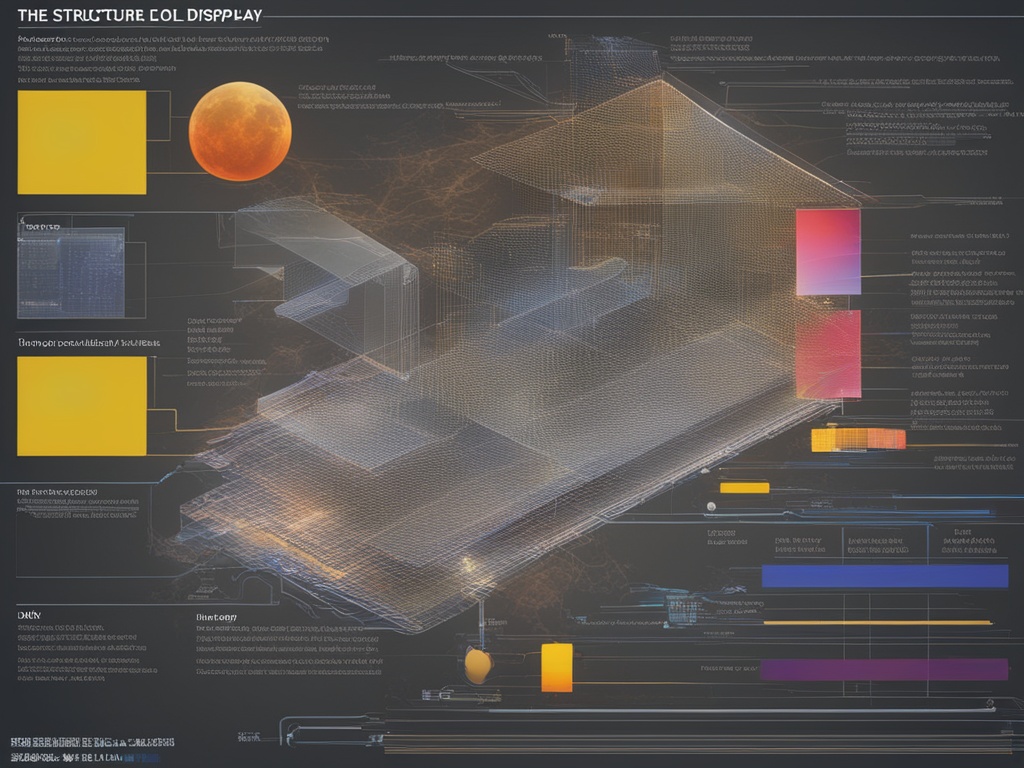

The Structure of OLED Display Panel: Unraveling the Layers of Technology

OLED (Organic Light-Emitting Diode) technology has revolutionized the display industry, offering a range of unique advantages that traditional display technologies cannot match. The essence of an OLED display lies in its innovative structure, which combines the latest advancements in materials science and electronics to create a highly efficient and visually stunning display medium.

At the core of an OLED display panel is the OLED cell. This fundamental unit is the building block of the entire display and is responsible for emitting light. It consists of a stack of thin organic layers, sandwiched between a conducting anode and a conducting cathode. These layers, each with their unique function, work in concert to produce the desired visual output.

Let's delve deeper into the structure of an OLED cell and understand the role of each component.

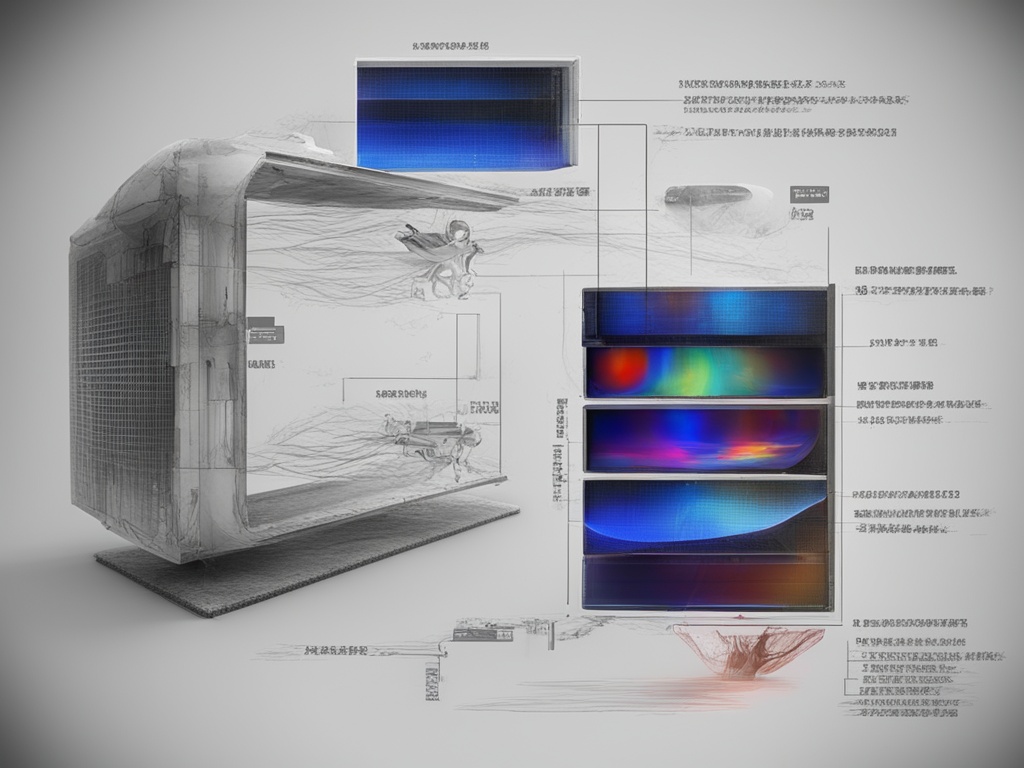

1. Substrate: Foundation of the OLED

The substrate is the base layer of the OLED display, providing a solid foundation for the subsequent layers. It can be made from a variety of materials, including plastic, glass, or metal foil, depending on the specific requirements of the display. The choice of substrate material significantly impacts the overall flexibility, durability, and cost of the OLED display.

2. Anode: The Positive Electrode

The anode, or the positive electrode, is the first layer applied to the substrate. It is typically made from transparent conductive materials like Indium Tin Oxide (ITO) on glass or a thin metal layer on a flexible substrate. The anode's primary function is to inject holes (positive charges) into the organic layers.

3. Hole Injection Layer (HIL) and Hole Transport Layer (HTL)

The hole injection layer (HIL) and hole transport layer (HTL) are the next layers deposited on top of the anode. These layers facilitate the efficient injection and transport of holes through the OLED structure. The HIL helps in the smooth injection of holes from the anode into the HTL, while the HTL ensures that the holes move smoothly through the organic stack.

4. Emissive Layer (EML)

The emissive layer (EML) is the heart of the OLED cell. It is responsible for converting the injected electrons and holes into light. This layer consists of a specific organic material that emits light when excited by the recombination of electrons and holes. The color of the emitted light depends on the material used in the emissive layer, allowing for a wide range of color possibilities in OLED displays.

5. Electron Transport Layer (ETL) and Electron Injection Layer (EIL)

The electron transport layer (ETL) and electron injection layer (EIL) are analogous to the hole injection and transport layers but work with electrons instead. These layers ensure that electrons are efficiently injected from the cathode and transported through the OLED structure to meet the holes in the emissive layer.

6. Cathode: The Negative Electrode

The cathode, or the negative electrode, is the final layer of the OLED cell. It is typically made from a thin metal film like aluminum or magnesium, depending on the specific requirements of the display. The cathode's role is to inject electrons into the organic stack and facilitate their movement towards the emissive layer.

In summary, the OLED display panel's structure is a carefully crafted arrangement of organic and inorganic layers that work together to produce bright, vivid, and efficient light emission. The choice of materials and the precision with which these layers are deposited are crucial to achieving the desired performance characteristics of the OLED display. As technology continues to evolve, we can expect further improvements in OLED display technology, leading to even more immersive and engaging visual experiences.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey