How Does a Resistive Touch Screen Work?

In the world of modern technology, touchscreens have become an integral part of our daily lives,revolutionary izing the way we interact with electronic devices.Among the various types of touchscreens available, resistive touch panels stand out as a reliable and cost-effective solution for a wide range of applications. This article delves into the working principle of resistive touch screens, exploring their structure and functionality.

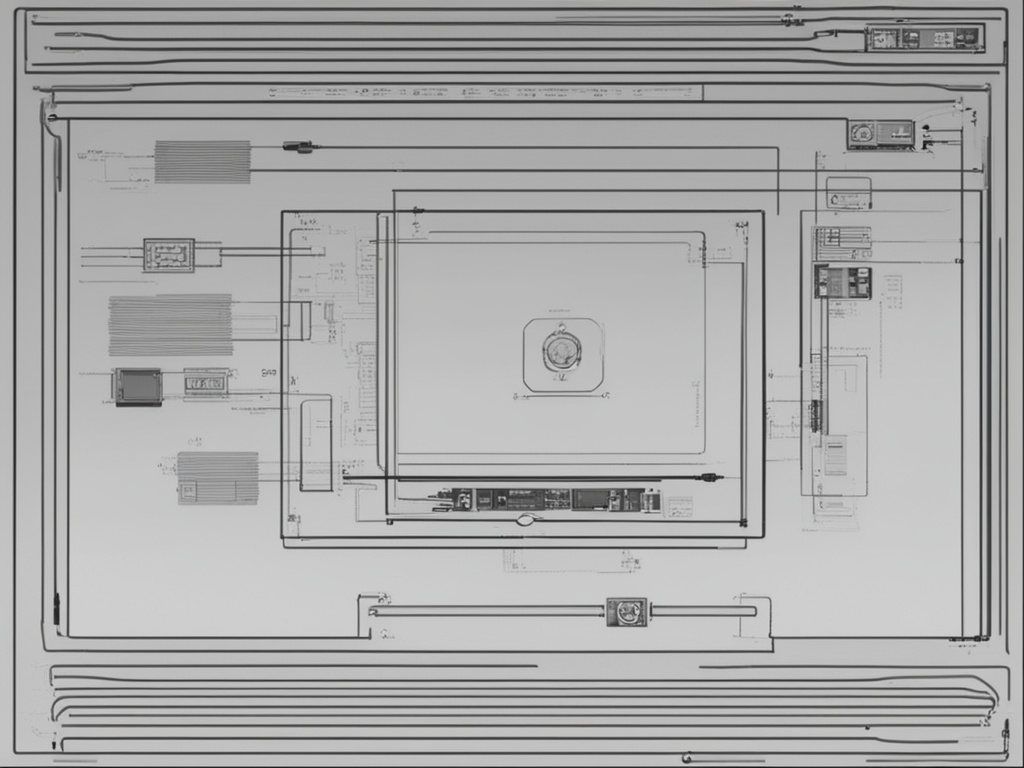

At the heart of a resistive touchscreen lies its unique design, which consists of two thin, flexible sheets of transparent conductive material. These sheets, often coated with a thin layer of resistive material, are separated by a small air gap or microdots. The outer layer, usually made of glass or plastic, is coated with a transparent conductive material such as indium tin oxide (ITO), while the inner layer is made from a similar material but with a different resistance value.

When the screen is not being touched, a constant voltage is applied across the two layers, creating a uniform electrical field. This field remains undisturbed until a pressure is applied to the outer layer, causing it to make contact with the inner layer at the point of pressure. At the contact point, the resistance between the two layers changes, creating a voltage difference that is detected by the touchscreen controller.

The controller, which is connected to the touchscreen through electronic circuits, continuously monitors the voltage difference across the layers. When a touch occurs, it迅速identifies the exact location of the contact point by measuring the voltage difference at different points along the layers. This information is then processed and converted into coordinates that represent the position of the touch on the screen.

The precision of the touch coordinates depends on several factors, including the resolution of the touchscreen, the sensitivity of the controller, and the accuracy of the voltage measurements. High-end resistive touchscreens can achieve impressive levels of accuracy, making them suitable for applications that require precise input, such as graphics-intensive applications or fine-motor tasks.

In addition to its accuracy, resistive touchscreens are also known for their durability and reliability. The flexible sheets and resistive material are designed to withstand repeated pressure and scratching, making them suitable for use in harsh environments or industrial applications. Furthermore, resistive touchscreens are relatively inexpensive to produce, making them a popular choice for budget-conscious consumers.

Despite their many advantages, resistive touchscreens do have some limitations. One of the main drawbacks is their relatively slow response time compared to other types of touchscreens, such as capacitive touchscreens. This is because resistive screens require physical contact between the layers, which takes time to establish. Additionally, resistive screens can be prone to wear and tear over time, especially at the contact points, which may affect their performance.

Nevertheless, resistive touchscreens remain a popular choice for a wide range of applications due to their reliability, durability, and cost-effectiveness. From industrial equipment to ATM machines and even some smartphones, resistive touchscreens play a crucial role in enabling user interaction with electronic devices. As technology continues to evolve, resistive touchscreens will likely remain a relevant and valuable component of the interactive electronics landscape.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey