capacitive touch lcd panel free sample

Capacitive touch screen to help the emergence of iPhone has changed the world, its principle is to determine the specific location of one or more fingers by detecting the capacitive touch screen surface changes, including support for complex gestures, complete multi touch function, the reaction speed is extremely sensitive, for the user to bring extraordinary experience.

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for high brightness security monitor, 10 Inch Touch Screen Monitor, SDI public view monitor, We hope to establish additional organization interactions with prospects all over the entire world.

Factory Free sample 8 Inch Touch Screen Touch Monitor - 779GL-70NP/C/T _ 7 inch high brightness capacitive touch montior – LILLIPUT Detail:

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for Factory Free sample 8 Inch Touch Screen Touch Monitor - 779GL-70NP/C/T _ 7 inch high brightness capacitive touch montior – LILLIPUT , The product will supply to all over the world, such as: Namibia, Sheffield, UK, Customer"s satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for yourself in China. Of course, other services, like consulting, can be offered too.

We often stay with the principle "Quality Very first, Prestige Supreme". We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for Gps Navigation Tft-Lcd Screen, Medical Tft-Lcd Screen, Custom Touch Lcd Displays, We focus on to make excellent quality products to supply service for our clients to establish long-term win-win relationship.

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Factory Free sample Monitor Lcd Panel - 11.6inch TFT LCD Display for notebook and advertising machine system – DISEN , The product will supply to all over the world, such as: Madrid, Pretoria, Mexico, You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

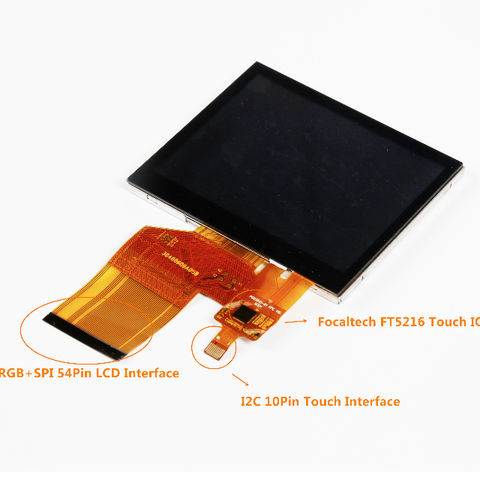

As a TFT LCD manufacturer, we import mother glass from brands including BOE, INNOLUX, and HANSTAR, Century etc., then cut into small size in house, to assemble with in house produced LCD backlight by semi-automatic and fully-automatic equipment. Those processes contain COF(chip-on-glass), FOG(Flex on Glass) assembling, Backlight design and production, FPC design and production. So our experienced engineers have ability to custom the characters of the TFT LCD screen according to customer demands, LCD panel shape also can custom if you can pay glass mask fee, we can custom high brightness TFT LCD, Flex cable, Interface, with touch and control board are all available.

As a TFT LCD manufacturer, we import mother glass from brands including BOE, INNOLUX, and HANSTAR, Century etc., then cut into small size in house, to assemble with in house produced LCD backlight by semi-automatic and fully-automatic equipment. Those processes contain COF(chip-on-glass), FOG(Flex on Glass) assembling, Backlight design and production, FPC design and production. So our experienced engineers have ability to custom the characters of the TFT LCD screen according to customer demands, LCD panel shape also can custom if you can pay glass mask fee, we can custom high brightness TFT LCD, Flex cable, Interface, with touch and control board are all available.

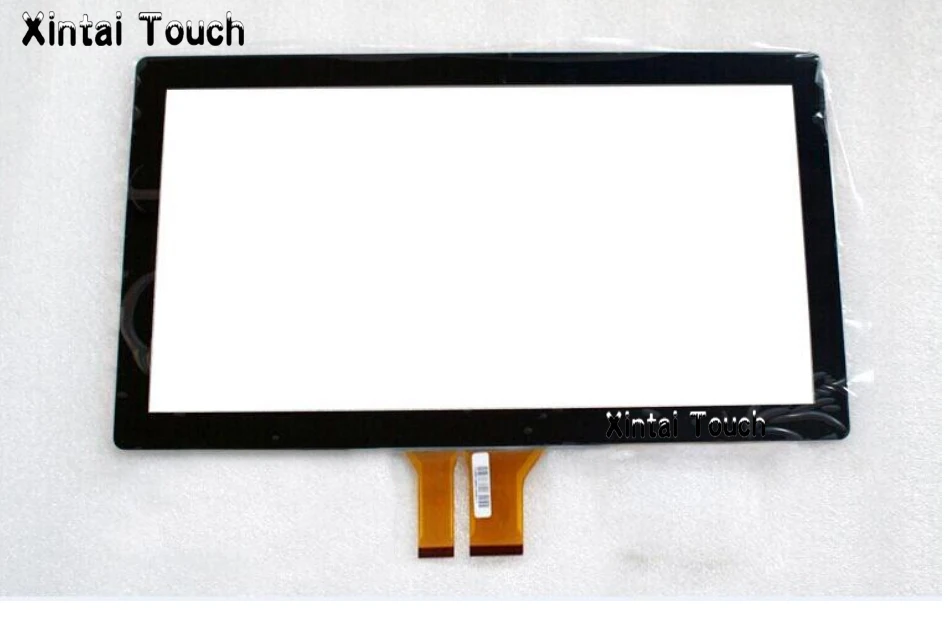

There are types of touch screen,such as resistive touch panel(RTP), capacitive touch panel (CTP), surface acoustic wave touch display, infrared touch screen. RTP and CTP are used more than others. Can you tell the difference between RTP and CTP? If not, you may want to read along.

In resistive touch screens, two very thin layers of material are separated by a thin gap of air. PET film and glass are typically used. Both upper and bottom layers are lined with conductors such as indium tin oxide (ITO). The conducting sides are placed facing one another. So, when you press the screen with finger or stylus, it connects top and bottom layers, creates a change in resistance (an increase in voltage). RTP controller detects this change, and calculates its coordinates, then determines the position of touch.

Capacitive touchscreens, on the other hand, respond directly to the touch of your finger or an input device such as a stylus. On top of LCD panel, lies a thin layer of transparent electrodes. When a human finger touches the screen, some of the electrical charge travels from screen to user. The change of capacitance is then detected by sensors located at screen"s four corners, allowing controller determine the touched location.

Resistive touch screens are effective in a variety of environments. Any object capable of applying force to the screen can trigger a touch event. For example, users wearing gloves can operate RTP with no difficulty.Resistive touch screens work well even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens, for example, agricultural equipment, boats and underwater machinery. Due to its mature technology and simple structure, cost of resistive screens is lower.

Supporting of Multiple touches is a clear winner for capacitive touch screens (CTP). Thanks to smartphone and tablet, users are comfortable with using gesture on screen. And capacitive touch screen is what user is familiar with. In more specialized settings, such as multi-player gaming application, capacitiv e touch screens can support more than 10 inputs at a single time. Additionally, CTP needs no calibration and is highly accurate.

Resistive touch display cannot determine the location of a touch if more than one input is present. In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can"t. If cost is a top concern for a project, CTP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

Touch panel technologies are a key theme in current digital devices, including smartphones, slate devices like the iPad, the screens on the backs of digital cameras, the Nintendo DS, and Windows 7 devices. The term touch panel encompasses various technologies for sensing the touch of a finger or stylus. In this session, we"ll look at basic touch panel sensing methods and introduce the characteristics and optimal applications of each.

Note: Below is the translation from the Japanese of the ITmedia article "How Can a Screen Sense Touch? A Basic Understanding of Touch Panels"published September 27, 2010. Copyright 2011 ITmedia Inc. All Rights Reserved.

A touch panel is a piece of equipment that lets users interact with a computer by touching the screen directly. Incorporating features into the monitor like sensors that detect touch actions makes it possible to issue instructions to a computer by having it sense the position of a finger or stylus. Essentially, it becomes a device fusing the two functions of display and input.

It"s perhaps not something we think of often, but touch panels have integrated themselves into every aspect of our lives. People who enjoy using digital devices like smartphones interact with touch panels all the time in everyday life—but so do others, at devices like bank ATMs, ticket vending machines in railway stations, electronic kiosks inside convenience stores, digital photo printers at mass merchandisers, library information terminals, photocopiers, and car navigation systems.

A major factor driving the spread of touch panels is the benefits they offer in the way of intuitive operation. Since they can be used for input through direct contact with icons and buttons, they"re easy to understand and easily used, even by people unaccustomed to using computers. Touch panels also contribute to miniaturization and simplification of devices by combining display and input into a single piece of equipment. Since touch panel buttons are software, not hardware, their interfaces are easily changed through software.

While a touch panel requires a wide range of characteristics, including display visibility above all, along with precision in position sensing, rapid response to input, durability, and installation costs, their characteristics differ greatly depending on the methods used to sense touch input. Some typical touch-panel sensing methods are discussed below.

As of 2010, resistive film represented the most widely used sensing method in the touch panel market. Touch panels based on this method are called pressure-sensitive or analog-resistive film touch panels. In addition to standalone LCD monitors, this technology is used in a wide range of small to mid-sized devices, including smartphones, mobile phones, PDAs, car navigation systems, and the Nintendo DS.

Capacitive touch panels represent the second most widely used sensing method after resistive film touch panels. Corresponding to the terms used for the above analog resistive touch panels, these also are called analog capacitive touch panels. Aside from standalone LCD monitors, these are often used in the same devices with resistive film touch panels, such as smartphones and mobile phones.

With this method, the point at which the touch occurs is identified using sensors to sense minor changes in electrical current generated by contact with a finger or changes in electrostatic capacity (load). Since the sensors react to the static electrical capacity of the human body when a finger approaches the screen, they also can be operated in a manner similar to moving a pointer within an area touched on screen.

Two types of touch panels use this method: surface capacitive touch panels and projective capacitive touch panels. The internal structures differ between the two types.

Surface capacitive touch panels are often used in relatively large panels. Inside these panels, a transparent electrode film (electrode layer) is placed atop a glass substrate, covered by a protective cover. Electric voltage is applied to electrodes positioned in the four corners of the glass substrate, generating a uniform low-voltage electrical field across the entire panel. The coordinates of the position at which the finger touches the screen are identified by measuring the resulting changes in electrostatic capacity at the four corners of the panel.

While this type of capacitive touch panel has a simpler structure than a projected capacitive touch panel and for this reason offers lower cost, it is structurally difficult to detect contact at two or more points at the same time (multi-touch).

Projected capacitive touch panels are often used for smaller screen sizes than surface capacitive touch panels. They"ve attracted significant attention in mobile devices. The iPhone, iPod Touch, and iPad use this method to achieve high-precision multi-touch functionality and high response speed.

The internal structure of these touch panels consists of a substrate incorporating an IC chip for processing computations, over which is a layer of numerous transparent electrodes is positioned in specific patterns. The surface is covered with an insulating glass or plastic cover. When a finger approaches the surface, electrostatic capacity among multiple electrodes changes simultaneously, and the position were contact occurs can be identified precisely by measuring the ratios between these electrical currents.

A unique characteristic of a projected capacitive touch panel is the fact that the large number of electrodes enables accurate detection of contact at multiple points (multi-touch). However, the projected capacitive touch panels featuring indium-tin-oxide (ITO) found in smartphones and similar devices are poorly suited for use in large screens, since increased screen size results in increased resistance (i.e., slower transmission of electrical current), increasing the amount of error and noise in detecting the points touched.

Larger touch panels use center-wire projected capacitive touch panels in which very thin electrical wires are laid out in a grid as a transparent electrode layer. While lower resistance makes center-wire projected capacitive touch panels highly sensitive, they are less suited to mass production than ITO etching.

Above, we"ve summarized the differences between the two types of capacitive touch panels. The overall characteristics of such panels include the fact that unlike resistive film touch panels, they do not respond to touch by clothing or standard styli. They feature strong resistance to dust and water drops and high durability and scratch resistance. In addition, their light transmittance is higher, as compared to resistive film touch panels.

On the other hand, these touch panels require either a finger or a special stylus. They cannot be operated while wearing gloves, and they are susceptible to the effects of nearby metal structures.

Surface acoustic wave (SAW) touch panels were developed mainly to address the drawbacks of low light transmittance in resistive film touch panels—that is, to achieve bright touch panels with high levels of visibility. These are also called surface wave or acoustic wave touch panels. Aside from standalone LCD monitors, these are widely used in public spaces, in devices like point-of-sale terminals, ATMs, and electronic kiosks.

These panels detect the screen position where contact occurs with a finger or other object using the attenuation in ultrasound elastic waves on the surface. The internal structure of these panels is designed so that multiple piezoelectric transducers arranged in the corners of a glass substrate transmit ultrasound surface elastic waves as vibrations in the panel surface, which are received by transducers installed opposite the transmitting ones. When the screen is touched, ultrasound waves are absorbed and attenuated by the finger or other object. The location is identified by detecting these changes. Naturally, the user does not feel these vibrations when touching the screen. These panels offer high ease of use.

The strengths of this type of touch panel include high light transmittance and superior visibility, since the structure requires no film or transparent electrodes on the screen. Additionally, the surface glass provides better durability and scratch resistance than a capacitive touch panel. Another advantage is that even if the surface does somehow become scratched, the panel remains sensitive to touch. (On a capacitive touch panel, surface scratches can sometimes interrupt signals.) Structurally, this type of panel ensures high stability and long service life, free of changes over time or deviations in position.

Weak points include compatibility with only fingers and soft objects (such as gloves) that absorb ultrasound surface elastic waves. These panels require special-purpose styluses and may react to substances like water drops or small insects on the panel.

All in all, however, these touch panels offer relatively few drawbacks. Recent developments such as improvements in manufacturing technology are also improving their cost-performance.

The category of optical touch panels includes multiple sensing methods. The number of products employing infrared optical imaging touch panels based on infrared image sensors to sense position through triangulation has grown in recent years, chiefly among larger panels.

A touch panel in this category features one infrared LED each at the left and right ends of the top of the panel, along with an image sensor (camera). Retroreflective tape that reflects incident light along the axis of incidence is affixed along the remaining left, right, and bottom sides. When a finger or other object touches the screen, the image sensor captures the shadows formed when the infrared light is blocked. The coordinates of the location of contact are derived by triangulation.

While this type differs somewhat from the above touch panels, let"s touch on the subject of electromagnetic induction touch panels. This method is used in devices like LCD graphics tablets, tablet PCs, and purikura photo sticker booths.

This input method for graphics tablets, which originally did not feature monitors, achieves high-precision touch panels by combining a sensor with the LCD panel. When the user touches the screen with a special-purpose stylus that generates a magnetic field, sensors on the panel receive the electromagnetic energy and use it to sense the position of the pen.

The table below summarizes the characteristics of the touch panels we"ve looked at. Keep in mind that even in devices based on the same sensing method, performance and functions can vary widely in the actual products. Use this information only as an introduction to general product characteristics. Additionally, given daily advances in touch-panel technological innovations and cost reductions, the information below is only a snapshot of current trends as of September 2010.

Each touch-panel type offers its own strengths and weaknesses. No single sensing method currently offers overwhelming superiority in all aspects. Choose a product after considering the intended use and environmental factors.

Point of Sales Machines, Multi-function Printers, Instrumentation, Home Security Systems, Graphic touch pad – remote, dial pad, Tele/Video Conference Systems, Phones and Switchboards, Medical Appliances, Breathalyzers, Gas chromatographs, Power meter, Home appliance devices, Set-top box, Thermostats, Sprinkler system displays, GPS / Satnav, Vending Machine Control Panels, Elevator Controls, and many more....

I purchased this as a display (version 2.1) for my OctoPrint-running Raspberry Pi 2 with the awesome TouchUI plugin. This display works great, and is higher resolution than the official Raspberry Pi display (1024x600 vs 800x480). The color is fairly accurate although those used to over-saturated LCDs might find it a bit dull. The capacitive touch works well, however there is some error very close to the corners which can cause some mis-clicks but is a small enough area to be avoidable. Everything works out of the box once you set the display information in config.txt, even display rotation and touchscreen event rotation for a portrait orientation.

While having just two cables run to the display to power it, provide the video in, and the touch out back to the pi is convenient, it really pulls a lot of power on the 5V line, about 600-700mA when the display is on in addition to the ~400mA needed by a Pi 3. I would have preferred there to be an external power input so all this current is pulled through the Pi"s traces. Even better if I could power it from 12V like many other HDMI driver boards can. I examined the PCB layout of the display board and it is good, using name brand components from companies like Atmel and TI. The drivers for the LCD power and LED backlight are all rated for 6V absolute maximum so there"s no chance of modding this to use 12V instead of 5V.

The LCD backlight has a convenient switch on the back of the driver board to allow the user to turn on and off the backlight to save power. I found this a curious solution rather than allowing the display to power off based on HDMI input and DPMS standard. This means that when the Pi sits idle long enough, it tries to put the display to sleep but it just turns black-- the backlight is left on so power saving is minimal. What I ended up doing is reworking the board to link the driver chip"s SCDT to !PDO and the LED driver Enable line to be able to power on/off the display via the Pi. Why Waveshare did not design the board like this I don"t understand and that"s my biggest reason for deducting a star from this review.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (5" diagonal) bright (18 white-LED backlight) and colorful 800x480 pixels with individual pixel control. As a bonus, this display has a capacitive touch panel attached on screen by default.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey