low power lcd display factory

This is a thin, extremely low-power 128x64 graphic LCD display module. It has no backlight, so consumes no power illuminating the display. However, if you wanted to backlight the module, the rear polarizer is transflective, so you could add your own lighting solution there. This display is perfectly suited for hand-held or any application requiring low power consumption or a very thin display. A row of icons is shown automatically top of the display without having to be rendered. This display has an integrated controller and the tail is designed to mate with standard 18-conductor 0.5mm pitch ZIF connectors (typical would be Omron XF2L18351A/ DigiKey P/N OR754CT-ND).

Do you need a display that draws the lowest current possible? Want long lasting battery-powered LCD project? Well, you have come to the right place. We compiled this list of digital displays that consume the least amount of power. These displays are perfect for when you are trying to extend the battery life of your product by pulling the least amount of current possible.

Other than a pen and paper, ePaper provides the lowest power consumption available for electronic displays. It does this via an electrochemical process that requires zero power once the pixels are in their desired location. These displays are ideal for when the content is not updated very often. Low-power ePapers only use power during updates, so the longer time between updates, the lower the power consumed.

The beauty of OLED displays and power consumption is that OLEDs only draw current for pixels that are on. For instance, when displaying a black and white checkerboard pattern, an OLED display consumes 50% less current than when displaying a completely white screen. Keeping that in mind, user interfaces can be designed to conserve as much power as possible by limiting how many pixels are lit.

Ultra-low-power displays consume very little energy, and the two primary technologies used for these types of displays are bistable and low refresh rate displays. They are used when there is a need for a battery-powered device, want maximum life between charges, and the content being displayed does not change very frequently.

The common uses for ultra-low-power displays are e-readers and electronic price tags. Some of the other applications we have seen are secondary displays for handheld devices and battery-powered products like locks, remote-mounted homes, and industrial products.

Probably the most well know bi-stable low-power display is e-paper technology historically used on e-readers. This technology is available in both monochrome and color.

In a monochrome e-paper display, millions of tiny liquid-filled capsules contain black and white charged ink particles. These capsules are sandwiched between a grid of electrodes. Applying a charge to the electrodes causes the ink particles to migrate to the top of the capsule, and depending on the polarity of the charge, it changes the color of the surface of the display.

E-paper is a reflective technology and, with good ambient light, has an excellent contrast ratio. One of the characteristics of e-paper is that the background is white, whereas many reflective display technologies like LCD have a gray or greenish background. One disadvantage is that E-paper requires front lighting if used in low-light conditions.

Displaying static images on an e-paper display uses very little energy (uW). However, it can require more power (mW) to update the screen than other technologies like LCD in the same size and resolution.

The backlight uses most of the power in a standard TFT display. For example, on a 7” TFT panel, the backlight uses almost 80% of the energy consumed for an average brightness display. The digital circuitry utilizes the remaining power to sustain the picture.

The first step of building a low-power TFT is to move to a reflective or transflective display and eliminate the power consumption of the backlight when the display can use ambient light.

Choosing a Transflective display is a good trade-off since it comes with a backlight that, when turned, the display becomes reflective. However, there is some trade-off in that the reflectance of a transflective display is lower than a pure reflective display. We use an advanced LCD driver chip to reduce the power further to drive the display at different refresh rates.

We use an advanced LCD driver chip to reduce the power further, which allows the display to be driven at different refresh rates. The drivers have two modes; a standard TFT mode that enables the display to operate like a standard TFT being able to do video rate, 60Hz, updates, and a low-power mode where the display refreshes at a rate of 1Hz. This mode is excellent for holding static images and using very little energy. Figure 2.0 depicts the driving methodology. Using these drivers, you can reduce the power of the digital portion of the display by 60%.

Table 2.0 shows a comparison study that we did for a thermostat application to compare different low-power technologies. In this study, the display is active for 15 minutes, and then it shows static images for the remainder of the day.

Conclusion: Depending on your application, either low-power TFT or e-paper may be suitable. If power is critical for your application and requires maintaining an image on display for long periods, consider these great technologies.

US Micro Products has designed displays with both technologies for special low-power applications and can do the same for your product. So let us help you with your display requirements; we have expertise that spans multiple markets and technologies.

If you have a project that is considering taking advantage of any display technology, US Micro Products can provide a solution designed for your application. Send us an email at sales@usmicroproducts.com.

A low-power display is a display that draws the lowest power possible. It is specifically designed to consume low levels of energy. These displays rely on technologies that allow the device to operate using minimal power inputs.

In recent times, there is a growing demand for low-power displays in order to lessen the stress on the environment. Another reason is customers needing wireless products without big power cables or the need for frequent charging. A low-power display is perfect when you try to improve the product"s hours of battery life by drawing the least amount of power possible. A device that uses less power to function is also cheaper to run.

LCDs were the only choice for low power until the arrival of two exciting options into the display market - E-ink display and Electrochromic display. This article will discuss these three low-power display technologies in brief and compare different features like power consumption, display quality, and more.

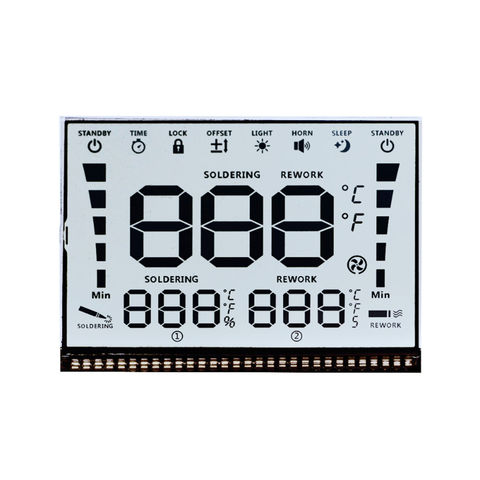

Reflective LCDs are prevalent in consumer electronics because of their low power consumption, ease of production, and cost-effectiveness. Low power seven segment display is widely used in calculators, digital clocks, radios, microwave ovens, and washing machines. It works by reflecting ambient light - such as natural light - from a reflective layer back to the viewer.

Electrophoretic display technology (which is used in E-ink displays) has a paper-like ultra contrast appearance that replicates the appearance of ordinary ink on paper. This display technology is popular because of its contrast, readability, thickness, low power consumption, and flexibility. It is widely used in e-readers like Amazon"s Kindle, real-time bus arrival information, electronic shelf label (ESL) segment, menu boards, etc. When the display is electrically charged, charged ink particles rise to the top of the display to create images.

Features:The electrophoretic displays are bistable, meaning they only need energy when there is a change in display. E-Ink display (a specific brand of electrophoretic displays) is the most suitable choice for low-frequency switching, i.e. if the display switches no more than approximately four times in a day.

An electrochromic display is the best low-power display technology in the market today. These ultra-low-power displays are lightweight, thin, energy-efficient, and cost-effective to produce and operate. They can also be bendable, meaning that they are easily customizable to individual business needs. As a result, these displays are widely used in logistics monitoring, consumer electronics, medical devices, smart cards, and more. Like the LCD, it works by reflecting ambient light. Using electrochromism, when a voltage is applied, the display will change color.

The electrochromic display is the most energy-efficient display technology for medium-frequency switching, i.e. if the display switches between 4-600 times a day.

In terms of display cost, electrochromic displays are among the cheapest technologies both to operate and produce - as they can be produced cheaply using roll-to-roll screen printing.

The design is highly customizable, allowing for a range of design options, including different sizes, shapes, and forms, and it can also easily incorporate a graphic overlay.

Of all the three technologies, only electrochromic displays are bendable. If you need a flexible display then, electrochromic displays are the best option for you.

High quality and low power consumption lcd screen from shenzhen risingstar, LCD screen with LG AUO Samsung"s original LCD module.Equipped with LED backlight, uniform brightness.

Low power consumption lcd screen with the standard automatic dimming system can adjust the brightness of the bright LCD screen according to the ambient light to achieve clear visibility in the sun.

It is widely used in outdoor LCD advertising player, electronic bus stop advertising screens, new energy charging piles, etc. In addition, there is no doubt that the free editing software can support any split screen in horizontal and vertical orientation.

2. You’re right – the Sharp displays are expensive. Adafruit provides only the display for $45 (which I purchased and used for early prototyping). The NEWT includes the display plus:

That being said… $92 is a lot of money… so I’m all for people building their own – or better yet, building a better version. I’ll add a comment below with links to all the software (device and server side) and hardware designs.

A. I might use a NE555 to send a 1 HZ pulse to the display, and use a different RTC- as long as it was low cost, low power, and supported multiple alarms/timers. Or maybe I’d add a crystal to the ESP32 and use internal RTC (which is super inaccurate w/o an RTC).

C. I think I’d add a legit battery fuel monitor (I use a voltage monitoring chip right now, that goes HIGH when the batt voltage falls below 3.5V). There were few to no LiPO fuel gauge chips in stock when I launched NEWT

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

Interface Devises Business includes Display and Senor, Sensor, and Application Solutions. As a leading company in the global semiconductor display industry, BOE has made the Chinese display industry develop from scratch to maturity and prosperity. Now, more than one-quarter of the global display panels are made by BOE, with its UHD, flexible display, microdisplay, and other solutions broadly applied to well-known worldwide brands.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

LG Display now operates back-end assembly plants in South Korea, China, and Vietnam. In addition, LG Display operates a sales subsidiary with a global network to effectively serve overseas markets.

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

From the introduction of Japan’s original washing machines, refrigerators, and other household appliances, to the world’s first laptop, the first 16MB flash memory, the world’s smallest 0.85-inch HDDs; Create advanced HDDVD technology; Toshiba created many “world firsts” in the research and manufacture of new SED displays and contributed to changing people’s lives through constant technological innovation.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Energy efficiency is crucial for future technologies. We need to make our products more power efficient to reduce the stress we put on the environment. Consumers demanding wireless products without bulky cables is another reason to reduce power. Hardware engineers developing IoT projects are struggling to stay within the power budget where the display often is the main problem. To meet these challenges there is a huge demand for ultra-low power IoT displays. In this article, we summarize the three most common low energy displays from a power perspective.

Reflective LCD displays, such as 7 segment displays, have been around for a long time. We recognize them from all kinds of household appliances including thermometers, ovens, watches, toys and medical devices. Until recently, LCD has been the only option for low power but now two alternative technologies exist on the market; the E Ink display based on electrophoresis and the Rdot display based on electrochromism, both offering features that LCD is lacking.

In this article, we investigate E Ink, Reflective LCD and the Rdot Display from a power perspective. All these technologies are categorized as reflective displays. Reflective displays are essentially required for ultra low power applications since emitting light is very power consuming (read more about reflective, transflective, and transmissive displays here). We want to clarify that displays from different manufacturers have slightly different energy consumption, and the data presented here is an average from the suppliers with the most energy efficient displays.

Before we go too deep it is important to understand the driving requirements of each display technology. Reflective LCD displays need an active driver that varies the polarity of the voltage across the pixel in a frequency of about 60Hz. E Ink, on the other hand, doesn"t need any active control once the display has been updated, this feature is often referred to as bistability. Rdot Displays is somewhere in between LCD and E Ink; once the display has been switched the controller can go idle for about 15 minutes (there exist versions that can be idle for up to 24 hours as well). We usually call this phenomenon "semi-bistability". After this time a small refresh pulse is required to maintain the state. For E Ink and Rdot, energy is only required during switching and updating while no energy is consumed during idle state. Typically, the energy required for a full switch on an E Ink display is about 7 to 8mJ/cm2. The corresponding number for the Rdot display is about 1mJ/cm2 with the addition of 0,25mJ/cm2 every 15-60 minutes. LCD continuously consumes about 6µW/cm2.

Followed by the different driving characteristics of the displays, we need to look into how often the display is updated to truly understand which display is the most energy efficient for your specific application. This is done by calculating the average power as a function of the number of switches per day. As seen in the diagram the E Ink display is the most power effective choice if the application is switching less than seven times a day. Between 4 and 600 switches, the Rdot display is the most energy efficient choice. If the display switches more than 600 times a day reflective LCD would be the best option from a power perspective.

To summarize the findings we can conclude that the Rdot display is the most power efficient choice if you need a display that is supposed to switch 4-600 times a day. However, we need to remember that there might be other features to take into consideration as well. For example, the Rdot display is flexible in its standard appearance and can be offered in multiple different colors without additional cost.

These wide viewing angle Small Format TFT LCDs with optional touch are industrial grade and cost competitive. Therefore these products are a popular display choice to integrate in many projects.

Using only high-tech factories that we partner with, we provide clients with the service of designing liquid crystal display panel (LCD) and liquid crystal display module(LCM), and is committed to the customized service, R&D, sales, after-sales service of display products. Our factories have hundreds of engineers focusing on creating the highest quality displays including monochrome LCD (TN, STN), colour LCD (CSTN and TFT), Custom LCD’s, LCD module (both COG* and COB*) which are widely used in mobile phones and many other applications.

Our state of the art factory produces High Resolution TFT glass panel cells, has TN, HTN, STN and TFT technologies for LCD panels. The Factory has class 1000 clean rooms, high accuracy bonding, pre bonding and heat seal machinery, many production lines specifically for TFT production, OCA and OCF bonding machines, In-House LCD glass cleansing process, output thousands of pieces per month.

Touchscreen overlay cover glass only available (so you do not have to purchase the display)These displays can come with: touchscreen components, touchscreen overlays, industrial touch screen,Wide LCDs, LED TFTs, and TFT Colour displays.

Other options are: LCD drivers, LVDS Touchscreen displays, automotive LCD Display, TFT high resolution screens, TFT LCD capacitive touchscreens, TFT capacitive touchscreens, high brightness LCDs, Letterbox Displays, small VGA Displays, LCD panel without backlights,Variations of our Small Format TFT LCDs include: TFT Display touchscreens, TFT IPS Display, monochrome displays, TFT or LCD, embedded components, LCD components, TFT Drivers, industrial range of Displays,

CDS also offers industrial TFT LCDs,Our displays are used in: touch screen vending machines, automotive touch screen displays, vending machine display panel, Touch screen vending, TFT Automotive, LCD Dislay panel kits, Touch screen TFT monitors, LCD Display components, LCD Screen components, and POS LCD Displays.As you can see from the tables above we have sizes including: 8.8 inches, 4.3 inch LCD Display, 10.1″ TFT LCD, 3.5 inch LCD Display, 4.3 inch display, 3.5 inch TFT LCD Display, 4.3″ screen, 7 inch LCD panel, 3 inch LCD Displays, and 4.3″ TFT LCDs as well as other small LCD Display screens.We have options on and equivalents to the following displays and TFT panel manufacturers: Raystar, Kingtech LCD, Digital View, OLED modules, OLED products, Powertip LCD Displays, Data Vision LCD, LG TFT Display, Tianma NLT, Powertip Displays, Mitsubishi LCD Displays, DMC components, Kyocera LCDs, NLT Technologies Ltd, Sharp LCD TFT modules, LCD manufacturers in the USA, PMOLED Displays, innolux display corp, Industrial touchscreens, A Grade TFT LCD Displays, Panoramic TFT Displays, Samsung TFT Displays, Touchscreen components, Transparent TFT Displays, Touchscreen components, TFT LCD controllers, as well as other TFT LCD manufacturers and Liquid crystal Display manufacturers.

CDS offers the widest range of displays and touchscreens including Abon touchscreens, Ampire LCD distributor, alternative Prisma interface baord supplier including Prisma iiia, Solomon Goldentek, Panasonic TFT, Winmate display, USB IO, and Apollo monitors

Our range includes AMOLED, circular displays, circular monitors, circular screens, circular TFT screens, round displays, Round TFT LCD displays, TFT AMOLEDs, TFT and IPS, TFT display interface microcontroller, TFT LCD or AMOLED, TFT LCD super AMOLED, WXGA TFT Displays, and WXGA TFT screens

As well as large format displays CDS also offers DSI TFT Display, large monochrome LCD displays, mono displays, mono OLEDC displays, mono TFT LCDs, monochrome displays, PCT Touchscreens, projected capacitive touch PCT technology, sq monitors and squid IDS.

CDS added a number of additional controller boards nd accessories which include TFT adaptor boards, TFT boards, TFT display controller boards, USB c LCD controller, USB touch kit, resistive touch screen, TFT accessories com, LCD controller board, LCD controller board USB c, LCD controller board, HDMI to MiPi DSI board, HDMI to MiPi DSI bridge, HDMI to MiPi LCD controller board, EDP adaptor bard, elite C microcontroller, Displaylink DL 3000 .

Whether it be bar type LCDs or any of CDS display solutions or many TFT displays we can help with comparing mipi dsi vs lvds interfces or mipi to edp wch can include use on pos shelf displays and rgb epaper for example.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey