How to Manufacture OLED Display: A Detailed Overview

Introduction:

OLED (Organic Light Emitting Diode) displays have become increasingly popular due to their vibrant colors, high contrast ratio, and energy efficiency. The manufacturing process of OLED displays is a complex and intricate one, involving several key steps to ensure high-quality and reliable products.

The Mass Production Process:

The mass production process of OLED displays can be divided into three main steps: the pre-process, vapor deposition process, and post-process.

Step 1: Pre-Process

The pre-process is the first step in manufacturing OLED displays and primarily involves the fabrication of the Thin-Film Transistor (TFT) circuits. TFT circuits are essential for controlling the individual pixels on the display and ensuring proper functionality. During this step, the TFT circuits are deposited onto a glass or plastic substrate using various techniques such as sputtering or evaporation.

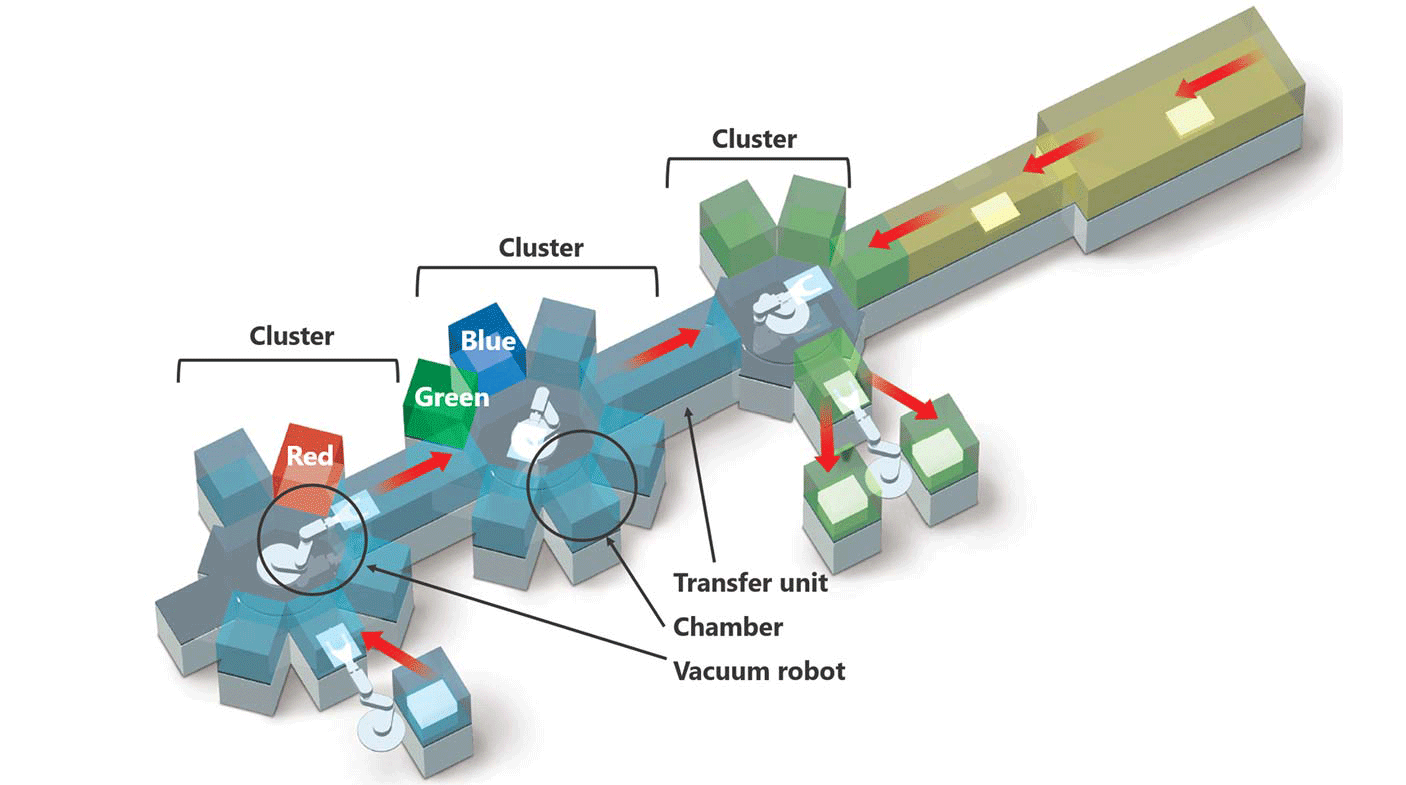

Step 2: Vapor Deposition Process

The vapor deposition process is the heart of OLED display manufacturing, where organic materials are deposited onto the TFT circuits to create the light-emitting layers. This process involves heating the organic materials in a vacuum chamber, causing them to vaporize and condense onto the substrate in a controlled manner. Different organic materials are used to create the red, green, and blue subpixels that combine to form the full-color display.

Step 3: Post-Process

The post-process is the final step in manufacturing OLED displays and involves several key processes such as sealing, cutting, and wiring connections. Sealing is essential to protect the delicate organic layers from moisture and oxygen, which can degrade the display over time. Cutting the large substrate into individual display panels and creating the necessary wiring connections to drive the display are also crucial steps in the post-process.

Conclusion:

In conclusion, the manufacturing process of OLED displays is a complex and multi-step process that requires precision, expertise, and advanced technology. By following the pre-process, vapor deposition process, and post-process, manufacturers can produce high-quality OLED displays with vibrant colors, high contrast ratios, and energy-efficient performance. As the demand for OLED displays continues to grow, advancements in manufacturing technology will further improve the efficiency and quality of these innovative display panels.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey