lcd panel space engineers glowing text brands

Did you try disabling Post Processing ? As KSWH completely overblew Chromatic Aberration for some bizarre (read non-existent) reason it might blur the text like that.

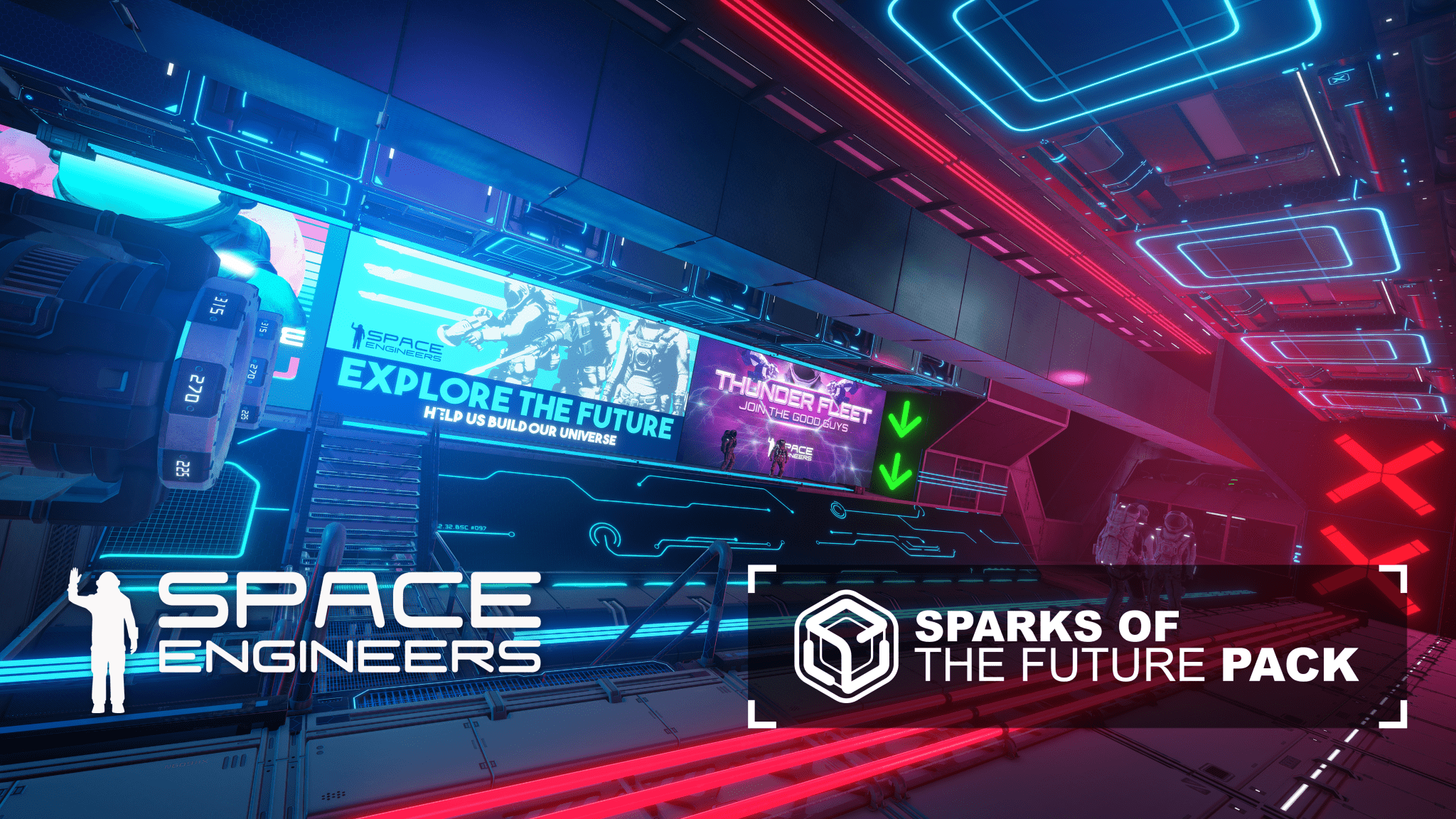

The Space Engineers – Sparks of the Future includes the Sci-Fi LCD, the Neon Tubes, the Sci-Fi Ion Thrusters, the Sci-Fi Atmospheric Thrusters, the Sci-Fi Interior Wall, the Bar Counter, the Sci-Fi Control Panel, the Sci-Fi 1-Button Panel, the Sci-Fi 4-Button Panel, the Sci-Fi Sliding Door, the Sci-Fi Armor Skin, the 2 Neon Armor Skins, the 8 new character emotes.

Space Engineers Ultimate Edition includes the base game and all of the past DLCs for Space Engineers. Our newest DLC is sold separately (PC version only). Enjoy the definitive version of Space Engineers as you build and explore across the stars!

Space Engineers is a sandbox game about engineering, construction, exploration and survival in space and on planets. You can build space ships, space stations, planetary outposts of various sizes and uses, pilot ships and travel through space to explore planets.

Space Engineers: Warfare 2 “Broadside” pack includes Warfare Ion Thruster, Warfare Reactor, Warfare Hangar Door variants, Warfare Rocket Launcher, Warfare Gatling Gun, Searchlight, Bridge Windows, Passenger bench, Light panel, Helm, Warfare Battery, Heat vent, Sliding Hatch Door, Woodland Camo Armor Skin, Shark mouth helmet skin, “Rock paper scissors” emotes, “Salute” Emote

Space Engineers “Heavy Industry” pack includes Large Magnetic plate, Beam Blocks, Industrial conveyor pipes, Cylindrical Column, Vertical button panel, Large Hydrogen Tank Reskin, Large Cargo Container Reskin, Industrial Refinery, Industrial Assembler, Industrial Hydrogen Thrusters and Hazard pattern armor skin.

Space Engineers “Warfare 1: Field Engineer” pack includes Fire Cover Block, Half window Block, Weapon Rack Block, Five new passage blocks, Embrasure Block, Two new Emotes and the Assault Suit skin.

Space Engineers “Wasteland” pack includes Off road wheels, Exhaust pipes, Buggy cockpit, 2 View port blocks, Barred Window, Offset Light, Offset Spotlight, 3 Storage Shelves, Concrete Armor Skin, Dust Armor Skin, Rust 2 Armor Skin, Retro future Armor Skin, Scavenger Character skin, and 2 new character emotes.

The Space Engineers - Sparks of the Future includes the Sci-Fi LCD, the Neon Tubes, the Sci-Fi Ion Thrusters, the Sci-Fi Atmospheric Thrusters, the Sci-Fi Interior Wall, the Bar Counter, the Sci-Fi Control Panel, the Sci-Fi 1-Button Panel, the Sci-Fi 4-Button Panel, the Sci-Fi Sliding Door, the Sci-Fi Armor Skin, the 2 Neon Armor Skins, the 8 new character emotes.

The Space Engineers - Frostbite includes: the Frostbite Scenario, the Antenna Dish, the Dead Engineers, the Gate, the Offset door, the Frozen Armor Skin, the I"m Cold Emote, the Check Wrist Emote and the LCD Posters.

The Space Engineers - Decorative Pack #2 includes the Dispenser, the Jukebox, the Lab equipment, the Shower, the Window walls, the Medical station, the Transparent LCD, the Grated catwalks, the Grated stairs and half stairs, the Railings, the Rotating Light and the Freight.

The Space Engineers - Economy Deluxe Pack includes the Miner suit, the Soldier suit, the Disco armor skin, the Silver armor skin, the Glamour armor skin, fourteen Safe zone skins, thirty two Faction icons, the Vending machine and the ATM machine.

The Space Engineers - Style Pack includes four character skins, four character emotes and four armor skins. The character and armor skins, as well as the emotes included in the Style Pack, do not bring new functionality and game mechanics to Space Engineers; they are purely decorative and provide an extra layer of entertainment for players.

The Space Engineers - Decorative Pack #1 includes the decorative blocks, which can be used for various decorations of your spaceships, vehicles and space stations.

Neon lighting consists of brightly glowing, electrified glass tubes or bulbs that contain rarefied neon or other gases. Neon lights are a type of cold cathode gas-discharge light. A neon tube is a sealed glass tube with a metal electrode at each end, filled with one of a number of gases at low pressure. A high potential of several thousand volts applied to the electrodes ionizes the gas in the tube, causing it to emit colored light. The color of the light depends on the gas in the tube. Neon lights were named for neon, a noble gas which gives off a popular orange light, but other gases and chemicals are used to produce other colors, such as hydrogen (red), helium (yellow), carbon dioxide (white), and mercury (blue). Neon tubes can be fabricated in curving artistic shapes, to form letters or pictures. They are mainly used to make dramatic, multicolored glowing signage for advertising, called neon signs, which were popular from the 1920s to 1960s and again in the 1980s.

Although some neon lamps themselves are now antiques, and their use in electronics has declined markedly, the technology has continued to develop in artistic and entertainment contexts.plasma displays and plasma television sets.

When Georges Claude demonstrated an impressive, practical form of neon tube lighting in 1910, he apparently envisioned that it would be used as a form of lighting, which had been the application of the earlier Moore tubes that were based on nitrogen and carbon dioxide discharges. Claude"s 1910 demonstration of neon lighting at the peristyle of this large exhibition space.Cinzano illuminated the night sky in Paris, and by 1919 the entrance to the Paris Opera was adorned with neon tube lighting.

The small size of the negative glow region of a neon lamp, and the flexible electronic properties that were exploited in electronic circuits, led to the adoption of this technology for the earliest plasma panel displays. The first monochrome dot-matrix plasma panel displays were developed in 1964 at the University of Illinois for the PLATO educational computing system. They had the characteristic color of the neon lamp; their inventors, Donald L. Bitzer, H. Gene Slottow, and Robert H. Wilson, had achieved a working computer display that remembered its own state, and did not require constant refreshing from the central computer system. The relationship between these early monochrome displays and contemporary, color plasma displays and televisions was described by Larry F. Weber in 2006, "All plasma TVs on the market today have the same features that were demonstrated in the first plasma display which was a device with only a single cell. These features include alternating sustain voltage, dielectric layer, wall charge, and a neon-based gas mixture."

Weber, Larry F. (April 2006). "History of the plasma display panel". IEEE Transactions on Plasma Science. 34 (2): 268–278. Bibcode:2006ITPS...34..268W. doi:10.1109/TPS.2006.872440. S2CID 20290119.

So, why is this important? A monitor’s panel technology is important because it affects what the monitor can do and for which uses it is best suited. Each of the monitor panel types listed above offer their own distinctive benefits and drawbacks.

Choosing which type of monitor panel type to buy will depend largely on your intended usage and personal preference. After all, gamers, graphic designers, and office workers all have different requirements. Specific types of displays are best suited for different usage scenarios.

The reason for this is because none of the different monitor panel types as they are today can be classified as “outstanding” for all of the attributes mentioned above.

Below we’ll take a look at how IPS, TN, and VA monitors affect screen performance and do some handy summaries of strengths, weaknesses, and best-case uses for each type of panel technology.

IPS monitors or “In-Plane Switching” monitors, leverage liquid crystals aligned in parallel to produce rich colors. IPS panels are defined by the shifting patterns of their liquid crystals. These monitors were designed to overcome the limitations of TN panels. The liquid crystal’s ability to shift horizontally creates better viewing angles.

IPS monitor variations include S-IPS, H-IPS, e-IPS and P-IPS, and PLS (Plane-to-Line Switching), the latter being the latest iteration. Since these variations are all quite similar, they are all collectively referred to as “IPS-type” panels. They all claim to deliver the major benefits associated with IPS monitors – great color and ultra-wide viewing angles.

Another important characteristic of IPS monitors is that they are able to support professional color space technologies, such as Adobe RGB. This is due to the fact that IPS monitors are able to offer more displayable colors, which help improve color accuracy.

With regard to gaming, some criticisms IPS monitors include more visible motion blur coming as a result of slower response times, however the impact of motion blur will vary from user to user. In fact, mixed opinions about the “drawbacks” of IPS monitor for gaming can be found all across the web. Take this excerpt from one gaming technology writer for example: “As for pixel response, opinions vary. I personally think IPS panels are quick enough for almost all gaming. If your gaming life is absolutely and exclusively about hair-trigger shooters, OK, you’ll want the fastest response, lowest latency LCD monitor. And that means TN. For the rest of us, and certainly for those who place even a modicum of importance on the visual spectacle of games, I reckon IPS is clearly the best panel technology.” Read the full article here.

IPS monitors deliver ultra-wide 178-degree vertical and horizontal viewing angles. Graphic designers, CAD engineers, pro photographers, and video editors will benefit from using an IPS monitor. Many value the color benefits of IPS monitors and tech advances have improved IPS panel speed, contrast, and resolution. IPS monitors are more attractive than ever for general desktop work as well as many types of gaming. They’re even versatile enough to be used in different monitor styles, so if you’ve ever compared an ultrawide vs. dual monitor setup or considered the benefits of curved vs. flat monitors, chances are you’ve already come into contact with an IPS panel.

TN monitors, or “Twisted Nematic” monitors, are the oldest LCD panel types around. TN panels cost less than their IPS and VA counterparts and are a popular mainstream display technology for desktop and laptop displays.

Despite their lower perceived value, TN-based displays are the panel type preferred by competitive gamers. The reason for this is because TN panels can achieve a rapid response time and the fastest refresh rates on the market (like this 240Hz eSports monitor). To this effect, TN monitors are able to reduce blurring and screen tearing in fast-paced games when compared to an IPS or VA panel.

On the flip side, however, TN panel technology tends to be ill-suited for applications that benefit from wider viewing angles, higher contrast ratios, and better color accuracy. That being said, LED technology has helped shift the perspective and today’s LED-backlit TN models offer higher brightness along with better blacks and higher contrast ratios.

The greatest constraint of TN panel technology, however, is a narrower viewing angle as TN monitors experience more color shifting than other types of panels when being viewed at an angle.

Today’s maximum possible viewing angles are 178 degrees both horizontally and vertically (178º/178º), yet TN panels are limited to viewing angles of approximately 170 degrees horizontal and 160 degrees vertical (170º /160º).

TN monitors are the least expensive panel technology, making them ideal for cost-conscious businesses and consumers. In addition, TN monitors enjoy unmatched popularity with competitive gamers and other users who seek rapid graphics display.

Vertical alignment (VA) panel technology was developed to improve upon the drawbacks of TN. Current VA-based monitors offer muchhigher contrast, better color reproduction, and wider viewing angles than TN panels. Variations you may see include P-MVA, S-MVA, and AMVA (Advanced MVA).

These high-end VA-type monitors rival IPS monitors as the best panel technology for professional-level color-critical applications. One of the standout features of VA technology is that it is particularly good at blocking light from the backlight when it’s not needed. This enables VA panels to display deeper blacks and static contrast ratios of up to several times higher than the other LCD technologies. The benefit of this is that VA monitors with high contrast ratios can deliver intense blacks and richer colors.

MVA and other recent VA technologies offer the highest static contrast ratios of any panel technology. This allows for an outstanding visual experience for movie enthusiasts and other users seeking depth of detail. Higher-end, feature-rich MVA displays offer the consistent, authentic color representation needed by graphic designers and other pro users.

There is another type of panel technology that differs from the monitor types discussed above and that is OLED or “Organic Light Emitting Diode” technology. OLEDs differ from LCDs because they use positively/negatively charged ions to light up every pixel individually, while LCDs use a backlight, which can create an unwanted glow. OLEDs avoid screen glow (and create darker blacks) by not using a backlight. One of the drawbacks of OLED technology is that it is usually pricier than any of the other types of technology explained.

When it comes to choosing the right LCD panel technology, there is no single right answer. Each of the three primary technologies offers distinct strengths and weaknesses. Looking at different features and specs helps you identify which monitor best fits your needs.

LCD or “Liquid Crystal Display” is a type of monitor panel that embraces thin layers of liquid crystals sandwiched between two layers of filters and electrodes.

While CRT monitors used to fire electrons against glass surfaces, LCD monitors operate using backlights and liquid crystals. The LCD panel is a flat sheet of material that contains layers of filters, glass, electrodes, liquid crystals, and a backlight. Polarized light (meaning only half of it shines through) is directed towards a rectangular grid of liquid crystals and beamed through.

Note: When searching for monitors you can be sure to come across the term “LED Panel” at some point or another. An LED panel is an LCD screen with an LED – (Light Emitting Diode) – backlight. LEDs provide a brighter light source while using much less energy. They also have the ability to produce white color, in addition to traditional RGB color, and are the panel type used in HDR monitors.

Early LCD panels used passive-matrix technology and were criticized for blurry imagery. The reason for this is because quick image changes require liquid crystals to change phase quickly and passive matrix technology was limited in terms of how quickly liquid crystals could change phase.

Thanks to active-matrix technology, LCD monitor panels were able to change images very quickly and the technology began being used by newer LCD panels.

Ultimately, budget and feature preferences will determine the best fit for each user. Among the available monitors of each panel type there will also be a range of price points and feature sets. Additionally, overall quality may vary among manufacturers due to factors related to a display’s components, manufacturing, and design.

Alternatively, if you’re into gaming and are in the market for TN panel these gaming monitor options may be along the lines of what you’re looking for.

The cold-cathode display tube is a neon lamp with multiple cathodes. Each cathode is shaped like one of the digits 1 to 9, and they are mounted in a closely spaced stack.

If a display tube is kept with one cathode constantly glowing (ie. one number displayed all the time) then material is sputtered from that cathode. This only affects the glow of that cathode

each digit, and required less manual assembly during manufacture and so was cheaper per digit. It also made more efficient use of space so that more digits could be packed into a smaller size. Although more common in

The latest models in the Panaplex II line, which includes panels with 0.25-, 0.4-, and 0.7-in. digits, comes close to the magic dollar-a-digit figure—Burroughs quotes a price of $1.10 per digit in quantities of 50,000 eight-digit monolithic displays.

This eight-digit panel, furthermore, measures 2.65 in. long, 0.69 in. high, and is only 0.197 in. thick—not including the tubulation projecting from the rear, a relic of the process of evacuating the individual digit tubes and filling them with neon gas.

The panel is also quite economical in its power dissipation. It requires only 0.35 to 3.0 milliwatts per segment, depending on the brightness needed, and typically will use less than 1 mw per segment. This corresponds to a maximum of 7 mw per digit or 56 mw for the entire panel, when everything is lighted; but on the average, perhaps no more than five digits of five segments each are on, reducing the average dissipation to 5 mw per digit or 25 mw for the panel. At this rate, four standard carbon-zinc batteries, AA size, would last about 200 hours.

In one test, Burroughs engineers purchased a small calculator and replaced its LED display with the new Panaplex unit. This reduced the calculator"s total power requirements for display and computation from 800 mw to 350 mw.

In most hand-held calculators made with metal-oxide-semiconductor circuits, no interface drivers are necessary. Even though the Panaplex II panels are 170-volt gas-discharge devices, their anodes can be driven with voltage swings and current that conventional MOS circuits can provide—sometimes even through passive components instead of transistors.

Like Nixies, the Panaplex panels emit an orange-red light, which is spread over a relatively broad part of the visible spectrum and is centered near the middle of the perception range of the human eye. Therefore, the panels can be viewed continuously for long periods without discomfort, and are not difficult for color-blind persons to read, as are some bright-red LED displays, which cover a narrow spectral range."

were very widely used in both desktop and hand-held calculators. However, from the mid-1970s VFDs started to be replaced in hand-held calculators by Liquid Crystal Displays (LCDs) which used much less power and so gave

The LED eventually lost out to the Liquid Crystal Display (LCD, see below) which has a much lower power consumption (it is passive and does not emit light) and has a larger size at little extra cost.

Liquid Crystal Displays (LCDs) were developed in the late 1960s and early 1970s. Thomson-CSF of France was one company involved in their development and demonstrated a calculator with a 16-digit LCD

The first successful use of LCD displays in calculators were in models made by Rockwell for Lloyds (Accumatic 100), Rapid Data (Rapidman 1208LC), and Sears in 1972. These use DSM (Dynamic Scattering Mode) LCDs where the liquid crystal is normally clear but turns opaque white when a voltage is

The true COS calculator has a circuit board which is made of a glass-like ceramic, as shown on the left, viewed from the rear of the calculator. The LCD display is formed directly

The main board is made of a glass ceramic with the DSM LCD formed under another sheet of glass. The glass circuit board is noteworthy in that there are no holes in it for mounting components; they are all surface-mounted. Conductors are printed on both sides of the circuit board and are covered with a white layer. Connections between the conductors on both side of the circuit board are made by the connector at lower right and the small conventional circuit board attached at lower left.

LCD displays have conventional circuit boards, though the LCD display modules have a similar construction to the display section on the glass circuit boards.

LCDs have the great advantage of very low power consumption since they are passive displays, altering the reflection of ambient light rather than actively generating light. However, a DSM LCD does require a small current to

When LCDs were first introduced in calculators there was a lot of discussion about the stability of the early liquid crystal material. This may be justified since calculators with DSM LCDs often have defective displays, though

region appears black. Since the TN LCD is a field-effect device the current consumption is extremely small, which is highly desirable for a battery-powered calculator.

Calculators with early TN LCDs usually have a yellow filter in front to remove Ultra Violet (UV) rays from the ambient light which might damage the liquid crystal.

Second-generation LCD. An example of a TN LCD with black digits and a yellow background - the yellow is actually a filter in front of the display to absorb damaging Ultra Violet light and prolong

generation LCDs are used for the displays of modern hand-held calculators and in conjunction with modern integrated circuit techniques result in calculators running for years on one button cell or just on solar power.

calculators in 1971 they were used extensively in hand-held calculators until the late 1970s when they were largely replaced by liquid crystal displays (LCDs).

the TN (Twisted Nematic) type. Then there was no stopping the LCD and by 1978/9 it dominated the hand-held calculator market and allowed credit card-sized calculators to be produced.

LCD panels are backlit by LED lights, so they rely on a backlight behind the panel to make the picture visible, and the LCD layer can"t prevent all light from escaping out of the screen. This means that even in a black scene, the backlight is still on, and some light escapes, causing blacks to appear gray.

Local dimming features on LED TVs are a way to improve the contrast ratio. Since these TVs consist of LED backlights behind an LCD panel, local dimming aims to turn off, or dim, certain zones of the LED backlight, making blacks look darker and highlights brighter. However, there may be some issues with local dimming on some TVs as it could cause blooming around bright objects or for entire zones to light up when there"s a small object. Overall, most local dimming features on modern TV do an effective job at improving the picture quality in dark scenes, and only some lower-end models will have glaring problems.

The above monitor is great and I’m still using it 5+ years later but the Dell U2518D makes for a very good alternative that is slightly newer. It has the same resolution and nearly the same low level specs and panel. It’s basically the successor to the U2515H and happens to only be $300 too. If I were buying a new monitor today it would be this one.

My Chromebook has a 13.3” 1080p display, and so does my secondary 22” 1080p monitor. Both monitors offer the same exact screen real estate. Meaning if I have a Sublime Text 3 code editor open, both of them can comfortably display 2x 80 character code windows side by side along with a sidebar.

The only difference is, a Retina enabled display will look nicer because it’s essentially cramming twice as many pixels into the same physical space. This will make fonts and porn…I mean professional Photoshop graphics that you design look really sharp.

If you’re curious the 15” MBP advertises itself as 2880x1800 which in turn gives it a “real” resolution of 1080p. That means you’ll be able to run your 2x 80 character Sublime Text code windows with a sidebar just as someone did 20 years ago with a first generation 1080p monitor.

The gist of it is, the higher the PPI, the more tightly packed the pixels are which in turn make the image sharper. This is why modern smartphones look liquid smooth. For example an iPhone 7 is 750 x 1334 at 4.7” gives you 325.61 PPI. That is awesome for text reading.

If you’re curious the recently purchased 24” ViewSonic VG2455-2K 1440p monitor in October 2021 is also very comfortable to read text at 122.38 PPI (5 more PPI than 25”), but it’s worth pointing out I personally wouldn’t want to go physically smaller than this.

The goal here is to be standing or sitting at a certain distance away from your monitor and be able to comfortably read text at 100% scaling without eye strain.

At 39 inches away I can still read the smallest Sublime Text status bar text without straining but 1 inch beyond that and things get difficult. This is mainly due to the contrast of this theme not being the best, but for every day computer use, you can’t expect everything to be the best case scenario.

I mentioned earlier that my Chromebook is 1080p at 13.3” and I can comfortably code on it with Sublime Text at a typical laptop viewing distance which is about 12 inches away. Viewing it from 24” is far too much eye strain for me.

Using this logic, I can deduce that a 27” 4k monitor at 163 PPI would likely strain my eyes a bit because the Chromebook’s PPI is 165 PPI. Yeah sure, I can technically read the text, but it takes way too much effort.

If you took a 4k monitor and scaled it up to 200%, you would end up with exactly the same screen space as a 1080p monitor. Things will look quite a bit smoother, sort of like a Retina display, but you’re not really gaining anything.

At 150% scaling you end up with the same space as a 1440p monitor, in which case you might as well buy a 1440p monitor because it’s going to be a lot cheaper and come with much better specs for your money.

However, I’m not convinced it’s going to be as big of a change as going from 2 windows to 3 and 50 LOCs to 75 LOCs. Why? Probably due to how coding is in real life. How much vertical space do you really need, and is 4 going to be that much better than 3?

Having 2x 1440p monitors offers more horizontal space than a single 4k monitor or most ultra wide monitors. Seriously, for editing video you can’t get enough horizontal space.

Vertical space helps too in this case and a 4k or 3440x1440 monitor would be better for that, but I wouldn’t want to make the other trade offs for this alone.

LCD manufacturers are notorious for borderline lying to their customers. Before that rant comes out, let’s first go over what determines quality and color accuracy.

TN panels tend to have the best response times and refresh rates. You’ll find most high end gaming monitors with 144hz have TN panels. They give a smoother feel to everything at that refresh rate, and you’ll notice less motion blur in fast action games.

The downside to TN panels is their color accuracy tends to be the worst, and as web developers, being able to see “red” as “red” is quite important. TN panels are often very washed out looking and also have terrible color shifting issues depending on the angle you’re looking at.

IPS (In-Plane Switching) panels are often considered the best type of panels for accuracy. Their viewing angles are fantastic without any loss of image quality. They also have the highest color accuracy of the bunch. As a software developer who does design, you’ll likely want an IPS panel. All 3 monitors listed in this post have IPS panels.

The downside is they typically come at 60hz and have worse response times than TN panels. However for real life software development and movie watching this won’t be a big deal. Even gaming will be more than fine unless you’re playing games at a highly competitive level.

It’s also worth noting that not all IPS panels are created equal. There’s an issue with some of them that people have labeled as “IPS glow” which means there’s a noticeable amount of brightness at various parts of the display. It makes a non-uniform glowing effect.

This is different from another term called “back light bleeding” which affects all panel types. This is the amount of whiteness that bleeds through the edges of your monitor when its background is set to black. This is usually most noticeable when you have your lights off or at a very dim setting.

VA (Vertical Alignment) panels are somewhere in between. You can kind of think of VA panels as being a jack of all trades. They are pretty good in all areas of computing but excel at nothing.

I see no point in getting a VA panel driven monitor unless the price is amazing and the other aspects of the monitor happen to be excellent, while not compromising much on the things that matter.

Other panel types do exist like PLS and AHVA but I have to draw the line somewhere in this article. I recommend trying to find a good IPS panel but if you find a monitor that you absolutely love don’t let it not being an IPS panel shatter your dreams. Go test it out.

Now, back to the rant about LCD manufacturers. Not only have they been caught doing price colluding but they go as far as releasing early versions of their monitors to review sites with IPS panels, but then go ahead and sell cheaper TN panels to the general public with the same exact model number.

They often make the switch in batches, and often times you can only tell whether or not a monitor has a specific panel type by looking at what characters its serial number begins with.

For software development and occasional gaming 60hz is fine. You will notice a nice buttery smoothness at 120hz and 144hz but if you’re just moving 2D windows around all day it’s not really worth the trade off of losing an IPS panel, since most 144hz monitors are TN panels aimed towards competitive gamers.

There’s 2 things to think about when it comes to refresh rates:You can’t always trust LCD manufactures with refresh rate too because they will list 120hz on a 4k monitor when in fact the monitor itself runs at 30hz or 60hz at 4k resolutions but 120hz if you down scale it to 1080p. LCD manufacturers love tricking the uninformed.

So this is where things get interesting. Input lag is much different than what most LCD manufacturers list on their spec sheets. They often list things like refresh rate and response times like 4ms or 2ms GTG (grey to grey), but both things are different than input lag.

I think realistically, having 1x or 2x 1440p monitors is going to offer you a really good development experience. You’ll have plenty of room to get work done and you won’t have to squint to read text since by having read this article, you know how to measure what PPI will be good for you.

One of the most important aspects of any display you can understand is the panel technology being used. Specifications alone won’t give you the full picture of a displays performance, and we all know that manufacturers can exaggerate specs on paper to suit their marketing. With an understanding of the panel technology being used you will get a feel for the overall performance characteristics of the display and how it should perform in real terms. Our extensive panel search database helps you identify the panel technology (and manufacturer and part number where known) of many screens in the market. This article which follows will help you understand what the different panel technologies can offer you. A lot of manufacturers now list the panel technology as well in their specs, something which wasn’t included a in the past.

TN Film panels are the mostly widely used in the desktop display market and have been for many years since LCD monitors became mainstream. Smaller sized screens (15″, 17″ and 19″) are almost exclusively limited to this technology in fact and it has also extended into larger screen sizes over the last 7 years or so, now being a popular choice in the 20 – 28″ bracket as well. The TN Film panels are made by many different manufacturers, with the big names all having a share in the market (Samsung, LG.Display, AU Optronics) and being backed up by the other companies including most notably Innolux and Chunghwa Picture Tubes (CPT). You may see different generations of TN Film being discussed, but over the years the performance characteristics have remained similar overall.

TN Film has always been so widely used because it is comparatively cheap to produce panels based on this technology. As such, manufacturers have been able to keep costs of their displays down by using these panels. This is also the primary reason for the technology to be introduced into the larger screen sizes, where the production costs allow manufacturers to drive down retail costs for their screens and compete for new end-users.

The other main reason for using TN Film is that it is fundamentally a responsive technology in terms of pixel latency, something which has always been a key consideration for LCD buyers. It has long been the choice for gaming screens and response times have long been, and still are today, the lowest out of all the technologies overall. Response times typically reach a limit of around 5ms at the ISO quoted black > white > black transition, and as low as 1ms across grey to grey transitions where Response Time Compensation (overdrive) is used. TN Film has also been incorporated into true 120Hz+ refresh rate desktop displays, pairing low response times with high refresh rates for even better moving picture and gaming experiences, improved frame rates and adding 3D stereoscopic content support. Modern 120Hz+ refresh rate screens normally also support NVIDIA 3D Vision 2 and their LightBoost system which brings about another advantage for gaming. You can use the LightBoost strobed backlight system in 2D gaming to greatly reduce the perceived motion blur which is a significant benefit. Some screens even include a native blur reduction mode instead of having to rely on LightBoost ‘hacks’, providing better support for strobing backlights and improving gaming experiences when it comes to perceived motion blur. As a result, TN Film is still the choice for gamer screens because of the low response times and 120Hz+ refresh rate support.

The main problem with TN Film technology is that viewing angles are pretty restrictive, especially vertically, and this is evident by a characteristic severe darkening of the image if you look at the screen from below. Contrast and colour tone shifts can be evident with even a slight movement off-centre, and this is perhaps the main drawback in modern TN Film panels. Some TN Film panels are better than others and there have been improvements over the years to some degree, but they are still far more restrictive with fields of view than other panel technologies. The commonly quoted 170/160 viewing angles are an unfair indication of the actual real-life performance really, especially when you consider the vertical contrast shifts. Where viewing angles are quoted by a manufacturer as 160/160 or 170/160 that is a clear sign that the panel technology will be TN Film incidentally.

Movie playback is often hampered by ‘noise’ and artifacts, especially where overdrive is used. Black depth was traditionally quite poor on TN Film matrices due to the crystal alignment, however, in recent years, black depth has improved somewhat and is generally very good on modern screens, often surpassing IPS based screens and able to commonly reach contrast ratios of ~1000:1. TN Film is normally only a true 6-bit colour panel technology, but is able to offer a 16.7 million colour depth thanks to dithering and Frame Rate Control methods (6-bit + FRC). Some true 8-bit panels have become available in recent years (2014 onwards) but given the decent implementation of FRC on other 6-bit+FRC panels, the real-life difference is not something to concern yourself with too much.

Most TN Film panels are produced with a 1920 x 1080 resolution, although some larger sizes have become available with higher resolutions. A new generation of Quad HD 2560 x 1440 27″ TN Film panels emerged in 2014. We’ve also seen the introduction of 28″ Ultra HD 3840 x 2160 resolution TN Film panels become available, and adopted in many of the lower cost “4k” models in the market. Where used, the Anti-Glare (AG) coating used on most TN Film panels is moderately grainy – not as grainy as some older IPS panel coatings, but not as light as modern IPS, VA or equivalents. Also at the time of writing there are no ultra-wide (21:9 aspect ratio) or curved format TN Film panels in production.

MVA technology, was later developed by Fujitsu in 1998 as a compromise between TN Film and IPS technologies. On the one hand, MVA provided a full response time of 25 milliseconds (that was impossible at the time with IPS, and not easily achievable with TN), and on the other hand, MVA matrices had wide viewing angles of 160 – 170 degrees, and thus could better compete with IPS in that parameter. The viewing angles were also good in the vertical field (an area where TN panels suffer a great deal) as well as the horizontal field. MVA technology also provided high contrast ratios and good black depth, which IPS and TN Film couldn’t quite meet at the time.

In MVA panels, the crystals in the domains are oriented differently, so if one domain lets light pass through, the neighboring domain will have the crystals at an angle and will shutter the light (of course, save for the display of white color, in which case all the crystals are placed almost in parallel to the matrix plane).

As MVA developed over the years the problem became that the response times were not as good as TN film panels and was very difficult to improve. Sadly, the response time grows dramatically when there’s a smaller difference between the pixel’s initial and final states (i.e. the more common grey to grey transitions). Thus, such matrices were unsuitable for dynamic games. With the introduction of RTC and overdrive technologies, the manufacturers launched a new breed of MVA discussed in the following sections.

Premium MVA (P-MVA) panels were produced by AU Optronics, and Super MVA (S-MVA) panels by Chi Mei Optoelectronics (now Innolux) and Fujitsu from 1998 onwards. AU Optronics have since entered a more recent generation referred to as AMVA (see the next section) and S-MVA panels are rarely used in mainstream monitors nowadays. When they were launched they were able to offer improved response times across grey to grey (G2G) transitions which is a great improvement in the MVA market. While responsiveness was still not as fast as TN Film panels using similar RTC technologies, the improvement was obvious and quite drastic. This was really the first time that MVA matrices could be considered for gaming, and arrived at the time when overdrive was being more widely implemented in the market.

While some improvements have been made, the color-reproduction properties of these modern MVA technologies can still be problematic in some situations. Such panels give you vivid and bright colors, but due to the peculiarities of the domain technology many subtle color tones (dark tones often) are lost when you are looking at the screen strictly perpendicularly. When you deflect your line of sight just a little, the colors are all there again. This is a characteristic “VA panel contrast shift” (sometimes referred to as ‘black crush’ due to the loss of detail in dark colours) and some users pick up on this and might find it distracting. Thus, MVA matrices are somewhere between IPS and TN technologies as concerns color rendering and viewing angles. On the one hand, they are better than TN matrices in this respect, but on the other hand the above-described shortcoming prevents them from challenging IPS matrices, especially for colour critical work.

Traditionally MVA panels offered 8-Bit colour depth (a true 16.7 million colours) which is still common place today. We have yet to see any new breed of 10-bit capable MVA panel even using Frame Rate Control (8-bit + FRC). Black depth is a strong point of these P-MVA /S-MVA panels, being able to produce good static contrast ratios as a result of around 1000 – 1200:1 in practice. Certainly surpassing IPS matrices of the time as well as most TN Film panels. This has improved since with more recent AMVA panels to 3000 – 5000:1 (see next section).

MVA panels also offer some comparatively good movie playback with noise and artifacts quite low compared with other technologies. The application of overdrive doesn’t help in this area, but MVA panels are pretty much the only ones which haven’t suffered greatly in movie playback as a result. Many of the MVA panels are still pretty good in this area, sadly something which overdriven TN Film, IPS and PVA panels can’t offer. While CMO are still manufacturing some S-MVA matrices, AU Optronics no longer produce P-MVA panels and instead produce their newer generation of MVA, called AMVA (see below).

AU Optronics have more recently (around 2005) been working on their latest generation of MVA panel technology, termed ‘Advanced Multi Domain Vertical Alignment’ (AMVA). This is still produced today although a lot of their focus has moved to the similarly named, and not to be confused AHVA (Advanced Hyper Viewing Angle, IPS-type) technology. Compared with older MVA generations, AMVA is designed to offer improved performance including reduced colour washout, and the aim to conquer the significant problem of colour distortion with traditional wide viewing angle technology. This technology creates more domains than conventional multi-domain vertical alignment (MVA) LCD’s and reduces the variation of transmittance in oblique angles. It helps improve colour washout and provides better image quality in oblique angles than conventional VA LCD’s. Also, it has been widely recognized worldwide that AMVA technology is one of the few ways to provide optimized image quality through multiple domains.

AMVA provides an extra-high contrast ratio of greater than 1200:1, reaching 5000:1 in manufacturer specs at the time of writing for desktop monitor panels by optimized colour-resist implementation and a new pixel design and combining the panels with W-LED backlighting units. In practice the contrast ratio is typically nearer to 3000:1 from what we’ve seen, but still far beyond IPS and TN Film matrices. The result is a more comfortable viewing experience for the consumer, even on dimmer images. This is one of the main improvements with modern AMVA panels certainly, and remains way above what competing panel technologies can offer.

AMVA still has some limitations however in practice, still suffering from the off-centre contrast shift you see from VA matrices. Viewing angles are therefore not as wide as IPS technology and the technology is often dismissed for colour critical work as a result. As well as this off-centre contrast shift, the wide viewing angles often show more colour and contrast shift than competing IPS-type panels, although some recent AMVA panel generations have shown improvements here (see BenQ GW2760HS for instance with new “Color Shift-free” technology). Responsiveness is better than older MVA offerings certainly, but remains behind TN Film and IPS/PLS in practice. The Anti-Glare (AG) coating used on most panels is light, and sometimes even appears “semi glossy” and so does not produce a grainy image.

At the time of writing AMVA panels are typically offered with an HD 1920 x 1080 resolution, although some are available in sizes up to 32″ maximum, at a resolution of 2560 x 1440 (Quad HD). At this time there are no native 120Hz+ AMVA panels from AU Optronics in production although at one point AUO were looking into them. Also at the time of writing there are no ultra wide (21:9 aspect ratio) or curved format MVA-type panels in production.

AUO developed a series of vertical-alignment (VA) technologies over the years. This is specifically for the TV market although a lot of the changes experienced through these generations applies to monitor panels as well over the years. Most recently, the company developed its AMVA5 technology not only to improve the contrast ratio, but also to enable a liquid crystal transmission improvement of 30% compared to AMVA1 in 2005. This was accomplished by effectively improving the LC disclination line using newly developed polymer-stabilized vertical-alignment (PSA) technology. PSA is a process used to improve cell transmittance, helping to improve brightness, contrast ratio and liquid crystal switching speeds.

We have included this technology in this section as it is a modern technology still produced by Sharp as opposed to the older generations of MVA discussed above. Sharp are not a major panel manufacturer in the desktop space, but during 2013 began to invest in new and interesting panels using their MVA technology. Of note is their 23.5″ sized MVA panel which was used in the Eizo Foris FG2421 display. This is the first MVA panel to offer a native 120Hz refresh rate, making it an attractive option for gamers. Response times had been boosted significantly on the most part, bringing this MVA technology in line with modern IPS-type panels when it comes to pixel latency. The 120Hz support finally allowed for improved frame rates and motion smoothness from VA technology, helping to rival the wide range of 120Hz+ TN Film panels on the market.

Of particular note also are the excellent contrast ratios of this technology, reaching up to an excellent 5000:1 in practice, not just on paper. Viewing angles are certainly better than TN Film and so overall these MVA panels can offer an attractive all-round option for gaming, without some of the draw-backs of the TN Film panels. Viewing angles are not as wide as IPS panel types and there is still some noticeable gamma shift at wider angles, and the characteristic VA off-centre contrast shift still exists.

The liquid crystals in a PVA matrix have the same structure as in a MVA matrix – domains with varying orientation of the crystals allow keeping the same color, almost irrespective of the user’s line of sight and viewing angle. Viewing angles are not perfect though, as like with MVA matrices when you are looking straight at the screen, the matrix “loses” some shades, which return after you deflect your line of sight from the perpendicular a little. This ‘off-centre’ contrast shift, or ‘black crush’ as it is sometimes called is the reason why some colour enthusiasts prefer IPS-type displays. The overall viewing angles are also not as wide as IPS-type panels, showing more obvious colour and contrast shifts as you change your line or sight.

There was the same problem with traditional PVA matrices as with MVA offerings – their response time grew considerably when there’s a smaller difference between the initial and final states of the pixel. Again, PVA panels were not nearly as responsive as TN Film panels. With the introduction of MagicSpeed (Samsung’s overdrive / RTC) with later generations (see below), response times have been greatly improved and are comparable to MVA panels in this regard on similarly spec-ed panels. They still remain behind TN Film panels in gaming use, but the overdrive really has helped improve in this area. There are no PVA panels supporting native 120Hz+ refresh rates and Samsung have no plans to produce any at this time. In fact Samsung’s investment in PVA seems to have been cut back significantly in favour of their IPS-like PLS technology.

The contrast ratio of PVA matrices is a strong point, as it is with MVA. Older PVA panels offered contrast ratios of 1000 – 1200:1 typically, but remained true to their spec in many cases. As such at the time of their main production they were better than TN Film, IPS and even MVA in this regard. Movie playback is perhaps one area which is a weak point for PVA, especially on Samsung’s overdriven panels. Noise and artifacts are common unfortunately and the panels lose out to MVA in this regard. Most PVA panels were true 8-bit modules, although some generations (see below) began to use 6-bit+FRC instead. There are no 10-bit supporting PVA panels available, either native 10-bit or 8-bit+FRC. Panel coating is generally light on PVA panels, quite similar to a lot of MVA panels.

The introduction of overdrive to PVA panels lead to the next generation of Super Patterned Vertical Alignment (S-PVA) technology in 2004. Like P-MVA panels were to MVA, these are really just an extension of the existing PVA technology, but with the MagicSpeed (overdrive) technology, they have managed to make them more suitable for gaming than the older panels. One other difference is that the liquid crystal cell structure is a boomerang shape, splitting each sub pixel into two different sections with each aligned in opposite directions. This is said to help improve viewing angles and colour reproduction when viewed from the side. Limitations still exist with S-PVA and they don’t offer as wide viewing angles as IPS-type panels, and still suffer from the off-centre contrast shift we’ve described. Most S-PVA panels offered a true 8-bit colour depth, but some did feature Frame Rate Control (FRC) to boost a 6-bit panel (6-bit+FRC).

In late 2009 Samsung started to produce their latest generation of so called “cPVA” panels. These new panels featured a simpler sub-pixel structure in comparison with S-PVA, but allowed Samsung to produce the panels at a lower cost, and drive down the retail cost of their new screens. It’s unclear what the “c” stands for. This is a similar approach to e-IPS which we discuss a little later on.

In practice, cPVA do not look any worse than S-PVA panels and in fact offer even better contrast ratios in early cPVA panel tests. Other performance characteristics including the off-centre contrast shift remained the same as S-PVA panels. Some cPVA panels are in fact using Frame Rate Control to produce their 16.7m colour depth (6-bit+FRC) as opposed to true 8-bit panels. See this news piece for more information about these 6-bit + AFRC cPVA panels.

There is very little official information about this technology but some Samsung monitors started to be labelled as having an A-PVA panel around 2012 onwards. We suspect that nothing has really changed from S-PVA / cPVA panels, but that the term “Advanced” has been added in to try and distinguish the new models, and perhaps compete with LG.Display’s successful IPS technology and AU Optronics AMVA technology where they have also added the word “Advanced” for their latest generations (see AMVA and AH-IPS).

During 2014 Samsung started to label their PVA panels as SVA, although the definition is currently unknown. In fact these are probably the only remaining mass-produced PVA panels on the market. Little information is available regarding any possible changes although we expect some improvements to response times and contrast ratios. We believe PSA has been used for these panels as well, much like AU Optronics have used it for their more recent AMVA generations. PSA is a process used to improve cell transmittance, helping to improve brightness, contrast ratio and liquid crystal switching speeds.

At the time of writing we have only seen this term used for their latest curved VA panels, so it may be something linked to that format. Contrast ratios of 3000:1 are now quoted for modern VA panels like this. Resolutions are offered at 1920 x 1080 and also 3440 x 1440 in ultra-wide 21:9 aspect ratio and curved formats. High refresh rate support is not offered at the moment so PVA variants are limited to 60Hz maximum.

In Plane Switching (IPS – also known as ‘Super TFT’) technology was developed by Hitachi in 1996 to try and solve the two main limitations of TN Film matrices at the time, those being small viewing angles and low-quality color reproduction. The name In-Plane Switching comes from the crystals in the cells of the IPS panel lying always in the same plane and being always parallel to the panel’s plane (if we don’t take into account the minor interference from the electrodes). When voltage is applied to a cell, the crystals of that cell all make a 90-degrees turn. By the way, an IPS panel lets the backlight pass through in its active state and shutters it in its passive state (when no voltage is applied), so if a thin-film transistor crashes, the corresponding pixel will always remain black, unlike with TN matrices.

IPS matrices differ from TN Film panels not only in the structure of the crystals, but also in the placement of the electrodes – both electrodes are on one wafer and take more space than electrodes of TN matrices. This leads to a lower contrast and brightness of the matrix. IPS was adopted for colour professional displays due to its wide viewing angles, good colour reproduction and stable image quality. However, response times were very slow originally, making IPS unsuitable for dynamic content.

The original IPS technology became a foundation for several improvements: Super-IPS (S-IPS), Dual Domain IPS (DD-IPS), and Advanced Coplanar Electrode (ACE). The latter two technologies belong to IBM (DD-IPS) and Samsung (ACE) and are in fact unavailable in shops. The manufacture of ACE panels is halted, while DD-IPS panels are coming from IDTech, the joint venture of IBM and Chi Mei Optoelectronics – these expensive models with high resolutions occupy their own niche, which but slightly overlaps with the common consumer market. NEC is also manufacturing IPS panels under such brands as A-SFT, A-AFT, SA-SFT and SA-AFT, but they are in fact nothing more than variations and further developments of the S-IPS technology.

In 1998 production started for Super-IPS panels, and were mostly produced by LG.Philips (now LG.Display). They have gone through several generations since their inception. Initially S-IPS built upon the strengths of IPS by employing an advanced “multi-domain” liquid crystal alignmentt. The term S-IPS is actually still widely used in modern screens, but technically there may be subtle differences making them S-IPS, e-IPS, H-IPS, or p-IPS (etc) generations for example. See the following sections for more information.

Since their initial production in 1998 S-IPS panels have gained the widest recognition, mostly due to the efforts of LG.Philips LCD (now known as LG.Display), who were outputting rather inexpensive and high-quality 19″ – 30″ matrices. The response time was among the serious drawbacks of the IPS technology – first panels were as slow as 60ms on the “official” black-to-white-to-back transitions (and even slower on grey-to-grey ones!) Fortunately, the engineers dragged the full response time down to 25 ms and then 16ms later, and this total is equally divided between pixel rise and pixel fall times. Moreover, the response time doesn’t greatly grow up on black-to-gray transitions compared to the specification, so some older S-IPS matrices at the time could challenge TN Film panels in this parameter.

The IPS technology has always been at the top end when it comes to colour reproduction and viewing angles. Colour accuracy has always been a strong point, and even in modern displays the IPS matrices can surpass the performance of TN Film and VA equivalents. The viewing angles are a key part in this, since IPS matrices are free of the off-centre contrast shift that you can see from VA type panels. This is the reason why IPS is generally considered the preferred choice for colour critical work and professional colour displays, combining the excellent colour accuracy with truly wide viewing angles (178/178). S-IPS panels can show a purple colour when viewing dark images from a wide angle.

One main problem of the S-IPS technology traditionally was the low contrast ratio. Black depth was often a problem with S-IPS panels and contrast ratios of 500 – 600:1 were common for the early S-IPS offerings. However, these have been improved significantly, and contrast ratios are now much better as a result with modern IPS generations (see following sections). One other area which remains problematic for modern IPS panels is movie playback, again with noise being present, and only accentuated by the heavy application of overdrive technologies. S-IPS panels are sometimes criticized for their Anti-Glare (AG) coating, which can appear quite grainy and dirty looking, especially when viewing white/light backgrounds in office applications. Again that has been improved significantly in recent generations.

Moving Picture Image Sticking (MPIS) – S-IPS panels do not show any image sticking when touching a moving image. On the other hand severe image sticking happens in VA panel and lasts after the image is changed for a short time.

Sometimes you will see these terms being used, but S-IPS is still widely used as an umbrella for modern IPS panels. In 2002 Advanced Super IPS (AS-IPS) boosted the amount of light transmitted from the backlighting by around 30% compared with the standard Super IPS technology developed in 1998. This did help boost contrast ratios somewhat, but they could still not compete with VA panel types. In 2005 with the introduction of RTC technologies (Overdrive Circuitry – ODC) and dynamic contrast ratios, LG.Display started to produce their so called “Enhanced IPS” (E-IPS, not to be confused with e-IPS) panels. Pixel response times were reduced across G2G transitions to as low as 5ms on paper.

Enhanced S-IPS builds on S-IPS technology by providing the same 178° viewing angle from above and below and to the sides, and greatly improves the off-axis viewing experience by delivering crisp images with minimal colour shift, even when viewed from off-axis angles such as 45°. You will rarely see this E-IPS term being used to be honest. You may also occasionally see the name “Advanced S-IPS” (AS-IPS) being used, but this was just a name given specifically by NEC to the E-IPS panel developed and used in their very popular NEC 20WGX2 screen, released in 2006. The AS-IPS name was also (confusingly) used by Hitachi in some of their earlier IPS generations as shown below, back in 2002.

In 2006 – 2007 LG.Display IPS panels have altered the pixel layout giving rise to ‘Horizontal-IPS’ (H-IPS) panels. In simple terms, the manufacturer has reportedly reduced the electrode width to reduce light leakage, and this has in turn created a new pixel structure. This structure features vertically aligned sub-pixels in straight lines as opposed to the arrow shape of older S-IPS panels.

In practice, it can be quite hard to spot the difference, but close examination can reveal a less ‘sparkly’ appearance and a slightly improved contrast ratio. Some users find a difference in text appearance as well relating to this new pixel structure but text remains clear and sharp. H-IPS will also often show a white glow from a wide angle when viewing black images, as opposed to the purple tint from S-IPS matrices. This is actually more noticeable than the S-IPS purple tint and is referred to as “IPS glow”. Some IPS panels in high end displays are coupled with an Advanced True Wide (A-TW) polarizer which helps improve blacks from wide viewing angles, and reduces some of the pale glow you can normally see. However, this A-TW polarizer is not included in every model featuring H-IPS and this should not be confused. It is very rarely used nowadays unfortunately. H-IPS panels from around this time are sometimes criticized for their Anti-Glare (AG) coating, which can appear quite grainy and dirty looking, especially when viewing white backgrounds in office applications.

Close inspection of modern IPS panels can show this new H-IPS pixel structure, although not all manufacturers refer to their models as featuring an H-IPS panel. Indeed, LG.Display don’t really make reference to this H-IPS version, although from a technical point of view, most modern IPS panels are H-IPS in format. As an example of someone who has referred to this new generation, NEC have used the H-IPS name in their panel specs for models such as the LCD2690WXUi2 and LCD3090WUXi screens.

The following technical report has feedback from the LG.Philips LCD laboratory workers: “Wedesigned a new pixel layout to improve the aperture ratioof IPS mode TFT-LCD (H-IPS). This H-IPS pixel layout design has reducedthe width of side common electrode used to minimize thecross talk and light leakage which is induced by interferencebetween data bus line and side common electrode of conventionalIPS mode. The side common electrodes of a pixel canbe reduced by horizontal layout of inter-digital electrode pattern whereconventional IPS pixel designs have vertical layout of inter-digital electrodes.We realized 15 inch XGA TFT LCD of H-IPS structurewhich has aperture ratio as much as 1.2 times ofcorresponding conventional IPS pixel design.” ©2004 Society for Information Display.

During 2009 LG.Display began to develop a new generation of e-IPS (it is unclear what the “e” actually stands for) panels which is a sub-category of H-IPS. They simplified the sub-pixel structure in comparison with H-IPS (similar to cPVA vs. S-PVA) and increased the transparency of the matrix by producing a wider aperture for light transmission. In doing so, they have managed to reduce production costs significantly by integrating the panels with lower cost, lower power backlight units. This allowed LG.Display to compete with the low cost TN Film panels and Samsung’s new cPVA generation. Because transparency is increased, they are able to reduce backlight intensity as you need less light to achieve the same luminance now.

The drawback of e-IPS in comparison with S-IPS is that the viewing angles are slightly smaller. When you take a look at an e-IPS matrix from a side, the image will lose its contrast as black turns into grey. On the other hand, there is no tonal shift (as with TN and cPVA matrixes) and the viewing angles, especially vertical ones, are still much larger than with TN Film. Many e-IPS panels are actually 6-bit + AFRC modules (as opposed to true 8-bit) which might explain how the costs are kept very low in some cases, although in practice the FRC algorithm is very well implemented and you are unlikely to see any obvious side affects. Like H-IPS panels from years prior, e-IPS panels are sometimes criticized for their Anti-Glare (AG) coating, which can appear quite grainy and dirty looking, especially when viewing white backgrounds in office applications.

Although it’s unknown what the “e” stands for here, it’s likely that it means “economic” or similar, since these new panels are all about trying to keep production and retail costs low. With lower retail costs there is of course an added risk of inter-panel variance, which may lead to some quali

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey