The Difference between LCD Panel and Module

In the realm of modern electronics, the terms LCD panel and LCD module (LCM) are often encountered, especially when dealing with devices like smartphones, tablets, televisions, and other display-intensive products. Although both terms are closely related to liquid crystal displays (LCDs), they differ significantly in terms of their function, structure, and usage.

LCD Panel

An LCD, or liquid crystal display, is a flat-panel display technology that relies on the modulation of light passing through liquid crystals to produce images. LCDs are not self-luminous; they require a backlight to illuminate the liquid crystal layer, which then controls the transmission of light to create an image.

When referring to an LCD panel, we are generally speaking about the actual display component itself: the layer of liquid crystals sandwiched between two polarizing filters. This panel is responsible for converting the raw data sent to it into visible pixels that form an image. LCD panels are often separate components that require additional electronics to function properly.

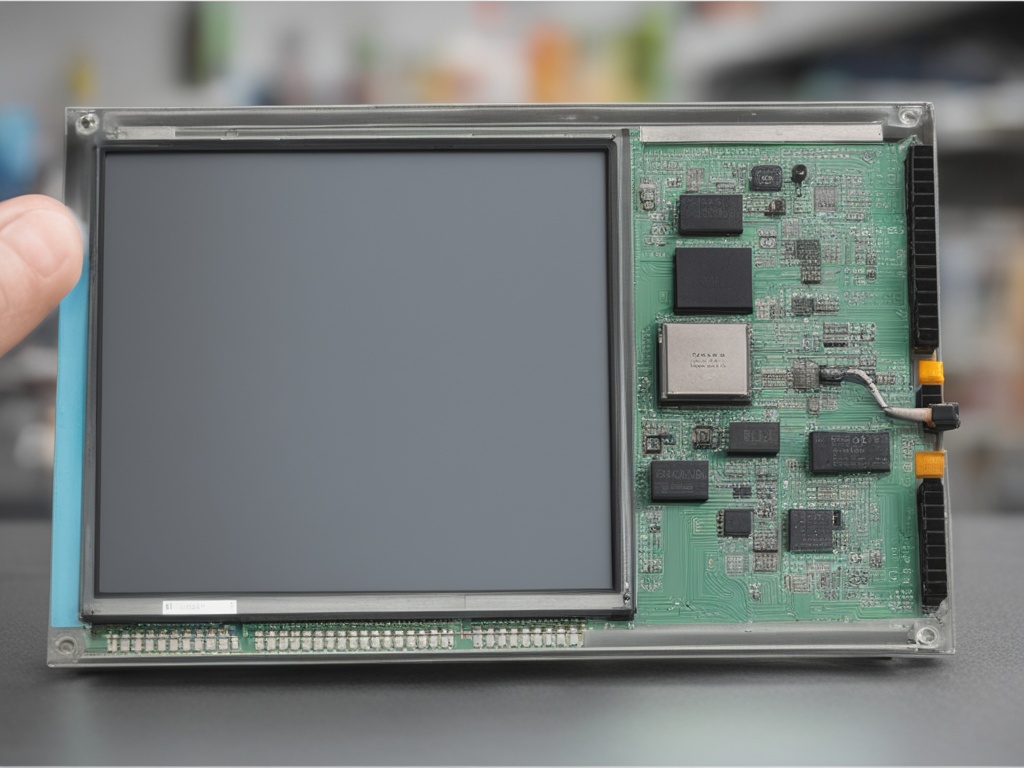

LCD Module (LCM)

An LCD module (LCM), on the other hand, is a complete package that integrates an LCD panel with additional electronics to form a functional display unit. An LCM typically includes the following components:

1. LCD Panel: The actual display element, as described above.

2. Driving Circuit: This circuit is responsible for supplying the necessary voltages and signals to the LCD panel. It converts the incoming data into a format that the panel can understand and display.

3. Control Circuit: The control circuit manages the operation of the LCM. It receives commands from a microcontroller or other host device and interprets them, sending appropriate signals to the driving circuit.

4. Connectors and Interfaces: LCMs are designed with connectors or interfaces that allow them to be easily integrated into a larger system, such as a circuit board.

By combining the LCD panel with these additional electronics, LCMs offer a more turnkey solution for display needs. They can be directly connected to a microcontroller or other processor, eliminating the need for the user to design and assemble a separate driving and control circuit.

Comparison

Here are some key differences between LCD panels and LCMs:

Completeness: LCD panels are standalone components that require external electronics to function. LCMs, on the other hand, are complete systems that include all the necessary electronics for operation.

Ease of Integration: LCD panels require more work to integrate into a system as they need to be connected to a separate driving and control circuit. LCMs, with their integrated electronics, are much easier to integrate.

Cost: LCD panels tend to be cheaper than LCMs because they lack the additional electronics. However, this cost saving may be offset by the extra design and assembly work required to interface an LCD panel with a microcontroller.

Flexibility: LCD panels offer more flexibility in terms of customization. Since they are separate from the driving and control electronics, they can be paired with a variety of different circuits to suit different applications. LCMs, on the other hand, are more limited in terms of customization as they are designed as a complete system.

In conclusion, LCD panels and LCMs both play important roles in the world of liquid crystal displays. LCD panels are the core components responsible for displaying images, while LCMs provide a more comprehensive solution by integrating the panel with the necessary electronics for operation. The choice between the two depends on the specific requirements of the application, such as cost, ease of integration, and customization needs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey