touch screen monitors used in a manufacturing line free sample

Just as there are different types of touch screens for different purposes, there are also different types of touch screen monitors for specific industries. When it comes to industrial touch screens, these are designed to meet the specific needs of industrial applications. This means that they need to be durable enough to withstand the rigors of the industrial environment, as well as being able to function in extreme temperatures.

Construction and architecture are two industries that heavily rely on industrial grade monitors. These monitors need to be durable and able to withstand constant use. Industrial monitors are used to create and view architectural drawings, as well as to control construction equipment. They are an essential part of both industries and need to be able to withstand a lot of wear and tear.

There are a number of industries that rely on industrial strength touch screen displays to function properly. Retail and hospitality are two such industries. In the retail sector, industrial monitors are used to keep track of inventory, process sales, and provide customer service. In the hospitality industry, industrial monitors are used to manage reservations, check guests in and out, and provide information about amenities and services. Both industries require monitors that are durable and able to withstand constant use.

Healthcare is one of the most important industries in the world, and it relies heavily on industrial monitors. Industrial strength touch screens are designed to withstand the rigors of heavy use, and they are an essential part of healthcare facilities. Such devices could be used in kitchens, in logistics, in maintenance and supply inventory, in addition to specific medical applications.

There are a variety of different types of industrial strength touch screen monitors available, and each has its own advantages and disadvantages. Healthcare facilities should carefully consider their needs before selecting an industrial strength touch screen monitor.

The manufacturing and automotive industries rely heavily upon sturdy capacitive multi touch and projected capacitive displays in addition to sunlight readable or high brigtness monitors with a led backlight. These monitors can be used to control machinery and keep track of production. They can also be used in warehouses and distribution centers to track inventory and ensure that goods are being shipped out correctly. In addition, rugged touch screens can be used in hospitals and clinics to keep track of patient information and medical records.

The food and beverage industry is one of the most important industries in the world. It is responsible for providing food and drink to billions of people every day. The industry is also one of the most demanding, with a constant need for innovation and new ideas.

One of the most important aspects of the food and beverage industry is the production line. This is where food and drink are prepared for consumption. The production line is a highly demanding environment, with a need for speed and efficiency.

Touch screen monitors with DVI D input and VGA input with a solid LCD panel mount are an essential part of the production line. They provide a quick and easy way to input data and track progress. They are also extremely durable, able to withstand the demands of the production line.

The government and military can benefit from industrial strength touch screen monitors because they are designed to withstand heavy use and abuse, and are built to last. They offer superior durability and performance, and are an ideal choice for industries that require reliable and tough equipment.

Transportation is one industry that requires industrial strength touch screen monitors. These monitors are often used in high-traffic areas, such as airports and train stations. They are designed to withstand heavy use and can be used in a variety of applications, such as check-in, baggage claim, and ticketing.

There is a growing need for more durable hardware in many industries. The benefits of using industrial touch screen monitors and computers can be seen in a growing number industries that particularly need industrial strength touch screen monitors.

When it comes to industrial PCs and LCD monitors, there are a few key factors that make them more durable than consumer PCs. First, industrial PCs are built to withstand harsher environments. They’re designed for use in factories, warehouses, and other industrial settings where they might be subjected to dust, vibration, and extreme temperatures. Second, industrial PCs and monitors use higher-quality components than consumer PCs. This includes things like stronger enclosures, higher-quality displays, and more rugged connectors. Finally, industrial PCs and monitors are often backed by longer warranties than consumer PCs. This is because they’re built to last longer and withstand more abuse.

An industrial PC or monitor is designed for durability and reliability in demanding environments. They are built to withstand shock, vibration, dust, and extreme temperatures. This makes them ideal for use in industrial settings where traditional consumer PCs and LCD monitors would not be able to withstand the conditions. Industrial PCs also have a longer lifespan than consumer PCs, making them a more cost-effective solution in the long run.

Industrial PCs and monitors are designed to be more durable than consumer PCs for a number of reasons. First, they are typically made from higher-quality materials that can withstand more wear and tear. Second, they often have better cooling systems to prevent overheating. Finally, they are often designed with redundant components so that if one part fails, the whole system does not have to be replaced.

Industrial PCs and monitors are designed to be more rugged and resistant to the elements than consumer PCs. They typically have a stronger casing, more durable components, and are designed to operate in harsher environments. This makes them ideal for use in industrial settings where they may be exposed to dust, dirt, vibration, and extreme temperatures. Industrial PCs and monitors also usually have longer lifespans than consumer PCs, making them a more cost-effective solution in the long run.

An industrial PC or monitor is more durable than a consumer PC for a variety of reasons. Firstly, industrial PCs and monitors are designed for harsher environments, with features such as thicker casing and tempered glass that can withstand higher temperatures and vibrations. Secondly, industrial PCs and monitors often have more robust power supplies and cooling systems to prevent overheating. Finally, industrial PCs and monitors typically have longer lifespans due to higher-quality components and better build quality.

Industrial PCs and monitors are designed to be more durable and reliable than consumer PCs. They are built to withstand harsh environments and are made with high-quality components that can withstand extended use. Industrial PCs and monitors are also typically backed by a more robust warranty than consumer PCs. This is because businesses and factories need them to be more durable and reliable in order to maintain productivity.

Touchscreens are not the newest technology since the monitor technology has been in use since the 1970s and recent advances in mobile phone technology, computer tablets and PDA’s have seen them receive a boost in recent years.

With a quickly expanding digital signage market which is expected to continue to expand, they will become the norm for desktops& rugged monitors and other screen signage applications.

A recent report from industry analysts suggests that touchscreen will play a key role in the digital advertising or signage market in the coming years with revenues from these touch displays expecting to reach a value of $101.6 Billion by the year 2026, growing with a CAGR of 9.1% between 2018 and 2026.

Much of this increase, the report concludes, will have been generated for the demand for touchscreens in mobile and personal computing but also, the report suggests, many traditional LCD or plasma screens currently used in signage and rugged environments are likely to be replaced with LCD technology.

With innovations like the iPhone and the latest Microsoft Windows operating system being very touch-orientated, combined with the falling costs of the technology, we may even see the costs of conventional displays and industrial LCD monitors greatly diminishing over time. This is one of the goals of faytech NA – improving value and performance while offering competitive pricing.

The touch screen is versatile for digital signage in that it allows interactivity that is not possible with conventional LCD unless they are combined with a keyboard or other input device.

However, having a single flat screen that acts both as a dynamic output and input device for little additional cost is far more attractive to the digital signage market than conventional output.

One area that industrial touch screen monitor may struggle to operate safely in, however, is in the digital outdoor signage market. As touch monitors need to have an exposed screen, protecting the surface from the natural elements can be problematic. Thanks to the development of enclosures, we can eliminate that problem.

In any setting that it is used, the industrial touchscreen monitor offers the advantage of durability. Aside from being both an input and output device, it is also something that can weather everyday wear and tear more effectively. In fact, these machines are comparably more resistant to possible causes of damage such as water and grease and they are also more electrically stable.

When choosing a industrial touchscreen display to use for your store, laboratory, fabrication plant, shop or office, consider the volume of people who will probably be using it as well as the level of clarity and sensitivity to touch that will make the machine most useful both to you as a business owner and especially to your customers or clients. Even for a small business owner, there’s a lot that you can do to make a difference among your target customers and prospect customers.

Using an LCD touch device in your shop is one example when a Faytech North America touch screen solution would be handy. With this, there is a better way of managing their queries regarding what you offer, and you’ll also have a better way of giving them the information they need. You will have the advantage of the technology at your fingertips, and you will be able to use it not just for your personal pleasure but also for the growth of your business.

In most cases, touchscreen manufacturers have simply become more competitive. This means lower prices and better quality for all of us! Imagine the convenience you’ll be giving your clients when you have a touch-screen monitor in your store. Whether it’s a bookshop, a boutique or other businesses, people can just come and use the screen to inquire about your available products. In a bookshop, for example, they can inquire about the availability of a certain book they like. They can go through the screen and find out about the details of such a book, what it’s all about, who the author is and etc.

In a boutique, using a Faytech North America solution, people can just choose the item number perhaps and check the available sizes or if there are other such items available. Imagine also the amount of effort and time that you will be saving when you have a self-serving device in your store. You don’t have to answer people’s queries yourself, and you don’t have to stop in the middle of sorting through your accounts receivables just to answer their questions. Especially for small businesses, the amount of time saved really means a lot. Instead of having to go and check if there is a certain size available for a certain dress, the customer can easily run through your inventory on a computer and immediately know the answer.

Having an interactive device in your store is a win-win situation for both you, as the business owner, and your customer. When people don’t have to bug you about questions the computer can answer and when you don’t have to stop in the middle of a crucial task to entertain questions, you are already doing each other a favor. This favor is simply to perform your role better in the businesses equation that you have found yourself in. Touch screen displays are also found in the retail and food industries.

Having a touch device to quickly take orders, receive payments, request information, preview product or service details or view merchandise not only saves valuable desk space but provides an intuitive interface for employees and customers. Recently flat-panel touchscreen monitors have replaced CRT or larger displays saving even more space.

The contrast on touch monitors is not always as good as their regular counterpart. This is because of the various touch sensors (capacitive or resistive) that need to be included to replace a keyboard or a mouse.

Another setback is the cost. While the cost is generally low, touch screen display still cost more than regular ones because of the additional built-in sensors. Even with these minor cost increases, they are becoming popular with consumers. As the demand increases, the cost will go down and the technology will improve to the point where nearly each of them is touch-enabled.

The touchscreen user interfaces and software not only motivate line workers, they create a more team based approach to manufacturing execution that instills a new culture, and closed-loop of accountability in the factory

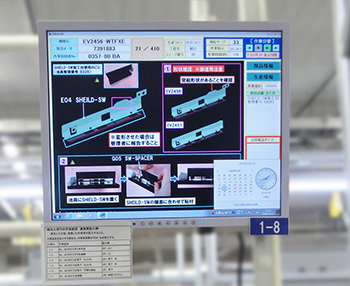

When a leading aerospace manufacturer sought a solution to manage assembly line workers with no previous manufacturing experience, they decided to try something novel that set a precedent for their future manufacturing operations management (MOM) strategy. Using the latest manufacturing software featuring situational awareness graphics on plant floor touchscreens, they quickly trained an unskilled workforce to build safety critical electronics without defects, and in-turn ramped up production within days. With the touchscreen software monitoring and controlling the hundreds of process steps needed to build the products, problems and defects could not go unchecked so error-proofing was maximized.

All manufacturing stakeholders become accountable for the quality of the product, and the efficiency or timing in which it is assembled when individuals report to their own work station touchscreens. The information created because of those individual’s interaction with the touchscreens is also broadcast to larger plant floor displays for all team members to see, critique, and ultimately act on. This manufacturing methodology emphasizes every line worker’s and supervisor’s own responsibility to contribute positively to the over-all goal of manufacturing products of high quality in an efficient way, i.e. in time with the least amount of waste produced.

The assembly line workers and area supervisors become fully-accountable for the finished product the instance they log into the user interface software with their own unique login and password.Figure 1 shows an example SmartScreen user interface with various situational awareness graphics reporting the individual line worker/work station details and real-time performance; including the scheduled production time, the real-time status of the Goal Planned Actual (GPA), and Overall Equipment Effectiveness (OEE) ensuring the line worker is aware and reminded of how they are progressing in the process steps they are required to complete within cycle time.

Since each manufacturing stakeholder is identified by her/his own credentials, they must succumb to the first level of assembly line error-proofing. The software behind the user interface touchscreen identifies the worker and then confirms (before any work can start or tools are enabled) whether that person is actually “qualified” to do the work or not. The software ensures quality by authenticating that the person has received the proper training to perform the process steps; and that they are aware of the latest quality alerts, and safety requirements unique to their workstation or processes. Much more than a simple touchscreen, at the heart of the user interface software is a manufacturing execution system (MES) and multi-dimensional database containing all the information required to build the product, along with the record of the line worker’s credentials, their training, and their historical assembly line performance up-to-the-second.

Once the line worker is verified the user interface presents her/him work instructions so they can begin performing process steps to build the product. In the case of the common fastening operation, the user interface displays the tolerances required for the fastening operation. Figure 2 shows an example SmartScreen where the line worker has progressed to “Process Step 4” requiring them to perform 20 total fastening operations within the parameter set (PSet) of 5.00 – 7.00Nm at an angle of 5 - 7°.

The line worker is motivated to perform each process step carefully and quickly since they are made aware of the cycle time remaining to complete the operation via thecycle time gauge shown at the bottom left side of the main screen. Along the bottom of the screen are colored bars that can also be configured to indicate and further re-enforce visually how they are progressing.

Once the worker begins performing the fastening operation the touchscreen displays their “Fastening Results” step-by-step with textual data and graphics that clearly show the worker’s progress (see Figure 3). Not only does the touchscreen guide the worker in each fastening operation, the system closely monitors their performance and can halt their progress, and even turn off their tools should any operation be performed outside the set parameters.

The touchscreen user interfaces and software not only motivate line workers, they create a more team based approach to manufacturing execution that instills a new culture, and closed-loop of accountability in the factory where all manufacturing stakeholders are made accountable for what they contribute. The data generated by the line workers activities and the data recorded from the machines also becomes indispensable given its’ importance as business intelligence and manufacturing intelligence reports that are output and essential for further optimizing manufacturing operations.

PINpoint V5 software is meticulously designed and tested to "Information Technology Infrastructure Library" (ITIL) standards before any official version release. Thoroughly proven the software is in use daily around the World in multiple languages by leading manufacturers.

Headquartered in Burlington, Ontario, PINpoint services industry internationally from their offices in Canada, the United States, and China. For more information, please call: +1 (905) 639-8787, email: sales@pinpointinfo.com or visit: http://pinpointinfo.com/

Anthony offers over fourteen years of manufacturing optimization knowledge, with an aptitude for solving problems which increase business and manufacturing efficiency. He has successfully provided solutions to various multinational manufacturers involving the latest technology in sensors, laser (detection, measurement, welding, cutting, and marking systems), PLC, machine vision, digital microscope, and manufacturing software.

Imagine a global, end-to-end partner for industry - dedicated to solving your problems so you can drive your business forward. We can. On February 6, 2023, we officially changed our name to RS. It"s just one way we"re evolving to make our partnership and doing business with us even more rewarding. As RS, you have access to more support, more expertise, and more possibilities for your big and small projects - from concept and design to build and maintenance. Going forward, you"ll see the RS logo on our website, social media, communications, and packaging. And rest assured, our current systems and procedures will remain intact to seamlessly process your order.

Interactive touchscreen experiences are a fantastic way to connect with customers, whether at events, tradeshows and exhibitions or in your showroom or marketing suite. They are intuitive to use, look great, by creating a sense of WOW, and can help to project a brand as innovative and dynamic.

Not only that, but they can really help to simplify complex ideas, products and services and demonstrate them visually. Which goes a long way to making them memorable and quick to understand.

And where businesses may not be able to meet with customers or attend events, interactive experiences are ideal for staying connected with customers. Depending on the software, they can be shared over the web or used to create virtual demo spaces for customers to explore in their own time.

The hardware – This is the physical touchscreen itself and also the PC the visual experience runs on. There are lots of different types of touchscreens, from wall-mounted to touch-tables, stand-mounted as well as custom-built enclosures.

The visual experience – This is the content shown on the screen, which people will interact with. It’s this visual content that you’ll need software to create.

Before embarking on a project, it’s important to clarify your business objectives. This is crucial as the answers may determine what software you use to create your experience. If you choose the wrong software option at the beginning you may have to start the whole project again to achieve the result you need.

When developing any Interactive experience – whether that be a sales tool or touchscreen experience – for our clients, we run an Initial workshop – the Customer-First Blueprint® – to reflect upon our client’s objectives. It helps clients to think about:

Specialist software, which is designed for building touchscreen experiences and interactive digital signage. We create our own bespoke software and also use Showpad, Intuiface, Tumult Hype and Ventuz

We have had years of developing experience using all of the above for clients. Whilst many of the software options can be developed in-house, our experienced team of designers and developers have encountered the highs and lows of all these solutions for every scenario. Resulting in a high-quality touchscreen experience in a fraction of the time.

A Progressive Web App(PWA) uses the same language, HTML, Javascript and CSS, as a website and the functionality is built in a very similar way. It can be run over the internet and uses a standard browser. We use Google Chrome in Kiosk mode, which enables the experience to be run full-screen, so you don’t see the browser menu and scroll bars.

But that is where the similarities between a Progressive Web App and a website end. A PWA is a very sophisticated option, allowing you to create almost any type of experience you can imagine. You can include videos, PDFs, presentations, 3D models, Augmented Reality and Virtual Reality into the experience. Unlike a website, a PWA is built with a Touchscreen user in mind.

A touchscreen is a very different user experience for the customer, even for those of us used to Smartphones. You’re generally dealing with a much bigger screen, which impacts on the layout. Your audience will be using their finger rather than a mouse to move around and interact. Clear prompts and navigation are essential to make it obvious to the user what they need to do. Small differences can have quite far-reaching consequences.

A PWA can be run through any browser making it accessible. It can also work offline, so an internet connection isn’t necessary for the touchscreen experience to work

It can easily connect to other systems to pull or push information backwards and forwards. For example, it could connect to an organisation’s Content Management System so any content within those systems can be automatically pulled into your touchscreen experience. Similarly, if you collect customer information through your touchscreen this can be automatically posted back into your CMS for future marketing or sales campaigns

There are specialist software applications for creating touchscreen experiences. Programs such as Intuiface and ShowPad are well-established applications for creating professional touchscreen experiences.

Experiences can be created for any touchscreen type from tablets up to video walls, so you can make experiences as large as you like to cover multiple displays.

It is fairly straightforward to create simple interactive experiences for small businesses or projects. But it can get very complicated if you require something more complex

If you’re not planning on using a specialist agency you may be limited to the default templates, unless you want to spend some time learning the platforms

Some are only designed to work at one screen resolution, they are not responsive systems (Intuiface is an example of this). This means if you are going to use your touchscreen experience on a large touchscreen, a laptop and tablets most likely they will have different screen ratios (16×9, 16×10 or 4×3 etc.) So although the experience will still work, it won’t fill the screen on all those devices

The editing software has a license fee to use and each device that will run the touchscreen experience also needs a licence. So, if you have 10 touchscreens running your experience you’ll need 10 licences, so it could be quite expensive.

This option involves creating an experience using online templates that are designed to perform a certain function, such as displaying product information or advertising.

You simply drag and drop the information you need into the template of the web portal and connect your digital signage screens over the internet to the portal, which then displays your content on your digital screens.

You are limited by the functionality of the system though, so it will only do certain things within the template but some do have a lot of options to cover most use cases

As it is templated, you won’t have a lot of control over the branding and layout of the experience> But bear in mind, this may not be an issue when the end goal is to create a very simple user experience

Interactivity is very limited so the user experience can be quite simple and a little boring, you certainly wouldn’t call them immersive. So, if you’re trying to create a personalised customer experience through a touchscreen we’d avoid these systems.

Don’t laugh or scoff but PowerPoint has very sophisticated interactive features which will let you create touchscreen experiences. You can put a lot of things into them such as video, images, PDFs and 3D elements.

With a good PowerPoint developer (such as POPcomms) you’d be hard-pressed to spot the difference between a PowerPoint experience or a custom-built one with HTML or Intuiface

Again, we recommend using a presentation design agency or touchscreen specialist. It would still be quite an advanced presentation you’d be creating, and you may not have the in-house skills yourself.

We hope this has been useful and we’ve managed to shed some light on the various options available when creating an interactive touchscreen experience.

We are platinum certified Intuiface creative partner (one of only 2 in the UK) and a creative partner of Showpad so have plenty of expertise to help with any questions.

To quickly install and maintain large machines or kiosks used in public places, most customers want to use modular semi-finished products, that is, open frame touch screen monitors. AMT understands that customers’ projects have a variety of needs, and some specifications of ready-made open frame touch screen monitor modules may not meet the requirements. Therefore, we provide a full range of design options to create a suitable open frame touch screen monitor for you:Sizes from 7” to 32”

To facilitate installation, the AMT open frame touch screen monitor provides standard VESA holes and also a fixture that is easy to install in the chassis. For example, we can design side brackets on the four sides of the screen to adjust various installation depths to facilitate installation in any embedded application. In terms of mechanism, we will recommend that you choose the appropriate metal material (such as galvanized steel, stainless steel... etc.), whether it is a ruggedized mechanism design or an economical mechanism design, it is up to you!

In addition to providing basic dust-proof and water-repellent designs for the AMT open frame touch screen monitor, we can also provide corresponding certified designs in terms of impact resistance and water resistance according to customer needs for outdoor and industrial applications.

AMT has been deeply involved in the touch-field for more than 20 years, coupled with our own Lucent Gel and optical bonding technology, and now further provides a new product line - according to your ideas to design your exclusive open frame touch screen monitor. We have a wealth of experience and knowledge to assist customers in solving assembly problems. Whether it is industrial, medical, or commercial, if you have any open frame touch screen monitor needs, please feel free to discuss with us, and we will provide you with the best solution!

As computer display technology advances and user preferences evolve, the use of wide touch screen monitors is gaining popularity. Unlike traditional monitors that served simply as display screens, touch screens are interactive, responding to light taps from a fingertip or stylus instead of input from a keyboard or mouse. As people have become accustomed to this technology on their smartphones and personal tablets, it is a natural progression to use it in computers for retail and restaurant environments, such as point of sale (POS) systems and kiosks.

A wide touch screen monitor features a screen that is mounted in more of a landscape orientation than traditional rectangular POS or kiosk layouts. This wider horizontal format provides greater visibility of displayed information, which can lead to improved worker productivity in many environments. Let’s take a look at the benefits that are causing increased demand for touch screen monitors and the features to look for when upgrading your all-in-one POS system.

Increased Productivity: With a wide touch screen monitor, users can view more information or data at once, providing greater ease of use for certain applications or environments. For example, servers in a restaurant can see more of the menu and complete orders with fewer clicks and less scrolling through the options. Touch screens are also intuitive and faster to operate than trying to input data with a traditional keyboard or mouse. Less time placing orders and completing the payment process means servers have more time to upsell customers and focus on customer service. Faster checkout also increases throughput as well as customer satisfaction.

Ergonomics: Real estate or rental space for retailers and restaurateurs is one of the biggest cost centers, especially in larger metropolitan areas. Many owners are forced into smaller restaurant or retail footprints, meaning space is at a premium. The wide touch screen format is ideal for environments where footprint and ergonomics are important. The wide format allows you to use that valuable counter space to display impulse items for sale or utilize limited space for complimentary POS peripherals. Wide touch screen monitors can also be mounted, so they can fit wherever your workplace needs them to be.

Cleanliness: The pandemic has made businesses of all types more mindful of the importance of sanitizing work and technology equipment. A wide touch screen that comes in a bezel-less, true flat design also makes it easier to clean high touch surfaces. Many all-in-one POS systems are now often semi-ruggedized making them able to withstand constant wipe downs and cleaning. In addition, many POS systems and mobile devices are now being designed as anti-microbial solutions reducing the spread of germs and microbes from user to user.

Improved Aesthetics: For most businesses, image is important, especially in high-end retail or hospitality. The simple lines and uncluttered appearance of a wide touch screen monitor will provide your business with the modern, sleek look that customers expect. Your establishment will appear more up-to-date and tech-savvy, which will further improve customers’ perceptions.

Superior Performance: If you are going to invest in a wide monitor, don’t forget about performance. Make sure that your selection has the latest microprocessor chip set. You’ll also want to pay attention to processing speed, since the unit will need enough horsepower to handle the most demanding applications. Newer wide touch screen monitors also have the latest technology for reducing power consumption, resulting in lower utility bills. Finally, look for the capability to support the latest operating systems (OS), including Windows 11, Windows 10 IOT, Windows 10 Pro, Windows 11 Pro, and Linux.

With advantages ranging from greater productivity to a compact footprint, wide touch screen monitors are an excellent solution for businesses to adopt. If you’re ready to upgrade, there’s one more factor to consider: the provider. You want to select a technology partner with not only the right product but also knowledge of your industry and the unique needs of your business.

Our industrial display touch screen monitors can help your factory personnel and workshops handle complex industrial tasks on intuitive factory grade touch screens. Our wide range of rugged LCD displays with multi-touch and various touch technologies such as resisitive, SAW, optical imaging, projected capacitive and infrared are tough and suitable for virtually any industrial applications. We can help you choose the best touch screen technology and solution that fits best with your needs, and close the gap between your vision and implementation of the digital factory.

Viewsonic"s Touch Screen Solutions helped us simplify the hassle of operating complex machinery in our factory. It really helped us improve our factory line operations and reduced labor input.”

Do you find it difficult to communicate between the front office and production areas? Do warehouse employees sometimes miss important messages? Whether it’s in the office, on the production line or in the stockroom, real-time data is the key to productivity.

Our digital signage software lets you deliver unified messages to all sectors of your business from one easy-to-use application. This gives you more ways to engage your workforce, build community and increase efficiencies.

Keeping your employees informed of progress toward goals is an important part of daily operations and encouraging your team. With Visix digital signage, you can show current news and metrics to keep your employees updated and motivated. And our room signs let you extend messaging to shared spaces.

Digital signage lets you show the right thing, on the right screen, at the right time. Because you can choose what’s shown where, you can share office announcements with manufacturing personnel and production data with office workers – unifying your front and back office operations.

Recognizing individual and team achievements is one of the most powerful motivators you have, and our digital signage software makes it easy. With digital signage displays, you can:

“Visix technical people are superior, and always have the right fix and the right answers when we get ourselves in trouble. Communication success for our organization is their priority.”

“I had a request to change something in Visix and was not sure how to do it, and sent an email to Visix Support. Visix Support actually called me and walked me through the process! That’s what I call great customer service.”

“Visix sets the standard rarely seen in support. The team is both knowledgeable and professional. Issues are dealt with swiftly – better yet, they rarely occur.”

As an introductory offer, we"re offering a FREE 30-DAY TRIAL. If you"d like to continue with a paid subscription, the affordable annual fee covers an unlimited number of players and screens.

Our award-winning artists design our safety subscription messages specifically for digital signs, with general OSHA-inspired EHS tips, quotes, trivia, calendar highlights and messages tailored to a variety of specialty tasks and environments.

Don’t let those spreadsheets go to waste. Show Excel data updates in real time on your digital signs to keep your workforce updated, motivated and engaged. AxisTV Signage Suite widgets let you map data from Excel and other sources, so your screens update automatically.

A headless HMI is an HMI without a built-in touchscreen. Our Headless HMIs are controlled over the network and have a graphical interface that can be accessed from any PC or smartphone, or through a separate touch display or touch monitor.

The cMT-FHDX data processing unit is a fully functional Smart HMI and can be thought of as the "brain" data processing center which allows you to monitor and control your automation process.

By dividing the traditional all-in-one HMI into two parts: a data processing unit and a separate visual display. No longer is your screen size limited to the available HMIs on the market – you can now display your real-time production data on a large wall-mounted status display station, easily visible from any plant floor location.

Powerful HMI functionality and features with the ability to add a display or monitor of your choice. Track and display process data, equipment status, and efficiency metrics in real-time using any large-screen TV or multimedia projector. Allow onsite operators to keep tabs on production from across the room, or from across the factory.

The ability to output video to large screens makes this Headless HMI a great choice for Andon Message Boards and onsite display of Key Performance Indicators.

A touchscreen or touch screen is the assembly of both an input ("touch panel") and output ("display") device. The touch panel is normally layered on the top of an electronic visual display of an electronic device.

A user can give input or control the information processing system through simple or multi-touch gestures by touching the screen with a special stylus or one or more fingers.zooming to increase the text size.

The touchscreen enables the user to interact directly with what is displayed, rather than using a mouse, touchpad, or other such devices (other than a stylus, which is optional for most modern touchscreens).

Touchscreens are common in devices such as smartphones, handheld game consoles, personal computers, electronic voting machines, automated teller machines and point-of-sale (POS) systems. They can also be attached to computers or, as terminals, to networks. They play a prominent role in the design of digital appliances such as personal digital assistants (PDAs) and some e-readers. Touchscreens are also important in educational settings such as classrooms or on college campuses.

The popularity of smartphones, tablets, and many types of information appliances is driving the demand and acceptance of common touchscreens for portable and functional electronics. Touchscreens are found in the medical field, heavy industry, automated teller machines (ATMs), and kiosks such as museum displays or room automation, where keyboard and mouse systems do not allow a suitably intuitive, rapid, or accurate interaction by the user with the display"s content.

Historically, the touchscreen sensor and its accompanying controller-based firmware have been made available by a wide array of after-market system integrators, and not by display, chip, or motherboard manufacturers. Display manufacturers and chip manufacturers have acknowledged the trend toward acceptance of touchscreens as a user interface component and have begun to integrate touchscreens into the fundamental design of their products.

The prototypeCERNFrank Beck, a British electronics engineer, for the control room of CERN"s accelerator SPS (Super Proton Synchrotron). This was a further development of the self-capacitance screen (right), also developed by Stumpe at CERN

One predecessor of the modern touch screen includes stylus based systems. In 1946, a patent was filed by Philco Company for a stylus designed for sports telecasting which, when placed against an intermediate cathode ray tube display (CRT) would amplify and add to the original signal. Effectively, this was used for temporarily drawing arrows or circles onto a live television broadcast, as described in US 2487641A, Denk, William E, "Electronic pointer for television images", issued 1949-11-08. Later inventions built upon this system to free telewriting styli from their mechanical bindings. By transcribing what a user draws onto a computer, it could be saved for future use. See US 3089918A, Graham, Robert E, "Telewriting apparatus", issued 1963-05-14.

The first version of a touchscreen which operated independently of the light produced from the screen was patented by AT&T Corporation US 3016421A, Harmon, Leon D, "Electrographic transmitter", issued 1962-01-09. This touchscreen utilized a matrix of collimated lights shining orthogonally across the touch surface. When a beam is interrupted by a stylus, the photodetectors which no longer are receiving a signal can be used to determine where the interruption is. Later iterations of matrix based touchscreens built upon this by adding more emitters and detectors to improve resolution, pulsing emitters to improve optical signal to noise ratio, and a nonorthogonal matrix to remove shadow readings when using multi-touch.

The first finger driven touch screen was developed by Eric Johnson, of the Royal Radar Establishment located in Malvern, England, who described his work on capacitive touchscreens in a short article published in 1965Frank Beck and Bent Stumpe, engineers from CERN (European Organization for Nuclear Research), developed a transparent touchscreen in the early 1970s,In the mid-1960s, another precursor of touchscreens, an ultrasonic-curtain-based pointing device in front of a terminal display, had been developed by a team around Rainer Mallebrein[de] at Telefunken Konstanz for an air traffic control system.Einrichtung" ("touch input facility") for the SIG 50 terminal utilizing a conductively coated glass screen in front of the display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreenMagnavox Plato IV Student Terminal and thousands were built for this purpose. These touchscreens had a crossed array of 16×16 infrared position sensors, each composed of an LED on one edge of the screen and a matched phototransistor on the other edge, all mounted in front of a monochrome plasma display panel. This arrangement could sense any fingertip-sized opaque object in close proximity to the screen. A similar touchscreen was used on the HP-150 starting in 1983. The HP 150 was one of the world"s earliest commercial touchscreen computers.infrared transmitters and receivers around the bezel of a 9-inch Sony cathode ray tube (CRT).

In 1977, an American company, Elographics – in partnership with Siemens – began work on developing a transparent implementation of an existing opaque touchpad technology, U.S. patent No. 3,911,215, October 7, 1975, which had been developed by Elographics" founder George Samuel Hurst.World"s Fair at Knoxville in 1982.

In 1984, Fujitsu released a touch pad for the Micro 16 to accommodate the complexity of kanji characters, which were stored as tiled graphics.Sega released the Terebi Oekaki, also known as the Sega Graphic Board, for the SG-1000 video game console and SC-3000 home computer. It consisted of a plastic pen and a plastic board with a transparent window where pen presses are detected. It was used primarily with a drawing software application.

Touch-sensitive control-display units (CDUs) were evaluated for commercial aircraft flight decks in the early 1980s. Initial research showed that a touch interface would reduce pilot workload as the crew could then select waypoints, functions and actions, rather than be "head down" typing latitudes, longitudes, and waypoint codes on a keyboard. An effective integration of this technology was aimed at helping flight crews maintain a high level of situational awareness of all major aspects of the vehicle operations including the flight path, the functioning of various aircraft systems, and moment-to-moment human interactions.

In the early 1980s, General Motors tasked its Delco Electronics division with a project aimed at replacing an automobile"s non-essential functions (i.e. other than throttle, transmission, braking, and steering) from mechanical or electro-mechanical systems with solid state alternatives wherever possible. The finished device was dubbed the ECC for "Electronic Control Center", a digital computer and software control system hardwired to various peripheral sensors, servos, solenoids, antenna and a monochrome CRT touchscreen that functioned both as display and sole method of input.stereo, fan, heater and air conditioner controls and displays, and was capable of providing very detailed and specific information about the vehicle"s cumulative and current operating status in real time. The ECC was standard equipment on the 1985–1989 Buick Riviera and later the 1988–1989 Buick Reatta, but was unpopular with consumers—partly due to the technophobia of some traditional Buick customers, but mostly because of costly technical problems suffered by the ECC"s touchscreen which would render climate control or stereo operation impossible.

Multi-touch technology began in 1982, when the University of Toronto"s Input Research Group developed the first human-input multi-touch system, using a frosted-glass panel with a camera placed behind the glass. In 1985, the University of Toronto group, including Bill Buxton, developed a multi-touch tablet that used capacitance rather than bulky camera-based optical sensing systems (see History of multi-touch).

The first commercially available graphical point-of-sale (POS) software was demonstrated on the 16-bit Atari 520ST color computer. It featured a color touchscreen widget-driven interface.COMDEX expo in 1986.

In 1987, Casio launched the Casio PB-1000 pocket computer with a touchscreen consisting of a 4×4 matrix, resulting in 16 touch areas in its small LCD graphic screen.

Touchscreens had a bad reputation of being imprecise until 1988. Most user-interface books would state that touchscreen selections were limited to targets larger than the average finger. At the time, selections were done in such a way that a target was selected as soon as the finger came over it, and the corresponding action was performed immediately. Errors were common, due to parallax or calibration problems, leading to user frustration. "Lift-off strategy"University of Maryland Human–Computer Interaction Lab (HCIL). As users touch the screen, feedback is provided as to what will be selected: users can adjust the position of the finger, and the action takes place only when the finger is lifted off the screen. This allowed the selection of small targets, down to a single pixel on a 640×480 Video Graphics Array (VGA) screen (a standard of that time).

Sears et al. (1990)human–computer interaction of the time, describing gestures such as rotating knobs, adjusting sliders, and swiping the screen to activate a switch (or a U-shaped gesture for a toggle switch). The HCIL team developed and studied small touchscreen keyboards (including a study that showed users could type at 25 wpm on a touchscreen keyboard), aiding their introduction on mobile devices. They also designed and implemented multi-touch gestures such as selecting a range of a line, connecting objects, and a "tap-click" gesture to select while maintaining location with another finger.

In 1990, HCIL demonstrated a touchscreen slider,lock screen patent litigation between Apple and other touchscreen mobile phone vendors (in relation to

An early attempt at a handheld game console with touchscreen controls was Sega"s intended successor to the Game Gear, though the device was ultimately shelved and never released due to the expensive cost of touchscreen technology in the early 1990s.

Touchscreens would not be popularly used for video games until the release of the Nintendo DS in 2004.Apple Watch being released with a force-sensitive display in April 2015.

In 2007, 93% of touchscreens shipped were resistive and only 4% were projected capacitance. In 2013, 3% of touchscreens shipped were resistive and 90% were projected capacitance.

A resistive touchscreen panel comprises several thin layers, the most important of which are two transparent electrically resistive layers facing each other with a thin gap between. The top layer (that which is touched) has a coating on the underside surface; just beneath it is a similar resistive layer on top of its substrate. One layer has conductive connections along its sides, the other along top and bottom. A voltage is applied to one layer and sensed by the other. When an object, such as a fingertip or stylus tip, presses down onto the outer surface, the two layers touch to become connected at that point.voltage dividers, one axis at a time. By rapidly switching between each layer, the position of pressure on the screen can be detected.

Resistive touch is used in restaurants, factories and hospitals due to its high tolerance for liquids and contaminants. A major benefit of resistive-touch technology is its low cost. Additionally, as only sufficient pressure is necessary for the touch to be sensed, they may be used with gloves on, or by using anything rigid as a finger substitute. Disadvantages include the need to press down, and a risk of damage by sharp objects. Resistive touchscreens also suffer from poorer contrast, due to having additional reflections (i.e. glare) from the layers of material placed over the screen.3DS family, and the Wii U GamePad.

Surface acoustic wave (SAW) technology uses ultrasonic waves that pass over the touchscreen panel. When the panel is touched, a portion of the wave is absorbed. The change in ultrasonic waves is processed by the controller to determine the position of the touch event. Surface acoustic wave touchscreen panels can be damaged by outside elements. Contaminants on the surface can also interfere with the functionality of the touchscreen.

The Casio TC500 Capacitive touch sensor watch from 1983, with angled light exposing the touch sensor pads and traces etched onto the top watch glass surface.

A capacitive touchscreen panel consists of an insulator, such as glass, coated with a transparent conductor, such as indium tin oxide (ITO).electrostatic field, measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing. Touchscreens that use silver instead of ITO exist, as ITO causes several environmental problems due to the use of indium.complementary metal–oxide–semiconductor (CMOS) application-specific integrated circuit (ASIC) chip, which in turn usually sends the signals to a CMOS digital signal processor (DSP) for processing.

Unlike a resistive touchscreen, some capacitive touchscreens cannot be used to detect a finger through electrically insulating material, such as gloves. This disadvantage especially affects usability in consumer electronics, such as touch tablet PCs and capacitive smartphones in cold weather when people may be wearing gloves. It can be overcome with a special capacitive stylus, or a special-application glove with an embroidered patch of conductive thread allowing electrical contact with the user"s fingertip.

A low-quality switching-mode power supply unit with an accordingly unstable, noisy voltage may temporarily interfere with the precision, accuracy and sensitivity of capacitive touch screens.

Some capacitive display manufacturers continue to develop thinner and more accurate touchscreens. Those for mobile devices are now being produced with "in-cell" technology, such as in Samsung"s Super AMOLED screens, that eliminates a layer by building the capacitors inside the display itself. This type of touchscreen reduces the visible distance between the user"s finger and what the user is touching on the screen, reducing the thickness and weight of the display, which is desirable in smartphones.

A simple parallel-plate capacitor has two conductors separated by a dielectric layer. Most of the energy in this system is concentrated directly between the plates. Some of the energy spills over into the area outside the plates, and the electric field lines associated with this effect are called fringing fields. Part of the challenge of making a practical capacitive sensor is to design a set of printed circuit traces which direct fringing fields into an active sensing area accessible to a user. A parallel-plate capacitor is not a good choice for such a sensor pattern. Placing a finger near fringing electric fields adds conductive surface area to the capacitive system. The additional charge storage capacity added by the finger is known as finger capacitance, or CF. The capacitance of the sensor without a finger present is known as parasitic capacitance, or CP.

In this basic technology, only one side of the insulator is coated with a conductive layer. A small voltage is applied to the layer, resulting in a uniform electrostatic field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. The sensor"s controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel. As it has no moving parts, it is moderately durable but has limited resolution, is prone to false signals from parasitic capacitive coupling, and needs calibration during manufacture. It is therefore most often used in simple applications such as industrial controls and kiosks.

Although some standard capacitance detection methods are projective, in the sense that they can be used to detect a finger through a non-conductive surface, they are very sensitive to fluctuations in temperature, which expand or contract the sensing plates, causing fluctuations in the capacitance of these plates.

This diagram shows how eight inputs to a lattice touchscreen or keypad creates 28 unique intersections, as opposed to 16 intersections created using a standard x/y multiplexed touchscreen .

Projected capacitive touch (PCT; also PCAP) technology is a variant of capacitive touch technology but where sensitivity to touch, accuracy, resolution and speed of touch have been greatly improved by the use of a simple form of

"Artificial Intelligence". This intelligent processing enables finger sensing to be projected, accurately and reliably, through very thick glass and even double glazing.

Some modern PCT touch screens are composed of thousands of discrete keys,etching a single conductive layer to form a grid pattern of electrodes, by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid, or by forming an x/y grid of fine, insulation coated wires in a single layer . The number of fingers that can be detected simultaneously is determined by the number of cross-over points (x * y) . However, the number of cross-over points can be almost doubled by using a diagonal lattice layout, where, instead of x elements only ever crossing y elements, each conductive element crosses every other element .

In some designs, voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. This is measurable as a change in capacitance. If a finger bridges the gap between two of the "tracks", the charge field is further interrupted and detected by the controller. The capacitance can be changed and measured at every individual point on the grid. This system is able to accurately track touches.

Unlike traditional capacitive touch technology, it is possible for a PCT system to sense a passive stylus or gloved finger. However, moisture on the surface of the panel, high humidity, or collected dust can interfere with performance.

These environmental factors, however, are not a problem with "fine wire" based touchscreens due to the fact that wire based touchscreens have a much lower "parasitic" capacitance, and there is greater distance between neighbouring conductors.

This is a common PCT approach, which makes use of the fact that most conductive objects are able to hold a charge if they are very close together. In mutual capacitive sensors, a capacitor is inherently formed by the row trace and column trace at each intersection of the grid. A 16×14 array, for example, would have 224 independent capacitors. A voltage is applied to the rows or columns. Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field, which in turn reduces the mutual capacitance. The capacitance change at every individual point on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers, palms or styli can be accurately tracked at the same time.

Self-capacitance sensors can have the same X-Y grid as mutual capacitance sensors, but the columns and rows operate independently. With self-capacitance, the capacitive load of a finger is measured on each column or row electrode by a current meter, or the change in frequency of an RC oscillator.

Self-capacitive touch screen layers are used on mobile phones such as the Sony Xperia Sola,Samsung Galaxy S4, Galaxy Note 3, Galaxy S5, and Galaxy Alpha.

Self capacitance is far more sensitive than mutual capacitance and is mainly used for single touch, simple gesturing and proximity sensing where the finger does not even have to touch the glass surface.

Capacitive touchscreens do not necessarily need to be operated by a finger, but until recently the special styli required could be quite expensive to purchase. The cost of this technology has fallen greatly in recent years and capacitive styli are now widely available for a nominal charge, and often given away free with mobile accessories. These consist of an electrically conductive shaft with a soft conductive rubber tip, thereby resistively connecting the fingers to the tip of the stylus.

Infrared sensors mounted around the display watch for a user"s touchscreen input on this PLATO V terminal in 1981. The monochromatic plasma display"s characteristic orange glow is illustrated.

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any opaque object including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and POS systems that cannot rely on a conductor (such as a bare finger) to activate the touchscreen. Unlike capacitive touchscreens, infrared touchscreens do not require any patterning on the glass which increases durability and optical clarity of the overall system. Infrared touchscreens are sensitive to dirt and dust that can interfere with the infrared beams, and suffer from parallax in curved surfaces and accidental press when the user hovers a finger over the screen while searching for the item to be selected.

A translucent acrylic sheet is used as a rear-projection screen to display information. The edges of the acrylic sheet are illuminated by infrared LEDs, and infrared cameras are focused on the back of the sheet. Objects placed on the sheet are detectable by the cameras. When the sheet is touched by the user, frustrated total internal reflection results in leakage of infrared light which peaks at the points of maximum pressure, indicating the user"s touch location. Microsoft"s PixelSense tablets use this technology.

Optical touchscreens are a relatively modern development in touchscreen technology, in which two or more image sensors (such as CMOS sensors) are placed around the edges (mostly the corners) of the screen. Infrared backlights are placed in the sensor"s field of view on the opposite side of the screen. A touch blocks some lights from the sensors, and the location and size of the touching object can be calculated (see visual hull). This technology is growing in popularity due to its scalability, versatility, and affordability for larger touchscreens.

Introduced in 2002 by 3M, this system detects a touch by using sensors to measure the piezoelectricity in the glass. Complex algorithms interpret this information and provide the actual location of the touch.

The key to this technology is that a touch at any one position on the surface generates a sound wave in the substrate which then produces a unique combined signal as measured by three or more tiny transducers attached to the edges of the touchscreen. The digitized signal is compared to a list corresponding to every position on the surface, determining the touch location. A moving touch is tracked by rapid repetition of this process. Extraneous and ambient sounds are ignored since they do not match any stored sound profile. The technology differs from other sound-based technologies by using a simple look-up method rather than expensive signal-processing hardware. As with the dispersive signal technology system, a motionless finger cannot be detected after the initial touch. However, for the same reason, the touch recognition is not disrupted by any resting objects. The technology was created by SoundTouch Ltd in the ea

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey