0-80 2A x 3/16" Pan Head Machine Screw SS 100 ct#10106 - 3 16 machine screw

We also do analysis of morphology of all deposited layers using a high-resolution optical microscope (on the left) and scanning electron microscope (on the right).

OLED full form

Aug 30, 2020 — In the "About This Mac" Displays tab, you will see the resolution of. If you have more than one display attached to your Mac, you will see all ...

It comes with a 43.6-mm stainless steel case, sapphire crystal with an anti-reflective coating, and luminous hands and indices. The watch is water-resistant to ...

OLED vs QLED

Materize is a highly competent player in organic materials. This includes both aspects: original material research; as well as technical possibilities to fabricate experimental devices for various organic materials’ applications. Also, broad options of characterisation of materials and devices are available.

To fabricate your own device, we can offer you commercially available materials to work with, or you are welcome to bring your own materials. We have also established broad collaboration with chemists from many countries, enabling us to develop new original organic materials. In the case pictured here we used an original light emitting-material for the OLED, synthesised by our partners – chemists from Riga Technical University.

We use several methods to produce all the required layers for our device. One of the methods is wet chemical coating. For materials that can be damaged by oxygen, a wet chemical coating can be applied in an inert atmosphere (Ar), as was the case for our OLEDs. For that reason we have a spin-coater placed in the glovebox and, also, all solutions are prepared in the glovebox. If we need to transport the device to other systems, we use a specially designed box, thereby ensuring that devices are kept in an Ar atmosphere.

First OLED TV

First we add a sublime organic layer, and then the upper metallic electrode. In our case, it is aluminium, but we can make thin films from many different metals. During the sublimation process we can control thickness, sublimation rate and substrate temperature. In our cluster system, we can reach a vacuum of 1×10-6mbar.

QLED Full form

So I've had my XPS 13 for a few months now (still under warranty) and I noticed a bright pixel area on the left side of the screen (these should be covered under warranty) and I have also noticed 4 bright spots (small blob shaped) on my screen near the center. I am very careful with it and I have only put it in my backpack 4-5 times, when my backpack was full. I dont know why these have appeared and if they are blobs of bright pixels or pressure marks. They are very annoying and please let me know if there is any way without a screen replacement to fix these. Thanks.

For OLED devices, we can measure electroluminescence and photoluminescence; we can also determine the colour of electroluminescence in CIE coordinates and current-voltage-brightness characteristics, giving us information about the efficiency of our device (current and power efficiency). Knowing all these characteristics, we can tell whether the OLED we have made is better than those on the market.

Features ... GW Instek PSU-Series, a DC power supply with high power density design, is 1U in height and compatible with 19 Rack Mount Size. The series is ...

9 Mar 2022 — What does IPS mean? ... IPS stands for in-plane switching. This refers to an LCD panel technology that shifts how the liquid crystals align to ...

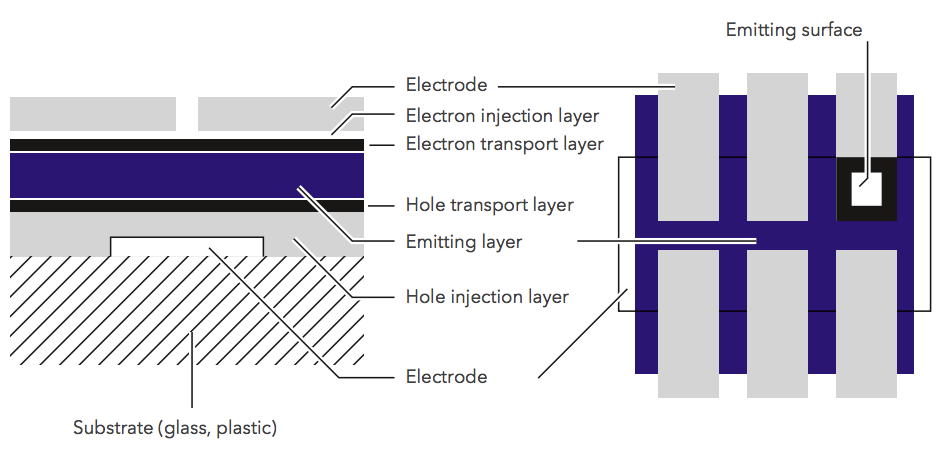

In our OLED example you will see many of the possibilities we can offer. We will make and characterise an organic light emitting diode after the particular design seen below. The thickness of each layer varies from 0.5 nm to 200 nm.

Advantages of OLED

Prior to fabrication of our OLEDs, we carry out: ionisation energy measurements (photoelectron spectroscopy method, determination of the energy structure of materials forming OLED), electron affinity energy determination (spectral dependence of intrinsic photoconductivity, determination of the energy structure of materials forming OLED), luminescence spectra measurements (determination of emission spectra of compound), photoluminescence quantum yield determination (determination of the highest possible efficiency of OLED), and charge carrier mobility determination (time of flight technique).

Quite different than LCD and QLED TVs, OLED panel technology does not use backlighting systems that adds to the panel thickness. Because OLED panels feature ...

Organic light emitting diodeprice

Organic materials are used in many innovative applications as organic light emitting diodes (OLED) for screens and lighting devices, transparent and flexible organic photovoltaics (OPV), optical modulators etc. Our modern infrastructure allows for working with any application of organic materials.

Investigation of organic materials and prototyping of organic light emitting diodes (OLED) for innovative screens and lighting applications

Organic light emitting diodevs oled

The substrates have been cleaned up to standard, including an ultrasonic bath and ozoniser. For our OLEDs, we use transparent ITO substrates to form the bottom electrode, but other different materials can be used, and any shape of bottom electrode can be created.

AMOLED is a type of OLED display device technology. OLED describes a specific type of thin-film-display technology in which organic compounds form the ...

OLED vs LED

USB Type A Male to Mini 4 Pin Cables found in many small devices such as cameras, cellphones, MP3 players, GPSs, etc.

21 Feb 2024 — An AMOLED display's pixels are self-emitting, in contrast with traditional LCD displays, which rely on a backlight to illuminate the pixels.

To fabricate an organic layer and upper electrode for our OLEDs, in this case, we use the SAF 25/50 vacuum coating cluster. We place the device in the system through a glovebox to ensure an inert atmosphere.

Our 128x64 Large LCD Graphic Display 3.24 inch with MCU offers a large-scale display with high-quality graphics and advanced control.

Another method for fabrication of thin layers is thermal evaporation in vacuum. We have decades of experience in thin-film preparation by material thermal evaporation in vacuum. The thermal evaporation in vacuum of organic and metallic materials can be combined with magnetron sputtering and plasma cleaning methods in the SAF 25/50 vacuum coating cluster system located in the clean-room facilities, where devices are easily transported in-between various process chambers by an automatic manipulator. All processes are managed through control software.

The fabrication of the OLED device takes place in our cleanrooms with an ISO classification of 7-8. We have the only classified laboratory cleanrooms in Latvia; suitable for setting up material acquisition technologies and research into materials science and nanomaterials.

4 Mar 2015 — LED Backlight LED backlighting is the most commonly used backlight for small, LCD panels. Light-emitting diodes, or LEDs, are practical ...

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey