2.4 tft lcd shield work with 3.3v pricelist

... We certainly cannot guess what you are using. Care to post all the required libraries you used? UTFT is a large library suited to several displays, micro-controllers and pinouts, even with the right model selected, there are different pinouts, plus we dont know if you are using an uno, a mega or anything in between.

I have both and you are right the display is different, but it still complies with the ST778x command set as described on previous posts. As far as i know they are not supported by UTFT, however it may be that one of the LCD"s has an extended command set, for example, some are known to be compatible with ILI9325. I have no idea what controller the GEEK24 model uses, this should be your first mystery to be solved - why are you using it and who told you it would be compatible?

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

Hi community, i have Wemos Lolin32, and a TFT display recognized by id 0x4532 (mcufriend 2.4 inch TFT LCD shield). I have connected just RS to 15, CS to 33 and RST to 32, but the display is very dark. I found the wiring to be this:

my question is, do GPIO33 and GPIO34 have to be connected both to LCD_CS? Same for RST--32--36, RS--15--35. I"m worried that connecting two pins (15-35 for example) may kill my hardware (like short circuit it), if i don"t understand the comments correctly, even that is directly written. I"m new in hardware. Is it "ok" to connect all this pins together? Please help.

ER-TFTM070-7 is 800x480 Pixels 7 inch color tft lcd display module with LT7683 controller board,superior display quality and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO, and ARM .It can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.

It supports 8080 6800 8-bit,16-bit parallel,3-wire,4-wire,I2C serial spi interface.Built-in MicroSD card slot.It"s optional for resistive touch panel and controller XPT2046,capacitive touch panel and controller FT5316, flash chip and microsd card. We offer two types connection,one is pinheader and the another is ZIF connector with flat cable mounting on board by default and suggested.

It"s optional for flash chip and microsd card. We offer two types connection,one is pin header and the another is ZIF connector with flat cable mounting on board by default and suggested.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" We prepared the interfacing documents,libraries and examples for arduino due,mega 2560,uno,For 8051 microcontroller user,we also prepared the interfacing document and demo code.

The ST7789 TFT module contains a display controller with the same name: ST7789. It’s a color display that uses SPI interface protocol and requires 3, 4 or 5 control pins, it’s low cost and easy to use. This display is an IPS display, it comes in different sizes (1.3″, 1.54″ …) but all of them should have the same resolution of 240×240 pixel, this means it has 57600 pixels. This module works with 3.3V only and it doesn’t support 5V (not 5V tolerant).

As mentioned above, the ST7789 TFT display controller works with 3.3V only (power supply and control lines). The display module is supplied with 3.3V (between VCC and GND) which comes from the Arduino board.

The first library is a driver for the ST7789 TFT display which can be installed from Arduino IDE library manager (Sketch —> Include Library —> Manage Libraries …, in the search box write “st7789” and install the one from Adafruit).

We try our best to reach each and every corner of India using a few of the best courier services running in the Country such as FedEx, Delhivery, DTDC, BlueDart, XpressBees, Ecom Express, etc. as per the feedback for the courier partner at the customer"s location. Few of the interior parts of India which are not covered by these courier services are covered by India-Post by us. We apply our best effort on daily basis to dispatch the order the same day it is ordered or within the next 24 hours of the order placed. Most of the orders that are placed before 1 PM are dispatched and shipped the same day. The orders placed post that is scheduled for next day shipment. The same effort is applied throughout the week including weekdays and sometimes weekends and public holidays as well. We facilitate local pickup (self-pickup for the local customers) on the weekdays and partially on weekends also.

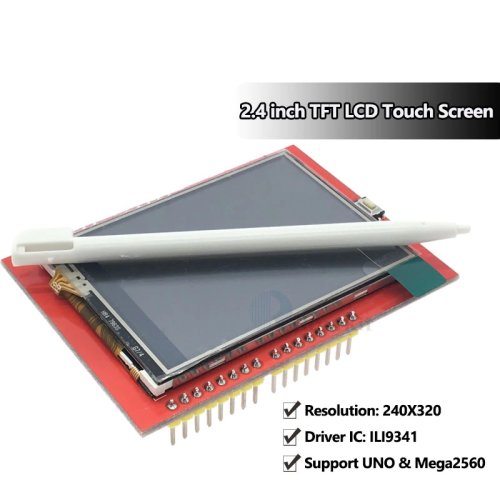

MMBasic version 5.0+ includes support for color LCD display panels using the ILI9341 controller and a SPI interface. These have a 240×320 pixel color TFT display, come in a variety of sizes (2.2”, 2.4″ and 2.8”) and are low cost.

The display pictured above also has a touch sensitive facility which is fully supported by MMBasic. There are versions of this display without the touch controller (the 16-pin IC on the bottom right of the PCB).

The SPI based display controllers share the SPI interface with the touch controller (if present) and the MMBasic program. Sharing the SPI channel is essentially transparent to the BASIC program.

Where a connection is listed as “configurable” then you get to pick the specific micocontroller (uC) pin for the purpose. The pin should then be specified with the OPTION LCDPANEL or OPTION TOUCH commands.

J1 on the back side of the ILI9341 LCD display is a jumper that sets the LCD to operate at 3.3V. A solder blob or very short piece of wire should be soldered in place on J1 for 3.3V operation.

Important:Care must be taken with display panels that share the SPI port between a number of devices (display controller, touch, etc). In this case all the Chip Select signals must be configured in MMBasic or disabled by a permanent connection to 3.3V. If this is not done any Chip Select pins that are not connected will float causing the wrong SPI device to respond to commands on the SPI bus.

‘CS pin’ can also be any I/O pin but is optional. If a touch controller is not used this parameter can be left off the command and the CS pin on the LCD display wired permanently to ground. If the touch controller is used this pin must then be specified and connected to an I/O pin.

This command only needs to be run once as the parameters are stored in non volatile memory. Every time MMBasic is restarted it will automatically initialize the display ready for use. If the LCD panel is no longer required the command OPTION LCDPANEL DISABLE can be used which will disable the LCD panel feature and return the I/O pins for general use.

To test the display you can enter the command GUI TEST LCDPANEL. You should see an animated display of color circles being rapidly drawn on top of each other. Press any key on the console’s keyboard to stop the test. Important: The above test may not work if the display has a touch controller and the touch controller has not been configured (ie, the touch Chip Select pin is floating). In this case configure the touch controller and then retry GUI TEST LCDPANEL.

To verify the LCD panel configuration you can use the command OPTION LIST to list all options that have been set including the configuration of the LCD panel.

Most ILI9341 based LCD panels are supplied with a resistive touch sensitive panel and associated controller chip. To use the touch feature in MMBasic the touch controller must first be connected to the CGMICROMITE2/CGMICROBOARD (see the above section for the details) and then configured (see below).

To use the touch facility MMBasic must be configured using the OPTION TOUCH command at the command prompt (not in a program). This should be done after the LCD panel has been configured (see above).

If the touch facility is no longer required the command OPTION TOUCH DISABLE can be used to disable the touch feature and return the I/O pins for general use (the ‘T_CS pin’ should then be wired to 3.3V to disable the controller).

3.5inch RPi LCD (A) and 3.5inch RPi LCD (B) are hardware compatible with each other (uses different driver), and can be mutually substituted in most cases. (A) for low cost ver. while (B) for IPS ver. with better displaying.

Why the LCD doesn"t work with my Raspbian?To use the LCD with the Raspberry Pi official image, driver (SPI touch interface only) should be installed first. Please refer to the user manual.

However, for the first testing, you may want to use our image directly (if provided).Why the LCD still doesn"t work with the Waveshare provided image?Make sure the hardware connection is correct and connects fine.

Since the first-generation Raspberry Pi released, Waveshare has been working on designing, developing, and producing various fantastic touch LCDs for the Pi. Unfortunately, there are quite a few pirated/knock-off products in the market. They"re usually some poor copies of our early hardware revisions, and comes with none support service.

I am planning a few (and visual) upgrades to this weather station in the near future to make it work and look better. As soon as i have enough free time of course......

The 3rd version is for McuFriend compatible displays. I had a 1580 and 5408 IC driver display which i did not use for almost 2 years. So i made some modification to work with them. I uploaded my modified McuFriend library.

A few weeks ago, I wrote this article about using a text variable as an array, either an array of strings or an array of numbers, using the covx conversion function in addition for the latter, to extract single elements with the help of the spstr function. It"s a convenient and almost a "one fits all" solution for most use cases and many of the demo projects or the sample code attached to the Nextion Sunday Blog articles made use of it, sometimes even without mentioning it explicitly since it"s almost self-explaining. Then, I got a message from a reader, writing: "... Why then didn"t you use it for the combined sine / cosine lookup table in the flicker free turbo gauge project?"105 editions of the Nextion Sunday blog in a little over two years - time to look back and forth at the same time. Was all the stuff I wrote about interesting for my readers? Is it possible at all to satisfy everybody - hobbyists, makers, and professionals - at the same time? Are people (re-)using the many many HMI demo projects and code snippets? Is anybody interested in the explanation of all the underlying basics like the algorithms for calculating square roots and trigonometric functions with Nextion"s purely integer based language? Are optimized code snippets which allow to save a few milliseconds here and there helpful to other developers?Looking through the different Nextion user groups on social networks, the Nextion user forum and a few not so official but Nextion related forums can be surprising. Sometimes, Nextion newbies ask questions or have issues although the required function is well (in a condensed manner for the experienced developer, I admit) documented on the Nextion Instruction Set page, accessible through the menu of this website. On top of that, there is for sure one of my more than 100 Sunday blog articles which deals not only with that function, but goes often even beyond the usual usage of it. Apparently, I should sometimes move away from always trying to push the limits and listen to the "back to the roots!" calls by my potential readers...Do you remember the (almost) full screen sized flicker free and ultra rapid gauge we designed in June? And this without using the built-in Gauge component? If not, it"s time to read this article first, to understand today"s improvements. The June 2022 version does its job perfectly, the needle movement is quick and smooth, and other components can be added close to the outer circle without flickering since there is no background which needs constantly to be redrawn. But there was a minor and only esthetic weak point: The needle was a 1px thin line, sometimes difficult to see. Thus, already a short time after publishing, some readers contacted me and asked if there were a way to make the needle thicker, at least 2 pixels.Recently, when playing with a ESP32 based NodeMCU 32S and especially with its WiFi configuration, I did as (I guess) everybody does: I loaded an example sketch to learn more about the Wifi library. When you set up the ESP32 as an access point, creating its own wireless network, everything is pretty straightforward. You can easily hard code the Wifi name (SSID) and the password. But what about the client mode ? Perhaps one needs to use it in different environments. And then, a hard coded network name and password are definitively not the best solution. Thus, I thought, why not use a Nextion HMI for a dynamic WiFi setup functionality?Although the Nextion MIDI I/O interface has been primarily designed as an add-on for Nextion HMI screens to transform these in fully autonomous MIDI devices as shown in previous blog posts here, it is also of great use for any Arduino based electronic music project! Many MIDI projects for Arduino suffer from a lack good hardware support. There are sophisticated code, excellent libraries and an infinity of use cases, but afterwards, things tend not to work in a rather rough environment in the studio or on stage. That"s because two resistors and a few Dupont wires on a breadboard besides the Arduino are not really an interface which could drive your Synth, Sequencer, or Drum machine over a 5m long MIDI cable.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey