graphic lcd display programming brands

Can you control the backlighting by using PWM on the backlight voltage pin? It"s connected to Vss by default which applies the entire 5v to the pin, but if I can PWM the pin and apply a lower voltage will that dim the display? In essence I"m looking for a way to dim the display using an MCU. Also, when dimmed does it draw less current? (I"m thinking it does, less photons means less work which means less current).

Also, I"m assuming that a lot of current is most likely drawn from that backlight pin so I plan on placing a transistor between the MCU and the LCD which I will drive from the MCU via PWM.

Thanks for sharing your library. I ported it to the XMEGA style and it worked except that I need to add a reset in lcd_init(). I initialized the control port with RESET low, and then I promptly set it high.

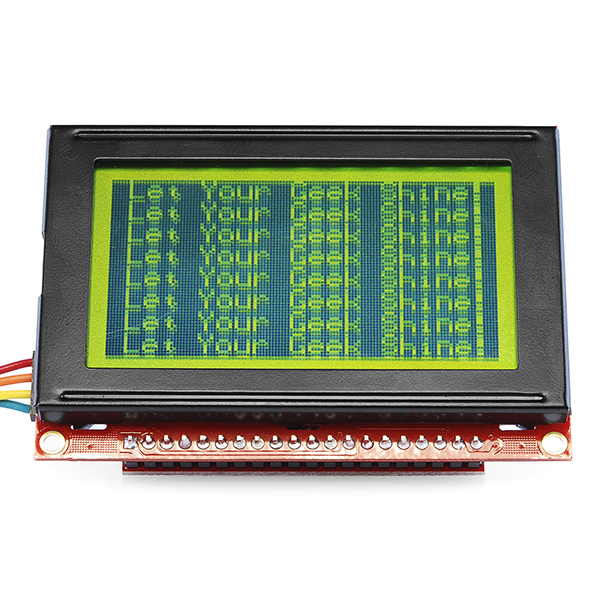

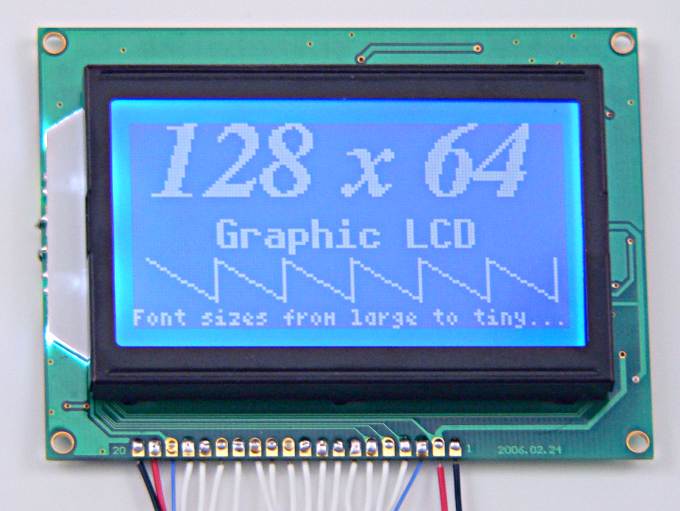

The current version of this graphic display (GDM12864H) has a unique feature that I have not seen in any other 128x64 graphic LCD. Its pixels (and pitch) are square (0.39x0.39mm) so your circles appear as circles -- no more ellipses!!!

Thanks for posting. Please explain why you have 2K ohm connected to the V0 and VEE pins? This LCD has built-in DC converter to drive the LCD already?

Someone noted above that the voltage needs to be fairly low (~-4V) to see the darkness of the pixels. If you hook a pot up, be sure to wipe it to both extremes to see if you can atleast see a big black box when the LCD has power, then you know atleast your contrast works and you"re getting power!

astromme - I am currently working on a project with this serial graphic display and I am interested in using the MSP430 could I get a copy of the adapted Arduino ks0108 library? Thank you, this would be greatly appreciated.

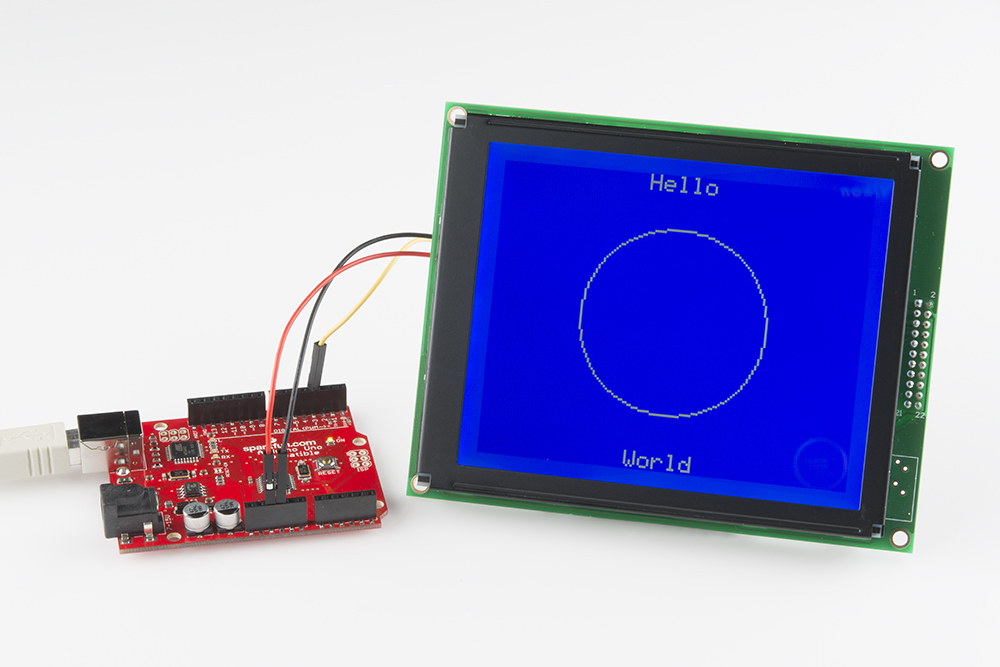

You should look on the product page"s documents. There"s links to get it working with an Arduino microcontroller. Also, there is an article on Arduino if you did an online search with example code and a hookup guide => http://playground.arduino.cc/Code/GLCDks0108.

I recently bought this LCD to use with a Maple Mini board. What Library should I use with it? I found the KS0108 Graphics LCD library on the Arduino page. That seems to be more useful than the LiquidCrystal library which doesn"t seem to work with this 20-pin LCD.

The one i ordered off sparkfun nearly a month ago was of the " small fraction of the glcds out there will need a reset pulse" variety? it took me a few days and several hours to realize, i had to waste another pin. The solution was to go into the library and un-comment part of the code as described at the bottom http://www.arduino.cc/playground/Code/GLCDks0108/

I"m looking for a similar specs LCD, but with a white or blue backlight.. I"m planning on adding it next to my motorcycle OEM screen, and being green would quite likely be an ugly mismatch.

Make sure that you have a 100 to 330 ohm resister in series with the LCD backlight. Some of the documentation is not clear on this, but the resister must be there or the LED backlight will act like a dead short as soon as the voltage rises above the LED forward bias - usually about 2.0V.

So, stupid question, the LCD screen says it needs 9V to work. Is that supplied by the circuits on the board, or do you need to create a step-up dc converter to change 5V into 9V?

While the microcontroller was running, i had to take the display off my test board, because (stupid as i was) i mounted the V0 pot-meter under it. When i connected it back it was working!

On the page Csloser links to, he recommends a pull down resistor. Could anyone comment on the importance of this? Could this be the cause of my one line LCD?

I grabbed the software and loaded it. The backlight works and at first I saw a few lines on the display itself (these faded). When I ran the software from that web page, nothing came out on the display. I played with the contrast potentiometer a little, but I still see nothing. The program is running (I added some Serial output for debugging).

I forgot to mention that the LCD voltage, in my experience, should be around -4V for the display to be readable. Close to -5V will turn all of the pixels fully on and above -3V they will be totally transparent. Other units may behave differently but this is how mine works.

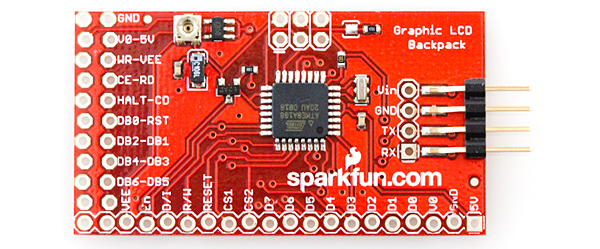

I intended to drive this LCD with an ATmega168, which now appears to be an astonishingly bad idea if the uC has only 1K RAM and you need that to drive the LCD. True? Or am I missing something completely obvious to the non-novice? It looks like I need a separate uC (like the DiosPro) to drive the LCD, with the 168 uC controlling the DiosPro via the UART? Happy to take advice....

You don"t have to devote any ATmega168 RAM to the LCD. This component has its own video RAM, one bit per pixel, 512 bytes total. I think you have to write whole bytes at a time (8 pixels), and it doesn"t know how to draw a letter "A" by itself, but the App Note from Kronos Robotics says they have a higher-level Dios library to deal with such operations.

I am current considering use of this display but have not ordered it yet. I am a little hesitant due to the number of users reporting problems with these displays.

I am in the process of creating a PCB footprint for this display, but when applying the 3D model provided, the hole spacing of the display"s connector pads do not appear to be on a 0.100" grid. Is this an error in the model or are the display"s connector pins on a weird spacing? If so, what is the spacing? Any help would be much appreciated.

I had a project that needed some live data display, and looking for the cheapest low-power solution for our loggers lead me to the Nokia 5110 LCD. Once you get the backlight current under control, you can power the entire display from a digital pin, and if you use shiftout for soft SPI you can then get rid of the Reset and CS control lines. This brings the display down to any four wires you can spare on your build (incl. the power pin) and a ground line. This is much more manageable than what you see with the standard hookup guides if your mc is I/O limited like our pro-mini based loggers:

This LCD (I have the old-old kind) is absolutely my favorite. Yes, it has a board-to-glass connector that ranges from bad to abysmal, but it offers such a simple interface and so many pixels for so little money (obviously less if you buy only the panel.) Here are some clever things I"ve discovered:

Will fully operate on as little as 2.0V. That"s power (Vdd) and i/o. It can be driven at 2MHz at these speeds; in fact, the LCD will work at even lower voltages but the contrast fades quickly and your microcontroller will likely approach its lower voltage limit too.

The LCD will work with the chip-select pin (SCE) tied to ground. This means that if it"s the only device on the SPI bus, don"t bother framing the i/o with a chip-select pin. If the bus is shared, frame the entire transaction, not every individual byte you send to the LCD. Interestingly, the display also seems to work fine with a floating Vdd pin - it must draw sufficient power just from i/o via clamping diodes; not surprising when you consider how low-power it is.

The Vout pin: Looks like you don"t have to worry about it on this product, but the bare LCD will generate positive 6-9V on that pin. This wasn"t totally clear to me from reading the datasheet.

(2) The second command byte (the 0xE0 shown above) is not arbitrary. It is 0x80, or"ed together with a 7-bit Vop value. I found my display to be somewhat sensitive to this value. At Vop=0xBF, my unit was initializing electronically, but had a blank display (or solid-black, I can"t remember now.) Anyway, I had to play with this value, and 0xB3 ended up working for me, so if you are initializing to this sequence and having trouble, try varying this parameter. The technical details of this parameter are explained in the datasheet, section 8.9, but really, you will just have to play with it.

(3) I didn"t find reset/init to be all that tricky, but it"s possibly because I"m powering the display unit from a port pin. That"s right, it only draws somewhere around a mA or less, so I just use an output-configured port pin to run the display VDD. (This lets me turn off the display easily when I want to go into low-power Sleep mode on my micro.) So I let my micro do it"s own reset sequence with all my port pins (including Display VDD, !Reset, and !SCE) at "0", and when I"m ready, I set, in sequence:

(4) !SCE tied to ground - yes, you could, but I"ve had fine results framing each byte with the !SCE signal - there"s nothing wrong with that. Yes, framing a whole transaction is fine, too. Note the datasheet timing diagrams show that !SCE serves a reset function on the incoming serial shift register, so if you ever get a glitch in your serial transmission that gets the bit count off, respecting the !SCE timing (whether on byte- or transaction-basis) will automatically get the display controller"s serial receiver synchronized back up on the next byte or transaction.

(5) If you are using a PIC to run ths thing, and using the PIC"s USART or EUSART in a synchronous mode, be sure to note that the LCD controller expects the MSBit of each byte to be transmitted first on the serial line. The PIC 18F EUSART transmits the LSBit first. For now, I have lots of extra code space, so I"ve wasted a 256-byte section on a lookup table that reverses the bits in a byte. This way, I just write my initialization code normally, and I have a TransmitCommandByte() function that looks up every byte it sends so I don"t have to think about that.

As a separate issue from the command bytes, all my graphic data are already created with the proper bit orientation, so I don"t have to look them up to do the reversal.

It may be possible to compensate for the low voltage by tweaking the contrast or updating slowly, but in my testing about three years ago journeys beneath 2.0V led to the display whiting slowly out like the face of an inexperienced fighter pilot in an aerobatic manoeuvre.

Thank you! I"m not quite sure I do want an LCD yet, to be honest, I"m just considering the different options available. I"ll check out the Sharp component, thanks!

Advice for others: It took me quite a while to get this working on an ARM Cortex. Since there is no way to read from the LCD, it is very hard to know if SPI is working without doing everything perfectly. SO:

Use the contrast value that Kuy gives (0xE0) or darker - this will cause the display to be all-black so you can confirm it works. THEN you can adjust the value and focus on getting characters to write.

I bought my display from eBay. A dirty cheap bargain from Hong Kong. I must say that it is exactly as the SFE breakout board, but of course, it didn"t work.

The problem I had was solid black display screen. No matter the combination of bias and contrast values that I set. The unit wasn"t totally defective, because under a strong lamp light you could see the display trying to show the letters and pictures that are in the tutorial for Arduino that I got from SFE.

Finally, after a long time of trials, I fixed it--> The problem: the bezel wasn"t tight to the board, so the contacts of the display didn"t work well.

Conclusions: You get what you pay, don"t expect well manufactured products and tested components comming from China at half the price you pay here. And second, it is totally no good idea to start up a new development with new technologies with untrusty material. Maybe you can try some cheap components after you are sure that you are used to certain technology (a display, a sensor, whatever), but don"t try to break the barrier of new knowledge and tricky materials at the same time; because you won"t be able to know who is the faulty.

The problem with these displays, and it seems to be common to all the manufacturers, is that the PCB material is too thin. After a month or two, the board slowly bows away from the glass display panel under pressure from the conductive rubber connector strip. Pressing on the top centre of the metal part of the display makes it work again, but only temporarily.

If the LCD module is soldered to another board and the two top screws installed and tightened carefully to pull the bow out of the module it seems to prevent (or solve) the problem.

The only real fix for this display is to redesign the metal cover with a hold-down tag in the top centre, or make it with a thicker PCB that doesn"t bow under pressure from the connector. Until that happens I won"t be buying any more.

I"m using voltage dividers to supply 3V in the inputs of the LCD, because of the Arduino works in 5V. LCD Vcc and LED are powered from the 3.3V output of the Arduino. The LCD only displayed something when I used: R1=470K,R2=820K. I have tried several values to obtain 3V, but the LCD showed nothing. I don"t understand that.

You"ll want to put a command byte of 0x20 in there, after the 0x14, and before the 0x0C. This is needed to put the display back into its "basic" command set, so it will correctly recognize the 0x0C command byte that puts it into "normal" (not inverse) display mode.

I"m interfacing this LCD with ATMEGA 32. Its been more than a week that I"ve been trying to get it right. All I get is the LED dimming effect. Here is my initialization code..CE=1;

Has anyone played around with minimum and maximum SPI clock rates with this display? I know the datasheet says up to 4 Mbit/s, but assuming this display is the only thing on the particular SPI bus, what"s a good minimum clock rate before you might start to notice delay in the display refresh? I mean TVs are 60 Hz - 120Hz.

I have a similar board made by mib-instruments and bought from ebay years ago. It has been my standard spi test tool because it"s so easy to work with. http://www.ebay.com/itm/Nokia-5110-LCD-84x84-dot-martix-backlight-PCB-RED-/320684678723 (specs http://i1119.photobucket.com/albums/k636/mib_instruments/diy/LCDC2A0SPEC.jpg)

I wanted another one so i bought the sparkfun item but it doesn"t quite work: it flickers and blackens occasionally but my graphic never shows up. Is there a bulletproof arduino sketch I could use to test it?

These LCD"s need cleaning. I have an average failure rate of about 15-20% on delivery. The most common problem is that the contrast is too high, and there"s constant flickering / changing of contrast compared to the other 80% of them.

The solution is fairly simple, unclip the LCD from it"s board and clean the pads on the PCB with 99% IPA. Then remove the lcd back plate and contact bar. Sometimes the contact bar is stuck fairly well to the glass, peel off carefully. Clean the contacts on the LCD glass with IPA, if any residue from the contacts is left on, rub it off carefully with IPA / tissue.

I love this little display! I wanted to be able to create images for it but nothing I saw did exactly what I wanted. So I wrote a processing sketch that creates 84x48 squares on the screen and allows you to click to turn them on or off. Also has buttons to invert, move up/down/left/right, and flip horizontally/vertically. Then, it saves the hex data to a text file to copy to your code. You can also load an image (any size, any colors) and it will scale it, convert to b/w, then put it in the rest of the program so that you can alter the pixels or move it. It isn"t perfect for every occasion but I"ve found it useful and I hope others might too. It is heavily commented so it should be easy to figure things out and change them if you want something different. http://thewanderingengineer.com/2014/07/12/nokia-5110-screen-photo-to-bitmap-converter/

I"ve got 3 of these and wired them up as suggested in the hookup guide and downloaded the example code, and the only thing that seems to work is brightening and dimming the LED. I"ve started again from scratch at least twice, tried all 3 units, and verified all the connections match the hookup guide, and I still the ssame result; no graphics, no text, just a border. Any ideas as to what might be wrong?

Anyone taken these things apart yet? You know the flexible rectangular blocky thing that connects the contact pad on the board to the LCD itself? What are these called?

Got mine running last night and found two problems with the code, one of which was the backslash a couple of others have already noted. Second was that the LCDCharacter() writes two blank vertical lines, one before the character and a second after, when only one is needed. Without the extra blank you get at least one additional character on each line. I"ll probably also move the ASCII font table to PROGMEM space to save on RAM and then start to work on some big digits for a clock.

I"m using this LCD for a large Arduino UNO project, but I"m running out of SRAM memory space. I was wondering if I used PROGMEM on the LCD ASCII array if that would help. If so, does anyone know what the right code for this would be? After looking through a lot of PROGMEM examples, I"m not advance enough to really grasp everything that"s going on. Any help you can give would be a great help. Thanks in advance!

I used one of these LCDs with an Arduino to display GPS information. I wrote a few functions that can display large numbers (28 px high) if anyone is interested, this lets me display speed, heading etc. A writeup of my project is here: http://mechinations.wordpress.com/2014/04/07/gps-sailing/

These are great displays. I ran into a problem using them with the nRF24L01+ radio transciever, which requires the use of the SPI bus. If one attaches both the radio and the display MOSI and SCK pins to pins 13 and 11 as instructed in the hookup guide, the SPI traffic of the other device (in this case the nRF24L01+ radio) will prevent the display from functioning. The easy solution is to move the Nokia 5110 MOSI and SCK pins to any other digital pin. This should be made clear in the hookup guide, where it says there is no choice but to use the hardware SPI pins for the display. I found out that is not true at all. I hope his helps others with the same problem. Despite the occasional bad display these carry much more information that the comparably prices 16 x 2 LCD and use fewer pins too boot. What a deal!

Hello people, is there anyone that can tell me the height of this display. I mean the displays height 45x45 mm is the size but i wonder the thickness of it. Only the display not the pcb. I couldn"t find this info on the datasheet. Best Regards..

This is a great display for the money, certainly the best bang for the buck of you can live with B&W and lower res graphics. I have a lcd driver for Arduino I will post on http://www.marchdvd.com/5110 so take a look there it draws text aligned on pixels boundaries of 8 and draws lines and has invert video options.

I just started messing around with this LCD using a STM32F103 microcontroller running at 72MHz... it works great. The only problem I had, and I suspect others might have if they are using fast processors, is that you have to deliberately introduce the setup and hold time delays on the DC pin... if you don"t you will get spurious pixels written to the display. I used a delay of 10uS, although the spec says 100nS is fine.

I been trying to display 8-10 images as an animation. The individual images all work, but when I trey more than 8 images, nothing happens on the screen, and above 2 images, I get errors in the drawing of the images. Is there some kind of buffer or violent reset I can do so that the data doesnt get jumbled up?

Can someone help me edit the code in the arduino example to display readings from a sensor, I"ve looked through all of the links and searched through the Internet but I couldn"t find an example anywhere, it would really help me if someone could tell me how to do this.

Has someone already been able to get this display to work with an Arduino Due? For some reason I cannot get it to work while it does work perfectly on my Mega. Any ideas why it may not work?

Added a driver for this display to the object-oriented arduino platform; Cosa. Please find example code at https://github.com/mikaelpatel/Cosa/blob/master/examples/Drivers/CosaPCD8544/CosaPCD8544.ino and source code at https://github.com/mikaelpatel/Cosa/blob/master/Cosa/IOStream/Driver/PCD8544.hh.

I just spent the last couple hours struggling with this LCD because of something very stupid of me. I was using an atmega328p in AVR-GCC and using hardware SPI. Thinking i didn"t need MISO I hooked it to DC. The LCD worked absolutely fine until I tried to set the x and y position in the ram. It started acting weird every time I tried it. Finally I put dc to another pin and BAM NO PROBLEMS. Looking back I feel pretty stupid but hopefully this post will save someone else the same mistake. Other than that great LCD for my projects

I used the ASCII font given in the example code in one of my projects and ran across a mystifying bug. I was developing code on a PIC12F675 to drive an OLED through its SPI interface. (Yes there are enough pins and memory to do this!) I was using the HI_TECH C compiler and tried several different approaches and never could get the "]" character to display. After pulling what is left of my hair out for 2 days, I realized there was a "\" in the comment for the previous line of the ASCII font definition which caused the compiler to treat the array entry for ] as a comment! Just replace the "// 5c \" comment with "//5c backslash" and everything works! I don"t know if this effect is peculiar to the HI-TECH compiler only.

The Energia folks have an example program for this LCD and the TI Launchpad written using their Arduino style tooling. I"ve updated their example and added the ability to report back the temperature over a UART. It is a very simple hardware setup since both systems are 3.3v. http://joe.blog.freemansoft.com/2012/08/digital-thermometer-with-ti-lanchpad.html

1) There seems to be a serious issue related to contrast and/or connections between the display and the breakout board. When running "Black on White" text, the background gradually darkens to a black rectangle covering the etire display area but will revert to normal if the centre of the metal surround is squeezed towards the pcb, however, putting a sprig clip on it to keep it comoressed doesn"t seem to cure the problem, but just slows the raste at which it fails - waggle it and it comes good again.

2) I"m really struggling to find unformation on using this display with the Arduino. The example (pcdtest.pde) provided with the Adafruit libraries (Adafruit_PCD8544 and Adafruit_GFX) won"t even compile and the only library I have found that I can make any sense of using is the PCD8544 library from Google (http://code.google.com/p/pcd8544/downloads/detail?name=PCD8544-1.4.zip) and I can"t really uderstand how to do graphics with that.

I did find another example (did"t save it and can"t find it again) that worked with the Adafruit libraries as it was supplied (including graphics), but trying to change it in any way beyond changing the text of the "Hello World !" string (which actually shoed on screen as "Hffmmp Wpsme !", so obviously a coding problem there!!!) just locked everythig up.

I tried using the "LCDAssistant" package to create a logo from a graphic that I resized to a b&w jpg of 84x48 but every byte generated was 0x00 so that was not right. I tried fiddling with the settings (flying blind) but still got nowhere - does anybody know the settings for LCDAssistant and this display and has used it successfully?

One of the things that I test regularly is a commercial item that features a 16x4 (HD44780) display. Currently I have a 20x4 on a flying lead that I plug in to determine if a display failure is down the lcd display or the main board.

Is there any way to get the 5110 Graphic Display to work with signals that were feeding to an HD44780? - if I could build that in then I would have a complete multi-testing set up in one box.

Might I suggest you (SFE) source some of the Electronic Assembly"s LCD Dog-S series. I think they would be a step up from these at a reduced price. I don"t think that they website is up to date, but their part number is LED39x41-GR.

I just got 2 of these. Haven"t had a chance to hook them up yet. But I gather that the LEDs are green. Has anyone managed to lift up the display and change the LEDs for white or other color?

I made a little font generator for the Nokia 5110 in the processing programming language (processing.org). It allows you to convert any font and any character that you can display on the screen into a list of hex codes that can be directly used in an embedded system (I"m using msp430). Just type a character and the corresponding hex codes will be in your clipboard and you can copy them into your program. It starts with an example with the chinese character for 5. It should work on any system that can run processing (e.g. mac osx).

I am guessing that you are seeing the PCB bent away from the back of the display, up near the "top" of the display region, when it is viewed in normal operation, right?

This is because this is where the connections are on the back of the "display glass". These connections are carried down into the PCB via a small strip of that elastomeric connector material. This material works by being compressed between the two substrates (the glass and the PCB) to hold it in place and make the connections between the pads on each surface. As a result of being compressed, it puts a force "up" on the glass, and "down" onto the PCB. In this particular design, this has the result of bowing the PCB in the units I have purchased.

I finally got around to running this LCD on my 3310 PCB. It is working fine with one minor problem. The SF 3310 display hides to first line of bytes for some reason and I had to offset everything to compensate. The 5110 doesn"t do this as behaves as expected. I haven"t heard anyone else report this so maybe my initialization code is different.

Using a 3V source, my LCD often worked OK using bias 0x14 like the other examples, but sometimes it would appear gray and faded. The fading would lessen if I touched the panel lightly with my hand for a few seconds, then let go, so maybe it"s a temperature-dependent thing?

Ack! After two days of working nicely with 0x15 bias, I reset the board today, and the LCD appeared way over-dark. I changed the bias back to 0x14 and it looks perfect. What the heck?! I think there must be some temperature-sensing or temperature-dependence going on, so the same init values may produce good-looking results one day but not the next.

Does anyone know whether this can be stripped of its backing so it can be used in transmission? I would love to use this as a modulator for a laser beam. Or if someone knows a similarly cheap transmission LCD that would be fine too.

Stuck. Blank LCD. Added 0x20, changed Vop to 0xB3. Guessing connections may be the issue? 3.3v for LED and VCC. GND to GND. Remainder connected to Arduino via voltage dividers. What am I doing wrong?

This is a great little lcd. When I first wired it up, the backlight was shorted (accidentally) against my 5v rail, so i got some magic smoke, and burnt to LEDs but it re-soldered the offending joints and it works very well now. Something to note: the refresh and write times are much, much slower if you use 5 volt logic. I stuck in a logic level converter and it ran at least 5x faster.

I did the same thing (see my comment above), but I still can"t seem to get anything to display. 3 of the 4 backlight LEDs still light up when I give them power, but I"m wondering what joints you re-soldered to get it to work again.

You can also use FastLCD to convert your bitmaps - google it. It outputs BASIC code, but you just search and replace &h to 0x and you"re grand. It has the added advantage of being an editor for touching up output.

I recently obtained a virtually identical LCD from a Nokia 5160, and although its backlight LEDs are green, not white and conversely use different voltages, I had success hooking up the LEDs" Vcc pin to a PWM capable pin on the microcontroller, allowing me to control backlight intensity (I didn"t need a current limiting resistor for this either, but adding one will help reduce current drain on the controller).

Seems like the PCD8544 library does it"s own SPI bit managing and it really doesn"t like me using the SD library (also talks SPI) at the same time. I"ve made sure I"ve got all the SPI pins matching for both libraries (MISO, MOSI, Clock are the same and each device has it"s own Select), but it looks like the SD.begin() call just breaks the SPI bus for the 5110 and it becomes non-responsive. The LCD works just fine if I don"t initialize the SD library and the SD card works fine if I do initialize the SD card.

I"m pretty sure I tracked down the problem- the PCD8544 library uses software SPI while the SD library uses hardware SPI and I"m pretty sure the Arduino can"t do both over the same SPI clock/miso/mosi pins. Anyone know if this LCD will work with hardware SPI?

I accidentally (well, intentionally, but stupidly) plugged the LED backlight line directly into 5V when I first got this, and I saw (and smelled) the magic black smoke escape. I believe the black smoke only came from one of the backlight LEDs burning out, because I only notice one of them not working now. The other backlight LEDs still light up okay, but I also now seem to be having trouble getting the display to show anything. I"m just wondering if I could have messed anything else up. It seems like others have had their issues with this display, so I was hoping I maybe had something misconfigured. I"m fairly certain I have the pins assigned properly, but maybe I"ll tinker with the contrast. Any recommendations for setting the contrast value?

I"ve had issues with the LCD not showing anything intermittently. You got to make sure that all the connections are secure, and for the reset pulse, be sure to have a delay that"s 30-50 milliseconds long.

As much as I love SFE products and will continue to order from them, this is one product I would not recommend. The connection between the LCD unit itself and the carrier board is via those rubber polymer connectors. All the planets must line up properly for them to work. In this case, the carrier board was warped preventing the connection from working. You will find other such remarks in the comments area.

Out of curiosity - what indication is it giving you that it is powering up, if there is nothing on the display? There are no outputs brought out from the controller, so what feedback are you seeing that leads you to believe it is powering up?

I"ve followed the linked-to Arduino example and I get nothing on the display. Should it just work without any other components? The link mentions a possible cap on VOUT but there"s no such pin. Googling has suggested my Duemilanove"s digital pins will be @5V but I need 3.3V?

Don"t do this. Each divider will be burning 20x the entire amount of current that the display needs to function, and the whole assembly will waste 100x the LCD"s needed power and many, many times more than even the atmega needs to run at full speed. This will kill battery life.

Hi, I just bought this wonderful LCD but I"m having huge huge problems connecting it..could anyone please point me in the right direction? Since there are pins that aren"t metioned in the code, for example the 6 - DNK(MOSI)...

Does anyone know the diode rating and package size, also does anyone know where to get the rubber ferroius connector behind the LCD mine is defective. Has anyone come into issues with the breadboard the LCD is connected to, a few aren"t working for me.

Yes, we have noticed that the PCB was bowing and as a result the LCD now only works when we press down on the metal strip at the top. I hope that only a small number of these LCDs have this problem. We"re expecting a shipment to arrive today, I will be running more tests.

Edit: After leaving glue to dry overnight, LCD simply does not turn on anymore. All the connections are good, but absolutely nothing shows on the LCD now at all. Only the LEDs come on.

Did you get either of the LCDs to display anything, at any time? Is it possible that the connections were OK, but you were not initializing or driving them correctly? Or did they start to work at one point, and then fail at some later point?

When I originally tried to get mine working, I was seeing NOTHING on the display. Then I had to get my initialization sequence correct, and adjusted my Vop value (ultimately using a byte of 0xB3) before the screen would display anything visible at all.

Note that the backlight LED"s are soldered onto the breakout board, and have nothing to do with the circuitry of the controller and LCD. So just because the backlights are shining doesn"t tell you anything about the operability of the LCD itself.

I have two display boards that both work, but I do see the bowing along the "top" edge of the metal bracket. I haven"t taken one apart yet, but I assume this is the edge nearest the elastomeric strip, which is creating this bowing force.

It depends on the code that you are using to control the LCD. If you are using the Arduino example above, the pins are defined in the beginning of the code.

FWIW I have connected this LCD with a 5V power supply to a 5V Arduino board with no level conversion and it worked. Presumably this may reduce the lifetime of the LCD.

I am attempting to use this with a Duemilanove (ATmega328). Up til now, I have been powering it with the 3.3V line, including the LED. The datasheet for the LDC claims: "VDDmax = 5 V if LCD supply voltage is internally generated (voltage generator enabled)." The logic levels should be kept from 2.7V to 3.3V. Since the Duemilanove uses 5V logic levels, I am using a simple voltage divider on the communication line with no issues.

The maximum logic value of 3.3 volts made me cautious of driving the LCDs at the native 5 volts of my Teensy AVR. That said, running purely off 5 volts seems to do no harm to the LCD.

For those interested, I have taken a few measurements of the current draw of the LED backlight of my LCD. As I said earlier, powering the LED with 5V external has caused permanent damage to one, perhaps two of the four LEDs. So, use the following graph at your own risk.

Is there any more documentation available for the additions to the LCD? For example, the datasheet has no information (that I could find, at least) on the LED. Everything seems fine on 3.3V, but what is the current limit on the LED? (note: if it wasn"t for work, I would just mess around with it myself.)

If you want to wire up several up these to a single microcontroller, you might take advantage of my freshly GPL"d C++ driver library for PCD8544 devices. It"s templated, so you can avoid duplicating code all over the place. Here"s a picture of two PCD8544 screens running off of an ATmega328. (The screens are operating independently, even though they happen to be showing the same logo graphic in that picture.)

Here is a PicBasic Pro example for the 3310, which should be compatible with the 5110. http://www.picbasic.co.uk/forum/content.php?r=174-Using-Nokia-3310-LCD

Fantastic! It appears from your example link that this uses the same controller as the Nokia 3310 that I"ve already used in past projects. The only thing that made it so cumbersome was trying to connect to its fine pitch press on type connector. This gives me a great low cost display option that is easy to connect to.

If anyone doesn"t have experience with this LCD, take a peak at the Arduino example link above to see just how easy it is to use. If you use plain C on your AVRs, I have sample code on http://tinkerish.com.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

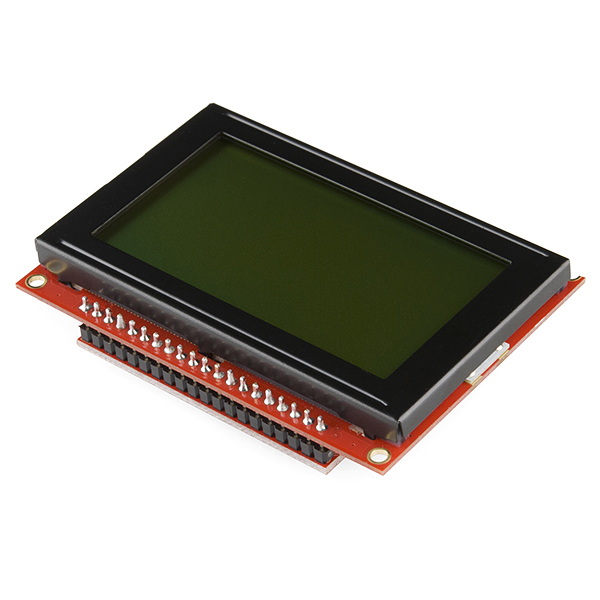

Graphic LCD displays do not offer color options such as a TFT (Thin Film Transistor) or OLED (Organic light emitting diodes). They display graphics in one color and require less power to operate.

A Graphic LCD display is just as its name implies. This LCD module is able to display images, letters and numbers that are generated through the customer’s software.

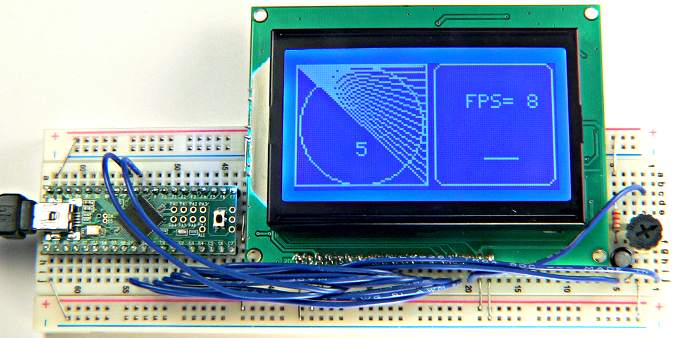

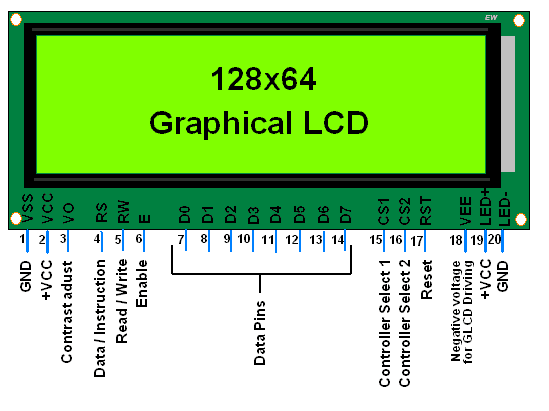

Dot Matrix displays are identified by two sets of numbers. An example of this is a 128 x 64. This display contains 128 dots along the X axis, or horizontal, and 64 dots along the Y axis or Vertical. Each of these dots, sometimes referred to as a pixel, can be turned ON and OFF independently of each other. The customer makes use of software to tell each dot when to turn ON and OFF. This is similar to the old ‘light bright’ toy.

Any application that needs to display more than just letters and numbers can make use of a Graphic LCD display. A crane manufacture provides a display that shows the position of the crane’s boom as it moves from ground level to full extension.

Gas pumps making use of a Graphic LCD Display are able to display more than just gallons or total dollars. They can now display advertising and weather reports and you can enter your zip code, select payment type and even obtain a receipt through the touch screen interface attached to the glass of the display.

The three types of fluid that are available for use in a Graphic LCD Display is FSTN, STN and TN. Though TN (Twisted nematic display) and STN (Super-twisted nematic display) are rarely used on Graphic LCD Display. The primary reason is that FSTN (Film compensated Super Twisted Nematic) offers a wider viewing angle and a shaper contrast. It is possible to substitute STN or even TN for FSTN to save cost, but the lower performance rarely justifies the cost savings.

The backlight is what sits behind the glass to light up the display when ambient conditions make it difficult to read. The most common type of backlight is a LED (light-emitting diode). LED’s offer a very long life time and does not produce electrical interference that is common with CCFL and EL backlights.

If the size of the display is small enough, the LCD display manufacturer may make use of a side-lit instead of a backlight. Side lit displays offer the advantage of being thinner. Side lit backlights do not work well for a large size glass since it will create hot spots (bright and dim areas) on the display.

CCFL is an excellent backlight for large size displays. It provides a more even light flow and is thinner than LED’s. The drawback is the availability of CCFL backlights. They are pretty much non-existent for monochrome Graphic LCD Displays. You may be able to locate a supplier, but the MOQ (Minimum Order Quantity) of this backlight is in the thousands. CCFL’s also produce electrical noise that may interfere with adjacent circuits.

LCD controller driver chips (C/D) or IC’s are the small chips on the back of the LCD display. The job of the LCD controller driver is to convert the customer’s software, or firmware, into images on the display screen.

It is common for LCD controller drivers to be discontinued over time. This means that your LCD Display manufacturer will recommend an ‘equivalent’ controller. As a general rule we find that equivalent controller drivers are compatible with the old C/D an estimated 95% of the time. If you find that you’re current controller driver is about to become ‘end of life’, it would be wise to order samples of your display with a new C/D that is compatible and not being phased out.

STN Blue background with White Edge-lit backlight, bottom (or 6:00) viewing angle, Transmissive (negative), RoHS Compliant. Available in both 3V or 5V power supply options.This display has a wide temperature range: -20° Celcius to +70° Celcius which equates to (-4° Fahrenheit to +158° Fahrenheit).

STN (super twisted nematic) provides a sharper image and wider viewing angle than TN (Twisted Nematic). The cost for STN if approximately 5% higher than TN. STN is an ideal fluid for outdoor products that need to be read at various angles. The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. When you have a need for a bright backlight with lower power drain, transmissive is a good choice.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

are given the difficult task of integrating state of the art optical devices into their products. And with this task comes the unpleasant job of coming up with the software to interface to these new devices. The most common optical device in the commercial marketplace is the Liquid Crystal Display (LCD). The LCD industry has broken down this technology into three main areas; Segmented, Alphanumeric, and Small Graphic Displays.

the sense that they just display numbers and characters. Often times these types of displays are sufficient to meet the requirements of the product being manufactured. But with our current era of multimedia, the customer expects to see a lot more out of their new product.

around for sometime, they have never been so compact and cost effective as they are today. A Small Graphic Display will usually range in resolution from 32×80 to 240×320 (240 pixels down and 320 across). The Small Graphic display is fully graphical, which means the pixels are configured tightly side by side, so as to resemble a miniature laptop computer screen. With a full graphic display there is no end to what you can visually represent. If your goal is to simply display text, you can do that in whatever font, size, and attribute you desire. As well as displaying things like logos, graphs, charts, or any other image that will differentiate your

Graphic Display is due to the misconception of the added cost and bulk of a larger display. But with new advancements in LCD technologies, Small Graphic Displays can now be found in sizes that are comparable with the other types of LCD displays and at roughly the same price. So you might ask yourself what other reason could there be to keep my company from upgrading our display to a more attractive and powerful Small Graphic LCD. The main hurdle in upgrading your display lies in the software.

signals that are sent to the display drivers. These controllers are made to interface in a parallel fashion to a microprocessor. This means that all the software written for the display will be done in a low level language like C++ or Assembly code.

the display is relatively small, due to the fact that the controllers on these displays have a built in ROM that stores predefined numbers and characters. So all you have to do is place your cursor to the appropriate place on your display and define which character should be placed there.

construct 8×8 or 8×16 character sizes, and refer to these subroutines when constructing their screen. But if that is the extent they are going to use their Small Graphics Display then they are no better off than if they went to a larger Alphanumeric Display. To take advantage of all 76,800 pixels would require a compilation of an extreme amount of data. And without the aid of any higher level language to help out, this data would have to come from manually created designs and drawings on special graph paper. Each picture would then have to be converted into 9,600 bytes of data. This time becomes exponential when we consider the amount of images most companies would like to create, along with the usual rework that will accompany this process.

By the time the final software becomes complete, the end product might not be on the cutting edge anymore and they would have been better off staying with their old Alphanumeric Display.

result is perfect bitmap pictures on your LCD screen that are defined, edited, and brushed up in Microsoft Paint™, or any other bitmap generating program.

painting the display with the bitmap images. By using the technique outlined in this document to incorporate bitmap pictures onto the LCD display, the user program size will remain the same, about 400 lines, but the data will be extracted out of a bitmap image. Not only is this time reducing, but the pictures are more easily drawn, edited, and copied from other software applications available in Windows or on the Internet.

“Attribute” menu should be selected. At the prompt you can enter the LCD display size you will be using. Then choose the “monochrome bitmap” option in this window. You can now close the “Attribute” window and start drawing, typing, or pasting in all the images you want to use. Once you have saved all of the pictures you will be using, then the bitmaps should be attached to the end of your assembled or compiled program in the order they are to be used. This can be done by using the COPY/B command in DOS. The COPY/B differs from the regular COPY command by copying directly as a binary format, and not adding an additional byte of data at the end as is done when using the COPY command for DOS text files.

bitmap code (like the type, size, and layout of the bitmap). Since this information will already be known (monochrome and layout dimensions), the first 62 bytes can be skipped. The 63rd byte will define the first eight pixels in the lower left hand corner of the display. The following bytes will then be sent sequentially to the screen until you hit the right hand edge of your display. The next byte will either be the first byte on the next row up (on the left hand side), or it will be a padded zero that the bitmap program has placed in there to maintain certain integers for row length.

pixels across), then 4 would not go evenly into 30. At this point we would round up the number to the nearest integer that 4 will go into. This number would be 32. And since we have 30 bytes of data, 32-30 = 2; so there are 2 bytes of padded zeros in your bitmap before the next line of data begins. Your internal program will have to reflect this and disregard these zeros before going on with the 33rd byte of data. (see Table 1 for quick reference to your display) So for example, if you had a 128×240 display, you would set up your assembly code so it would strip off the first 62 bytes of data from the bitmap file and discard that information. The 63rd byte would be the first byte in the lower left hand side of the LCD display. Then the next 29 bytes of data (240÷8 = 30) would get placed directly to the display. Now the next 2 bytes (the padded zeros – see Table 1) must be discarded. The next byte of data will then be placed in the next row up and over on the left hand side. The user will continue this process until he has walked up the display all 128 lines.

microprocessor, then once you paint the first page and increment the data pointer, you will be looking at the first byte of the next picture in your list. There is one thing to remember about a bitmap that is different from a LCD display. In bitmap programs, a 1 in binary is an “off” pixel and a 0 in binary is an “on” pixel. This is the opposite on the LCD. So the user will need to perform an “Exclusive-Or” with the number “FF Hex” and the data to be placed on the display.

Graphics Display with a SED1330 controller chip. If you are using a display that is not using the SED1330 controller chip, this same code can be used with modifications to the WRCMD and WRDATA subroutines and possibly some alterations on the direction the data is clocked in. The direction used in the SED1330 is the same as the T6963 controller chip. If you are using the HD61830 you will need to switch the direction of the data being clocked in (i.e. D7 becomes D0,D6 becomes D1, etc.)

There are also other tricks with using the pictures to act as your display background while you move discrete bytes of data around inside the image (like in a video game). Densitron

Corporation has more information on these processes and how they can be implemented in your particular display. If you would like more information on anything in this application note,please contact Todd Fitzsimmons at Densitron Corporation America at 562-941-5000×247.

4 different font categories are available : ANSI and Unicode international System fonts (installed on Windows) , the SVG fonts (for grayscale 256) based on vector graphics for a better anti-aliasing quality, and Freely Editable Font, for customized bitmap glyphs.

This module is engineered for high volume production. It uses a "TAB" (tape automated bonding) or "COF" (chip on flex) style flex tail mated with a "COG" (chip on glass) display. The TAB connector is soldered directly to corresponding pads on your PCB using a hot-bar soldering machine. High volume contract manufacturers will be familiar with this type of construction and its assembly methods. Hot-bar soldering machines designed for prototype, rework or repair of TAB connections are available from equipment suppliers at reasonable cost.

Graphic LCD Displays normally refer to monochrome graphics LCD displays or dot matrix LCD displays. Although color TFT (Thin Film Transistor) and OLED (Organic Light Emitting Diodes) displays to meet all the definitions of graphic LCD displays and can also be categorized as graphic LCD displays, monochrome graphics LCD displays have been in the market much earlier than color TFT displays and they become the legacy type of display. That is the reason that Graphic LCD displays only refer to monochrome, not the full color.

Compared with Character LCD Displays which can only display digits or alphanumeric, graphic LCD displays can display digits, alphanumeric, and graphics. They played very important roles in the early stages of LCD display history.

Graphic LCD displays are identified by the number of pixels in vertical and horizontal directions. For example, 128 x 64 dot matrix graphic display has 128 dots/pixels along the X axis, or horizontal, and 64 dots/pixels along the Y-axis or Vertical. Each of these dots sometimes referred to as a pixel, can be turned ON and OFF independently of each other. The customer makes use of software to tell each dot when to turn ON and OFF. The early engineering work has to light/map pixel by pixel, which is very tedious work. Thanks to the LCD controller advancement, Some Orient Display graphic LCD products have many images in the memory already which greatly helps engineers to reduce the workload and make the products much faster to the market. Please check with our engineers for details.

Orient Display provides dot matrix formats of 122×32, 128×64, 128×128, 160×32, 160×64, 160×160, 192×48, 192×64,202×32, 240×64, 240×160, 240×128, 282×128, 320×240 etc.

There are many options for graphic LCD displays, all of them derived from STN (Super-Twisted Nematic Display). TN (Twisted Nematic Display) or HTN (High-performance TN) displays are rarely used in graphic LCD displays because of their poor contrast and narrow viewing angles.

LCD itself can’t emit light. In order to be observed under the dim light, the backlight has to be used. Back to 10 years ago, Backlight can be LED (Light Emitting Diode), CCFL (Cold Cathode Fluorescent Lamps) or EL (Electroluminescent) backlight. Thanks to the development of LED technology, especially the breakthrough of the blue and white LED technologies, LED backlight dominates the market. LED backlight can be made either bottom lit and side lit with various colors For more information, please refer to Orient DisplayJazz Graphic LCD Display and Backlights.

The LCD controller is a small microprocessor that converts the customer’s software code (aka firmware) to information that the LCD can understand. LCD Drivers control the complex AC voltage requirements for the LCDs and they need a LCD controller to keep refreshing the individual pixel information to their drive circuitry. These ICs will typically be integrated into the LCD Modules either by COG (Chip on Glass) or COB (Chip on Board) technologies.

Sitronix is the world’s biggest graphic LCD controller manufacturers. The headache for most engineers is that LCD controllers can EOL (End of Life) a lot. Please make sure to discuss with Orient Display engineers for the most updated information to keep 5-10 years supply life.

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

First of all an object of LiquidCrystal_I2C class is created. This object takes three parameters LiquidCrystal_I2C(address, columns, rows). This is where you need to enter the address you found earlier, and the dimensions of the display.

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

This library is a professional graphical stack library to build Graphical User Interfaces (GUIs) with any STM32, any LCD/TFT display and any LCD/TFT controller, taking advantage of STM32 hardware accelerations whenever possible.

The STemWin Library is a comprehensive solution that comes with a rich feature set, such as JPG, GIF and PNG decoding, many widgets (checkboxes, buttons…) and a VNC server enabling the remote display of local displays, as well as professional development tools, such as GUIBuilder to create GUIs with a simple drag and drop.

STemWin is distributed as part of STM32Cube software packages or in a standalone standard library-based version. Part Number Manufacturer Description ST Professional graphical stack library enabling the building up of Graphical User Interfaces (GUIs) (AN4323)

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey