sda in lcd module factory

As the maker movement has increasingly grown, we’d like to share the way to use Arduino and begin with controlling the LCD module. Yes, we’d like to start from LCD module instead of installation since makers can find lots of related information from the Internet. So we’ll have less basic introduction here.

After reading this article and manipulating, you will have the basic understanding of I2C bus and LCD, and learn the way to connect modules with Arduino, use basic program to control your LCD module, and think about the applications. The advanced control techniques will be explained in the future articles.

I2C Bus enables 2 devices to communicate with each other in a stable, high-speed, bidirectional way and with the least I/O pins. I2C Bus utilizes 2 lines to communicate, Serial Data Line (SDA) and Serial Clock Line (SCL), so that the protocol I2C uses is also called “bidirectional” protocol.

What’s more special is I2C Bus allows multiple devices to share the common communication lines. Thus, I2C Bus could control the communication function.

Here we use Arduino as the main board to control; pin A4 and A5 on the board are SDA and SCL pins respectively. To use I2C function, you would need to use Wire Library, which is the built-in library of Arduino IDE.

LCD is the abbreviation of liquid-crystal display; it’s a commonly-used display device and utilized everywhere in our daily life, from watches, calculators, TV to bulletin board.

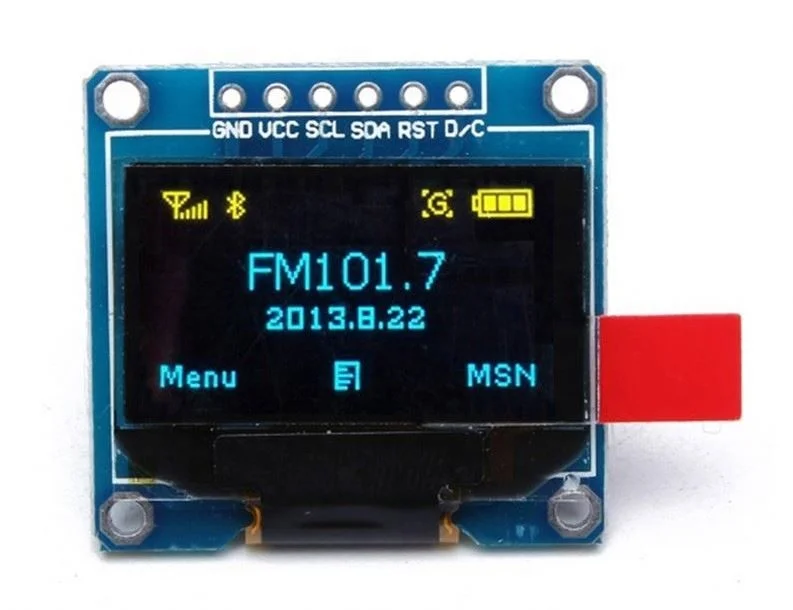

This LCD module is the basic one and the most commonly-used character display; The voltage is 5V. The voltage level Arduino I/O Port uses is 5V so that we choose the LCD module. Besides, the LCD module can display 16 characters per line and there are 2 such lines. Also, the module uses I2C protocol. Thus, there are 4 pins on the module, including Vcc, GND, SDA, and SCL.

It is also easy to connect the wires. Firstly, you need to connect pin Vcc of the module to Arduino pin 5V, connect pin GND to Arduino pin GND, and connect pin SDA to Arduino pin A4. Lastly, connect pin SCL to Arduino pin A5 to complete the wiring.

Before introducing the sample, we’d like you to download the 3rd party libraries of I2C_LCD first. You can download the files here, decompress, and install. In this sample, the version we use is NewliquidCrystal_1.3.4. The followings are the codes we use for this sample.

Then, at the setting of initialization, LCD backlight will be controlled to blink 3 times. The first line will display “ICshop&MakerPRO” for one second, and the second line will display “Hello, Maker!” for 8 seconds. Then all the display will be cleared.

Hope all of you successfully complete the I2C_1602_LCD module display with the description mentioned above. If you failed, please check the wiring or you bought a defective device.

So next, you could think of if you can use the module to make a clock or environment sensors. You might have tons of ideas now! Why don’t you connect a LCD module in your next project?

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I2C_LCD is an easy-to-use display module, It can make display easier. Using it can reduce the difficulty of make, so that makers can focus on the core of the work.

We developed the Arduino library for I2C_LCD, user just need a few lines of the code can achieve complex graphics and text display features. It can replace the serial monitor of Arduino in some place, you can get running informations without a computer.

More than that, we also develop the dedicated picture data convert software (bitmap converter)now is available to support PC platform of windows, Linux, Mac OS. Through the bitmap convert software you can get your favorite picture displayed on I2C_LCD, without the need for complex programming.

Select the board: Click Tools > Board > "Arduino Duemilanove or Diecimila"(Seeeduino V3.0 Or early version), "Arduino Uno"(Seeeduino Lotus or Seeeduino V4.0).

A regular LCD requires a lot of wires (parallel interface) to be connected with a Microcontroller.The Serial LCD backpack built on PCF8574 IC uses the I2C bus to convert the parallel interface to a serial one.This needs only2 wires SDA & SCL , apart from the power connections.

The blue preset is to adjust the contrast of the LCD. The black jumper on the left is to enable the Backlight of LCD. The I2C device has a HEX address by which a microcontroller can communicate with it.This is set by the 3 bits A0,A1 ,A2 .If no jumper is present , it is HIGH & a jumper means LOW. By default all the 3 jumpers are open . ie., A0,A1 A2 all are 1s.

The I2C bus has 2 bidirectional active wires SDA & SCL .They are joined to positive supply through a pull up resistor of 4k7.When the bus is idle both lines are pulled high.

lcd.setBacklightPin(HIGH); makes the P3 pin go High, which turns on the NPN transistor.This provides GND to the LED pin of LCD As the other LED pin is already connected to Vcc through the jumper , the LCD backlight glows.

SPI is a useful communication method if you have more than one device to hook up on a single bus. It requires more wires than basic serial, but it"s more dependable because it"s a synchronous interface.

In this example, we"ll only use a single display. Realize, though, that you could add more displays (or other SPI devices) to the same SPI bus, each requiring only an additional SS pin per device.

The SDI and SCK pins must remain where they are on the Arduino - those are the hardware SPI pins. The SS pin could be moved to any digital pin, as long as it"s changed in the code.

This example works a lot like the serial version. The s7s.print() functions from the previous example are replaced by SPI transfers. Take note that each time an SPI.transfer() occurs, it"s blanketed by two digitalWrite()s to the SS pin. The SS pin must go LOW, to let the display know that usable data is incoming. Once SS goes back to HIGH, the display will know that data is no longer being sent to it.

The parallel interface typically controls the LCD via 8 data pins and 3 control lines. The control lines used are Enable (E), Register Select (RS), and Read/Write (R/W). RS tells the LCD module if the information being sent is an Instruction or Data. The Enable tells the LCD module that the data or instruction in the register is ready to be interpreted by the LCD Module. Some controllers may have more than one Enable Control Line. The Read/Write tells the module whether to write data or read data from the register.

Serial LCD controllers typically have one Serial Data Line that writes data and cannot read. Normally, a Register Select Line(Sometimes designated A0) is used to tell the controller whether the incoming data is display information or a controller command

SPI, or Serial Peripheral Interface bus, is a synchronous (data is synchronized to the clock) serial data link standard that operates in full duplex mode, which means that devices that can communicate with one another simultaneously. To do this, two data lines are required. With this standard, devices communicate in a master/slave mode, where the master device (host processor) initiates the data and the clock. The LCD module is the (or one of the) peripheral slave device(s) attached to the data bus. Multiple peripherals (display modules and other devices) are addressed on the same serial data bus. However, the LCD module will only listen to the data it sees when the Chip Select line is active (usually low). If the Chip Select line is inactive (usually High), the LCD module listens to the data on the bus, but ignores it. The SDO line is not active when this state occurs. The SPI bus is comprised of four logic signals, two control lines and two data lines and is commonly referred to as SPI (4 wire).

Occasionally, SDI (serial data in) may be called out as MOSI (Master Out Slave In) from Motorola"s original name for these lines and MISO (Master In Slave Out) for SDO. The chip select line may be alternatively labeled SS (Slave-Select), or STE (Slave Transmit Enable). SPI is sometimes referred to as National Semiconductor"s trademark Microwire, which is essentially a predecessor of SPI, which only supports half duplex.

With CS (Chip-Select) the corresponding peripheral device is selected by the LCD Controller. This pin is mostly active-low. In the unselected state the SDO lines are hi-impedance and therefore inactive. The clock line SCL is brought to the device whether it is selected or not. The clock serves as synchronization of the data communication.

The chip select signal CS is optional for a single device system, because you could tie the CS input at the LCD Module low, if the other lines are dedicated to SPI use. This is sometimes called a 3 Wire SPI Interface.

SPI Data transmissions usually involve two shift registers. Most display module applications normally use 8-bit words. However, different size words, such as 12 bit, are also used. By convention, the most significant bit is shifted out of one shift register while the least significant bit is shifted in. The word is then written into memory if the CS (chip-select) is low (active). If not, the data is ignored.

Since the SPI interface protocol is a de facto standard, many variations of the standard protocol are used. For instance, chip manufacturers may use some of the parallel data lines when configuring the IC driver chip for serial communication. chip manufacturers may use some of the parallel data lines when configuring the IC driver chip for serial communication.

I2C uses only two bi-directional lines, Serial Data Line (SDA) and Serial Clock (SCL), which are both typically pulled up with resistors. Typical voltages used are +5 V or +3.3 V. One of the strengths of the I2C interface is that a micro can control multiple devices with just the two I/O pins and software. Because of the I2C design, it is only half-duplex. The interface generally transmits 8-bit words, sending the most significant bit first.

LVDS (Low Voltage Differential Signaling) technology provides a port with low voltage difference and differential signals. Developed by NS Technology Co., the American company uses digital video signal to resolve the excess amount of resource consumed and reducing EMI (Electromagnetic Interference) while transferring high bit rate data using TTL (Transistor-Transistor Logic). LVDS ports are able to perform differential data transfer between PCB traces or balanced cables with a relatively low output voltage swing (350mV), allowing a transfer speed up to several hundred megabit per second with low voltage difference. As a result, low voltage swing and low current drive applications have led to dramatic reduction in resource consumption and noise.

Using single circuit for transfers, the port implements 6 bit data for each primary color signals, thus delivering 18 bit RGB data. This output is also known as the 18 bit or 18 bit LVDS port.

Using two-path dual circuit transfers, the port implements 6 bit data for each primary color signals, delivering 18 bit for single and dual channel data, totaling 36 bit RGB data. This output is also known as the 36 bit or 36 bit LVDS port.

Using single circuit for transfers, the port implements 8 bit data for each primary color signals, delivering 24 bit RDB data. This output is also known as the 24 bit or 24 bit LVDS port.

Using two-path dual circuit transfers, the port implements 8 bit data for each primary color signals, delivering 24 bit for single and dual channel data, totaling 48 bit RGB data. This output is also known as the 48 bit or 48 bit LVDS port.

Connector ports for devices such like cameras, displays, basebands, and RF interfaces are standardized under MIPI Alliance specifications. These specifications include design, manufacturing costs, structural complexity, power consumption and degree of EMI.

This is another great I2C 16x2 LCD display compatible with Gadgeteer modules from DFRobot. With limited pin resources, your project will quicly run out of resources using normal LCDs. With this I2C interface LCD module, you only need 2 lines (I2C)to display the information.If you already have I2C devices in your project, this LCD module actually cost no more resources at all. The adress can be set from 0x20-0x27. Fantastic for Arduino or gadgeteer based projects.

This is another great I2C 16x2 LCD display compatible with Gadgeteer modules from DFRobot. With limited pin resources, your project will quicly run out of resources using normal LCDs. With this I2C interface LCD module, you only need 2 lines (I2C)to display the information.If you already have I2C devices in your project, this LCD module actually cost no more resources at all. The adress can be set from 0x20-0x27. Fantastic for Arduino or gadgeteer based projects.

Hello friends welcome back to Techno-E-solution, In previous video we see how to interface LCD 16×2 to Arduino uno, but there are very complicated circuits, so in this tutorial, I"ll show you how to reduce circuitry by using I2C module which is very compact & easy to connection. Simply connect I2C module with LCD parallel & connect I2C modules 4 pins to Arduino. I2C module has 4 output pins which contains VCC, GND,SDA, SCL where 5V supply gives to I2C module through VCC & GND to GND of Arduino. SDA is a data pin & SCL is clock pin of I2C module. To interface LCD and I2C with Arduino we need Liquid Crystal I2C Library in Arduino IDE software.

Some people experience problems. Usually that is because of not having the right library, not having that library installed properly or have it overwritten by an update.

Inthis link you will find the configuration that works for me on IDE 1.6.9. Put all those files (except the picture) in ONE directory, where also your INO file goes

Using an LCD on a small chip like an attiny85 is not really that hard and till recent I didnt even think it warranted an instructable, but I have received questions about it, so I may as well expand on the process.

With the attiny only having a max of 6 pins available, it goes without saying that it cannot directly control all the pins of the standard Hitachi based LCD"s

A little bit over a year ago, I described how to add an LCD to an Attiny or other chip, using only 2 pins. That circuit made use of an HC164 shift register, but as I2C modules for LCD"s are extremely cheap and even LCD"s with a module already in place also are dirt cheap, one might as well use I2C on the Attiny85.

I2CThe attiny85 can simulate I2C on PB2 (pin 7) (SCL) and PB0 (pin 5) (SDA). The "Wire" library that is used to read and write bytes from and to the I2C port on the arduino doesnt work on the attiny. It needs the TinyWireM library to act as an I2C master

The "NewLCD" library from Francisco Malpartida is my favorite library, but also that one fails in using I2C for the Attiny because it makes a call to the Wire library. A modification to make it work with Attiny85 can be found here.

The "Bro Hogan" library however does work. It is basically the same library as the standard arduino LCD library, but it is modified to recognize the Attiny85 and the Attiny2313 and then makes a call to "TinyWireM" rather than "Wire".

Adafruit also provides a libray that works with the Attiny85 and that is described in another instructable. I will be using the Bro Hogan library here.

Most problems you may encounter are related to the IDE getting confused regarding the libraries. If you are using the standard Arduino LCD library, best replace it by the Bro Hogan library. If you are using Malpartida"s library and want to keep that (as it is a great library), move it out of the way. Grab the entire folder and move it out of your sketchbook/libraries folder. Make sure you have the TinyWireM library installed and make sure your libraries are up to date.

If for whatever reason you cannot or do not want to move the Malpartida library out of the way, either rename the LiquidCrystal_I2C.h and LiquidCrystal_I2C.cpp modules in that library, or put the BroHogan LiquidCrystal_I2C.h and LiquidCrystal_I2C.cpp files in your sketch directory (and change the fishhook call into parenthesis).

Now obviously there is no bootloader for the attiny85, but the process of burning the bootloader sets the fuses of the attiny from factory mode, to the mode you want to use it in. So, presuming you use the Arduino as ISP,:

The newer versions of the IDE will tell you when there are updates for some of your libraries and often, the Liquid Crystal library is also suggested for an update. Don"t If you have the Bro Hogan library, it will be replaced by for instance the YW robot library, while the Malpartida library will probably be completely deleted.

The CFA533-***-KC series is a 16x2 I2C LCD with keypad. The I2C interface allows you to use just two lines (SDA & SCL) to have bi-directional communication with the I2C LCD. Other devices can also share those two I2C control lines with the LCD. Only 4 wires are needed to connect this I2C LCD: power, ground, SDA (I2C Serial DAta) and SCL (I2C Serial CLock).

The CFA533 can run on 3.3v to 5.0v directly, with no changes needed, so you do not need to do any level translation between your embedded processor and the I2C LCD. Simply power the CFA533 from the same supply as your processor and the I2C signal levels will match up.

Using only one address on your I2C bus, you can add all the elements that you need for your front panel. The CFA533 I2C LCD can also read up to 32 DS18B20 digital temperature sensors, giving you an easy way to integrate temperature sensing over the I2C bus. No additional firmware or pins are needed on the host system.

This CFA533-TFH variant features crisp dark letters against a white, backlit background. The keypad has a matching white LED backlight. Since the LCD is a backlit positive FSTN, the CFA533-TFH I2C LCD is readable in direct sunlight, as well as complete darkness.

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

In addition, there is a jumper on the board that supplies power to the backlight. To control the intensity of the backlight, you can remove the jumper and apply external voltage to the header pin that is marked ‘LED’.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

According to the Texas Instruments’ datasheet, the three address selection bits (A0, A1 and A2) are placed at the end of the 7-bit I2C address register.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x20. The range of all possible addresses spans from 0x20 to 0x27. Please see the illustration below.

According to the NXP Semiconductors’ datasheet, the three address selection bits (A0, A1 and A2) are also placed at the end of the 7-bit I2C address register. But the other bits in the address register are different.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x38. The range of all possible addresses spans from 0x38 to 0x3F. Please see the illustration below.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

Now we are left with the pins which are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected accordingly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also known as A5 (SCL) and A4 (SDA).

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

To install the library navigate to Sketch > Include Libraries > Manage Libraries… Wait for Library Manager to download the library index and update the list of installed libraries.

Filter your search by typing ‘liquidcrystal‘. There should be some entries. Look for the LiquidCrystal I2C library by Frank de Brabander. Click on that entry, and then select Install.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

As discussed earlier in this tutorial a character is made up of a 5×8 pixel matrix, so you need to define your custom character within that matrix. You can use the createChar() function to define a character.

To use createChar() you first set up an array of 8 bytes. Each byte in the array represents a row of characters in a 5×8 matrix. Whereas, 0 and 1 in a byte indicate which pixel in the row should be ON and which should be OFF.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Creating custom characters has never been easier! We have created a small application called Custom Character Generator. Can you see the blue grid below? You can click on any 5×8 pixel to set/clear that particular pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

Your imagination is limitless. The only limitation is that the LiquidCrystal library only supports eight custom characters. But don’t be discouraged, look at the bright side, at least we have eight characters.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

Let’s examine the Heart[8] array as an example. You can see how the bits (0s and 1s) are forming a heart shape. 0 turns the pixel off and 1 turns the pixel on.

In setup, a custom character is created using the createChar() function. This function takes two parameters. The first parameter is a number between 0 and 7 to reserve one of the 8 supported custom characters. The second is the name of the array.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey