small lcd displays for microcontrollers free sample

There are a number of different kinds of displays that can be driven by a microcontroller. This repository contains examples for many of them, along with information about display technologies and some of the more popular libraries for controlling them.

Multi-Segment LED display - There are many models of multi-segment LED displays, including the classic 7-segment LEDs, alphanumeric displays, dot-matrix diplays, bar graph displays, RGB LEDs, and others. What these share in common is that they will have either a common-cathode or common-anode structure. Common cathode LEDs have multiple anodes, one for each LED segment, and one cathode for all. common anode LEDs have a single anode and multiple cathode for all the segments. Driving these displays requires a control pin for each LED segment. They are usually driven by a multiplexer or LED driver, which can provide both a common interface for all the LEDs (such as an SPI or I2C interface), and a controlled current supply for all the LEDs.

Broadcom/Avago’s HCMS-29xx display is multi-segment LED display that has several 5-7 LED matrices with a synchronous serial interface. It has the smallest visibly discrete LEDs in its display that I have encountered.

LCD - Liquid crystal display. LCDs are made up of long-chain molecules in a state between crystal and liquid. When a charge is applied, the molecules align, acting as a polarizer. When paired with a second polarizer, they can either block light or allow it to pass through, appearing either light or dark. A grid of these can form a single-color display. Liquid crystals do not emit light, so a backlight is required to light them up. They come im low-resolution, passive-matrix displays which are usually monochrome or higher-resolution, active-matrix screens which have higher resolution and are usually full color.

OLED - an OLED screen replaces the liquid crystal with a matrix of organic LEDs. This eliminates the need for a backlight, since each pixel generates its own light. For more on OLEDs, see this introduction from ehergy.gov. CNET provides this comparison of LCD vs OLED displays.

ePaper - ePaper displays use a matrix of tiny capsules which are black or colored on one side, and white on the other. Applying a charge to each capsule causes it to turn one way or the other. Unlike LCD or LED displays, ePaper displays maintain their state when powered off. ePaper displays cannot be refreshed as fast as LCD or LED, however. ePaper displays are typically not backlit, and require external lighting. eInk, the primary maker of ePaper displays, has a good FAQ on the technology. Visionect.com has a helpful illustrated explanation as well.

LCD and OLED screens drive their pixels in one of two ways. A passive matrix uses a grid of wires which control each pixel using a row-column scanning method. Voltage is applied to each column in sequence. Then the rows are scanned. If the pixel on that column at a given row should be on, then the row wire voltage is taken low to create a voltage difference, and the pixel turns on. An active matrix uses a grid of thin film transistors (TFT) instead of a row-column scanning apparatus. TFTs allow for greater pixel density and therefore sharper image quality and better response time for each pixel. Jameco offers a good explanation of passive vs. active matrix driver technology.

The oldest form of LCD display, patented in the 1980’s, is known as Twisted Nematic (TN) LCD, and has limits to its viewing angle. Newer LCD technologies such as in-plane switching (IPS) or plane-to-line switching (PLS) afford wider viewing angles and brighter screens.

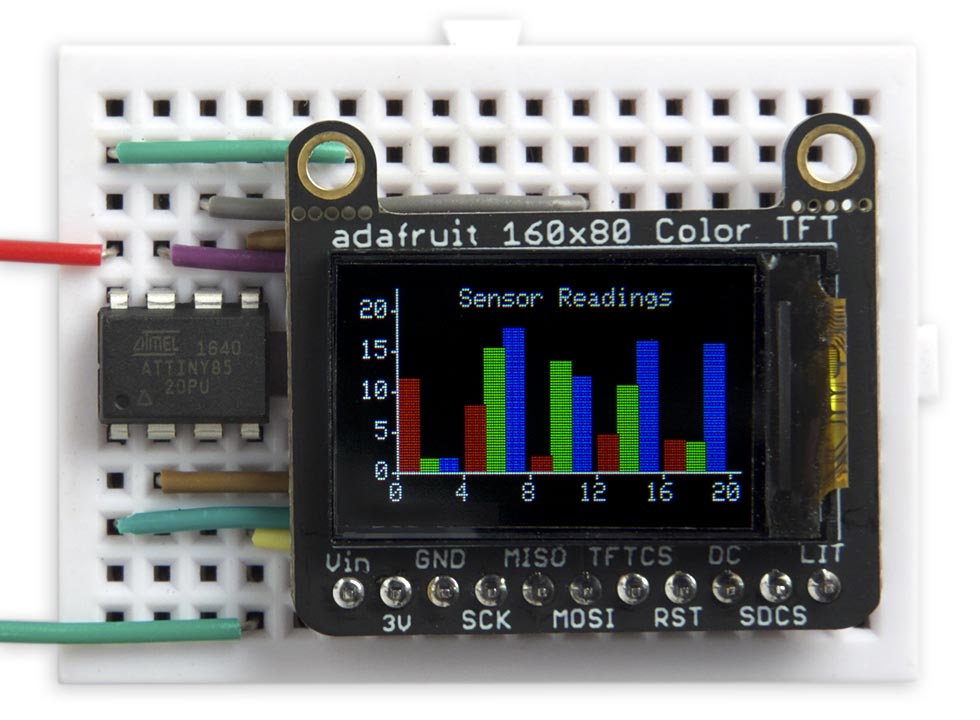

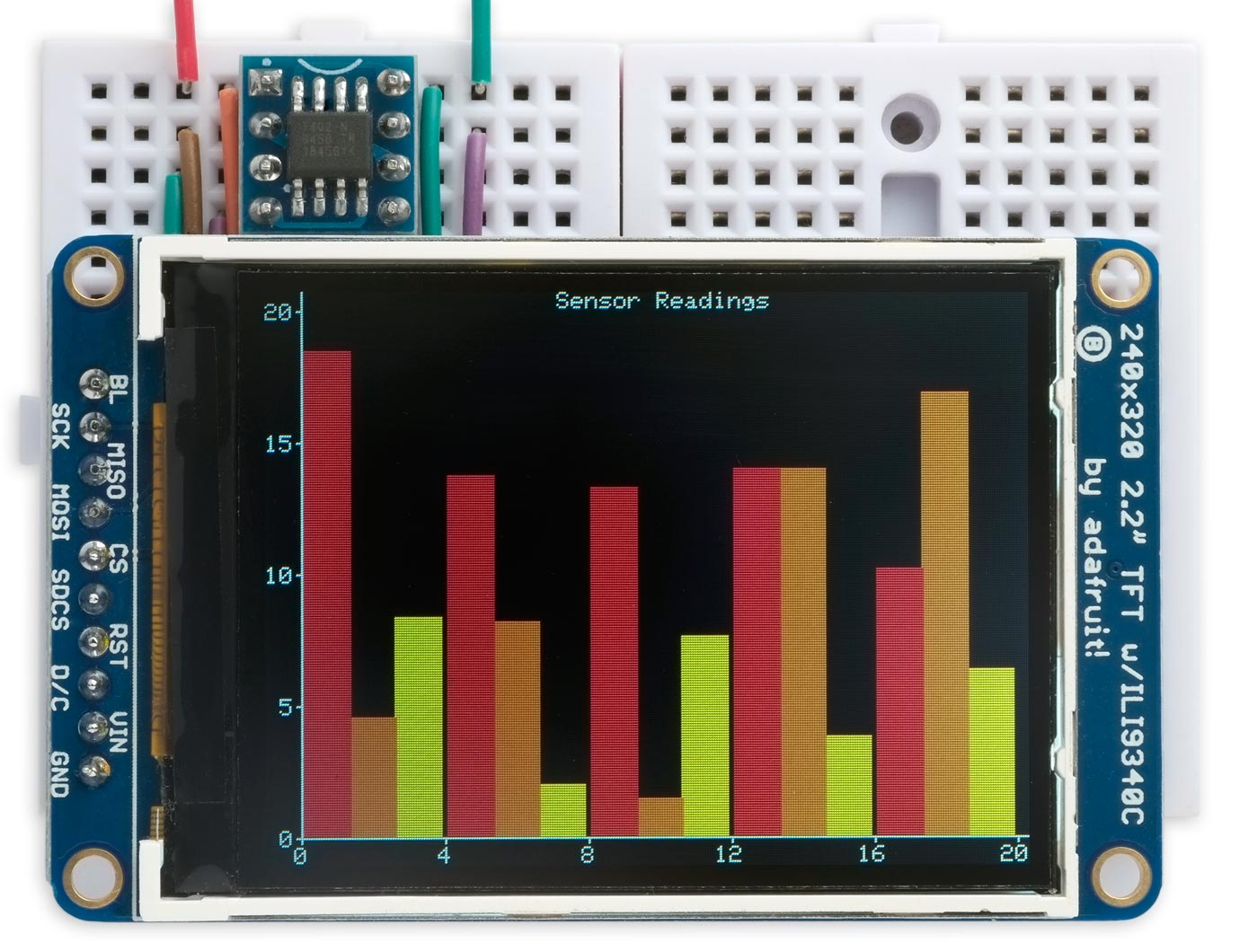

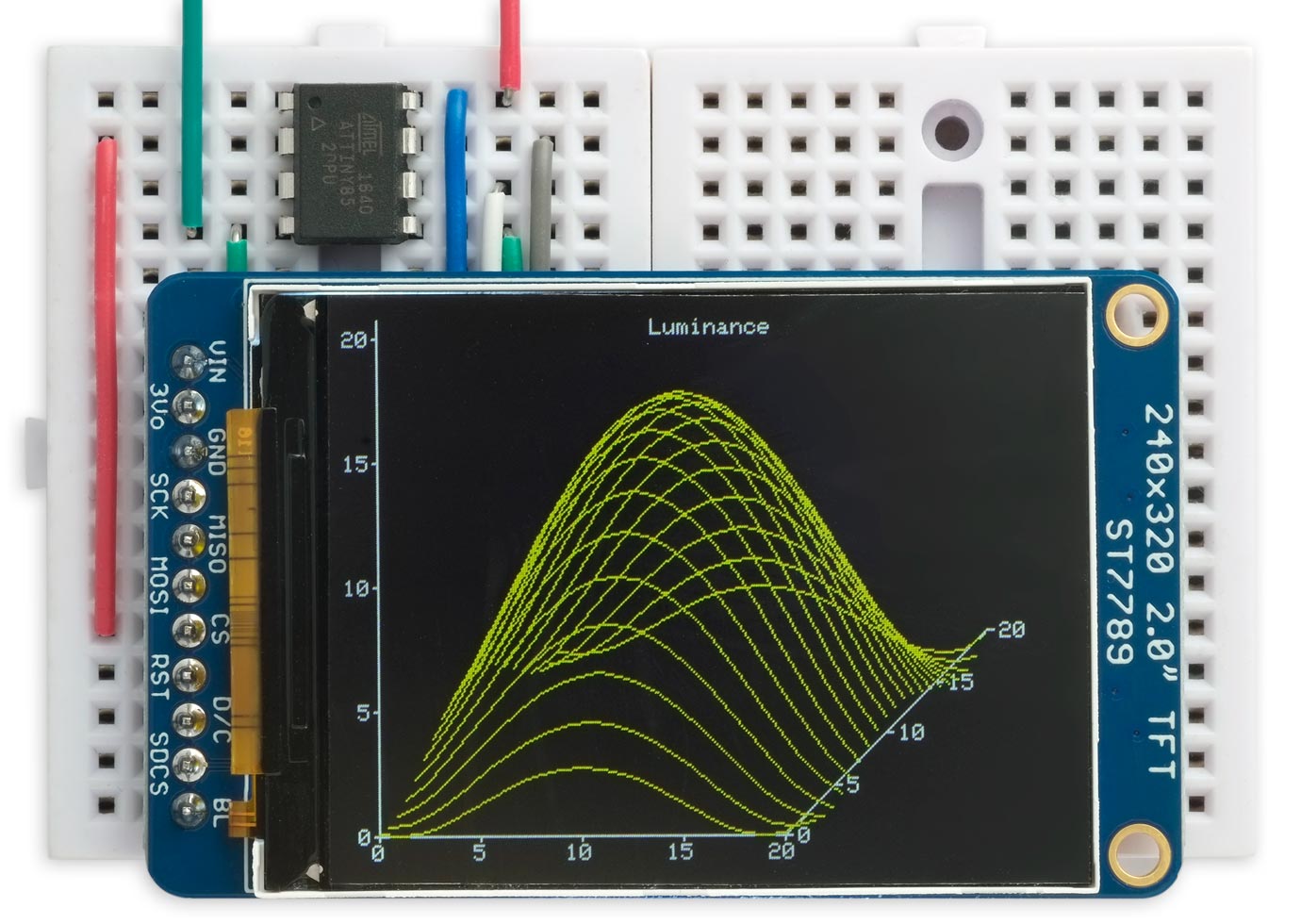

There are a number of common display driver ICs on the market. Typically a driver IC will be capable of controlling many different sizes and shapes of display, if they are of the same class. For example, you’ll see many TFT displays that use Sitronix’ driver ICs, notably the ST7735 and ST7789. Ilitek’s ILI9225 chip is also common in TFTs. This means that libraries written for one vendor’s display are likely to work for displays from another vendor, if they use the same chipset. This can be convenient, as it means you can sometimes choose the library whose API you find easiest to work with.

There are many LED driver ICs on the market, which give you control over multiple LED segments from a single synchronous serial interface. Some include PWM control over each channel as well. Popular ones include Maxim’s MAX7219 and Texas Instruments’ TLC5947. Many of the hobbyist electronic vendors carry breakout boards for these chips.

Recently, drivers for LEDs have reduced in size to the point where a driver can drive a single pixel. Usually made of three to four LEDs and a single driver, these are very popular with electronics hobbyists. For more on these, see this repository.

Displays for microcontrollers use a variety of control interfaces. The most common are the ones you see for other electronic modules as well: synchronous serial interfaces like I2C and SPI, or asynchronous serial interfaces. also feature parallel interface, requires a large number of I/O pins from your controller.

BUSY - an output pin to indicate that the display controller is busy. connects to whicheve pin the microcontroller has assigned for this function. This pin is less common on TFT displays than on ePaper displays.

Backlight - most TFT screens have a pin which enables or disables the backlight of the screen. The naming for this is not standardized: BLK, LITE, TE are all in use. Read the module’s datasheet for details.

Adafruit tends to add an SD card reader and sometimes a static RAM chip to its modules, which are also controlled by the SPI bus. When these are present, you’ll see chip select pins for them, usually labeled CCS or SCDS for the SD card and SRCS for the SRAM. If you’re not using the SD card or SRAM in your application, you won’t need these.

Note: the electronics industry has used the terms “master/slave” to refer to controller devices and peripheral devices for decades without regard for the historical context of, and offense caused by, those terms. As a result, you will see the terms MOSI/MISO/SS in data sheets to refer to the pins of an SPI device While a modern standard naming scheme has not yet emerged to replace these, there are proposals in discussion. The Open Source Hardware Association has this proposal, for example. Make Magazine has this proposal. The debate is not resolved, and you will likely see some variations on the terms. The SDO, SDI, and SCK terms are the most widely accepted terms with the least historical baggage, but unfortunately, it’s still necessary to be aware of the other possible terms for pins in SPI.

Hitachi HD44780 LCD display. See the Arduino LiquidCrystal library. These 2x16 character LCD displays are ubiquitous in the hobbyist market and come in many starter kits for the Uno. They are a passive-matrix LCD with a parallel interface (6 pins) that runs on 5 volts. They will typically not run on 3.3 volts. Each character is a 5x7 pixel matrix, so these are very low-resolution displays. They can usually be foung for $10-$15, which was a bargain in the early Arduino days. Nowadays, if you need an inexpensive 2-line display, some of the OLED displays like the SSD1306 are a better bargain.

Finding the right display library for your Arduino or Arduino-compatible display can be challenging. Vendors who design and sell their own breakout boards tend to publish libraries that are compatible with their own boards. Smaller vendors may not make their own libraries, relying on third-party libraries instead. The Arduino site lists over 300 display-related libraries. The ease-of-use and adaptability of those libraries varies widely. The ones I’ve found most useful are Adafruit’s GFX library and Oli Kraus’ U8g2 library.

Since there is a relatively small number of driver chip manufacturers (Hitachi, Ilitek, Solomon-Systech, and Sitronix among them), different vendors’ boards often use the same driver hardware. This means that the libraries from one vendor can support the hardware from another. When you shop for displays, it’s worthwhile to check what the driver is for each one, and see if there’s a compatible library from your favorite library writer.

Adafruit_GFX is a hardware-independent graphics library written to work with all the Arduino-compatible displays that Adafruit sells. They complement this with display specific libraries like Adafruit_SSD1306 for SSD1306 OLED libraries, Adafruit_EPD for ePaper displays, Adafruit_ST7735 for some TFT libraries, and others. The advantage of the GFX library is that you get a common drawing API regardless of which display you’re using. It uses the Arduino Printable interface too, so commands like print() and println() work with this library just like they do in the serial monitor. There’s a good guide to the GFX library as well. Sparkfun’s got their own complement to the GFX library, Hyperdisplay.

u8g2 is designed as a universal library for many different displays. It supports a wider range of displays than any other I’ve used so far. It has its own graphics API which is more or less similar to Adafruit’s, and a wide font set as well. There’s also U8g2_for_Adafruit_GFX, a library which allows you to add U8g2 fonts to any Adafruit_GFX-based library.

Adding a display to your Arduino can serve many purposes. Since a common use for microcontrollers is reading data from sensors, a display allows you to see this data in real-time without needing to use the serial monitor within the Arduino IDE. It also allows you to give your projects a personal touch with text, images, or even interactivity through a touch screen.

Transparent Organic Light Emitting Diode (TOLED) is a type of LED that, as you can guess, has a transparent screen. It builds on the now common OLED screens found in smartphones and TVs, but with a transparent display, offers up some new possibilities for Arduino screens.

Take for example this brilliant project that makes use of TOLED displays. By stacking 10 transparent OLED screens in parallel, creator Sean Hodgins has converted a handful of 2D screens into a solid-state volumetric display. This kind of display creates an image that has 3-dimensional depth, taking us one step closer to the neon, holographic screens we imagine in the future.

Crystalfontz has a tiny monochrome (light blue) 1.51" TOLED that has 128x56 pixels. As the technology is more recent than the following displays in this list, the cost is higher too. One of these screens can be purchased for around $26, but for certain applications, it might just be worth it.

The liquid crystal display (LCD) is the most common display to find in DIY projects and home appliances alike. This is no surprise as they are simple to operate, low-powered, and incredibly cheap.

Available for only a few dollars (or as little as a couple of dollars on AliExpress with included I2C adapter), these simple displays can be used to give real-time feedback to any project.

The screens are capable of a large variety of preset characters which cover most use cases in a variety of languages. You can control your LCD using the Liquid Crystal Library provided by Arduino. The display() and noDisplay() methods write to the LCD, as shown in the official tutorial on the Arduino website.

Are you looking for something simple to display numbers and a few basic characters? Maybe you are looking for something with that old-school arcade feel? A seven-segment display might suit your needs.

These simple boards are made up of 7 LEDs (8 if you include the dot), and work much like normal LEDs with a common Anode or Cathode connection. This allows them to take one connection to V+ (or GND for common cathode) and be controlled from the pins of your Arduino. By combining these pins in code, you can create numbers and several letters, along with more abstract designs—anything you can dream up using the segments available!

These tiny LCD screens are monochrome and have a screen size of 84 x 48 pixels, but don"t let that fool you. Coming in at around $2 on AliExpress, these displays are incredibly cheap and usually come with a backlight as standard.

Depending on which library you use, the screen can display multiple lines of text in various fonts. It"s also capable of displaying images, and there is free software designed to help get your creations on screen. While the refresh rate is too slow for detailed animations, these screens are hardy enough to be included in long-term, always-on projects.

For a step up in resolution and functionality, an OLED display might be what you are looking for. At first glance, these screens look similar to the 5110 screens, but they are a significant upgrade. The standard 0.96" screens are 128 x 64 monochrome, and come with a backlight as standard.

They connect to your Arduino using I2C, meaning that alongside the V+ and GND pins, only two further pins are required to communicate with the screen. With various sizes and full color options available, these displays are incredibly versatile.

For a project to get you started with OLED displays, our Electronic D20 build will teach you everything you need to know -- and you"ll end up with the ultimate geeky digital dice for your gaming sessions!

These displays can be used in the same way as the others we have mentioned so far, but their refresh rate allows for much more ambitious projects. The basic monochrome screen is available on Amazon.

Thin-film-transistor liquid-crystal displays (TFT LCDs) are in many ways another step up in quality when it comes to options for adding a screen to your Arduino. Available with or without touchscreen functionality, they also add the ability to load bitmap files from an on-board microSD card slot.

Arduino have an official guide for setting up their non-touchscreen TFT LCD screen. For a video tutorial teaching you the basics of setting up the touchscreen version, YouTuber educ8s.tv has you covered:

With the touchscreen editions of these screens costing less than $10 on AliExpress, these displays are another great choice for when you need a nice-looking display for your project.

Looking for something a little different? An E-paper (or E-ink depending on who you ask) display might be right for you. These screens differ from the others giving a much more natural reading experience, it is no surprise that this technology is the cornerstone of almost every e-reader available.

The reason these displays look so good is down to the way they function. Each "pixel" contains charged particles between two electrodes. By switching the charge of each electrode, you can influence the negatively charged black particles to swap places with the positively charged white particles.

This is what gives e-paper such a natural feel. As a bonus, once the ink is moved to its location, it uses no power to keep it there. This makes these displays naturally low-power to operate.

This article has covered most options available for Arduino displays, though there are definitely more weird and wonderful ways to add feedback to your DIY devices.

Now that the business is starting to a small business, Alibaba.com offers a wide variety of microcontroller lcd displays available. Lcd displays are available in a variety of colors and sizes to help customers keep the business well-supplied.

microcontroller lcd displays help users keep the information simple and efficient, while still using the displays. Browse the wide range of microcontroller lcd displays for them to make an order today.

Microcontrollerers (LCD) are embedded in the electronic industry as they contain a variety of LCD components and are embedded in the electronic environment (LED), LEDCD, or LED Light display (LCD)) are embedded in the electronic room (LCD), and for a more serious role, using microchroller chips to power the electronic components. LCD displays can be used in bulk, for a variety of purposes, such as DIY interDocks or LED-based displays, such as those that are embedded in the electronic process, such as a Different Programmable LED (LCD), and microchroller chips, are powered by the environment and are used to deliver a value at the same time.

Modern microcontroller chips are used in smartphone displays, as they have the same functions as a smartphone display. Check out the small LCD chips and microchroller chips used in smartphones, for example, may not be used on smartphones.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Liquid Crystal displays or LCDs have been used in electronics equipment since the late 1970s. LCD displays have the advantage of consuming very little current And they are ideal for your Arduino projects.

In this article and in the accompanying video I’ll show you how easy it is to add an LCD display to your next Arduino design. I’ll also show you a very popular Arduino Shield that has a keypad which you can use in your projects as well.

Today LCD displays are used in a variety of items from test equipment to televisions. They’re inexpensive and versatile, this makes them ideal for all sorts of designs.

LCD displays do not emit light. Instead they block the passage of light, like little windows which open and shut the let light through. The liquid crystals used inside LCD displays are sandwiched between two layers of polarized material. By changing the orientation of the liquid crystals they allow light to pass or they block the light entirely.

Because transmissive LCD displays (the type we will be using) work by blocking light they require a backlight. Several methods have been used to create back lights including electroluminescent panels and fluorescent tubes. these days the most common form of backlight is an LED, in fact so-called LED televisions are usually just LCD screens with an LED backlight system.

Another type of LCD display, the passive-matrix display, does not require a backlight, it works using reflected light. This type of display is often found in digital watches.

The principles of liquid crystals were discovered in the late 1880s but work on Modern LCD displays did not begin until the mid-1960s. a number of patents were filed in the early 1970s and in 1973 the Sharp Corporation introduced LCD displays for calculators.

The first color LCD displays were developed in the early 1980s but production units were not commonly available until the mid-1990s. By the late 1990s LCD displays were quite common.

A number of LCD displays are available for experimenters. These low-cost monochrome displays are ideal for use with microcontrollers like the Arduino and micro computers like the Raspberry Pi.

These displays are available in a number of different configurations. The part number for the display generally relates to the number of rows and columns in the display.

Common display configurations include 16 x 2, 16 x 4 and 20 x 4. All of these displays are used in a virtually identical fashion the only difference being the number of columns and rows they have.

The LCD1602 display module is a very popular and inexpensive LCD display. It is available in a number of different colors such as blue yellow and green and can easily be connected to an Arduino or Raspberry Pi.

In operation data is sent down the parallel data lines for the display. There are two types of data that can be sent to the display. The first type of data are the ASCII characters which are to be displayed on the display. The other type of data are the control characters that are used to activate the various display functions.

Brightness– This is the input for the brightness control voltage, which varies between 0 and 5 volts to control the display brightness. On some modules this pin is labeled V0.

Because the LCD module uses a parallel data input it requires 8 connections to the host microcontroller for the data alone. Add that to the other control pins and it consumes a lot of connections. On an Arduino Uno half of the I/O pins would be taken up by the display, which can be problematic if you want to use the I/O pins for other input or output devices.

We will begin our experiments by hooking up the LCD1602 to an Arduino Uno and running a few of the example sketches included with the Arduino IDE. This will allow you to get familiar with the display without needing to write any code.

We need to hookup our LCD display to our Arduino. The display can use any of the Arduino digital I/O pins as it has no special requirements, but if you hook it up as I’ve illustrated here you can run the example sketches without needing to make any modifications.

In addition to the LCD1602 display ands the Arduino Uno you will need a 10K trimpot ot potentiometer, this is used a s a brightness control for the display. You’ll also need a 220 ohm resistor to drop the voltage for the displays LED backlight.

The sketch starts with a number of credits and a description of the required hardware hookup. You’ll note that this is the same hookup you just performed on your Arduino and LCD module.

We then initialize an object that we call “lcd” using the pinouts of the LCD display. If you decide to hook up your display to different pins then you’ll need to modify this section.

The second example we will try isthe Scroll sketch. Scrolling is a useful technique when you can’t get your text to fit on one line of the LCD display.

Custom characters are useful when you want to display a character that is not part of the standard 127-character ASCII character set. Thi scan be useful for creating custom displays for your project.

A character on the display is formed in a 5 x 8 matrix of blocks so you need to define your custom character within that matrix. To define the character you’ll use thecreateCharfunctionof the LiquidCrystal library. You are limited to defining a maximum of eight characters.

As with the previous sketches we examined this one starts by loading theLiquidCrystallibrary and defining an object calledlcdwith the connection information for the display. It then moves on to define the custom characters.

Finally the setup routine ends by printing a line to the first row of the LCD display. The line makes use of two of the custom characters, the “heart” and the “smiley”.

One thing you may have noticed about using the LCD display module with the Arduino is that it consumes a lot of connections. Even in 4-wire mode there are still a total of seven connections made to the Arduino digital I/O pins. As an Arduino Uno has only 14 digital I/O pins that’s half of them used up for the display.

But there is another solution. Use the I2C bus adapter for the LCD display and connect using I2C. This only consumes two I/O pins and they aren’t even part of the set of digital I/O pins.

The I2C or IIC bus is theInter Integrated Circuitbus. It was developed by Philips Semiconductors in 1982 for use in the television industry. The idea was to allow the integrated circuits in televisions to “talk” to one another using a standard bus.

The bus has evolved to be used as an ideal method of communicating between microcontrollers, integrated circuits, sensors and micro computers. You can use it to allow multiple Arduinos to talk to each other, to interface numerous sensors and output devices or to facilitate communications between a Raspberry Pi and one or more Arduinos.

The I2C Adapter for the LCD display is a tiny circuit board with 16 male header pins soldered to it. These pins are meant to be connected directly to the 16-pin connection on the LCD1602 display (or onto other displays that use the same connection scheme).

The device also has a 4-pin connector for connection to the I2C bus. In addition there is a small trimpot on the board, this is the LCD display brightness control.

Most Arduino Unos also have some dedicated pins for I2C, these are internally connected to A4 and A5 and are usually located above the 14 digital I/O pins. Some models of the Uno have additional I2C connectors as well.

Note how much easier it is to use the I2C connection, which does not consume any of the Arduino Unos 14 digital I/O pins. Since A4 and A5 are being used for the I2C bus they can’t be used as analog inputs in this configuration.

If you don’t know the address you’ll need to find it out before you can run the sketches I’m about to show you. Fortunately there is a simple way of doing this, thanks to the great work of Nick Gammon.

Nick has written a simple I2C scanner sketch that he’s put into the public domain. It scans your I2C bus and gives you back the address of every I2C device it finds. I’ve repeated Nick’s sketch here, it’s also in the ZIP file that you can download with all of the code for this article.

Load this sketch into your Arduino then open your serial monitor. You’ll see the I2C address of your I2C LCD display adapter. You can then make note of this address and use it in the sketches we’ll be looking at now.

This library includes libraries for running the I2C adapter, which is why we are going to use it. But ist also can be used as a replacement for the original LiquidCrystal library and it offers improved performance over the original.

Remember that you’ll need to know the address of your I2C adapter before you run this sketch, so if you don’t know it go back and run Nick Gammon’s I2C Scanner first.

On the next line we define the connections to the LCD display module from the I2C Adapter,. Note that these are NOT the connections from the Arduino, they are the connections used by the chip on the adapter itself.

Load the sketch and run it on your Arduino. If you can’t get it to work check out the address and connection information to be sure you have it right.

The sketch is similar to our demo sketch in that it creates an “lcd” object with the I2C and display connection information. It also defines a couple of parameters for the DHT22 sensor, as well as some floating variables to hold the temperature and humidity values.

Note that this displays the temperature in Celsius. If you want to change this to Fahrenheit its a simple matter of using some math. The formula( temp * 1.8 ) + 32will convert the results to Fahrenheit.

So far we have used the LCD1602 display module for all of our experiments. For our final demonstration we’ll switch to a popular Arduino shield that contains a LCD1602 along with some push buttons.

The LCD Keypad Shield is available from several different manufacturers. The device fits onto an Arduino Uno or an Arduino Mega and simplifies adding an LCD display to your project.

The other five push buttons can really be used for anything you’d like to use them for. And the way they are hooked up is very interesting, at least it is to me!

Instead the buttons are connected to a resistor array that acts as a voltage divider. The entire array is connected to the Arduino’s analog A0 pin. One pin for five push buttons.

Note that the LCD is being used in 4-wire mode. The LCD itself is the same one used on the LCD1602 module, so all of the code for that module will work with the LCD Keypad Shield as well.

Now that you know how the LCD Keypad module works and which Arduino pins it uses all that remains is to install it onto your Arduino and load the demo sketch.

Use a shield that exposes the pins for prototyping before you install the LCD Keypad shield. In the video associated with this article I use a “Screw Shield” that brings all of the Arduino I/O pins out to a series of screw connectors. There are other similar shields. Using one of these shields is the easiest way to work with the LCD Keypad shield, as well as other Arduino shields.

The sketch begins by including theLiquidCrystallibrary. You can use the original one or the one includes with theNewLiquidCrystallibrary. We then set up an object with the LCD connections, note that these are just hard-coded as they won’t change.

Next we define a number of constants, one for each of the push buttons. Note that nothing is defined for the Reset button as it simply mimics the Arduino Reset button, however a constant is defined for the “none” condition.

After that we define a function calledread_LCD_buttons(). This function reads the value on analog port A0 and returns an integer corresponding to the button integers we defined earlier. Note that the function adds approximately 50 to each of the manufacturers specified values to account for intolerances in the resistors in the voltage divider.

We then call ourread_LCD_buttons()function and use it to display the value of the push button, right before the counter. Then we end the loop and do it again.

As you can see LCD displays are pretty simple to use thanks to the availability of some excellent libraries for the Arduino. As these displays are also very inexpensive they will make an ideal addition to many of your Arduino projects.

And finally the LCD Keypad Shield is a convenient method of adding both a display and a simple keypad to your project, no wiring or soldering required.

Most of the time we use the serial plotter of the Arduino IDE to visualize our solutions or output of a sketch. This is great and a big time saver when you are doing prototyping. But there is a time when your system will go live. If you are for example only sending data from sensors to a database on a Raspberry Pi, than you are able to view the output remote from your PC by connecting to the database. But there are use cases like an indoor weather station, where you want to see the output like the current temperature directly and not when you are on you PC.

Than displays are the way to go. There are different kinds of displays like 7 Segment LED display, 4 Digit 7 Segment display, 8×8 Dot Matrix display, OLED display or the easiest and cheapest version the liquid crystal display (LCD).

Most LCD displays have either 2 rows with 16 characters per row or 4 rows with 20 characters per row. There are LCD screen with and without I2C module. I highly suggest the modules with I2C because the connection to the board is very easy and there are only 2 instead of 6 pins used. But we will cover the LCD screen with and without I2C module in this article.

The following table gives you an overview of all components and parts that I used for this tutorial. I get commissions for purchases made through links in this table.

The LCD display has an operating voltage between 4.7V and 5.3V with a current consumption of 1mA without backlight and 120mA with full backlight. There are version with a green and also with a blue backlight color. Each character of the display is build by a 5×8 pixel box and is therefore able to display custom generated characters. Because each character is build by (5×8=40) 40 pixels a 16×2 LCD display will have 16x2x40= 1280 pixels in total. The LCD module is able to operate in 8-bit and 4-bit mode. The difference between the 4-bit and 8-bit mode are the following:

If we use the LCD display version without I2C connection we have to add the potentiometer manually to control the contrast of the screen. The following picture shows the pinout of the LCD screen.

Also I added a table how to connect the LCD display with the Arduino Uno and the NodeMCU with a description of the LCD pin. To make it as easy as possible for you to connect your microcontroller to the display, you find the corresponding fritzing connection picture for the Arduino Uno and the NodeMCU in this chapter.

4RSD12D2Select command register to low when we are sending commands to the LCD like set the cursor to a specific location, clear the display or turn off the display.

7Data Pin 0 (d0)Connected to microcontroller pin and toggled between 1 and 0 for data acknowledgement. So if we want to send data via the data pins 0 to 7, we have to make sure that the enable pin is high.

8Data Pin 1 (d1)Data pins 0 to 7 forms an 8-bit data line. The Data Pins are connection to the Digital I/O pins of the microcontroller to send 8-bit data. These LCD’s can also operate on 4-bit mode in such case Data pin 4,5,6 and 7 will be left free.

Of cause we want to try the connection between the microcontroller and the LCD display. Therefore you find an example sketch in the Arduino IDE. The following section shows the code for the sketch and a picture of the running example, more or less because it is hard to make a picture of the screen ;-). The example prints “hello, world!” in the first line of the display and counts every second in the second row. We use the connection we described before for this example.

Looks very complicated to print data onto the LCD screen. But don’t worry like in most cases if it starts to get complicated, there is a library to make the word for us. This is also the case for the LCD display without I2C connection.

Therefore the next step is to install the library “LiquidCrystal”. You find here an article how to install an external library via the Arduino IDE. After you installed the library successful you can include the library via: #include < LiquidCrystal.h>.

Like I told you, I would suggest the LCD modules with I2C because you only need 2 instead of 6 pins for the connection between display and microcontroller board. In the case you use the I2C communication between LCD and microcontroller, you need to know the I2C HEX address of the LCD. In this article I give you a step by step instruction how to find out the I2C HEX address of a device. There is also an article about the I2C communication protocol in detail.

The following picture shows how to connect an I2C LCD display with an Arduino Uno. We will use exact this connection for all of the examples in this article.

To use the I2C LCD display we have to install the required library “LiquidCrystal_I2C” by Frank de Brabander. You find here an article how to install an external library via the Arduino IDE. After you installed the library successful you can include the library via: #include < LiquidCrystal_I2C.h>.

The LiquidCrystal library has 20 build in functions which are very handy when you want to work with the LCD display. In the following part of this article we go over all functions with a description as well as an example sketch and a short video that you can see what the function is doing.

LiquidCrystal_I2C()This function creates a variable of the type LiquidCrystal. The parameters of the function define the connection between the LCD display and the Arduino. You can use any of the Arduino digital pins to control the display. The order of the parameters is the following: LiquidCrystal(RS, R/W, Enable, d0, d1, d2, d3, d4, d5, d6, d7)

If you are using an LCD display with the I2C connection you do not define the connected pins because you do not connected to single pins but you define the HEX address and the display size: LiquidCrystal_I2C lcd(0x27, 20, 4);

xlcd.begin()The lcd.begin(cols, rows) function has to be called to define the kind of LCD display with the number of columns and rows. The function has to be called in the void setup() part of your sketch. For the 16x2 display you write lcd.begin(16,2) and for the 20x4 lcd.begin(20,4).

xxlcd.clear()The clear function clears any data on the LCD screen and positions the cursor in the upper-left corner. You can place this function in the setup function of your sketch to make sure that nothing is displayed on the display when you start your program.

xxlcd.setCursor()If you want to write text to your LCD display, you have to define the starting position of the character you want to print onto the LCD with function lcd.setCursor(col, row). Although you have to define the row the character should be displayed.

xxlcd.print()This function displays different data types: char, byte, int, long, or string. A string has to be in between quotation marks („“). Numbers can be printed without the quotation marks. Numbers can also be printed in different number systems lcd.print(data, BASE) with BIN for binary (base 2), DEC for decimal (base 10), OCT for octal (base 8), HEX for hexadecimal (base 16).

xlcd.println()This function displays also different data types: char, byte, int, long, or string like the function lcd.print() but lcd.println() prints always a newline to output stream.

xxlcd.display() / lcd.noDisplay()This function turn on and off any text or cursor on the display but does not delete the information from the memory. Therefore it is possible to turn the display on and off with this function.

xxlcd.scrollDisplayLeft() / lcd.scrollDisplayRight()This function scrolls the contents of the display (text and cursor) a one position to the left or to the right. After 40 spaces the function will loops back to the first character. With this function in the loop part of your sketch you can build a scrolling text function.

Scrolling text if you want to print more than 16 or 20 characters in one line, than the scrolling text function is very handy. First the substring with the maximum of characters per line is printed, moving the start column from the right to the left on the LCD screen. Than the first character is dropped and the next character is printed to the substring. This process repeats until the full string is displayed onto the screen.

xxlcd.autoscroll() / lcd.noAutoscroll()The autoscroll function turn on or off the functionality that each character is shifted by one position. The function can be used like the scrollDisplayLeft / scrollDisplayRight function.

xxlcd. leftToRight() / lcd.rightToLeft()The leftToRight and rightToLeft functions changes the direction for text written to the LCD. The default mode is from left to right which you do not have to define at the start of the sketch.

xxlcd.createChar()There is the possibility to create custom characters with the createChar function. How to create the custom characters is described in the following chapter of this article as well as an example.

xlcd.backlight()The backlight function is useful if you do not want to turn off the whole display (see lcd.display()) and therefore only switch on and off the backlight. But before you can use this function you have to define the backlight pin with the function setBacklightPin(pin, polarity).

xlcd.moveCursorLeft() / lcd.moveCursorRight()This function let you move the curser to the left and to the right. To use this function useful you have to combine it with lcd.setCursor() because otherwise there is not cursor to move left or right. For our example we also use the function lcd.cursor() to make the cursor visible.

xlcd.on() / lcd.off()This function switches the LCD display on and off. It will switch on/off the LCD controller and the backlight. This method has the same effect of calling display/noDisplay and backlight/noBacklight.

The following code shows you the Arduino program to use all three LCD display functions of the library divided into three separate functions. Also the video after the program shows the functions in action.

The creation of custom characters is very easy if you use the previous mentioned libraries. The LiquidCrystal and also the LiquidCrystal_I2C library have the function “lcd.createChar()” to create a custom character out of the 5×8 pixels of one character. To design your own characters, you need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a wiggling man.

In the section of the LCD display pinout without I2C we saw that if we set the RS pin to how, that we are able to send commands to the LCD. These commands are send by the data pins and represented by the following table as HEX code.

The LCD module interface with a microcontroller is simple and it is a primitive means of adding a visual appeal to your embedded application. There are two basic types of LCD modules in the market they are, Character LCD and Graphics LCD. Character LCDs are the some of the cheapest means LCD displays available today.

This post is first of a series of four posts that walks through entire process of interfacing an LCD module with a (any) microcontroller with all the basic concepts dealt in detail. Subscribe to our posts and get free updates on these follow-up posts.LCD Module Basic Theory (LCD Controllers, CG&DD RAM, PIN description,Timing Diagram, Commands)

This post will cover the basic theory that you should have a clear understanding of, before getting started with the programming. Some of the sections below are not really essential for the interface but it is a good practice to have a thorough knowledge about what you are indulging in. Whereas some listed below are absolutely mandatory to understand how the LCD module works and to predict how it will behave for a given situation.

The LCD module has display controller that are used to receive the data from the controller and uses it to display the data in a legible format. These controllers have an embedded font set that can be addressed by sending the corresponding ASCII value of the the character to be printed.

Most LCD modules have a HD44780 or compatible controller which is specially designed to build LCDs with one or two lines with a maximum of 40 character positions each. They are ASIC (Application Specific Integrated Circuit). A single HD44780 is able to display two lines of 8 characters each.

This the most common configuration of LCD that most people prefer mostly due to reduced cost and small footprint. In a 16 x 2 line display LCD module, each the two lines have 40 character positions of which only 16 can be displayed at a time. The remaining positions are invisible and cannot be seen. To display the remaining 24 characters, the LCD has an option to move the window of characters displayed to the right or left so that; it appears as though the characters are scrolling. Here is a table of the DD RAM addresses that are within the visible data region. Note that in this module, DD RAM locations 10 to 27 on the first line and 51 to 67 are not covered by the displayable window of 16A character per line.Line/Col0123456789101112131415One000102030405060708090A0B0C0D0E0F

The 20 x 4 display module is a slight variant of the 16 x 2 Module such that, a single 40 character (of which 16 are displayable) line is split up into 2 halves of 20 displayable characters each to make 4 lines. Here the first line displays the first 20 DD RAM locations (00 - 13) and the third line displays the remaining 20 DD RAM locations (14 - 53) of the first line in the case of 16 x 2 LCD Module and the second line displays the first 20 DD RAM locations (40 - 53) and the fourth line displays the remaining 20 DD RAM locations (54 - 67) of the second line in the case of 16 x 2 LCD Module. This is the module that I am using in this post. It has the disadvantage of not being able to scroll but looks better with 4 displayable lines.Here is a table of the DD RAM addresses that are within the visible region.#000102030405060708090A0B0C0D0E0F101112131000102030405060708090A0B0C0D0E0F10111213

7DB0LCD Data Bus line. They are responsible for the parallel data transfer. DB7 is used to check the busy Flag.In 4 bit mode, DB0 to DB3 are not used and are left open.

There are two registers in an LCD, they are Instruction register and the Data register. The register select (RS) pin is used to select either of the two the registers. When held low, the Instruction register is selected and similarly, when it is high, the data register is selected. A write to the data register will write to the Display Data RAM (DD RAM) in the address last pointed by the address pointer. The address pointer is automatically incremented after each write operation.

In the 20 x 4 LCD Module, all the locations of the DD Ram are mapped on to a character position in the display. Hence a write to the data register with proper ASCII code will produce proper displayable character in the screen. You can find a good ASCII table here. Some of the values in the ASCII table are not printable and hence are not mapped on to any character. A write to the DD Ram with one such data will display some glyph that you cannot recognize.

The LCD datasheet comes with a lot of electrical and Mechanical specifications. Though they are not redundant, for now we will consider only the command sheet and the timing diagram without which it is impossible to interface the module.

The command sheet is a table which contains the various commands that can be issued to the LCD module so that it behaves as intended. I have not attached an image of the command sheet as I could not find any of a good readable resolution. So I created a HTML version of the command sheet that you could use at any resolution dYtm, You can find the Command Sheet here (or I should call it command page). The cells that are filled with absolute values have to be used as such and the ones that are having letters are variables and take either 0 or 1 based on the task it has to perform.

Here, D4 to D7 are 0, D3 is 1 and RS and R/W are held low. These are all constant values and hence have to be used as such. But the, bits D0 to D2 are all variables. Depending on the values return at positions B, C and D the following action are performed by the LCD controller,

There are two basic timing diagrams, one for the read operation and another for the write operation. Both of them are very important and has to be adhered to. Reading and understand timing diagrams is an important skill that has to be mastered.

As you know these LCDs have a built in font set and can be used by indexing the ASCII value of the corresponding character. It capable of operating on 8 data lines (D0 to D7) or on 4 data lines (D4 to D7). The upcoming posts will discuss the 8 bit and 4 bit mode of LCD interface. Other than the data lines the LCD needs 3 command lines - RS, R/W and EN. Therefore in total, an LCD interface will need 11 (8+3) or 7 (4+3) pins of the microcontroller.

It is possible to further reduce the total number of port pins required from 7 (4+3) to 6 (4+2) by shorting the R/W pin to ground. If the R/W pin is connected to the ground, the LCD can be used to write data only. Reading from it is not possible. So we are not able to read the busy flag from the module. To live with this disability, we are forced to provide ample amount of delay loops (and hence compromise on the speed of execution) so that the LCD is seldom busy doing thing when new data is given.

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

Most displays are classified as reflective, transmissive,oremissive. Reflective displays depend on light reflected from the front of the display. The background of such displays are usually reflective, with the displayed pattern selectively blocking the reflection.

Transmissive displays depend on allowing or blocking a backlight to display an image. The backlight is normally white, and each pixel actually consists of three sub-pixels that can selectively pass the Red, Green, and Blue part of the white backlight.

Emissive displays actually emit light on their own. Each pixel emits its own light in the three primary R, G, B colors. By varying the intensity of emitted light, full color images can be created.

Color gamut is a measure of how broad the range of available colors are in a display. Monochrome displays, on the other hand, have only one available color.

Full color displays typically consists of three primary colors – Red, Green and Blue (RGB). Various combinations of these primary colors with various intensities can reproduce realistic looking full color displays.

Color depth specifies the number of intensity levels for each color component. A color depth of N, means that each color can be displayed at N different intensities.

For example, an RGB display, with each color having a color depth of N, can thus have N x N x N possible color combinations. The simplest color depth is two. That is, a segment, or a pixel is either full ON, or full OFF.

If you need to simply display some numbers and, say, a small set of letters, then you should consider a segmented display. Typical examples of segmented displays are found in digital clocks.

Typically, these types of displays use LED’s (Light Emitting Diodes) for each segment, and their color is commonly red. However, segmented LCD displays are also available. A picture of a typical seven-segment LED display is shown in Figure 1 below.

The next level of functionality in displays is an alphanumeric display. This display consists of one or more rows of character cells. Each character cell actually consists of a fixed-size array of pixels that can display predefined, and some user-defined, characters or symbols.

There can be many such character cells per row. Displays of this type are 16 x 1, 16 X 2, 24 X 1, 24 x 2, 16 X 4 and others. These refer to the number of such cells in the display. For example, a 16 X 2 display has two rows of sixteen character cells each.

The most commonly available displays of these types are reflective LCD’s (Liquid Crystal Display). A picture of an LCD alphanumeric display is shown below in figure 2.

Displays in this category consist of individually addressable pixels. They are capable of displaying anything from simple text to complete static, from animated images to full motion video.

Unsurprisingly, they cost more than displays in the previous categories. Even so, there are quite a few varieties with varying cost-benefits ratios. This section will explore a few of the most commonly available varieties.

E-ink, or e-paper, displays are very low power displays suitable for specific applications where fast update speed is not required. They are available in a variety of sizes. Typically they are monochrome, but some can display limited color combinations.

One unique characteristic of this display is that once rendered, the image stays on the screen, even if power is turned off. In certain applications this can allow for extremely low power consumption.

I2C is a relatively low speed, but simple, interface used by some displays. Only two wires, plus a return wire, are needed for this interface, and data is sent out pixel by pixel.

SPI is a medium speed interface used by some displays. Usually three to four wires, plus a return wire, are needed for this interface. While data is also sent pixel by pixel, it is generally faster than the I2C bus.

OLED (Organic LED) displays are somewhat similar to the LED matrix displays described previously, except that the pixel density, or DPI (Dots Per Inch), can be very high.

Therefore, each pixel only gets a fraction of the total time required to refresh the entire display area. Hence this OLED drive scheme is usually limited to fairly low resolution screens.

In AMOLEDs, each color sub-pixel is individually controlled by a transistor acting like an electronic switch. The fabrication process is more complicated than the PMOLED, but the display is faster and more uniform.

Color depth 2 to 256 and more per primary color Simple displays can be black and white. However, the most sophisticated of these displays can reproduce millions of colors.

Interface complexity Low to high Models with SPI or I2C are available for the simpler displays. High resolution displays have sophisticated interfaces such as a digital parallel interface or MIPI.

More complex displays will typically interface via either a digital parallel port (sometimes called a Digital Video Port or DVP), or a specialized serial port called Mobile Industry Processor Interface (MIPI).

Note that MIPI is typically only supported by more advanced microprocessors, and is not available on most microcontrollers. One exception is the STM32F469 microcontroller from ST Microelectronics that does offer a MIPI display interface.

The last category of graphics displays is the LCD. These displays can have very high pixel densities, and can display a full range of colors with full motion capabilities.

This performance makes driving them quite complicated, and dedicated controller chips are needed for anything but the simplest models. Also note that many small to medium size LCD displays are also available with a touchscreen overlay.

An active matrix LCD is typically implemented using a Thin-Film-Transistor (TFT) technology. To manufacture a TFT display a thin film of silicon is deposited on a glass panel to form the transistors.

Interface complexity Low to high Models with SPI or I2C are available for the lower resolution displays. High resolution displays have sophisticated interfaces such as digital parallel interface, HDMI or MIPI.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey