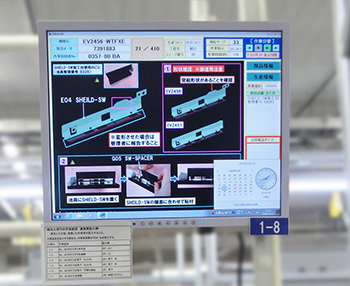

touch screen monitors used in a manufacturing line factory

Our industrial display touch screen monitors can help your factory personnel and workshops handle complex industrial tasks on intuitive factory grade touch screens. Our wide range of rugged LCD displays with multi-touch and various touch technologies such as resisitive, SAW, optical imaging, projected capacitive and infrared are tough and suitable for virtually any industrial applications. We can help you choose the best touch screen technology and solution that fits best with your needs, and close the gap between your vision and implementation of the digital factory.

Viewsonic"s Touch Screen Solutions helped us simplify the hassle of operating complex machinery in our factory. It really helped us improve our factory line operations and reduced labor input.”

SCADA is an integral part of a business, not just its operations. The flow of data from the control room to the board room must be seamless. In the past, supervisory control and manufacturing information systems have not been integrated. This is changing and companies are realizing both investments only achieve their full potential when they are capable of seamlessly working together.

We offer all the components you need to create your own unique level of supervisory data acquisition and control, from the simplest stand-alone machine to sophisticated multi-device networked production line(s), all the way to enterprise-level operations and IIoT functionalities leveraging cloud connectivity.

Automation has been on the rise since the invention of microprocessors and their widespread implementation in electronic devices starting in the 1970’s. Their ability to measure, monitor, and control industrial processes continues to propel innovations that seek to increase efficiency and productivity. Traditionally, highly trained personnel interacted with these devices using mechanical dials, switches, buttons, and levers. Over the years, as the complexity of tasks and data requirements went up, graphical screens started to be employed more frequently. This forced manufacturers to adopt keyboards and point and click devices to interact with such systems. The problem is that these devices have poor reliability in industrial applications. Enter touch screen technology.

Touch screen technology is all around us and has been making an impact on industry for years. Industrial tasks and processes that were once managed by bulky computers, low-resolution monitors, complicated interfaces, and a team of highly trained personnel are now being streamlined with industrial touch screen monitors and interactive production displays. A survey conducted by Ansell found that 65% of companies across the U.S. have implemented touch screens, and the global market for automation technology will post a turnover of $200 billion this year alone.

As the price of touchscreen displays continues to decrease, you can leverage them to automate industrial tasks, decrease equipment costs, and provide personnel with an intuitive interface to control costly machinery and equipment.

Industrial monitors, computers, and equipment have to operate continuously in the harshest conditions. A great example of this is how touch can be used to improve factory productivity in automotive manufacturing assembly lines. As the automobile industry continues to expand into new markets there has been a strong demand for highly precise manufacturing machines to streamline tasks. One of the most important tasks during assembly at an automotive plant is proper bolt tightening. This task requires precision control of torque and rotation angle, as well as intelligent monitoring of the hardness and softness of bolt material to adjust speed.

Performing this task manually is arduous, so manufacturers have implemented a number of human machine interfaces (HMI) consisting of large computers and monitors to reduce human error and improve productivity. However, the operating environment in an assembly factory poses many challenges to these systems. There are many airborne pollutants that can cause computers to crash unexpectedly. When combined with machine vibrations, dust, humidity, and electromagnetic interference, these systems have significant reliability issues.

With new touch screen technology, automobile manufacturers are overcoming these issues and facilitating more intuitive controls over complex industrial tasks, reducing labor input by up to 70%. In the bolt tightening example, industrial touch screen monitors were successfully implemented to replace slow computers, monitors, and keyboards. The implementation of these screens allowed personnel overseeing the tightening machine to accurately control angle transducers, torque monitors, and fine parameters with a high resolution multi-touch display.

If you are looking to automate tasks at your facility but are concerned about reliability and performance, touch screens are a robust solution. New advances are durable enough to withstand exposure to harsh chemicals, debris, moisture, heat and other industrial contaminants. For some technologies, even metal particulate in the air can immobilize their functionality. Touch screens can also act as both an input and output device, recognizing touch inputs from gloved fingers, so there’s no need to house bulky computer components such as a mouse, CPU, and keyboards on your factory floor. This will help you optimize space and improve safety. A recent survey finds that 91.1% of manufacturers say that integration and automation will increase operator safety.

Food processing is another challenging industrial task that requires strict adherence to hygiene and safety guidelines. These guidelines not only extend to personnel but also to the machinery and systems that control production. Traditional industrial computers and monitors in this setting face many tough challenges. Aside from having to withstand rigorous cleaning protocols, production systems have to be durable enough to handle intense heat and cold, liquid, scratching, and must operate continuously without any hesitation.

In order to comply with the strict hygiene and safety regulations of industrial-scale food processing, many manufacturers are replacing their old production displays and computers with industrial touch screen monitors. In the meat-processing line, touch screens have to be impact resistant, because personnel work with knives, heavy boxes, and chain gloves that can damage the surface. In addition, these touch screens have to be waterproof to allow for easy cleanup during the sanitation process.

New advancements in touch monitors are helping food-processors control production with intuitive interfaces that are easy for personnel to operate in the processing line. This is because touch screens present personnel with a more functional graphic user interface that makes it easy to learn procedures and command sequences.

If you are looking to reduce equipment costs at your facility, touch screen industrial monitors are the best solution. Keyboards rated for industrial use have to be made of tough, often waterproof materials, a process that could up costing more than a comparable touch panel.

Baanto’s ShadowSense technology is taking industrial touch screen panels even further. Our solutions offer your business reliable 24/7 operation in any environment and are sealed to prevent contamination from dust, liquids, debris, and industrial contaminants, so that your personnel and systems can keep up with the continuous demands of production lines. To find out more about industrial touch screen monitors and other related trends that can impact your bottom line, contact us today and join our growing community.

The NEMA 4 computer cabinet protects the enclosed PC and monitor from liquid splashes, airborne particles and physical damage. You benefit from greater systems protection and increased manufacturing uptime. With an expected lifespan of up to a decade, the industrial enclosure protects several generations of computer and delivers an excellent ROI.

Specify the most optimized set up for your needs. Choose from wall, stand or worktop mounting and an optional keyboard shelf, keyboard drawer or NEMA 4 integrated keyboard with touch pad. The manufacturing floor touch screen enclosure has two key-operated locks, giving you peace of mind about the security of your investment in any location.

Protects the PC and screen from dust, dirt, liquid splashes and physical impact. Install a touch screen with confidence in harsh environments. You benefit from reduced production downtime and increased systems protection.

Benefit from complete hardware flexibility by using the computer of your choice. Access the PC at any time to update, replace or repair it, without calling out a specialist engineer.

Seals prevent liquid ingress through the door, locks and window. Clean the manufacturing floor touch screen enclosure without risk to internal components.

All Armagard enclosures are built in accordance with International NEMA and European IP standards, guaranteeing protection from liquids and particulates.

Industrial and manufacturing plants utilize industrial-grade LCD monitors and touch screen monitors for a variety of purposes. These include process monitoring and control and motion control. Additionally, they are used in factory automation and machine vision inspection. You will find them deployed in safety, digital signage, and surveillance.

These particular uses demand an industrial-grade lcd monitor. But, retail or even commercial-grade displays will not endure many of the challenging environments. As a result, you will have to keep replacing monitors that cannot handle the challenges that industrial use presents. Specifically, ours are built with these challenges in mind. Consequently, We will provide the benefits you need for your specific application.

TRU-Vu rugged LCD monitors are ideal for such demanding environments due to their industrial-grade components. For example, they are designed to operate 24/7/365, non-stop. Have you heard of our exclusive TRU-Tuff treatment? TRU-Tuff is a unique treatment to maximize shock and vibration resistance.It ensures that every monitor will withstand the shock and vibration of industrial and manufacturing environments. To clarify, this process includes RTV silicone on all critical components and connections. All wires are dressed, tie-wrapped and secured. Furthermore, ThreadLock is applied to all screws on our TRU-Tuff models.

First, we utilize grade-A LCD panels, high-end image processing boards and superior graphics engines. This is to ensure bright, sharp images and vivid colors. Secondly, we also offer daylight viewable and high brightness Sunlight Readable monitors. These ensure excellent visibility even in direct bright sunlight, where standard monitors would be rendered useless.

Touch screen monitors are ideal for operator interface and control panels. Additionally, Human Machine Interface (HMI) and machine monitoring benefit. Open frame and panel mount monitors facilitate easy mounting. Outdoor Waterproof LCD monitors enable use in wash-down environments. Also, TRU-Vu also offers protective Anti-Reflective glass panels. These panels protect the LCD monitor screens.

Sunlight readable monitors and optically bonded monitors provide sharp images in bright sunlight. Our industrial-grade LCD monitors are also ideal for use with borescopes and video probes. Furthermore, microscopes, X-Ray, and other visual imaging systems benefit. Similarly, they are also used extensively as video image displays. Additionally, you will find them on screen printing machines and packaging machines. Finally, you may find them useful in monitoring stations. The applications are endless. Our expertise will provide you with many options for an exact solution to your requirements. We have 30 years of experience to assist you with your selections.

TRU-Vu industrial LCD monitors and industrial touch screen solutions are designed and built with industrial-grade components. Our rugged TAA compliant LCD displays deliver the highest level of quality and reliable performance both indoors and out. TRU-Vu Monitors provides rugged displays for the most challenging environments.

We are based out of Chicago with over 30 years experience in the video industry. All of our monitors are TAA Compliant as well as NDAA Compliant. Learn more Reasons to Choose TRU-Vu!

TRU-Vu Monitors offers over 200 industrial rugged TAA-Compliant monitors and industrial touch screen displays. Therefore, selecting the ideal monitor or touchscreen solution may sometimes be a bit overwhelming. Use our Advanced Search Tool to help narrow down your choices. Just enter your project specifications. The Search Tool will filter the choices to show only those computer monitor models that meet your criteria. Or just give us a call! Learn more About Us, or view our full site map. View all of our informative VIDEOS on our tech center page.

A touchscreen monitor incorporates the function of the pointing device into the display, replacing both mouse and keyboard. Interaction with the computer takes place via a system which detects contact with the screen surface.

These devices are used for the control of industrial machinery or production lines. They provide the operator a comprehensive view of the needed data and controls.

Resistive screens are differentiated by the number of wires they have. The five-wire system compensates for their fragility, making them more durable and less prone to scratches and cracks.

Capacitive models respond to the transfer of electrical charges when touched, and cannot be used while wearing a glove. They are very bright, but have a fragile surface coating. Projected capacitive versions take advantage of the proximity transfer effect. Their surface is protected by reinforced glass.

Infrared technology uses light detection, the screen responding even before it is touched. However, it offers limited resolution and is prone to accidental activation. The most common type is the surface acoustic wave (SAW) screen. It responds to a wide variety of touch techniques, some screens even taking into account the amount of pressure applied. It is very bright and has excellent resolution.

In addition to size and resolution, choice of touchscreen will depend on the conditions under which it will be used and the possible need for multi-touch capability.

The touchscreen user interfaces and software not only motivate line workers, they create a more team based approach to manufacturing execution that instills a new culture, and closed-loop of accountability in the factory

When a leading aerospace manufacturer sought a solution to manage assembly line workers with no previous manufacturing experience, they decided to try something novel that set a precedent for their future manufacturing operations management (MOM) strategy. Using the latest manufacturing software featuring situational awareness graphics on plant floor touchscreens, they quickly trained an unskilled workforce to build safety critical electronics without defects, and in-turn ramped up production within days. With the touchscreen software monitoring and controlling the hundreds of process steps needed to build the products, problems and defects could not go unchecked so error-proofing was maximized.

All manufacturing stakeholders become accountable for the quality of the product, and the efficiency or timing in which it is assembled when individuals report to their own work station touchscreens. The information created because of those individual’s interaction with the touchscreens is also broadcast to larger plant floor displays for all team members to see, critique, and ultimately act on. This manufacturing methodology emphasizes every line worker’s and supervisor’s own responsibility to contribute positively to the over-all goal of manufacturing products of high quality in an efficient way, i.e. in time with the least amount of waste produced.

The assembly line workers and area supervisors become fully-accountable for the finished product the instance they log into the user interface software with their own unique login and password.Figure 1 shows an example SmartScreen user interface with various situational awareness graphics reporting the individual line worker/work station details and real-time performance; including the scheduled production time, the real-time status of the Goal Planned Actual (GPA), and Overall Equipment Effectiveness (OEE) ensuring the line worker is aware and reminded of how they are progressing in the process steps they are required to complete within cycle time.

Since each manufacturing stakeholder is identified by her/his own credentials, they must succumb to the first level of assembly line error-proofing. The software behind the user interface touchscreen identifies the worker and then confirms (before any work can start or tools are enabled) whether that person is actually “qualified” to do the work or not. The software ensures quality by authenticating that the person has received the proper training to perform the process steps; and that they are aware of the latest quality alerts, and safety requirements unique to their workstation or processes. Much more than a simple touchscreen, at the heart of the user interface software is a manufacturing execution system (MES) and multi-dimensional database containing all the information required to build the product, along with the record of the line worker’s credentials, their training, and their historical assembly line performance up-to-the-second.

Once the line worker is verified the user interface presents her/him work instructions so they can begin performing process steps to build the product. In the case of the common fastening operation, the user interface displays the tolerances required for the fastening operation. Figure 2 shows an example SmartScreen where the line worker has progressed to “Process Step 4” requiring them to perform 20 total fastening operations within the parameter set (PSet) of 5.00 – 7.00Nm at an angle of 5 - 7°.

The line worker is motivated to perform each process step carefully and quickly since they are made aware of the cycle time remaining to complete the operation via thecycle time gauge shown at the bottom left side of the main screen. Along the bottom of the screen are colored bars that can also be configured to indicate and further re-enforce visually how they are progressing.

Once the worker begins performing the fastening operation the touchscreen displays their “Fastening Results” step-by-step with textual data and graphics that clearly show the worker’s progress (see Figure 3). Not only does the touchscreen guide the worker in each fastening operation, the system closely monitors their performance and can halt their progress, and even turn off their tools should any operation be performed outside the set parameters.

The touchscreen user interfaces and software not only motivate line workers, they create a more team based approach to manufacturing execution that instills a new culture, and closed-loop of accountability in the factory where all manufacturing stakeholders are made accountable for what they contribute. The data generated by the line workers activities and the data recorded from the machines also becomes indispensable given its’ importance as business intelligence and manufacturing intelligence reports that are output and essential for further optimizing manufacturing operations.

PINpoint V5 software is meticulously designed and tested to "Information Technology Infrastructure Library" (ITIL) standards before any official version release. Thoroughly proven the software is in use daily around the World in multiple languages by leading manufacturers.

Headquartered in Burlington, Ontario, PINpoint services industry internationally from their offices in Canada, the United States, and China. For more information, please call: +1 (905) 639-8787, email: sales@pinpointinfo.com or visit: http://pinpointinfo.com/

Anthony offers over fourteen years of manufacturing optimization knowledge, with an aptitude for solving problems which increase business and manufacturing efficiency. He has successfully provided solutions to various multinational manufacturers involving the latest technology in sensors, laser (detection, measurement, welding, cutting, and marking systems), PLC, machine vision, digital microscope, and manufacturing software.

Let"s listen to Arvind Krishnan, industry analyst at Lifecycle Insights and Michael Mayr, Industrial Equipment Sales Strategy Expert at Dassault Systèmes. They will discuss the robot industry and how startups can succeed in this market.

Our unique open-frame design is available in two convenient sizes and offers the optimal trade-off between screen size and cost. The 19” (5:4 ratio) provides excellent screen area and plenty of space for most applications. Or for those wanting even more screen area, the 21.5” (16:9 ratio) wide screen layout presents a large amount of information in a small amount of vertical space. These popular sizes allow information to be presented in the same format as your office monitors. Both screens can be mounted in both portrait and landscape modes.

Many mounting options provide easy integration into your industrial automation equipment, cabinetry, kiosk enclosure or other equipment. The VESA mounting holes on the rear, and the additional mounting points on the tops and sides, provide you with flexibility to install them perfectly in your environment. Also, the clever thin design enables them to easily fit into small spaces.

Projected Capacitive (PCAP) technology is the same fast, reliable technology that is used in most modern smartphones. When delivered on our toughened glass, with built-in scratch resistance, 10 point multitouch is a solid and robust technology that is ideally suited to industrial environments.

Touch Think VESA mount touch screen monitors with IP65 rated dustproof and waterproof make them widely used in a variety of applications. Especially, the front waterproof features are popular in industrial sites. Far more, our VESA mount monitors also support fully IP65 protection customization.

Due to the particularity of the use environment, the industrial monitors need to run for a long time, or even without shutting down for a 24/7 long time, which need the monitors to run for a long time and can maintain stability and reliable lifespan.

VESA mount industrial touch monitors are widely used in digital factories" smart production lines. And there is a variety of equipment are installed in workshops, thus release much electromagnetic and cause signal interference. Electromagnetic interference not only affects the normal operation of electronic equipment but even causes damage to certain components in electronic equipment.

Our industrial displays have passed the electromagnetic compatibility test and certification to ensure work normally without the surrounding electromagnetic interference. At the same time, the monitors also ensure that they won"t cause electromagnetic interference to other surrounding equipment and affect the normal operation of other equipment.

Touch Think industrial touch monitors support VESA 75/100mm installation. The VESA mount monitor is composed of a display, a cantilever, and a control panel, and supports a variety of coupling connectors for cantilever support profiles, which is suitable for most factory use scenarios.

Compared with the traditional installation, VESA mount monitors have the advantages of being beautiful, practical, strong applicability, easy to use, etc.

The Touch Think 17-inch 4th new generation of industrial touch screen monitor delivers high-quality picturesfor users no matter for indoor or outdoor devices. The monitors are designed for multi applications andwithstand a wide operating temperature range.

●Widely used in industrial automation, kiosk, factory production line, self-service vending machines, medical self-service devices, public self-help service devices, etc.

Just as there are different types of touch screens for different purposes, there are also different types of touch screen monitors for specific industries. When it comes to industrial touch screens, these are designed to meet the specific needs of industrial applications. This means that they need to be durable enough to withstand the rigors of the industrial environment, as well as being able to function in extreme temperatures.

Construction and architecture are two industries that heavily rely on industrial grade monitors. These monitors need to be durable and able to withstand constant use. Industrial monitors are used to create and view architectural drawings, as well as to control construction equipment. They are an essential part of both industries and need to be able to withstand a lot of wear and tear.

There are a number of industries that rely on industrial strength touch screen displays to function properly. Retail and hospitality are two such industries. In the retail sector, industrial monitors are used to keep track of inventory, process sales, and provide customer service. In the hospitality industry, industrial monitors are used to manage reservations, check guests in and out, and provide information about amenities and services. Both industries require monitors that are durable and able to withstand constant use.

Healthcare is one of the most important industries in the world, and it relies heavily on industrial monitors. Industrial strength touch screens are designed to withstand the rigors of heavy use, and they are an essential part of healthcare facilities. Such devices could be used in kitchens, in logistics, in maintenance and supply inventory, in addition to specific medical applications.

There are a variety of different types of industrial strength touch screen monitors available, and each has its own advantages and disadvantages. Healthcare facilities should carefully consider their needs before selecting an industrial strength touch screen monitor.

The manufacturing and automotive industries rely heavily upon sturdy capacitive multi touch and projected capacitive displays in addition to sunlight readable or high brigtness monitors with a led backlight. These monitors can be used to control machinery and keep track of production. They can also be used in warehouses and distribution centers to track inventory and ensure that goods are being shipped out correctly. In addition, rugged touch screens can be used in hospitals and clinics to keep track of patient information and medical records.

The food and beverage industry is one of the most important industries in the world. It is responsible for providing food and drink to billions of people every day. The industry is also one of the most demanding, with a constant need for innovation and new ideas.

One of the most important aspects of the food and beverage industry is the production line. This is where food and drink are prepared for consumption. The production line is a highly demanding environment, with a need for speed and efficiency.

Touch screen monitors with DVI D input and VGA input with a solid LCD panel mount are an essential part of the production line. They provide a quick and easy way to input data and track progress. They are also extremely durable, able to withstand the demands of the production line.

The government and military can benefit from industrial strength touch screen monitors because they are designed to withstand heavy use and abuse, and are built to last. They offer superior durability and performance, and are an ideal choice for industries that require reliable and tough equipment.

Transportation is one industry that requires industrial strength touch screen monitors. These monitors are often used in high-traffic areas, such as airports and train stations. They are designed to withstand heavy use and can be used in a variety of applications, such as check-in, baggage claim, and ticketing.

There is a growing need for more durable hardware in many industries. The benefits of using industrial touch screen monitors and computers can be seen in a growing number industries that particularly need industrial strength touch screen monitors.

When it comes to industrial PCs and LCD monitors, there are a few key factors that make them more durable than consumer PCs. First, industrial PCs are built to withstand harsher environments. They’re designed for use in factories, warehouses, and other industrial settings where they might be subjected to dust, vibration, and extreme temperatures. Second, industrial PCs and monitors use higher-quality components than consumer PCs. This includes things like stronger enclosures, higher-quality displays, and more rugged connectors. Finally, industrial PCs and monitors are often backed by longer warranties than consumer PCs. This is because they’re built to last longer and withstand more abuse.

An industrial PC or monitor is designed for durability and reliability in demanding environments. They are built to withstand shock, vibration, dust, and extreme temperatures. This makes them ideal for use in industrial settings where traditional consumer PCs and LCD monitors would not be able to withstand the conditions. Industrial PCs also have a longer lifespan than consumer PCs, making them a more cost-effective solution in the long run.

Industrial PCs and monitors are designed to be more durable than consumer PCs for a number of reasons. First, they are typically made from higher-quality materials that can withstand more wear and tear. Second, they often have better cooling systems to prevent overheating. Finally, they are often designed with redundant components so that if one part fails, the whole system does not have to be replaced.

Industrial PCs and monitors are designed to be more rugged and resistant to the elements than consumer PCs. They typically have a stronger casing, more durable components, and are designed to operate in harsher environments. This makes them ideal for use in industrial settings where they may be exposed to dust, dirt, vibration, and extreme temperatures. Industrial PCs and monitors also usually have longer lifespans than consumer PCs, making them a more cost-effective solution in the long run.

An industrial PC or monitor is more durable than a consumer PC for a variety of reasons. Firstly, industrial PCs and monitors are designed for harsher environments, with features such as thicker casing and tempered glass that can withstand higher temperatures and vibrations. Secondly, industrial PCs and monitors often have more robust power supplies and cooling systems to prevent overheating. Finally, industrial PCs and monitors typically have longer lifespans due to higher-quality components and better build quality.

Industrial PCs and monitors are designed to be more durable and reliable than consumer PCs. They are built to withstand harsh environments and are made with high-quality components that can withstand extended use. Industrial PCs and monitors are also typically backed by a more robust warranty than consumer PCs. This is because businesses and factories need them to be more durable and reliable in order to maintain productivity.

Touchscreens are not the newest technology since the monitor technology has been in use since the 1970s and recent advances in mobile phone technology, computer tablets and PDA’s have seen them receive a boost in recent years.

With a quickly expanding digital signage market which is expected to continue to expand, they will become the norm for desktops& rugged monitors and other screen signage applications.

A recent report from industry analysts suggests that touchscreen will play a key role in the digital advertising or signage market in the coming years with revenues from these touch displays expecting to reach a value of $101.6 Billion by the year 2026, growing with a CAGR of 9.1% between 2018 and 2026.

Much of this increase, the report concludes, will have been generated for the demand for touchscreens in mobile and personal computing but also, the report suggests, many traditional LCD or plasma screens currently used in signage and rugged environments are likely to be replaced with LCD technology.

With innovations like the iPhone and the latest Microsoft Windows operating system being very touch-orientated, combined with the falling costs of the technology, we may even see the costs of conventional displays and industrial LCD monitors greatly diminishing over time. This is one of the goals of faytech NA – improving value and performance while offering competitive pricing.

The touch screen is versatile for digital signage in that it allows interactivity that is not possible with conventional LCD unless they are combined with a keyboard or other input device.

However, having a single flat screen that acts both as a dynamic output and input device for little additional cost is far more attractive to the digital signage market than conventional output.

One area that industrial touch screen monitor may struggle to operate safely in, however, is in the digital outdoor signage market. As touch monitors need to have an exposed screen, protecting the surface from the natural elements can be problematic. Thanks to the development of enclosures, we can eliminate that problem.

In any setting that it is used, the industrial touchscreen monitor offers the advantage of durability. Aside from being both an input and output device, it is also something that can weather everyday wear and tear more effectively. In fact, these machines are comparably more resistant to possible causes of damage such as water and grease and they are also more electrically stable.

When choosing a industrial touchscreen display to use for your store, laboratory, fabrication plant, shop or office, consider the volume of people who will probably be using it as well as the level of clarity and sensitivity to touch that will make the machine most useful both to you as a business owner and especially to your customers or clients. Even for a small business owner, there’s a lot that you can do to make a difference among your target customers and prospect customers.

Using an LCD touch device in your shop is one example when a Faytech North America touch screen solution would be handy. With this, there is a better way of managing their queries regarding what you offer, and you’ll also have a better way of giving them the information they need. You will have the advantage of the technology at your fingertips, and you will be able to use it not just for your personal pleasure but also for the growth of your business.

In most cases, touchscreen manufacturers have simply become more competitive. This means lower prices and better quality for all of us! Imagine the convenience you’ll be giving your clients when you have a touch-screen monitor in your store. Whether it’s a bookshop, a boutique or other businesses, people can just come and use the screen to inquire about your available products. In a bookshop, for example, they can inquire about the availability of a certain book they like. They can go through the screen and find out about the details of such a book, what it’s all about, who the author is and etc.

In a boutique, using a Faytech North America solution, people can just choose the item number perhaps and check the available sizes or if there are other such items available. Imagine also the amount of effort and time that you will be saving when you have a self-serving device in your store. You don’t have to answer people’s queries yourself, and you don’t have to stop in the middle of sorting through your accounts receivables just to answer their questions. Especially for small businesses, the amount of time saved really means a lot. Instead of having to go and check if there is a certain size available for a certain dress, the customer can easily run through your inventory on a computer and immediately know the answer.

Having an interactive device in your store is a win-win situation for both you, as the business owner, and your customer. When people don’t have to bug you about questions the computer can answer and when you don’t have to stop in the middle of a crucial task to entertain questions, you are already doing each other a favor. This favor is simply to perform your role better in the businesses equation that you have found yourself in. Touch screen displays are also found in the retail and food industries.

Having a touch device to quickly take orders, receive payments, request information, preview product or service details or view merchandise not only saves valuable desk space but provides an intuitive interface for employees and customers. Recently flat-panel touchscreen monitors have replaced CRT or larger displays saving even more space.

The contrast on touch monitors is not always as good as their regular counterpart. This is because of the various touch sensors (capacitive or resistive) that need to be included to replace a keyboard or a mouse.

Another setback is the cost. While the cost is generally low, touch screen display still cost more than regular ones because of the additional built-in sensors. Even with these minor cost increases, they are becoming popular with consumers. As the demand increases, the cost will go down and the technology will improve to the point where nearly each of them is touch-enabled.

You don’t need to pay high prices for a high-quality industrial monitor or touch screen; you now have an affordable option. We are extremely confident in our products and back them up with a standard five-year warranty and a 30-day total satisfaction guarantee.

TDS (Hechuang Technology Company) was founded in 2003. Headquarter located in SHENZHEN, IT manufacturing center in China. In the past 10+ years, TDS focused on develop and product Touch Display products. Now we have owned 6 product-line and 10+ kinds of products including Desktop Touch Monitors, Kiosks Touch Monitors (Open-Framed and Embedded), Touch Computer (All-in One) and Touch Screen (Projected Capacitive, Infrared and 5-Wire Resistive). TDS products has been widely applicate in Banking, Transportation, Logistics Industry and Public Information Self-Service Equipment in China.

TDS has various number of patents including two Touch Display shapes, 6 Touch Management software, Touch Drive and Touch Controller. TDS Products has been authorized by PCC, CE, RoHS and IP65 agency.

Our open-frame monitors are no slouch when it comes to performance despite being contained in such a small housing, however; they’re specifically built for maximum reliability, durability, and user appeal for years to come without running into a slowdown or other forms of trouble. They’re available in a multitude of designs to suit various tastes and needs, including resistive and capacitive multi-touch configurations. Each of our open-frame monitors is compatible with Linux, Windows 7 and Mac operating systems (please note that a special driver is required to enable touch functionality on Mac OS).

There are all sorts of exciting and intuitive variations of our open-frame displays available, including the Mimo UM-1080-OF, which is an open-frame 10.1 USB-compatible monitor. Built with a high-grade IPS panel, it provides a stellar multimedia experience with a 180-degree wide viewing angle. Other products include Mimo UM-760R-OF resistive touchscreen monitor, which is a highly streamlined system built for instant integration with existing display enclosures and is perfect for everything from retail applications to gaming. Regardless which open frame touch screen monitor you decide to select, it will also be fully compatible with our USB Extender for single-cable connections that carry power, video, and audio in a clutter-free manner.

Do you need a new input and/or display device for a POS system, digital signage, or multimedia space? Regardless of your application, Mimo’s selection of open-frame displays are designed for absolute convenience and simplified integration with your existing setup, which helps to save on needless renovations, equipment upgrades, or other expenses. Cost-effective, built to last for years, and designed to handle whatever you throw at them, they’re made to suit essentially any application you can think of perfectly. Feel free to browse our selection of open frame touch screen monitors below and discover the one that’s perfect for your needs and budget.

Manufacturing the highest quality monitors starts with training our staff so they possess necessary skills before they step onto the factory floor. We have established a training center within our factory where new employees get these skills and veteran employees can acquire new ones. For example, several days of training and a written exam is required before new employees can work on basic assembly tasks. From then supervised training in the factory is required before trainees can work by themselves. More advanced skills such as safety inspections can require even more training.

Our training consists of studying written materials followed by "hands-on" practice where workers perfect the skills they will use in the factory. Each time a worker gains a new skill, they receive a sticker for that skill, which is displayed on a board in the training center.

Many EIZO manufacturing employees have been with the company for more than a decade. Worker retention is essential to performing specialized tasks. Putting personal importance and worth in our manufacturing process has the added benefits of encouraging creativity, evolution, and making our factory processes ever more efficient, environmentally sound, and globally competitive.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey