tft lcd and amoled factory

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

Both technologies have their own advantages and disadvantages. So, how do you know which one is best for your needs? We compare these two technologies below.

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

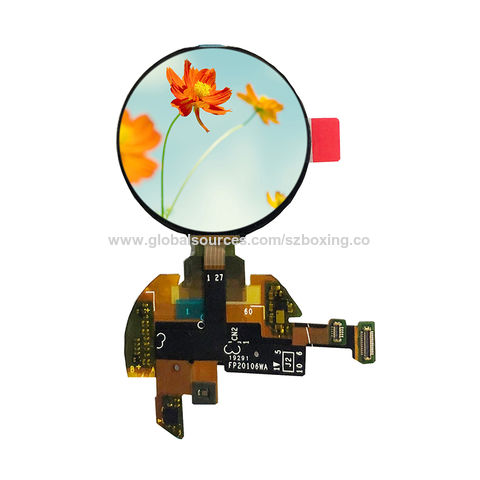

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

Nauticomp Inc.provides world-class fully customizable touchscreen displays for commercial and industrial settings. With features like sunlight readability, brightness adjustability, infrared lighting, full backlighting, all-weather capabilities, etc., our displays are second to none. Contact us today to learn more.

Steven Van Slyke and Ching Wan Tang pioneered the organic OLED at Eastman Kodak in 1979. The first OLED product was a display for a car stereo, commercialized by Pioneer in 1997. Kodak’s EasyShare LS633 digital camera, introduced in 2003, was the first consumer electronic product incorporating a full-color OLED display. The first television featuring an OLED display, produced by Sony, entered the market in 2008. Today, Samsung uses OLEDs in all of its smartphones, and LG manufactures large OLED screens for premium TVs. Other companies currently incorporating OLED technology include Apple, Google, Facebook, Motorola, Sony, HP, Panasonic, Konica, Lenovo, Huawei, BOE, Philips and Osram. The OLED display market is expected to grow to $57 billion in 2026.

AMOLED (Active Matrix Organic Light Emitting Diode) is a type of OLED display device technology. OLED is a type of display technology in which organic material compounds form the electroluminescent material, and active matrix is the technology behind the addressing of individual pixels.

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for PMOLED.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays. Brightness of AMOLED is determined by the strength of the electron current. The colors are controlled by the red, green and blue light emitting diodes. It is easier to understand by thinking of each pixel is independently colored, mini-LED.

IPS technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but with more enhanced features and more widespread usability compared with the older generation of TN type TFT screen (normally used for low-cost computer monitors). Actually, it is called super TFT. IPS LCD display consists of the following high-end features. It has much wider viewing angles, more consistent, better color in all viewing directions, it has higher contrast, faster response time. But IPS screens are not perfect as their higher manufacturing cost compared with TN TFT LCD.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

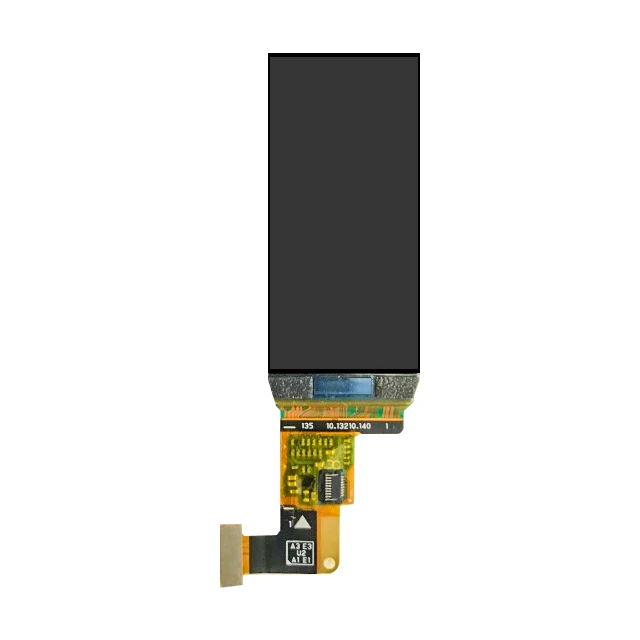

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

AMOLED displays are not only thin and fuel-intensive, but they also deliver the highest image quality available, so they can be made translucent, elastic, bendable, or even rollable and stretchy in the future, allowing for a variety of applications. AMOLEDs are a revolutionary technology in terms of display devices! It is possible to create an AMOLED by sandwiching a sequence of thin films across phase conductors. Electric charge causes a brilliant light to be emitted when the current flows through the coil.

The color display is fantastic. Color intensity, sharpness, and luminance settings that are second to none and can be customized to meet the needs of any application.

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

As it is more affordable than capacitive, resistive is typically the preferred option. However, capacitive technology is compatible with a wide range of contemporary smartphones and digital gadgets.

Backlighting is unnecessary for AMOLEDs. LCDs produce images by selectively blocking parts of the illumination, whereas AMOLEDs produce light. AMOLEDs utilize less energy than LCDs since they don"t need backlighting. This is critical for battery-powered devices such as phones.

While AMOLED light-emitting sheets are lightweight, the substrate can also be elastic rather than stiff. AMOLED films are not limited to glass-like LEDs and LCDs.

AMOLEDs offer 170-degree ranges of vision. LCDs operate by obscuring the light. Hence they have intrinsic viewing obstacles. In addition, AMOLEDs have a substantially wider viewing spectrum.

AMOLEDs outperform LEDs. Since AMOLED organic coatings are less than LED inorganic crystal levels, AMOLED conducting and particle emitters layers can just be multi-layered. Also, LEDs and LCDs need glass backing, which absorbs light. AMOLEDs don"t need it.

AMOLEDs seem to be simpler to implement and larger. AMOLEDs are constructed of polymers and may be produced into big sheets. It takes a lot of extra liquid crystals to build and set down.

While red and green AMOLED sheets have a greater lifespan (46,000 to 230,000 hours), azure compounds have significantly shorter longevity (up to roughly 14,000 hours).

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

Kingtech is one of the leading TFT LCD display OEM/ODM manufacturers in China since 2003. Customization is allowed for projects such as industrial devices, medical, POS, logistics devices, smart home applications and etc.

To provide a one-stop LCD display solution. During the last 17 years, based on LCD manufacturing as our center, we gradually expand to the TFT capacitive touchscreen, driving board, software hardware design, and complete industrial computer solution.

As a professional LCD screen supplier/ LCD display supplier/ LCD panel company/ LCD module manufacturer, Kingtech LCD aims to provide a one-stop service and solve your problems. With a strong LCD Display module R & D team and strict quality management of IS09001, IS01400ATF16949 certificates.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

These products are all widely used in various industries such as in medicine, home security, automotive, energy field solar charging, and domestic equipment use.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Tried and trusted TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen. The pixels themselves do not produce light; instead, the screen uses a backlight for illumination.

By contrast the Active Matrix OLED (AMOLED) display requires no backlight and can light up or turn off each of their pixels independently. As the name suggests, they are made of organic material.

An AMOLED display has many other benefits which make it a superior looking display including exceptional vieiwng angles and a display that looks practically black when it is switched off.

So, why use a TFT display? Well, it is a mature technology meaning the manufacturing processes are efficient, yields high and cost much lower than AMOLED.

TFT displays also have a much longer lifespan than AMOLED displays and are available in a far greater range of standard sizes, which can be cut down to fit a space restricted enclosure for a relatively low cost adder.

Which type of display you choose really depends on your application, environment and users, so why not get in touch with us today to discuss your requirements.

A Thin Film Transistor (TFT) FT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen. The pixels themselves do not produce light; instead, the screen uses a backlight for illumination. Discover our TFT Products

Standing for Active Matrix Organic Light Emitting Diode, this type of display requires no backlight and can light up or turn off each of their pixels independently, meaning they offer better contrast and colour. As the name suggests they are made of organic material.

Otherwise knows as the IPS display, this superior version of the TFT provides all round viewing angles and exceptional contrast ratio, however this comes at a premium cost compared to standard TFT models. Read more here.

As with all display choice, knowing your intended audience, user requirements and environmental conditions, all form part of the initial design process, which will ultimately determine the best display at the right price for your application. Before you make your choice, why not speak with us and we will be happy to talk you through your options.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This rise of small, powerful components has also led to significant developments in display technology. The most recent of which, AMOLED, is now the main competitor for the most common display used in quality portable electronics – the TFT–LCD IPS (In-Plane Switching) display. As more factories in the Far East begin to produce AMOLED technology, it seems likely we will enter a battle of TFT IPS versus AMOLED, or LCD vs LED. Where a large percentage of a product’s cost is the display technology it uses, which provides best value for money when you’re designing a new product?

TFT IPSdisplays improved on previous TFT LCD technology, developed to overcome limitations and improve contrast, viewing angles, sunlight readability and response times. Viewing angles were originally very limited – so in-plane switching panels were introduced to improve them.

Modern TFT screens can have custom backlights turned up to whatever brightness that their power limit allows, which means they have no maximum brightness limitation. TFT IPS panels also have the option for OCA bonding, which uses a special adhesive to bond a touchscreen or glass coverlens to the TFT. This improves sunlight readability by preventing light from bouncing around between the layers of the display, and also improves durability without adding excess bulk; some TFT IPS displays now only measure around 2 mm thick.

AMOLED technology is an upgrade to older OLED technology. It uses organic compounds that emit light when exposed to electricity. This means no backlight, which in turn means less power consumption and a reduction in size. AMOLED screens tend to be thinner than TFT equivalents, often produced to be as thin as 1 mm. AMOLED technology also offers greater viewing angles thanks to deeper blacks. Colours tend to be greater, but visibility in daylight is lower than IPS displays.

As manufacturers increasingly focus on smaller devices, such as portable smartphones and wearable technology, the thinness and high colour resolution of AMOLED screens have grown desirable. However, producing AMOLED displays is far more costly as fewer factories offer the technology at a consistent quality and minimum order quantities are high; what capacity there is is often taken up the mobile phone market Full HD TFT IPS displays have the advantage of being offered in industry standard sizes and at a far lower cost, as well as offering superior sunlight visibility.

The competition between displays has benefitted both technologies as it has resulted in improvements in both. For example, Super AMOLED, a marketing brand by Samsung, involves the integration of a touchscreen layer inside the screen, rather than overlaid on it. The backlight in TFT technology means they can never truly replicate the deep blacks in AMOLED, but improvements have been made in resolution to the point where manufacturers like Apple have been happy to use LCD screens in their smartphones, even as they compete with Samsung’s Super AMOLED.

Aside from smartphones, many technologies utilise displays to offer direct interaction with customers. To decide whether TFT LCD will survive the rise of AMOLED technology, we must first recap the advantages of LCD. The backlit quality means that whites are bright and contrast is good, but this will wear down a battery faster than AMOLED. Additionally, cost is a significant factor for LCD screens. They are cheaper, more freely available and are offered in industry standard sizes so can be ordered for new products without difficulty.

It seems hard to deny that AMOLED will someday become the standard for mobile phones, which demand great colour performance and are reliant on battery life. Where size is an issue, AMOLED will also grow to dominance thanks to its superior thinness. But for all other technologies, particularly in industrial applications, TFT-LCD offers bright, affordable display technology that is continually improving as the challenge from AMOLED rises.

Some subscribers prefer to save their log-in information so they do not have to enter their User ID and Password each time they visit the site. To activate this function, check the "Save my User ID and Password" box in the log-in section. This will save the password on the computer you"re using to access the site.

OLED is increasingly used in smartphones and televisions, but supply is tightening due to size issues and high production costs, making TFT LCD module demand stronger for the next 3 to 5 years. An organic light-emitting diode (OLED) refers to organic LED materials which light up in the presence of electric currents. OLED uses passive-matrix (PMOLED) or active-matrix (AMOLED). Most manufacturers use AMOLED.

OLED creates the deepest black, generating higher color quality than LCD displays. However, organic elements have lower lifespans than LCDs and AMOLED is not suitable for brightly-lit environments. Apple’s high demand has an impact on AMOLED production, among other factors, which has a subsequent positive effect on TFT LCD module demand.

AMOLED demands gets stronger, due to the pursuit for the best color in smartphones and televisions, but its supply is limited because of production factors. Apple is projected to require 100 million AMOLED panels annually for the next three years. Apple’s requirement creates high AMOLED demand in the small and medium display market. Displays are 9-inch in size, which creates a dent on AMOLED supply.

OLED is particularly harder to make than LCD modules because of the complexity in involved in creating substrate materials. OLED manufacturing is costlier than LCD modules, which may also create long-term production issues.

As AMOLED supply remains uncertain, numerous consumer product manufacturers would rather rely on TFT LCD modules. Innovations in TFT LCD can make them more competitive, especially as they cost less than OLED. Stronger TFT LCD demand will come from high-resolution smartphones and consumer electronics with short life cycles.

Though some say that the demand for TFT LCD is likely to contract, they are not considering the increasing use of OLED which already puts greater pressure on its suppliers. Without reducing OLED production costs, they might experience bottleneck problems in the future. Uncertain of OLED supply, some manufacturers of automotive, smartphone, and medical monitors would still prefer TFT LCD over OLED.

While OLED promises deeper colors, TFT LCD module can offer a more reliable, cost-efficient supply. As a result, companies that do not emphasize the demand for high color saturation would opt for TFT LCD. For the next 3 to 5 years, unless OLED vastly improves manufacturing costs and speed, TFT LCD makers are poised for higher demand.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

With the development of the times,display technology is also increasingly innovative,our smart phones,tablets,laptops,TVs,media players,smart wears white goods and other appliances with displays have many display options,such as LCD, OLED, IPS, TFT, SLCD, AMOLED, ULED and other display technologies that we often hear.Next we will focus on two more common display technologies,TFT LCD and AMOLED,to compare their differences and which technology is better.

TFT LCD refers to thin film transistor liquid crystal display,which is one of the most liquid crystal displays.TFT LCD has several different types, which can be classified as TN, IPS, VA, etc. Since TN displays cannot compete with AMOLED in terms of display quality, we use IPS TFT for comparison.

OLED means Organic Light Emitting Diode, and there are also several types of OLEDs, which can be divided into PMOLED (Passive Matrix Organic Light Emitting Diode) and AMOLED (Active Matrix Organic Light Emitting Diode). Similarly, we have also selected here to compare the better performance of Super AMOLED and IPS TFT.

On the issue of AMOLED and IPS which is better,the benevolent see the wisdom of the wise. For users whether it is IPS screen or AMOLED screen, as long as it can bring a good visual experience is a good screen.

If you are interesting in this kinds of two products,warmly welcome to contact with us any time,we are professional manufacturer for all kinds of customized LCD display with touch panel and PCB board whole set solution!

Large thin-film transistor liquid crystal display (TFT LCD) panel makers are expected to reduce production of comparatively smaller sized 32-, 40- and 43-inch panels, helping to stabilize panel prices in the third quarter of 2018. In the longer term, however, the oversupply issue still remains, eventually causing older TFT LCD fabs to be restructured, according to IHS Markit (Nasdaq: INFO).

According to the latest AMOLED and LCD Supply Demand & Equipment Tracker by IHS Markit, currently planned new factories will increase large display panel production capacity by 31 percent or 77.7M square meters from 2018 to 2021. However, based on the current demand forecast, there will be about 49 million square meters of capacity in the pipeline more than the market requires in 2021. The supply/demand glut level is expected to continue to increase from 12 percent in 2018 to 23 percent in 2021, remaining well above 10 percent or what is modeled to be a balanced market.

Between 2019 and 2021, there will be a great amount of LCD TV panel capacity built, mainly from generation Gen10.5/11 factories in China, according to IHS Markit.

“Some panel makers may be forced to reduce utilization rates, while some planned capacity may never be built,” said David Hsieh, senior director of displays at IHS Markit. “Furthermore, in the next few years, legacy factory restructuring will likely accelerate. For the TFT LCD industry to return to a balanced supply/demand level, multiple Gen 5, Gen 6 and even Gen 8 factories will likely need to be shut down.”

For example, shutting down half of all Gen 5 and Gen 6 amorphous silicon (a-Si) capacity in Taiwan would remove about 18 million square meters of production capacity, according to IHS Markit. Larger glass substrate capacity, such as Gen 8, will also likely need to be closed to bring the market back toward balance.

Possible restructuring of legacy factories may include fab shutdown, facility consolidation, or conversion to other technologies, such as active-matrix organic light-emitting diode (AMOLED) panels, ePaper backplanes and sensors.

According to the Display Production & Inventory Tracker by IHS Markit, fab restructuring can be attributed to multiple reasons, such as no longer competitive, old equipment, shifts in panel makers’ business focus, excessive overhead from under-utilized facilities and pressure on profitability.

“Oversupply is not the end of the crystal cycle. The industry has a long history of dynamically adjusting itself to balance supply and demand,” Hsieh said. “The process may create many challenges for supply chain companies. However, the delayed expansion of new factories, the restructuring of legacy fabs and the potential for faster demand growth spurred by lower panel prices will help the LCD industry to eventually return to equilibrium.”

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

If you are pleased with your purchase, please leave us positive feedback once receiving the item, and we will return the feedback upon you. If you have any problem with the outcome of the transaction or product, please don"t respond with negative feedback before contacting us. we will do our best to resolve your case ASAP. If you meet any questions,pls contact me first,i will try to solve for you. Negative feedback is not acceptable before contacting me. Bulk order is acceptable, low prices will be offered to you for bulk order. Any questions welcome to contact me! Thanks.

If you are pleased with your purchase, please leave us positive feedback once receiving the item, and we will return the feedback upon you. If you have any problem with the outcome of the transaction or product, please don"t respond with negative feedback before contacting us. we will do our best to resolve your case ASAP. If you meet any questions,pls contact me first,i will try to solve for you. Negative feedback is not acceptable before contacting me. Bulk order is acceptable, low prices will be offered to you for bulk order. Any questions welcome to contact me! Thanks.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey