lcd panel makers hope brands

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Back in 2016, to determine if the TV panel lottery makes a significant difference, we bought three different sizes of the Samsung J6300 with panels from different manufacturers: a 50" (version DH02), a 55" (version TH01), and a 60" (version MS01). We then tested them with the same series of tests we use in all of our reviews to see if the differences were notable.

Our Samsung 50" J6300 is a DH02 version, which means the panel is made by AU Optronics. Our 55" has an original TH01 Samsung panel. The panel in our 60" was made by Sharp, and its version is MS01.

Upon testing, we found that each panel has a different contrast ratio. The 50" AUO (DH02) has the best contrast, at 4452:1, followed by the 60" Sharp (MS01) at 4015:1. The Samsung 55" panel had the lowest contrast of the three: 3707:1.

These results aren"t really surprising. All these LCD panels are VA panels, which usually means a contrast between 3000:1 and 5000:1. The Samsung panel was quite low in that range, leaving room for other panels to beat it.

The motion blur results are really interesting. The response time of the 55" TH01 Samsung panel is around double that of the Sharp and AUO panels. This is even consistent across all 12 transitions that we measured.

For our measurements, a difference in response time of 10 ms starts to be noticeable. All three are within this range, so the difference isn"t very noticeable to the naked eye, and the Samsung panel still performs better than most other TVs released around the same time.

We also got different input lag measurements on each panel. This has less to do with software, which is the same across each panel, and more to do with the different response times of the panels (as illustrated in the motion blur section). To measure input lag, we use the Leo Bodnar tool, which flashes a white square on the screen and measures the delay between the signal sent and the light sensor detecting white. Therefore, the tool"s input lag measurement includes the 0% to 100% response time of the pixel transition. If you look at the 0% to 100% transitions that we measured, you will see that the 55" takes about 10 ms longer to transition from black to white.

All three have bad viewing angles, as expected for VA panels. If you watch TV at an angle, most likely none of these TVs will satisfy you. The picture quality degrades at about 20 degrees from the side. The 60" Sharp panel is worse than the other ones though. In the video, you can see the right side degrading sooner than the other panels.

It"s unfortunate that manufacturers sometimes vary the source of their panels and that consumers don"t have a way of knowing which one they"re buying. Overall though, at least in the units we tested, the panel lottery isn"t something to worry about. While there are differences, the differences aren"t big and an original Samsung panel isn"t necessarily better than an outsourced one. It"s also fairly safe to say that the same can be said of other brands. All panels have minute variations, but most should perform within the margin of error for each model.

Attendees visit the booth of TV panel maker Shenzhen China Star Optoelectronics Technology during an international exhibition in Shanghai on July 11, 2019. [Photo by Lyu Liang/For China Daily]

Chinese companies have gained a competitive edge in the large-screen display industry and the exit of South Korean counterparts such as Samsung Electronics and LG Display from the liquid crystal display market will bring opportunities for China"s panel makers despite the challenges posed by the COVID-19 pandemic.

Market research firm Sigmaintell said BOE Technology Group Co Ltd-a leading Chinese supplier of display products and solutions-became the world"s largest shipper of LCD TV panels for the first time in 2019.

The Beijing-based company shipped 53.3 million units of LCD panels in 2019, with production capacity increasing by more than 20 percent on a yearly basis.

The consultancy said the LCD TV panel production area of Chinese manufacturers will account for more than 50 percent of the global total this year, surpassing South Korean competitors who are accelerating the shutdown of large-sized LCD panel production capacity due to competition from Chinese manufacturers.

It estimated the production capacity of large-sized LCD panels will continue to increase in China over the next three years. In addition, global LCD TV panel shipments stood at 283 million pieces last year, a slight decrease of 0.2 percent year-on-year. Meanwhile, the shipment area was 160 million square meters, an increase of 6.3 percent year-on-year.

"Chinese companies have gained an upper hand in large-screen LCD displays. Samsung and LG"s decision to exit from the LCD sector means Chinese panel makers will take a dominant position in this field," said Li Dongsheng, founder and chairman of Chinese tech giant TCL Technology Group Corp.

Li said South Korean firms will focus on organic LED screens and quantum dot LED displays, while Chinese TV panel makers are catching up at a rapid pace.

Data consultancy Digitimes Research said it comes as little surprise that Samsung has opted to withdraw from the LCD panel sector as its LCD business was losing money in every quarter of 2019 due to challenges from Chinese competitors.

BOE said its Gen 10.5 TFTLCD production line achieved mass production in Hefei, Anhui province, in March 2018. The plant mainly produces high-definition LCD screens of 65 inches and above. With a total investment of 46 billion yuan ($6.5 billion), the company"s second Gen 10.5 TFT-LCD production line launched operations in Wuhan, Hubei province, in December.

The Gen 11 TFT-LCD and active-matrix OLED production line of Shenzhen China Star Optoelectronics Technology, a subsidiary of TCL, officially entered operations in November 2018, producing 43-inch, 65-inch and 75-inch LCD screens.

Chen Lijuan, an analyst at Sigmaintell, said panel manufacturers should not just invest in production lines, but also pay more attention to the establishment of the whole supply chain, including raw materials, equipment and technology.

Bian Zheng, deputy director of research at AVC Revo, a unit of market consultancy firm AVC, said China will have a 51 percent market share in global TV shipments in 2020, while South Korea will have 25 percent, adding that large-screen TV panels will bolster healthy development of the industry.

Bian said the OLED and QLED will be the next-generation flat-panel display technologies to be in the spotlight. LG Display is currently the world"s only supplier of large-screen OLED TV panels.

OLED is a relatively new technology and part of recent display innovation. It has a fast response rate, wide viewing angles, super high-contrast images and richer colors. It is much thinner and can be made flexible, compared with traditional LCD display panels.

Reflective displays really are a unique thing. You don’t have to hide them from the sun. You don’t have to shield your screen with your hand in order to eliminate glare. You don’t have to tilt it at funny angles that cause your neck to throb in pain, just so that you can read what’s on the screen. Funny, because those are our natural reactions whenever LCD and sunlight combine. Not with a reflective display though.

A decade ago, innovative Tai-wanese flat panel display companies started investing in a cutting-edge and cost-saving organic light-emitting diode (OLED) technology in an attempt to move beyond the slim profits associated with original equipment manufacturing.

Those companies, however, have all but given up hope as high technological barriers and cutthroat competition from cost-efficient liquid-crystal-display (LCD) makers have placed them deep in the red.

"Taiwanese companies hoped to make big money from manufacturing slimmer OLED displays at lower prices than LCD panels," said Roger Yu (游智超), a flat-panel industry analyst with Polaris Securities Co (寶來證券).

Low yields have prompted LCD panel makers AU Optronics Corp (友達光電) and Chi Mei Optoelectronics Corp (奇美電子), which are also developing OLED technology, to cut their OLED staff numbers, according to market research DisplaySearch.

"Sharp price reductions and difficulties in cutting costs are the major challenges for OLED display makers," said Kevin Liao (廖顯杰), a flat-panel industry analyst with DisplaySearch.

Technologically, OLED displays readily compete with LCDs in small-and-medium applications such as handset displays and MP3s palyers, but LCD makers are able to edge OLED suppliers out of the market by undercutting them on price.

With our G5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, we provide various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

BANGALORE (Reuters) - Sharp Corp will partner with Taiwanese firm Chimei Innolux Corp to produce television-use LCD panels, the Nikkei business daily reported.

Sharp will provide key technology for reducing power consumption of LCD TVs to Chimei, a unit of Taiwan’s Hon Hai Precision Industry Co or Foxconn International Holdings Ltd, and then outsource production of 20- to 39-inch panels, the paper said.

Sharp will provide panels 40 inches and larger to Chimei. The two firms have already signed a deal regarding the technology transfer and hope to start supplying panels to each other by year-end, the Nikkei reported.

LG Display has ceased making LCD iPhone screens, and abandoned hopes of doing so in the future, according to a supply-chain report. Separately, the company has stated that it may cease making its own smartphones.

Things changed when Apple began transitioning to OLED with the iPhone X. LG was late to recognize the industry trend from LCD to OLED, and was ill-prepared for Apple’s switch. That left Samsung as the sole supplier for Apple’s flagship phones for some time.

LG Display has halted production of liquid crystal display (LCD) panels for iPhones, TheElec has learned […] LG Display halted iPhone LCD production at its AP3 line at Gumi in the third quarter. The line also stopped making panels for other phones as well in the fourth quarter.

For LG Display, the LCD line for iPhones has been low in profitability. Apple also used organic light emitting diode (OLED) panels instead for its iPhone 12 series. Sales of iPhones with OLED is also expected to exceed that of those with LCD panels this year.

Apple’s LCD model, iPhone SE, which launched last year, will use LCD panels by JDI and Sharp instead. LG Display had previously attempted to supply LCD for the 2019-model iPhone SE but failed.

The factory which made the LCD screens is reportedly being repurposed to make display panels for cars. LG is the current market leader in automobile displays of nine inches or larger.

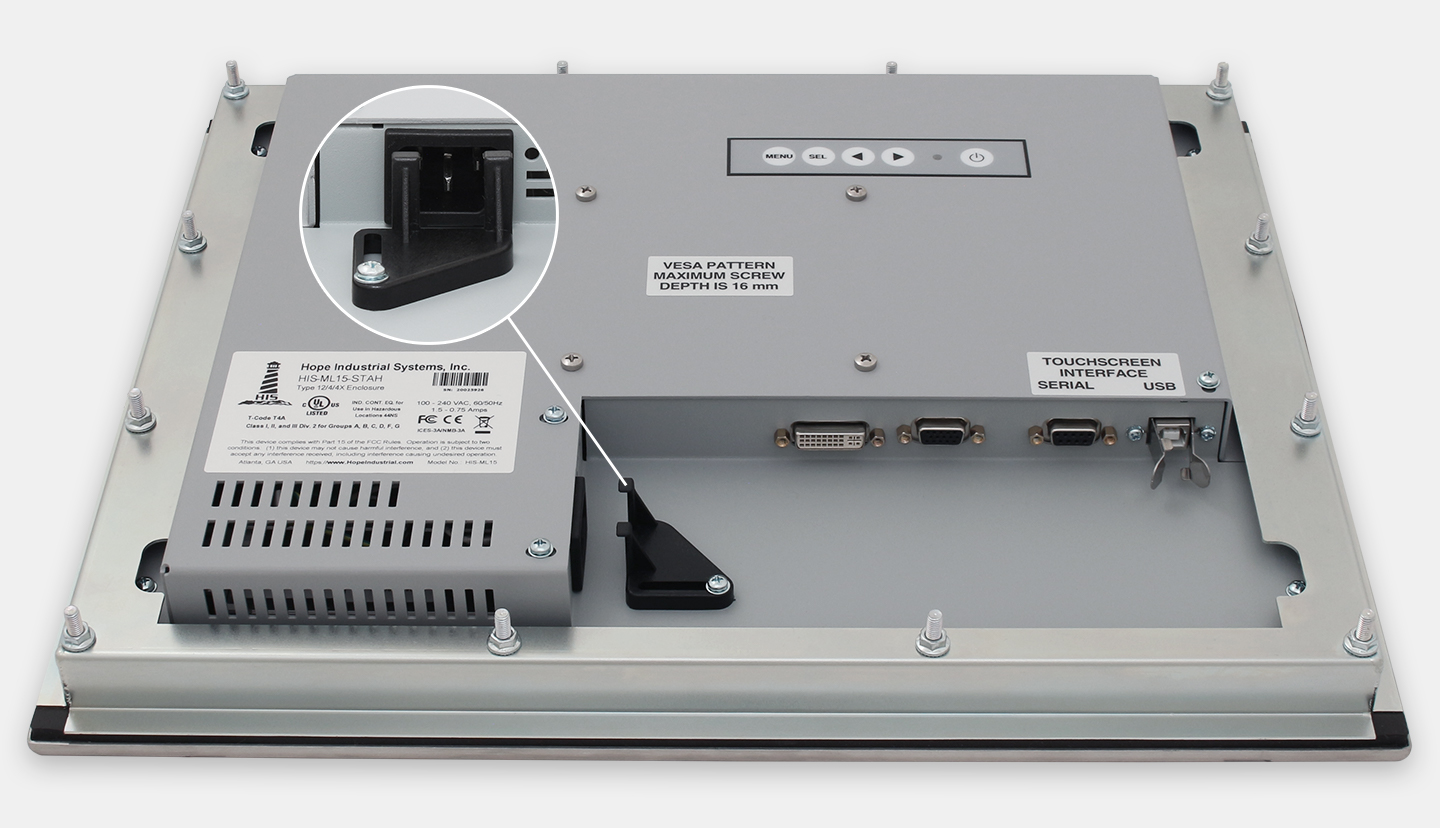

In order to meet our customers" safety requirements, Hope Industrial Systems certifies all display products to meet one or more of the following categories.

All of Hope Industrial Systems" Panel Mount Monitors (HIS-ML12, HIS-ML15, HIS-ML17, HIS-ML19, HIS-ML19.5, HIS-ML20, HIS-ML21, HIS-ML22, HIS-ML23 and HIS-ML23.8) are covered under UL 508.

All of Hope Industrial Systems" Panel Mount, Rack Mount and Rear Mount Monitors (HIS-ML12, HIS-ML/RL/RM15, HIS-ML/RL/RM17, HIS-ML/RL/RM19, HIS-ML/RL/RM19.5, HIS-ML20, HIS-ML22, HIS-ML/RM23 and HIS-ML23.8) are covered under UL 62368-1.

All of Hope Industrial Systems" Universal Mount Monitors (HIS-UM15, HIS-UM17, HIS-UM19, HIS-UM19.5, HIS-UM22, HIS-UM23 and HIS-UM23.8) and keyboards (KB-xx) are covered under UL 62368-1.

Equipment may be electronic or electromechanical in design or a combination thereof. Various groupings of equipment are covered under this category, such as flat-panel displays, LCD displays, monitors, and plasma displays.

All of Hope Industrial Systems" Panel Mount Monitors (HIS-ML12, HIS-ML15, HIS-ML17, HIS-ML19, HIS-ML19.5, HIS-ML20, HIS-ML21, HIS-ML22, HIS-ML23 and HIS-ML23.8) are covered under UL 60950 3rd Edition.

All of Hope Industrial Systems" Universal Mount Monitors (HIS-UM15, HIS-UM17, HIS-UM19, HIS-UM19.5, HIS-UM22, HIS-UM23 and HIS-UM23.8) are covered under UL 60950 3rd Edition.

Products Listed under this category include industrial control panels, which are factory wired assemblies of industrial control equipment such as motor controllers, switches, relays and auxiliary devices. The panels may include disconnect means and motor branch circuit protective devices. This category also covers industrial panel enclosures that are intended to house open type industrial control panels or individual items of industrial control equipment as noted above.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey