How Many Pins Does an LCD Need? A Deep Dive into the 20-Pin LCD Display

In the realm of liquid crystal displays (LCDs), the question of "how many pins does an LCD need?" often arises. This question is crucial as it relates to the fundamental operation and functionality of these displays. While the answer may vary depending on the type and specifications of the LCD, a comprehensive understanding of the 20-pin LCD display can provide insights into this matter.

To begin, let's consider a standard 16×2 LCD display, which typically requires 16 pins. These pins are organized into two rows of eight pins each. The pins serve various purposes, including power supply, data communication, and control signals. Let's delve deeper into the functionality of these pins and how they contribute to the overall operation of the LCD.

Power Supply Pins

The power supply pins are crucial for providing the necessary power to the LCD. Typically, there are two power supply pins: one for the positive voltage (Vcc) and another for the negative voltage (GND). The Vcc pin receives the positive voltage, usually 5V, while the GND pin is connected to the ground, providing a reference point for the voltage.

Data Communication Pins

Data communication pins are responsible for transmitting the information displayed on the LCD. For a 16×2 LCD display, there are typically eight data lines, each responsible for transmitting one bit of data. These data lines are usually labeled D0 to D7, representing the eight bits of data required to represent a character or pixel on the LCD.

Control Signal Pins

In addition to power supply and data communication pins, control signal pins play a vital role in the operation of the LCD. These pins control various functions such as cursor movement, display on/off, backlight control, and more. Common control signal pins include:

RS (Register Select): This pin selects between the command register and the data register. When RS is set to a low level, the LCD enters command mode, allowing the transmission of control commands. When RS is set to a high level, the LCD enters data mode, allowing the transmission of data.

RW (Read/Write): This pin determines the direction of data transmission. When RW is set to a low level, the LCD expects data to be written to it. When RW is set to a high level, the LCD is in read mode, allowing data to be read from it.

E (Enable): This pin controls the timing of data transmission and the activation of the LCD. When E is set to a high level, the LCD processes the data on the data lines. The duration of the high pulse on the E pin determines the time allowed for data transmission.

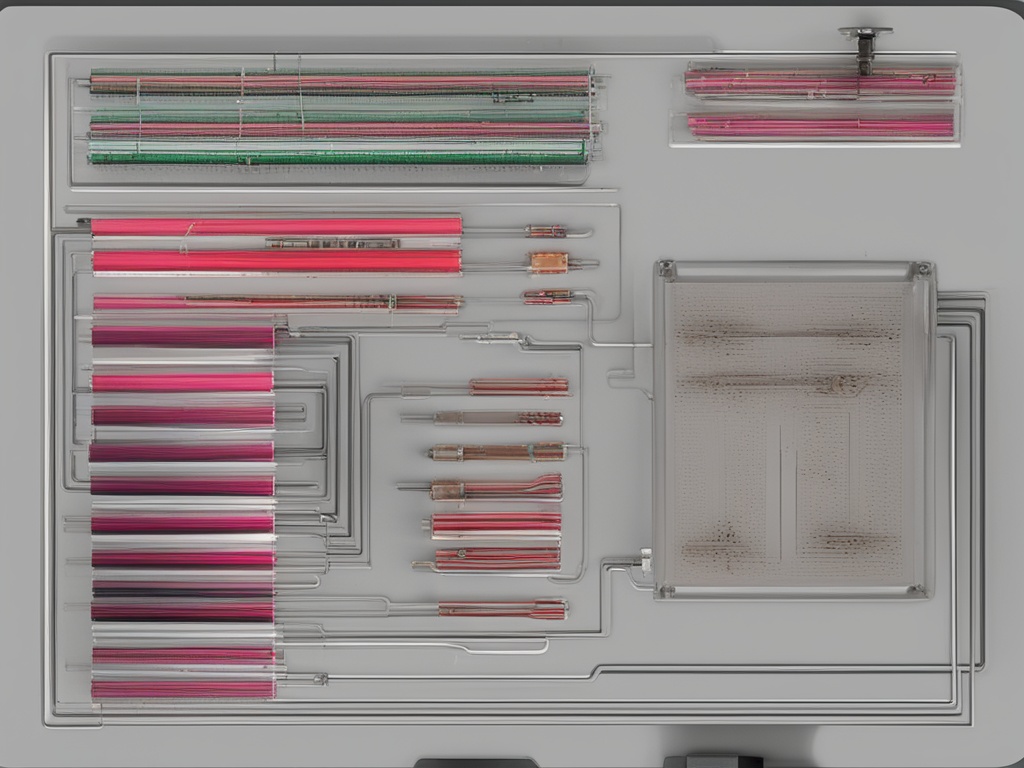

20-Pin LCD Display

Now, let's turn our attention to the 20-pin LCD display. A 20-pin LCD display is a more advanced version of the standard 16-pin display, offering additional functionality and capabilities. The extra pins provide additional control signals and features, such as backlight control, temperature compensation, and more.

While the basic functionality of the power supply and data communication pins remains the same in a 20-pin LCD display, the control signal pins are expanded to include additional features. For example, a 20-pin LCD display may include pins for backlight control, allowing you to turn the backlight on or off or adjust its brightness. Other pins may be dedicated to temperature compensation, ensuring optimal performance even under varying temperature conditions.

Conclusion

In summary, the number of pins required for an LCD display depends on its type, specifications, and desired functionality. A standard 16×2 LCD display typically requires 16 pins for power supply, data communication, and control signals. However, a more advanced 20-pin LCD display offers expanded functionality and capabilities through additional control signal pins. Understanding the purpose and operation of each pin is crucial for effective use and control of LCD displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey