lcd touch screen pic microcontroller in stock

The touch function uses the Peripheral Touch Controller (PTC) peripheral that is integrated into the SAME51 MCU to acquire touch sensor information from the capacitive touch sensor on the smart display module. We implemented this sensor using a unique 2D flower pattern that increases the precision of physical interpolation and provides for greater touch position linearity over standard diamond patterns. The SAME51 MCU leverages the MPLAB Harmony v3 Touch Library to correctly interpret 2D touch and gestures.

All firmware and application showcases are pre-loaded onto the IGaT Development Kit so that you can begin designing your product immediately. Our kit allows you to develop a striking, touchscreen-enabled GUI with a single chip to add value to your end products by maximizing their functionality for your customers.

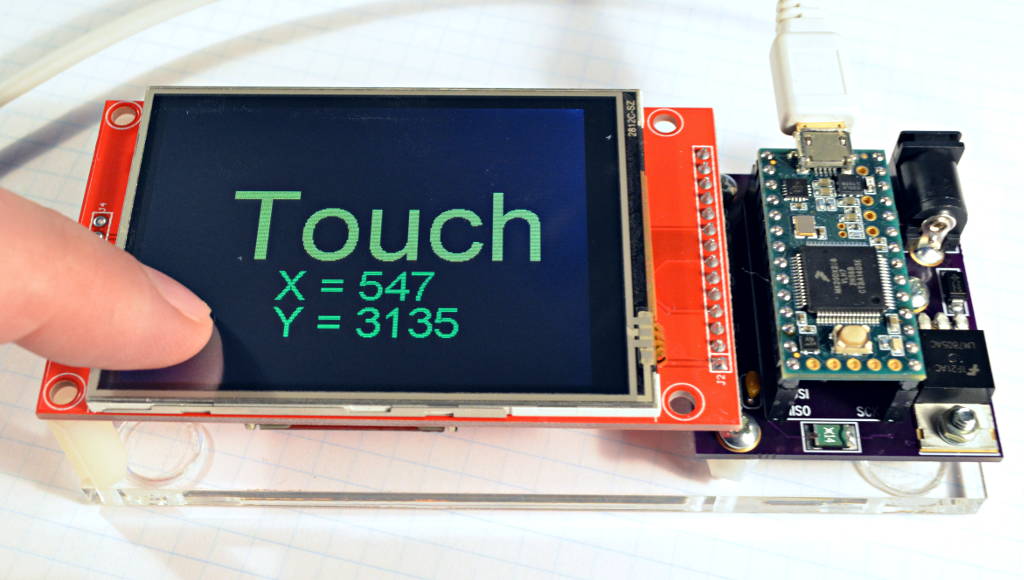

RF2BWNCRM–Man tapping, interacting with an lcd touch screen display on a single board microcontroller Progamming open source hardware micro controller apps tech

RF2FD5N9H–Modern DSLR with touch display, featuring BSI CMOS sensor with no optical low pass filter with Expeed 5 processor, build with an extremely durable rug

RF2JPCP67–Broken LCD screen with multiple colors and pixelations with color errors and problems forming abstract color stripes and patches background in gradien

RF2F8MHM2–Broken Mobile Smart Phone and pad with crashed Screen Glass Lcd. gadgets lying one on top of another. Devices are prepared for utilization.

I looked at a few libraries (Arduino ones) to get inspiration. In LCD_I2C_PCF8574.c I have added a lot of background and links to where you can get hold of other source, documentation and data on the PIC18F2685, I2C, the LCD and IO expander should you be so inclined. I also added a link to the library I ripped for the character generation. Thanks Mario. This file also contains details on how you may want to customise to your implementation, these are tagged with "TODO adapt" so you can use the MPLABX task list to grab them.

I took all my details/nomenclature etc. from an Hitachi hard copy LCD manual (yes hard copy, real paper an"all!) I obtained in the early 1980"s when we were still printing on flattened trees.

3.5inch RPi LCD (A) and 3.5inch RPi LCD (B) are hardware compatible with each other (uses different driver), and can be mutually substituted in most cases. (A) for low cost ver. while (B) for IPS ver. with better displaying.

Why the LCD doesn"t work with my Raspbian?To use the LCD with the Raspberry Pi official image, driver (SPI touch interface only) should be installed first. Please refer to the user manual.

However, for the first testing, you may want to use our image directly (if provided).Why the LCD still doesn"t work with the Waveshare provided image?Make sure the hardware connection is correct and connects fine.

Since the first-generation Raspberry Pi released, Waveshare has been working on designing, developing, and producing various fantastic touch LCDs for the Pi. Unfortunately, there are quite a few pirated/knock-off products in the market. They"re usually some poor copies of our early hardware revisions, and comes with none support service.

In this tutorial, you will learn to interface anLCD with a pic microcontroller. It is very simple and easy to understand the project for beginners and is commonly used in several electronic products. LCD (Liquid Crystal Display)provides a user-friendly interface and can be very useful for debugging purposes. After completion of this tutorial, you will be able to display data on an LCD using MPLAB XC8 Compiler and Mikro C compiler. We will provide examples with two Compilers such as MPLAB XC8 Compiler and Mikro C for PIC.

The reason LCD is more popular than LED, Seven Segment displays. Because we can display characters, numbers and custom characters with ease ( Just by easily programming a module).

First of all, to interface LCD with a pic microcontroller, we used GPIO pins. GPIO pins are general-purpose input-output pins. Because we send control and data signals to LCD through these I/O pins. Therefore, you should know how to use digital input-output pins of the pic microcontroller. To know about GPIO pins programming, check these tutorials:

It can work in two modes, 4-bit and 8-bit. In this tutorial, we have used the 4-bit mode which uses only 4 data lines, thus saving pins of the microcontroller. So It is recommended to use LCD in four bits mode to save pins of the microcontroller for other applications.

As you can see in this diagram, if we use 8-bit mode interfacing, we will need to use 11 pins of pic microcontroller. On the other hand, if we use 4-bit mode, we need only 6 GPIO pins. Therefore, it is recommended to use 4-bit mode interfacing. The only difference between 4-bit and 8-bit is that data transfer speed is faster for 8-bit mode. However, it doesn’t make any major difference.

A variable resistor is used to adjust the contrast of 5×8 dot pixels according to background light. Therefore, if you are not able to see anything on LCD after programming, the maximum changes are that you need to adjust contrast with the variable resistor. This contrast register makes adjust to the voltage applied on the VEE pin.

For MPLAB XC8 Compiler, we will use the PIC18F4550 microcontroller. For MikroC Pro for PIC, we will use the PIC16F877A microcontroller. In the case of MPLAB XC8, we will develop our own LCD library. Because the XC8 compiler does not provide built-in libraries. In the contrary, MikroC Pro provides libraries for all modules such as LCD, Keypad, ADC Module, UART module.

In this section, we will see how to write example code for 16×2 LCD interfacing with PIC18F4550 microcontroller. Although, you can use see code with other Pic microcontrollers also.

As we mentioned earlier, we can use the 8-bit mode and 4-bit mode interfacing. But due to the efficient use of MCU pins, we will be using 4-bit Mode. To interface LCD, we follow these steps:

In this circuit, we used the PORTB of PIC18F4550. But you can use any PORT. To do this, we need to change the pin assignment inside the code. I will show you how to assign pins for LCD in the next section.

These lines define which pins of the pic microcontroller should connect with LCD. For instance, in this example, we used the PORTD of PIC18F4550 microcontroller. Connect RD0-RD3 pins with D4-D7 pins of LCD respectively and other pins with RW, EN, RS and Power pins. But you can change PORT to other PORT of PIC microcontroller also by changing the PORT name with these commands.

LCDWriteNibble() function is used to write a nibble. Nibble is basically a half a byte. Because we are using LCD in four bits mode. Therefore, we need to send 8-bit commands/data in four bits chunks. This function writes the specified nibble to the LCD.

void LCDPutChar(char ch): Writes a character to LCD at current cursor position. This function displays the specified ASCII character at the current position on the LCD.

LCDGoto(char pos, char ln): This function positions the cursor at the specified line and column. Column and line at which the cursor should be positioned between 0-15 for pos (column) and 0-1 for ln(row).

In this section, we will see how to interface LCD with pic microcontroller and programming examples using MikroC for pic. MikroC pro has a built-in library.

We have used 16×2 LCD which means there are 2 rows and 16 characters in each row. So we can display a total of 32 characters at a time in two rows with 16 characters in each row.

This is the main command which prints our text on LCD. It also gives the privilege to specify the position of the text. In the horizontal direction, we count rows number and in a vertical direction, we count the column number. In above command,

However if your string is longer than the number of characters that could be displayed in a row from the starting position, the last characters will not be displayed. E.g. Lcd_Out (1, 6 “LCD Interface”);will display text in row 1 starting from column position 6 and will display only LCD Interfacethe rest of the characters will not be displayed as there is no room for them.

void Lcd_Out_Cp(char *text);will start printing the text from the current cursor position. For example after printing Lcd_Out (1, 1, “LCD”);if you write Lcd_Out_Cp(“Hello”);it will display “Hello”at a position from column position of 4 in row 1.

void Lcd_Chr(char row, char column, char out_char);allows only single characters to be displayed at specified positions. E.g. Lcd_Chr(2, 5, ‘A’); will print only A on column 5 row 2.

void Lcd_Chr_Cp(char out_char); allows to print only single character from current cursor position like after Lcd_Chr(2, 5, ‘A’);if your writeLcd_Chr_Cp(‘B’);it will be printed at row 2 column 6.

To interface LCD withPIC16F877A and display the text ‘LCD INTERFACE’ on it. LCDs come in different sizes and shapes. For this project, we have selected a 16×2 character, alphanumeric LCD. It contains 2 rows of 16 character.

When using PIC microcontroller, the mikroC compiler has a built-in LCD library that supports the commands to carry out LCD initialization. The library consists of a number of functions to control LCDs with 4-bit data interface.

The main program first clears the LCD screen and then displays “LCD INTERFACE” in the first row of LCD. The LCD pin directions are all set as outputs. The RS pin of LCD is set to 1, which indicates that the information received from DB4-DB7 is a valid text to be printed on LCD screen. The EN pin is also set to 1 which indicates that data is send to the LCD.

Programmed LCDs are vastly used for industrial as well as commercial applications. LCDs are used in UPSs or inverters, where voltage and current readings are displayed on the screen. Instructions to be followed are displayed on an LCD screen in airports, banks, hospitals, etc. If you still have any issue after reading this article, feel free to comment on this post with your issues.

This is our sixth tutorial in our PIC Tutorial Series, in this tutorial we learn Interfacing of 16x2 LCD with PIC Microcontroller. In our previous tutorials we have learnt the basics of PIC using some LED blinking Programs and have also learnt How to use Timers in PIC Microcontroller. You can check here all the tutorials on Learning PIC Microcontrollers using MPLABX and XC8 compiler.

This tutorial will be an interesting one because we will learn How to Interface 16×2 LCD with PIC16F877A, check the detailed Video at the end this tutorial. Gone are the old days where we used LEDs for user indications. Let us see how we can make our projects look more cool and useful by using LCD displays. Also check our previous articles on Interfacing LCD with 8051, with Arduino, with Raspberry Pi, with AVR.

To make things easier we have made a small librarythat could make things easy while using this LCD with our PIC16F877A. The header file "MyLCD.h" is given here for download, which contains all the necessary function to drive the LCD using PIC MCU. Library code is well explained by comment lines but if you still have doubts reach us through the comment section. Also check this article for Basic LCD working and its Pinouts.

Now, there are two ways to add this code into your program. You can either copy all the above lines of code in MyLCD.h and paste them before the void main(). Or you can download the header file using the link and add them to the header file of your project (#include " MyLCD.h ";). This can be done by right clicking on the header file and selecting Add existing Item and browsing to this header file.

Here I have copied and pasted the header file code into my main C file. So if you are using our code, then you don’t need to download and add the header file into your program, just use the complete Code given at the end of this Tutorial. Also note that this library will only support PIC16F series PIC Microcontroller.

void Lcd_Start():This function should be the first function that has to be called to start working with our LCD. We should call this function only once to avoid lag in the program.

void Lcd_Set_Cursor(x pos, y pos):Once started, our LCD is ready to take commands, we can instruct the LCD to set its cursor in you preferred location by using this function. Suppose if, we need out cursor at 5th character of 1st row. Then the function will be void Lcd_Set_Cursor(1, 5)

Each time the Lcd_Print_Char(char data)is called, its respective character values is sent to the data-lines of the LCD. These characters reach the HD44780U in form of bits. Now this IC relates the bits to the character to be displayed by using its ROM memory as shown the below table. You can find bits for all the characters in the datasheet of HD44780U LCD Controller.

The hardware for this project is very simple. We are going to reuse the same PIC module that we used last time and connect the LCD module to our PIC using jumper wires.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey