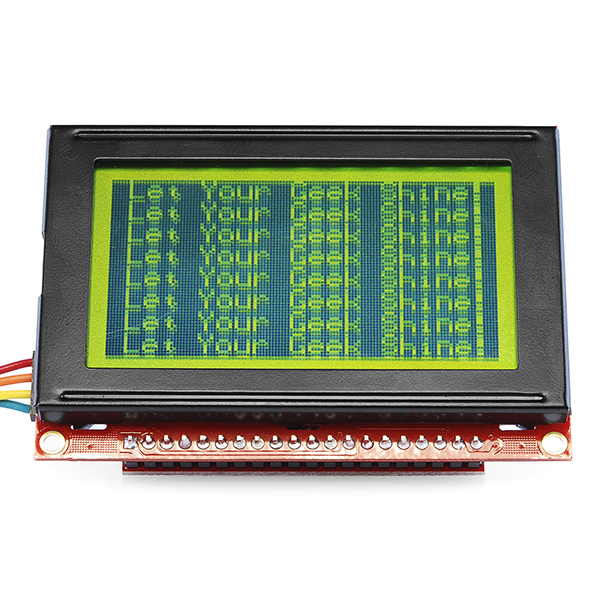

graphic lcd display programming in stock

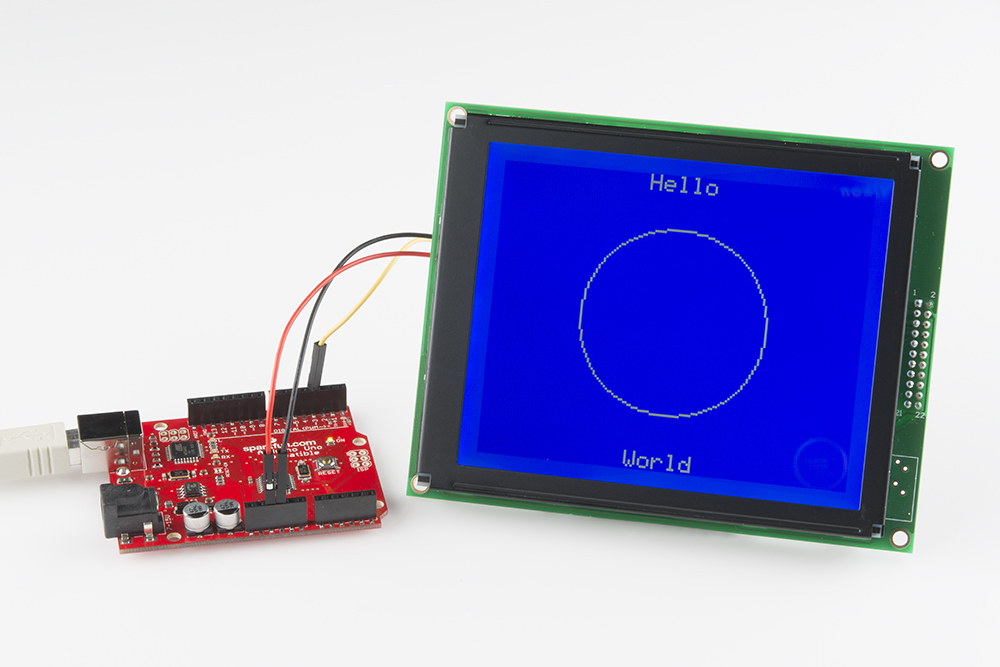

In this tutorial we will see how to interface and graphical LCD(GLCD) with PIC16F877A. In this tutorial we will look at interfacing KS0108 controller based JHD12864E display. There are many displays out there based on KS0108 or compatible display controller. They all work the same way, but make sure to check the datasheet for the pin diagram before doing the connection.

We will look at the working of the display, the hardware setup and programming with PIC16F877A. You may use any other AVR,8051,PIC,ARM controller as well. We have it tested and working on 8051, AVR, PIC and ARM. We have similar tutorials on these MCUs as well.

Unlike a 16 x 2 display, this does not have a character map for ascii values stored on its ROM. However it allows us the flexibility of creating fonts like Arial, times new roman etc. We could also display bit-map images on it and stretching it little further we can make GUI"s and little animation, but that"s for another day. So lets get started.

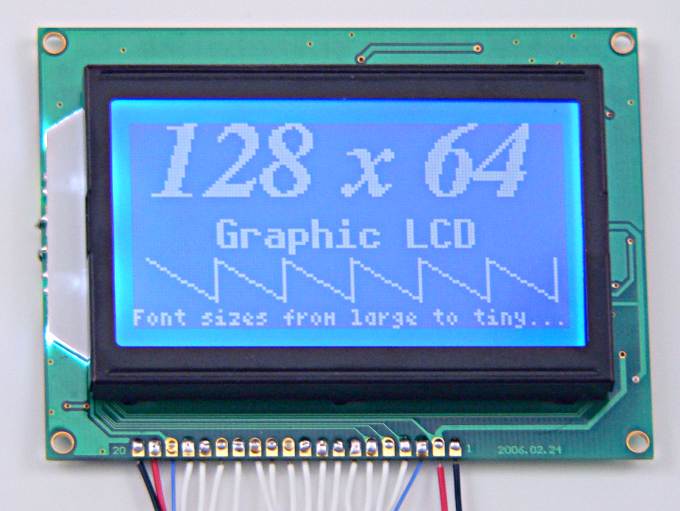

Ordinary LCDs can only display simple text or numbers within a fixed size. But in 128×64 graphical LCD display, there is 128×64 = 8192 dots, which is equivalent to 8242/8 = 1024 pixels. So, it can display not only simple text or numbers within a fixed size but also simple graphics.

In the above code, which is an example of Arduino, after installing the relevant library, we first need to uncomment the line that is related to the specific LCD settings (line 66, U8GLIB_ST7920_128X64_4X u8g (10);). Then upload the code to Arduino.

Can you control the backlighting by using PWM on the backlight voltage pin? It"s connected to Vss by default which applies the entire 5v to the pin, but if I can PWM the pin and apply a lower voltage will that dim the display? In essence I"m looking for a way to dim the display using an MCU. Also, when dimmed does it draw less current? (I"m thinking it does, less photons means less work which means less current).

Also, I"m assuming that a lot of current is most likely drawn from that backlight pin so I plan on placing a transistor between the MCU and the LCD which I will drive from the MCU via PWM.

Thanks for sharing your library. I ported it to the XMEGA style and it worked except that I need to add a reset in lcd_init(). I initialized the control port with RESET low, and then I promptly set it high.

The current version of this graphic display (GDM12864H) has a unique feature that I have not seen in any other 128x64 graphic LCD. Its pixels (and pitch) are square (0.39x0.39mm) so your circles appear as circles -- no more ellipses!!!

Thanks for posting. Please explain why you have 2K ohm connected to the V0 and VEE pins? This LCD has built-in DC converter to drive the LCD already?

Someone noted above that the voltage needs to be fairly low (~-4V) to see the darkness of the pixels. If you hook a pot up, be sure to wipe it to both extremes to see if you can atleast see a big black box when the LCD has power, then you know atleast your contrast works and you"re getting power!

astromme - I am currently working on a project with this serial graphic display and I am interested in using the MSP430 could I get a copy of the adapted Arduino ks0108 library? Thank you, this would be greatly appreciated.

You should look on the product page"s documents. There"s links to get it working with an Arduino microcontroller. Also, there is an article on Arduino if you did an online search with example code and a hookup guide => http://playground.arduino.cc/Code/GLCDks0108.

I recently bought this LCD to use with a Maple Mini board. What Library should I use with it? I found the KS0108 Graphics LCD library on the Arduino page. That seems to be more useful than the LiquidCrystal library which doesn"t seem to work with this 20-pin LCD.

The one i ordered off sparkfun nearly a month ago was of the " small fraction of the glcds out there will need a reset pulse" variety? it took me a few days and several hours to realize, i had to waste another pin. The solution was to go into the library and un-comment part of the code as described at the bottom http://www.arduino.cc/playground/Code/GLCDks0108/

I"m looking for a similar specs LCD, but with a white or blue backlight.. I"m planning on adding it next to my motorcycle OEM screen, and being green would quite likely be an ugly mismatch.

Make sure that you have a 100 to 330 ohm resister in series with the LCD backlight. Some of the documentation is not clear on this, but the resister must be there or the LED backlight will act like a dead short as soon as the voltage rises above the LED forward bias - usually about 2.0V.

So, stupid question, the LCD screen says it needs 9V to work. Is that supplied by the circuits on the board, or do you need to create a step-up dc converter to change 5V into 9V?

While the microcontroller was running, i had to take the display off my test board, because (stupid as i was) i mounted the V0 pot-meter under it. When i connected it back it was working!

On the page Csloser links to, he recommends a pull down resistor. Could anyone comment on the importance of this? Could this be the cause of my one line LCD?

I grabbed the software and loaded it. The backlight works and at first I saw a few lines on the display itself (these faded). When I ran the software from that web page, nothing came out on the display. I played with the contrast potentiometer a little, but I still see nothing. The program is running (I added some Serial output for debugging).

I forgot to mention that the LCD voltage, in my experience, should be around -4V for the display to be readable. Close to -5V will turn all of the pixels fully on and above -3V they will be totally transparent. Other units may behave differently but this is how mine works.

I intended to drive this LCD with an ATmega168, which now appears to be an astonishingly bad idea if the uC has only 1K RAM and you need that to drive the LCD. True? Or am I missing something completely obvious to the non-novice? It looks like I need a separate uC (like the DiosPro) to drive the LCD, with the 168 uC controlling the DiosPro via the UART? Happy to take advice....

You don"t have to devote any ATmega168 RAM to the LCD. This component has its own video RAM, one bit per pixel, 512 bytes total. I think you have to write whole bytes at a time (8 pixels), and it doesn"t know how to draw a letter "A" by itself, but the App Note from Kronos Robotics says they have a higher-level Dios library to deal with such operations.

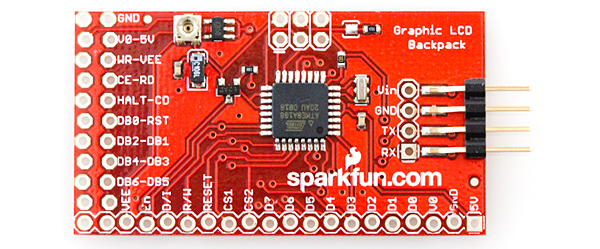

Below is a snippet of the example LCD control code. This small novella of a sketch shows off an array of graphics driver functions, character drawing tools, and other useful functions to help you get started using the LCD. You will need to include the LCD_Functions.h header in the same directory as the sketch folder from the download. Otherwise, your code will not compile when uploading to Arduino.

Heads up! If the display is not showing pixels even with the correct logic levels and example code, it may just have slight variances in the way that they were manufactured. You can see the pixels faintly on the screen at an angle or pushing down on the LCD. You will need to try and set the contrast where it says setContrast(40) on line 87 to a value of 60. There is probably some variances in the LCD’s contrast which might explain why certain LCDs have issues displaying defined pixels on the screen.

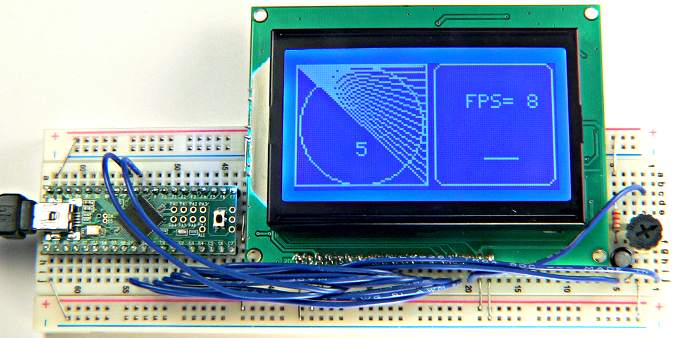

Once uploaded to your Arduino, the sketch will begin by running the demo -- a set of basic animations and graphics functions. To begin, we"ll draw some random pixels on the screen ("It"s full of stars..."). Then we"ll move on to examples of drawing lines, rectangles, and circles. Throughout there are examples of drawing characters and strings. Finally the demo closes out with an homage to a monochrome comic which seems a perfect fit for this little monochrome LCD.

After the demo runs its course, the sketch will enter into a serial echo mode. Open the serial monitor (set the baud rate to 9600 bps), and type stuff over to the Arduino. It should start printing everything you send it onto the LCD.

This is an extremely low-power 128x64 graphic LCD display module. It has an integrated white LED backlight that illuminates the display easily in low-light conditions. This display is perfectly suited for hand-held or any application requiring low-power or a very a thin display. It has an integrated controller and the FFC tail is designed to mate with standard 18-conductor 0.5mm pitch ZIF connectors (typical would be Omron XF2L18351A/ DigiKey P/N OR754CT-ND).

In this post/tutorial i am going to teach you how to interface graphical lcd jhd12864E with microchip pic16f877 microcontroller. I am going to display my website name “www.microcontroller-project.com” and a special pattern that displays thick lines on dotted graphical lcd display. In graphical lcd name “jhd12864” the number 128×64 means lcd has 128 coulombs and 64 rows. On graphical lcd’s data(character, numbers) is displayed on dots. A joint between coulomb and row is termed as dot. Total dots present in jhd12864 lcd are 128 x 64 = 8192 dots. When dots are combined they make a dot cluster. This cluster of dots in square form is know as matrix. On these 8192 dots we can display/make our data(character, number, image). In graphical lcd’s we are free to make character’s of our desired size unless the size is in the matrix of graphical lcd.

Before proceeding i would recommend you to please go through a small tutorial. This tutorial will helps you to understand how text is displayed on graphical lcd, how graphical lcd dots are arranged in pages, how graphical lcd is initialized(Graphical Lcd initializing commands), each and every pin of graphical lcd is deeply explained in the tutorial. You can easily understand the code below if you go through the tutorial.

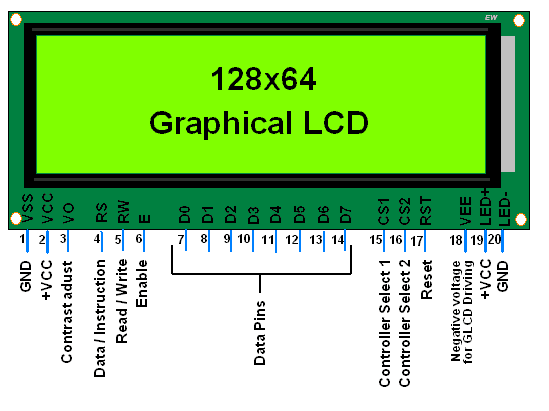

Graphical Lcd which i am using is JHD12864E. It comes in 20 Pin Package. Pin out of JHD12864E is given below. Its an 8-bit lcd. It comes with two built in controllers. Each controller is selected with chip select pins (cs1 and cs2).Visit the tutorial link given above to properly understand the pin functions and how to use them properly.

Lcd data pins are connected to Port-B of pic16f877 microcontroller. Lcd is interfaced in 8-bit mode with microcontroller. RS(register select) Pin of Lcd is connected to Port-D pin#7. RW(Read/Write) Pin of Lcd is connected to Port-D Pin#6. EN(Enable) Pin of Lcd is Connected to Port-D pin#5. CS1(Chip select) Pin of Lcd is connected to Port-D pin#4. CS2(Chip select) of lcd is connected to Port-C pin#4. RST(Reset) pin of Lcd is Connected to Port-D pin#2. A variable resistor is used between pins VEE and V0. This variable resistor is very important, it sets the Lcd contrast. Just connect the resistor, vary the resistance by rotating the knob, Adjust the best quality of lcd display that suites you. You can view highly black colour dots by increasing the resistance. If you want to see fant text reduce the resistance. LED+ and LED- are back light pins. I usually switch on the back light same i did for this project.

Clearlcd() function is half-filling each page with dots. Both halfs pages are filled in up and down position. If 2nd page of 1rst half is filled from down then 2nd page of 2nd half is filled from up.

Main() function contains the code that displays all stuff on lcd. First it jumps to clearLcd() function fills pages with dots. Then it displays my web site name on lcd. Pattern of each character of my site is commented in the code.

The 32128A is our smallest standard monochrome graphic LCD module. This LCD is ideal for remote controls and hand held products, as well as for applications that require a small, high-resolution display. The COG IC is the Sitronix ST7565V. This LCD has a FPC interface.

The ST7565V is a single-chip dot matrix LCD driver that can be connected directly to a microprocessor bus. 8-bit parallel or serial display data sent from the microprocessor is stored in the internal display data RAM and the chip generates a LCD drive signal independent of the microprocessor.

A graphical LCD is an electronic display unit which can display any type of elements provided by the user. Unlike a character LCD which can only display alphanumeric characters, a graphical LCD can display images, fonts and other structures. This article gives details of graphic LCD interfacing with a PIC microcontroller.

JHD12864 graphical LCD has a resolution of 128×64 which means that it can display 8192 pixels on the screen. In comparison with character LCD, it can display anything on the screen provided by the user. Character LCD only displays the alphanumerical characters. The user can create images, fonts and other structures and display on them. It uses KS0108 display controllers for controlling LCD panels on the GLCD.

KS0108 is a dot matrix display controller from Samsung with 64 channel output. It receives input as 8-bit parallel data and stores in data RAM which has a capacity of 512 bytes (512×8 = 4096 bits). To drive 128×64 graphic display, we will need two of these controllers and each will be controlling a half of 64×64 pixels. To generate timing signals for these two controllers, there is a common driver KS0107. There are also other display controllers for graphic LCD, an example is Toshiba T6963C. But we will be discussing about KS0108 based graphic LCD interfacing in this article.

The pin 18 is the output of a negative voltage generator. It generates -10V in the case of JHD12864 GLCD module. By using a potentiometer, we can generate the required operating voltage by feeding the negative voltage to the Vo pin. The resulting LCD voltage will be Vdd-Vo (If the pot is in minimum, 5-(-10) = 15V). From the datasheet of JHD12864 module, the maximum LCD voltage allowed is 18V. We can vary Vo to change the contrast of the display.

CS1 and CS2 pins are used to select the KS0108 controller from the two. CS1 selects the left side controller and CS2 selects the right one which in turn selects the corresponding side of the displays 64×64 pixels. RST is the reset pin, it is used to reset the entire display content by clearing whole of the display RAM. R/W pin selects the type of operation being performed by the GLCD, a High indicates read operation and a Low indicates write operation. Data/Instruction (D/I) selects between data transfer or instruction.

The Enable pin is the clock of GLCD. It is used to clock the data/instruction to the display module. For transferring the data or instruction, first you need to place the data on the data lines, then pull R/W and D/I High or Low according to the type of instruction and then set the Enable pin Low and then a High in order to transfer the data. One of the important consideration while clocking is, always give at least 1 microsecond delay after every instruction or data transfer. This parameter will be defined as Ecycle in the datasheet of the module. For JHD12864, the Ecycle value is 1us.

Graphical LCD block diagram is given below, it has two KS0108 segment drivers and a KS0107 common driver. KS0108 is a dot matrix LCD segment driver with 64 channel output which maintains one half of the GLCD. KS0107 is a 64 channel common driver which generates timing signals to control the other two KS0108 segment drivers.

There is also a negative voltage generator which outputs the negative voltage through Vee pin. In some display modules, this section may not be present. So we will need to generate the negative voltage from outside. In some GLCD displays, the segment and common drivers used will be made by different manufacturer, but they will be compatible with KS0108 controllers.

Each KS0108 controls half of 128×64, that is 64×64 pixels. To select the one half, make the chip select pin low while making the other’s pin high. There are 8 pages in each half which is controlled by each KS0108 controller. One page (one row) contains 64 columns of 8 rows. Whenever we transfer the data, we first selects the half by CS bits, then page address (X) and then the Y address. The byte will be transferred as a 1 bit wide strip and will be stored in display RAM location. We can summarise this process as follows.

Take an example of displaying ‘P’ in the first line of GLCD. We are making a font of size 5×7 pixels. We will be leaving first two columns, 8th column and last row of the page for spacing. These fonts are called 5×7 fonts. Below image explains how the fonts are created in graphic LCDs.

In order to display this, we need to transfer following bytes to the first page of the display by selecting left controller (CS1) in Y address from 0 to 7: 0x00, 0x00, 0x7F, 0x09, 0x09,0x09,0x06,0x00.

The above table lists different instructions available for KS0108 controller. For example, to turn the display ON, make RS and R/W Low, put 00111111 in DB7-DB0 pins and clock it by making enable pin Low to High. We will be discussing each of the instructions and implementation in the next part of this article.

To interface the graphical LCD, we need one 8-bit port and 6 other pins. We may avoid using RST pin, but we will need to ground it for using the LCD. Below is the circuit diagram of GLCD interfacing with PIC18F4550. We have used a 1K resistor to limit the current to the backlit LED.

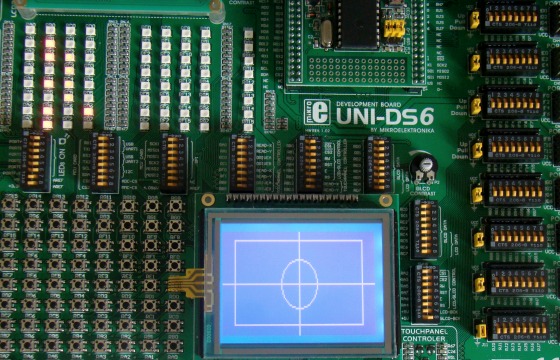

For interfacing Graphical LCD with PIC Microcontroller, PIC needs one 8 bit port (data port) and a 6 bit port (control port). Refer this guide for bit description of the GLCD.

Displaying images in GLCD is a simple task, but we need to convert the image in to an array of 128×64 array. For converting in to this format, first resize the image in to Monochrome bitmap format and the resolution should be 128×64. You can use any image editing programs like Microsoft Paint or Gimp etc for this purpose.

The graphic display used in this application note is Focus LCD’s G12864B-BW-LW63. Icons will be programmed into the display as bitmaps for non-moving images. The dynamic functions such as interactive buttons will be programmed on top of the bitmaps and will be continuously updated.

G12864C-BW-LW63 is a transmissive STN blue LCD with a white LED backlight. The embedded display driver is ST7565 which contains an internal oscillator and on chip RAM used to store display data. Features of this display are reviewed in the table below.

This display offers multiple interfaces to select from and is chosen through the hardware connections. The interface used in this application is a parallel 8-bit 8080 type. The alternative interfaces to select from are SPI and 6800 parallel. The display is interfaced with a STM32 Nucleo board. A simple 8-bit microcontroller would be sufficient to control this display because many of the features are provided internally by the display driver.

Graphic LCD’s provide internal RAM to support the frame buffer of images projected onto the display. This display has an internal RAM capacity of 8580 bits or approximately 1kB. Additional RAM can be provided externally or with the microcontroller.

The connection of the display to the microcontroller is through 30 pins which include the data lines, the voltage boosting circuit and the backlight. The voltage boosting circuit will step up the input voltage 3 times. There are different configurations for selecting the voltage boosting multiple which can be found in the datasheet of the driver. The 3X boost was chosen because the input voltage at VDD is at 3.3V and VLCD requires a voltage of 8.5V.

The voltage boosting circuit is used in configuration with the voltage divider circuit to produce a voltage of 8.5V for the display. This value can be measured at the pin VOUT. The capacitors used in the circuit can be in a range of values specified in the datasheet. Below is an outline of the hardware connections of the display.

The pin connections to the microcontroller and power supply are reviewed below. This application is using the 8080 parallel interface and all the data lines will need to be used. For the SPI interface the parallel data bus pins 6 and 7 will alternatively function as the clock and data pins. Some interface and display function pins are specified by pinning them to ground or to VDD. Below is a description of each of the pins and their connection.

The graphic LCD needs to be initialized before sending display data. This is done through a series of commands that specify voltage settings, bias, and display area. A detailed explanation of each of these commands can be found in the controller datasheet. This application will review a minimal initialization sequence used to set up the display.

The bias of the display is set by selecting the duty cycle specified in the datasheet. The duty cycle is 1/65 which means that the voltage bias ratio can be either 1/9 or 1/7. For this display, the 1/7 voltage bias ratio is selected. Below is the command to select the voltage bias ratio of 1/7.

The segment direction is set through the command “ADC Select”. This command can reverse the column address and the segment output. This would reverse the location of pixels projected onto the display. There is also a command to select the direction of the COM output. These commands are listed sequentially below.

The display start line will need to be set to indicate where the display data begins in RAM. The display start line can be a value from 0-65 corresponding to the vertical lines of pixels on the display. This value will be set the start address of line 0 to start at the top of the display lines.

The power functions of the display driver are set through a sequence of commands. These functions indicate which internal power systems are used. For this example, all of the power supply circuits are used. This is indicated by the following commands. These commands turn on the voltage converter, regulator and follower then sets the resistor ratio for the voltage divider.

The final commands are to turn the display on, active all points and set the electronic volume of the display. This is done by the following command sequence.

The controller in the display has a feature to program icons into different page addresses of RAM. This allows for multiple pages to be stored internally and to be accessed later. The controller offers eight pages of storage for the 128x64 pixels of visible display area. The pages are chosen through commands by setting the data bus pins D3, D2, D1 and D0 to a value from 0 to 8.

One full page consists of the data for each pixel of the display. The total RAM required for one page of data is calculated by the area of the resolution, 128x64=1024 pixels. Since the total RAM available in the controller chip is 8580 bits, the number of pages that can be stored is eight. Multiple icons can be stored in display RAM individually where each icon is less than the full area of the display.

A bitmap is created for the icons which contains the data for each pixel on the screen. Since the display has a resolution of 128x64, the icons will have to be very small. This makes the icon choices slim for graphic LCDs because there are only so many pixels to work with. This graphic LCD is monochrome and can only display pixels as on or off. Some creativity is needed when creating these icons because of these challenges.

Creating icon images can be done on Microsoft paint. The image can be a full page or individual icons that only take a portion of the resolution. You will zoom into the Paint application until the frame matches the resolution of the display (128x64). Now images can be created within these boundaries to be displayed on the screen.

Some available icons can be found when searching “vector icons”. The resolution is limited, so finding a standard set of tiny icons can be helpful when choosing what to display. Below are some examples of low-resolution icons that can be stored on the display.

A simple menu was created for this application that shows the options for setting the next display page. Each of these menu items can be selected to display the specified page in RAM where their bitmaps are stored. The menu was created on MS Paint and saved as a Monochrome .BMP file.

Once the bitmap is created it will need to be converted to an array of hexadecimal values to specify the on or off attribute of the pixels. The application that was used for this is called “LCD-imageconverter”. There are many applications that can be used for converting bitmap images into hexadecimal, binary, and c file types.

The bitmap can be uploaded onto one of the pages in RAM and accessed based on selection. Push buttons can be added to select menu options which will indicate which page is selected. The display has internal RAM of 1kB so there are eight possible page addresses to save data to. Below is the menu created from this application when read from page 0.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

Designer agrees that prior to using or distributing any applications that include FocusLCDs products, Designer will thoroughly test such applications and the functionality of such FocusLCDs products as used in such applications.

Newhaven 160x100 graphic Chip-On-Glass (COG) Liquid Crystal Display shows dark pixels on a gray background. This reflective LCD Display is visible with high ambient light while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C160100CZ-RN-FBW display has an optimal view of 6:00 and has no backlight. This display operates at 3V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

Note: We frequently get asked about ordering the adapter separately. Due to a number of displays on the market causing instability and incompatibility issues, we only sell a reputable GLCD screen and our adapter together as a bundle. We are not able to sell, nor support, the adapter separately. We do this to offer the best possible user experience and appreciate your understanding.

The dial knobs on the GLCD are press fit. The small white pot on the left controls the screen contrast. Turning it counter-clockwise makes the screen text brighter and clockwise makes the text darker.

The above values indicate where the machine is registering the head location in the coordinate system and which increment it will be displayed in. The WCS and MCS are the same unless you have applied a different offset (G54 is typically used for CNC builds, like for laser use). You will usually only focus on the left side WCS for the X, Y, Z coordinates.

The SD card containing the firmware and config.txt file is inserted into the controller, not the GLCD SD card slot. Power down to remove the card and make sure it is inserted back into the board before powering back up. Use a text editor, such as Sublime Text and not NotePad ++.

If the screen is coming on, but the encoder knob on the right is not responding to rotation or presses, make sure you have both the EXP1 and EXP2 cables connected to the adapter in the correct order and that the adapter is connected to the board in the proper orientation. Trace the ribbon cables to confirm. See the GLCD Installation Instructions for more information and images.

The EXP1 and EXP2 connectors being inserted backwards or not making proper contact. Review our GLCD Installation Instructions to confirm the proper orientation.

The LPSU is a particularly large source of electrical noise / interference, so you’ll want to make sure that the 2 ribbon cables going to the GLCD are tucked away as much as possible from that and any other wires, especially the high voltage wire from the LPSU.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey