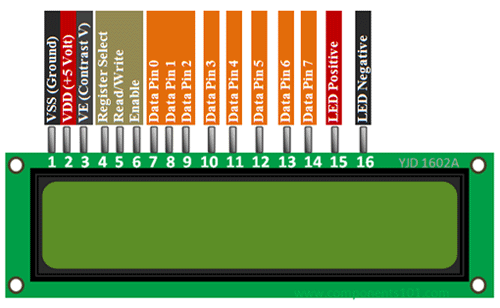

16x2 LCD modules are very commonly used in most embedded projects, the reason being its cheap price, availability, programmer friendly and available educational resources.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. but the most used one is the 16×2 LCD. So, it will have (16×2=32) 32 characters in total and each character will be made of 5×8 Pixel Dots. A Single character with all its Pixels is shown in the below picture.

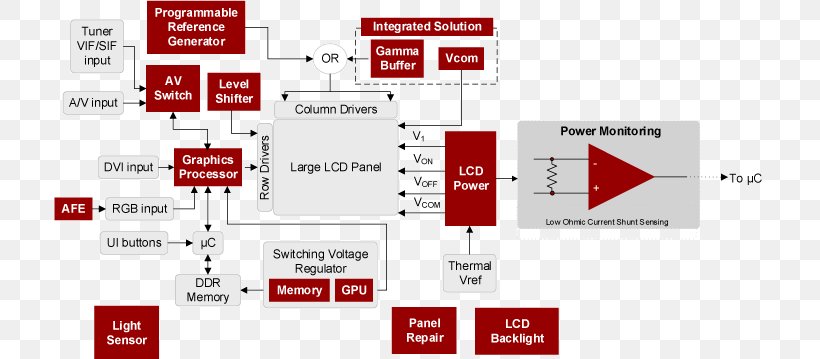

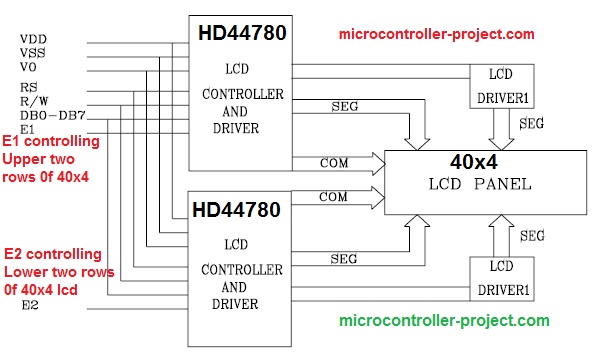

Now, we know that each character has (5×8=40) 40 Pixels and for 32 Characters we will have (32×40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels. Hence it will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780is used, which is mounted on the backside of the LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen. You can learn how to interface an LCD using the above mentioned links. If you are an advanced programmer and would like to create your own library for interfacing your Microcontroller with this LCD module then you have to understand the HD44780 IC working and commands which can be found its datasheet.

Elastomeric connectors, also known as ZEBRA strips, are a common connection type for LCDs with surface mount connections. A ZEBRA strip connector is comprised of a malleable insulation strip with alternating conduction lines and can be used as a substitute for a hardwire connection. These connectors get their name from their alternating conduction lines that appear as stripes, similar to a Zebra.

ZEBRA strips are positioned between a display’s connection ports and its controller. They then require a bezel to ensure a proper connection with the display. Once the bezel has been applied, the ZEBRA strips compress against an LCD’s surface mount connection ports. The resulting pressure from the bezel allows for a solid connection between the conductive strips and the display.

This connection type is a good option for testing and prototyping displays as there is no need to permanently connect pins to the display. ZEBRA strips are also a good option for thin, compact LCD and PCB designs. For example, if limited space is available within the enclosure, a ZEBRA strip can be used as an alternative to metal pins or ZIF connectors. ZEBRA connectors can also often be a cheaper alternative to other connection types.

The flexibility of an FPC cable is ideal for compact devices. The cable is made of a flat, bendable material that insulates the conductive wire connected to the LCD. The conductive leads to the display are heat sealed between durable insulative strips.

Throughholesarea standard connection type for many displays that offer a connection through small holes on the PCB. This connection type is most common for LCDs that have an external PCB controller circuit mounted to the display, such as most character and segment LCDs. Typically, the PCB will include the required liquid crystal driver, a voltage converting circuit, and backlight control.

Metal pins are a connection type for LCDs that have metal pins already mounted and connected to the display. Metal pins can be connected to the internal display controller or to the COM and Segment lines of an LCD. Typically, this connection type is used for character and segment LCDs.

Metal pins are good for applications that have standard pin mappings so that the display can be plugged into the controlling device. This connection type is less versatile than the previous LCD connection types as the pins are hardwired into place and cannot be moved unless unsoldered. The standard distance between pins is 2.54 mm.

Heat seal connections for LCDs are a reliable connection type utilizing a flexible cable connector that is heated and sealed to a displays’ interface ports. This connection uses a special heat seal paper that is then adhered to the display using a conductive glue and sealed by applying heat.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

Designer agrees that prior to using or distributing any applications that include FocusLCDs products, Designer will thoroughly test such applications and the functionality of such FocusLCDs products as used in such applications.

Character LCD modules are one of the most popular LCD technologies thanks to their ease of programming, low cost, low power consumption, and short lead times. They can be seen in a wide variety of products.

Most character LCDs are driven by an eight-bit parallel interface which makes use of the standard HD44780 protocol. The display has sixteen pins/connections to drive both the LCD and the optional LED backlight.

A character LCD contains several 5x8 pixel character blocks. Each block has five (5) dots across and eight (8) dots up and down. These dots are turned on and off to generate all possible characters.

it is explained about working of panel dc to dc ic working. G5562 is also same pinout dc to dc ic for TFT LCD PANEL#lcdpanelrepair #lcdtvrepair #6861aaqOur s...

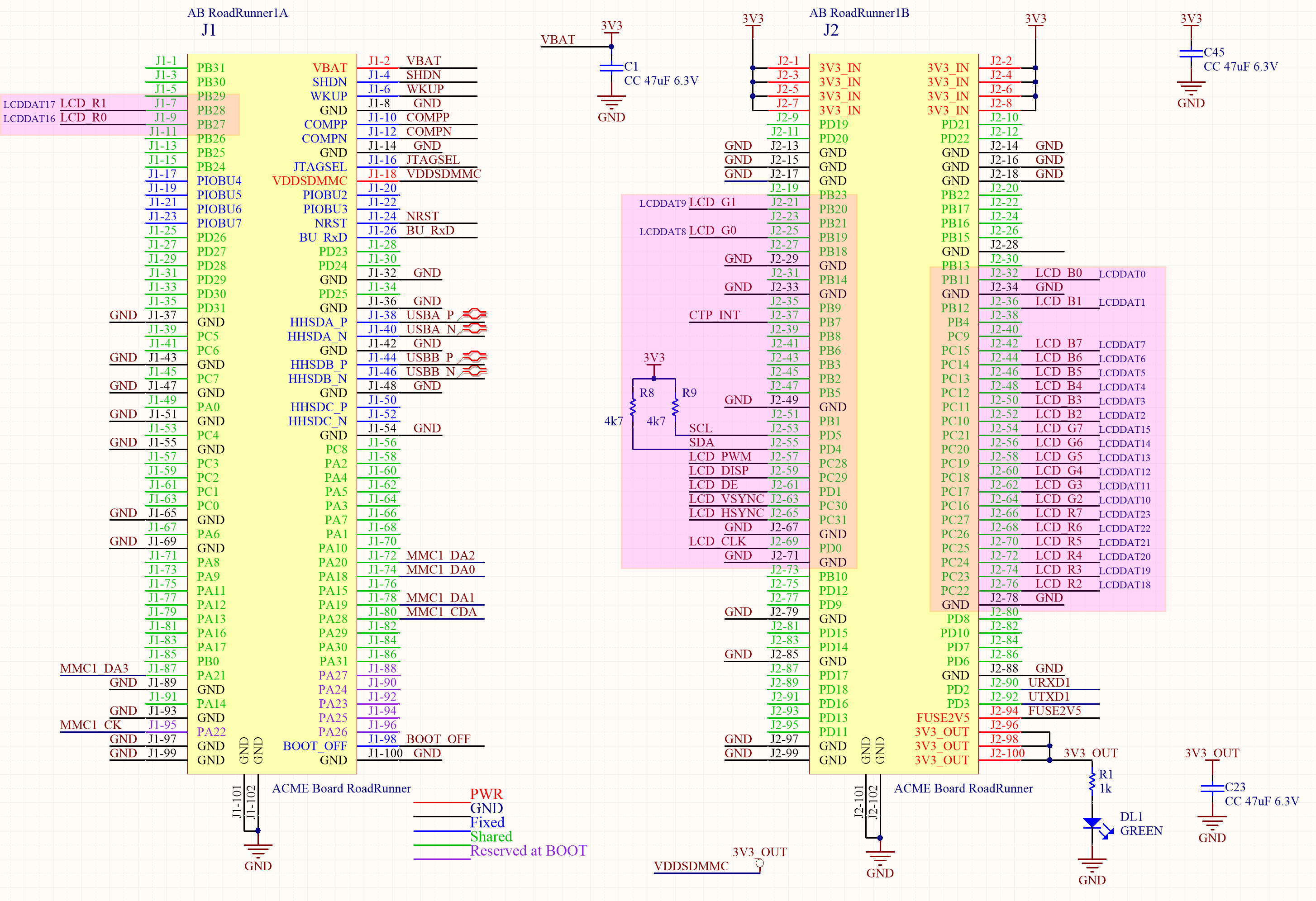

The Toradex module provides LCD interface(18/24-bit) which can be used to connect most of the RGB LCDs available in the market. On Apalis/Colibri Evaluation boards or Iris/Ixora/Viola carrier boards, a Unified Display Interface is provided to connect the RGB LCD to the EDT.

We have found the following 40 pin interface which many LCD manufacturers support (pin-outs mentioned below in the table), so we thought of doing an example display adapter board to make it easy for our customers.

NOTE: Generic Display Adapter Board design is just an example, not fully optimized for production. Toradex do not manufacture these boards, but we have given all design data.Also change the over-voltage and current resistors on the display adapter board according to the backlight power requirements of the LCD to connect.

Touch section is not compatible to adapter board LCD side 40 Pin connector(X7) due to touch signals not coming to 40 Pin flex cable, but via another four wire flex cable. We have for the same reason given another connector(X10) on adapter board which routes touch signals.

The 1.8inch LCD uses the PH2.0 8PIN interface, which can be connected to the Raspberry Pi according to the above table: (Please connect according to the pin definition table. The color of the wiring in the picture is for reference only, and the actual color shall prevail.)

ST7735S is a 132*162 pixel LCD, and this product is a 128*160 pixel LCD, so some processing has been done on the display: the display starts from the second pixel in the horizontal direction, and the first pixel in the vertical direction. Start to display, so as to ensure that the position corresponding to the RAM in the LCD is consistent with the actual position when displayed.

The LCD supports 12-bit, 16-bit and 18-bit input color formats per pixel, namely RGB444, RGB565, RGB666 three color formats, this routine uses RGB565 color format, which is also a commonly used RGB format

2. The module_init() function is automatically called in the INIT () initializer on the LCD, but the module_exit() function needs to be called by itself

Python has an image library PIL official library link, it do not need to write code from the logical layer like C, can directly call to the image library for image processing. The following will take 1.54inch LCD as an example, we provide a brief description for the demo.

The demo is developed based on the HAL library. Download the demo, find the STM32 program file directory, and open the LCD_demo.uvprojx in the STM32\STM32F103RBT6\MDK-ARM directory to check the program.

image.cpp(.h): is the image data, which can convert any BMP image into a 16-bit true color image array through Img2Lcd (downloadable in the development data).

There are two cable options for connecting the PanelDue, both options are included with the PanelDue V3 kit. Option 1 is the included 4-wire cable with Molex KK connector ends. Option 2 is the included 10-wire ribbon cable. For some boards, both cables need to be plugged in to enable both TFT panel and SD card socket.

The length of the 4-way cable is not critical, however the resistance per conductor should not exceed 0.1 ohm. The SD card socket on the TFT panel will not be functional. The cables supplied by Escher3D and Duet3D are about 800mm long. There have been reports of cables up to 1500mm long being successfully used. Take care to route the cable away from motor and endstop cables. Twisting the cables may help prevent cross talk interference.

A PanelDue can be connected to connector IO_0 using a 4-core cable wired like the one shown in the images below. The 4-wire cable supplied with the PanelDue has a 4-way Molex KK connecter on each end, but is supplied with a 5-way Molex KK connector for use with Duet 3. You will need to rewire one end. The 4-wire cable does not allow access to the SD card socket on the PanelDue.

Older versions of the Duet 2 WiFi/Ethernet need both the 4-wire and ribbon cable to be plugged in to use the TFT Panel and the SD card socket, when connecting PanelDue v2.0 or v3.0.

Use a 4-core cable terminated in a Molex KK or compatible connector at the PanelDue end and a 2x4 Dupont-style connector at the Duet end. This plugs into the end of the expansion connector. See https://miscsolutions.wordpress.com/pane....

In order to use the SD card slot on the PanelDue, you must use the ribbon cable option. If you do not wish to use the SD card slot, it"s recommended to use the 4-wire cable option described in Option 1.

The Duet 3 MB6HC has no PanelDue_SD socket. To use the external SD card, it requires RRF 3.4 or later, and a special wiring scheme; see "Duet 3 MB6HC using ribbon cable" section below.

Connect a 10-way ribbon cable between socket X5 on the PanelDue and socket CONN_SD (Duet 2) or PanelDue_SD (Duet 3). The connector is a standard 10 pin 2 row 2.54mm pitch box connector that accepts IDC connectors for 1.27mm ribbon cable.

Caution: if you are using a thermocouple and/or PT100 daughter board, the use of long ribbon cables between the Duet and PanelDue may affect communication between the Duet and the daughter boards, because the ribbon cable connection to the SD card on PanelDue uses the same SPI bus as the daughter boards.

Although the Duet 3 MB6HC does not have a connector for the PanelDue ribbon cable, if access to the SD card on PanelDue is required then this is possible using a special wiring arrangement. You must use RepRapFirmware 3.4 or later, and you must enable the external SD card using this command:

Note: if you are using an older version of either PanelDue 7i or PanelDue 5i, or a non-integrated version of PanelDue, then those do not support the CD signal. In that case you should omit the second port, for example:

The card detect signal (CD) is used to tell the Duet whether a card is inserted or not. Non-integrated versions of PanelDue (V2, V3) and older versions of PanelDue 5i and 7i (v1.0 of the 5i and v2.0 of the 7i) do not provide a card detect signal.

Duet 2 boards do not support the card detect signal on the external SD card, so can never tell whether a card is inserted or not except by trying to read it, and can"t detect a card being removed. No modifications are required connected older or newer PanelDue, or other external SD card adapters, to Duet 2 boards.

Duet 3 boards do support the card detect signal. Newer versions of the PanelDue 5i and 7i (v1.01 and later of the 5i and v2.01 and later of the 7i) provide this signal.

However, if you use a non-integrated versions of PanelDue or older versions of PanelDue 5i and 7i with Duet 3, it is necessary to ground the card detect signal, or the firmware will permanently think no card is inserted. There are a number of ways to achieve this.

This mod will enable the card detect signal. See the pictures below showing how to modify a PanelDue 5i v1.0. Connect a wire (thin enamelled copper in this instance) from the SD card socket Card Detect pin to the appropriate pin on the ribbon cable connector.

Generally it is best to run the latest version of the PanelDue firmware that is supported by the RepRapFirmware version on your Duet mainboard. See: Installing and Updating PanelDue Firmware

From RRF v3.2, PanelDue firmware releases are co-ordinated with the RRF release, and share the same version number. Use the PanelDue firmware version that matches your Duet mainboard"s firmware version.

PanelDue will display the bed heater H0 first (even if it is disabled), then iterate the defined tools. It then iterates the defined heaters below this. It expects a 1:1 relationship between tools and heaters. This means:if you have a machine that uses one heater for more than one tool (eg a 2-into-1, filament-swapping hot end), it will display more tools than heaters. Tools may not line up with their respective heaters.

The PanelDue also iterates the heaters from the first defined heater to the last, including all heaters in between, whether defined or not. This means if you have a heater defined on H0 (bed) and one on H5 (Duex output), it will show all the ones in between, eg H0, H1, H2, H3, H4 and H5. For an example, see |https://forum.duet3d.com/post/136207|this forum post|. Ideally, configure heaters on consecutive heater connections.

Due to constraints on display resolution, PanelDue can only display 7 heaters in total on 5" and 7" panels, and 5 on 4.3" panels. If there are more heaters and/or tools than this, some columns will overlap.

These restrictions are largely removed in later versions of the PanelDue firmware. However, they will require you to update RepRapFirmware on your Duet mainboard.

You can use the external SD card socket on the LCD panel if you have used a ribbon cable as described above. Please note, the SPI interface provided by this SD card socket is much slower than the on-board SD card socket built into the Duet. Therefore we recommend that you do not upload files to this card over the network. Use the external SD card socket only if you want to write files to the SD card on a PC and then move the SD card to your printer.

Caution! Do not use an SD extender cable from the SD socket on the Panel Due. Some types of SD card extender cable have been found to damage the SD card socket. Damage to the SD card socket from using an extender cable is not covered by the warranty.

You will need to make a custom 5-way cable using this table of connections. For the PanelDue 1.1, the X5 connector pins are numbered from the bottom end of the connector (the end close to the X5 legend). On the Duet 0.6 and 0.8.5 you need RepRapFirmware 1.17d or later to get support for the second SD card.

SD signal namePanelDue 1.1 X5 pin #PanelDue 2.0 X5 pin #Duet 2 signal nameDuet 2 CONN_SD pin #Duet 0.6/0.8.5 signal nameDuet 0.6/0.8.5 Expansion pinDueX4 Expansion1 pin

These displays are typically clones of the RepRapDiscount Full Graphic Smart Controller and look like this. The better ones include a contrast adjustment potentiometer. Unfortunately some manufacturers of other displays using the same controller chip reverse the pinouts on the two ribbon cable connectors. The ST7920 controller chip is invariably powered from 5V, which means that the display need 5V input signal levels.

An example of this is the Fysetc Mini 12864 Panel. The controller chip is run from 3.3V, so these displays normally include level shifters which tolerate a wide range of input voltages.

Duet 3 Mini provides two 2x5 ribbon cable headers for connecting a Fysetc 12864 Mini Panel version 1.2 or 2.1 (not 2.0) or compatible ST7567-based controller. When using a version 2.1 controller, the colours of the three Neopixel LEDs built into the display can be set using the M150 command with LED type parameter X2.

Use the pins +5V, GND, IO_0_OUT and IO_0_IN on the IO_0 header (Duet 3), or +5V, GND, TX and RX on the PanelDue header (Duet 2). These should be connected to +5V, GND, TX and RX on the TFT, making sure that TX and RX are swapped.

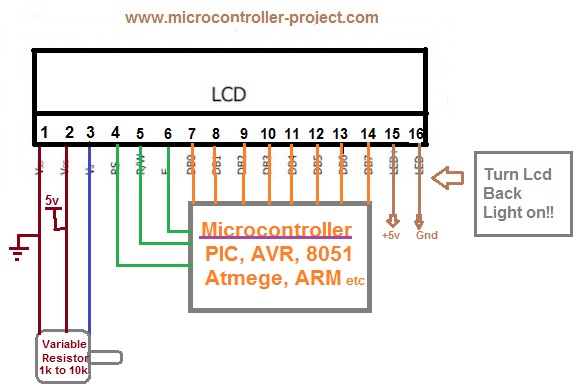

Printing “Hello, world!” is usually the first thing that programming tutorials will have you do in a new language. This guide starts by blinking an LED, but now we’re going to print out real text using a Liquid Crystal Display (LCD).

Character LCDs are designed to show a grid of letters, numbers and a few special characters. This makes them great for printing data and showing values. When current is applied to this special kind of crystal, it turns opaque. This is used in a lot of calculators, watches and simple displays. Adding an LCD to your project will make it super portable and allow you to integrate up to 32 characters (16 x 2) of information.

Pin 3 on the LCD controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, the contrast can be adjusted. As you rotate the knob on the potentiometer, you should notice that the screen will get brighter or darker and that the characters become more visible or less visible. The contrast of LCDs is highly dependent on factors such as temperature and the voltage used to power it. Thus, external contrast knobs are needed for displays that cannot automatically account for temperature and voltage changes.

If you look closely at the characters on the LCD, you will notice that they are actually made up of lots of little squares. These little squares are called pixels. The size of displays is often represented in pixels. Pixels make up character space, which is the number of pixels in which a character can exist.

The LCD has 16 pins, and it is polarized. The pins are numbered from left to right, 1 through 16. The LCD utilizes an extremely common parallel interface LCD driver chip from Hitachi called the HD44780. Thankfully, the Arduino community has developed a library to handle a great deal of the software-to-hardware interface. Below is a list of each of the pins on the LCD.

“Begin” the LCD. This sets the dimensions of the LCD that you are working with (16 x 2). It needs to be called before any other commands from the LCD library are used.

Move the cursor to the first space of the lower line lcd.setCursor(0,1);, then print the number of seconds that have passed since the RedBoard was last reset.

LiquidCrystal LCD_name(RS_pin, enable_pin, d4, d5, d6, d7);As with servos, you need to create an LCD object and give it a name (you can make more than one). The numbers in the brackets are pins on the RedBoard that connect to specific pins on the LCD.

lcd.setCursor(0,0);Move the cursor to a point on the 16x2 grid of characters. Text that you write to the LCD will start from the cursor. This line is starting back at position (0,0).

Count button pressesBy adding a button to the circuit, you can count the number of times the button was pressed or have the button change what the LCD is displaying. There could be many pages of information.

Rectangles in first rowIf you see 16 rectangles (like “█”) on the first row, it may be due to the jumper wires being loose on the breadboard. This is normal and can happen with other LCDs wired in parallel with a microcontroller. Make sure that the wires are fully inserted into the breadboard, then try pressing the reset button and adjusting the contrast using the potentiometer.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey