construction of tft display pricelist

At present, TFT LCD touch panel prices rebounded, after six months of continuous decline, TFT LCD touch panel prices began to rebound at the end of July. Global TFT LCD panel prices have rebounded since August, according to Displaysearch, an international market-research firm. The price of a 17-inch LCD touch panel rose 6.6% to $112 in August, up from $105 in July, and fell from $140 in March to $105 in July. At the same time, 15 – inch, 19 – inch LCD touch panel prices also showed a different range of recovery. The price of a 17-inch LCD touch panel rose 5.8 percent, to $110, from $104 in late July, according to early August quotes from consulting firm with a view. Analysts believe the rebound will continue through the third quarter; LCDS will see seasonal growth in the third quarter, driven by back-to-school sales in us and the completion of inventory liquidation in the first half of the year. Dell and Hewlett-Packard (HPQ) started placing orders for monitors in the third quarter, and display makers Samsungelectronics (SXG) and TPV (TPV) are expected to increase production by 25% and 18% respectively.

It seems that due to the increasing demand in the market, the production capacity of the display panel production line has been released. Domestic TFT-LCD touch panel makers boe and Shanghai guardian said their production schedules have been set for September, and their production capacity may reach full capacity by the end of the year. Jd will produce 85,000 glass substrates per month (with a designed capacity of 90,000), according to boe and Shanghai guardian. Previously, panel makers have been hit by falling prices, with boe, SFT, and even international panel giant LG Philips all reporting losses. If the rebound continues into the fourth quarter, boe, Shanghai radio and television and other panel makers will use the rebound to reverse the decline, according to industry analysts.

It is understood that the first quarter of the boe financial results show that the company’s main business income of 2.44 billion yuan, a loss of 490 million yuan.Jd.com attributed the loss to a drop in the price of 17-inch TFT-LCD displays made by its Beijing TFT-LCD fifth-generation production line of Beijing boe photoelectric technology co., LTD., a subsidiary. Boe has issued the announcement of pre-loss in the first half of the year in April. Due to the influence of the off-season of TFT-LCD business operation in the first quarter of 2006, the company has suffered a large operating loss, and the low price in the TFT-LCD market has continued till now. Therefore, it is expected that the operating loss will still occur in the first half of 2006.LG Philips, the world’s largest TFT LCD maker, reported a won322bn ($340m) loss in July, compared with a won41.1bn profit a year earlier.LG Philips attributed the loss to fierce price competition and market demand did not meet expectations.

Chino, CA, March 1, 2021– Tianma, a leading global manufacturer of flat panel displays, has introduced a new product family of TFT LCD Modules (Thin Film Transistor - Liquid Crystal Display). The new P-Series (Professional Series) of standard products is dedicated to support the various requirements of the industrial and medical display markets. The first products in this new series will include XGA displays (8.4”, 10.4” and 12.1”), as well as wide-format products, from 7” WVGA to 13.3” FHD.

The P-Series display products will be available in three grades – Advanced, Basic and Entry – to better support the different customer needs in a variety of markets, including a range of features and product specifications around pixel density, viewing angle, contrast ratio, color gamut, black level uniformity, etc.

The Advanced grade is designed for demanding applications that call for more robust product specifications and performance requirements, including: high-contrast rating and longer-life LED (as in medical diagnostic equipment); high brightness and wide temperature range (for marine environments); special ruggedization to withstand high shock and vibration conditions (as encountered in construction vehicles).

The Basic grade of P-Series displays will offer a very good performance-to-cost ratio, meeting the standard specification and performance requirements of the market with typical brightness ratings and long-life LED backlights. The Entry level provides more cost-effective solutions for price-sensitive markets and applications.

P-Series modules will be available with Tianma’s PCAP (Projected Capacitive) touch technology, featuring Tianma designed and manufactured PCAP touch sensors. PCAP will be integrated in-house, with optical bonding or air gap (perimeter bond) construction. Wet & Glove touch sensing technology is available for high-end devices, and customized cover glass is optional.

All three grades of the P-Series family will be available in production for a minimum of five years (typically seven years or more) with a small minimum order quantity (MOQ). The P-Series will also be engineered around dedicated design rules to meet the particular requirements of the professional market. Further, the manufacture and assembly of the TFT-LCDs and PCAP sensors will all be done in-house, with industrial level driver support.

Samples from the initial P-Series product offering will be available starting Q1 2021. These first displays will include wide-format 7” WVGA, 10.6” WXGA, and 13.3” FHD products, in the Advanced high brightness versions. The first products with 4:3 format will all have XGA resolution and include both Advanced high brightness and Basic, in sizes 8.4”, 10.4” and 12.1”.

Regarding Tianma’s legacy Professional TFT LCD products, both standard TM-series and all NL-series modules will be promoted alongside the new P-series product offering. All of these products will remain in production and will continue to be fully supported.

Tianma America (TMA) is the leading provider of small- to medium-size display solutions to the Americas market utilizing advanced technologies and manufacturing resources of the Tianma Group Companies, which includes Tianma Micro-electronics (Shenzhen and Shanghai) and Tianma Japan, Ltd. (formerly known as NLT Technologies Ltd.), as well as manufacturing locations in Chengdu, Wuhan, Xiamen, Shenzhen and Shanghai China. Tianma America technologies can be found in smartphones, tablet PCs, industrial and medical instrumentation, wearables, home automation, household appliances, office equipment, and automotive and rear seat entertainment devices. Additional applications include test and measurement systems, instrumentation equipment, point-of-sale and ATM systems, gaming systems, global positioning systems, radio-frequency identification devices and barcode scanners.

Tianma America’s technology portfolio comprises TFT, LTPS, Oxide-TFT, AM-OLED, flexible, transparent, 3D, PCAP and In-cell/On-cell integrated touch. With a network of best-in-class distributors and value-added partners, Tianma America provides complete display module solutions for a broad base of customers and applications.

The content in this press release, including, but not limited to, product prices and specifications, is based on the information as of the date indicated on the document, but may be subject to change without prior notice.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

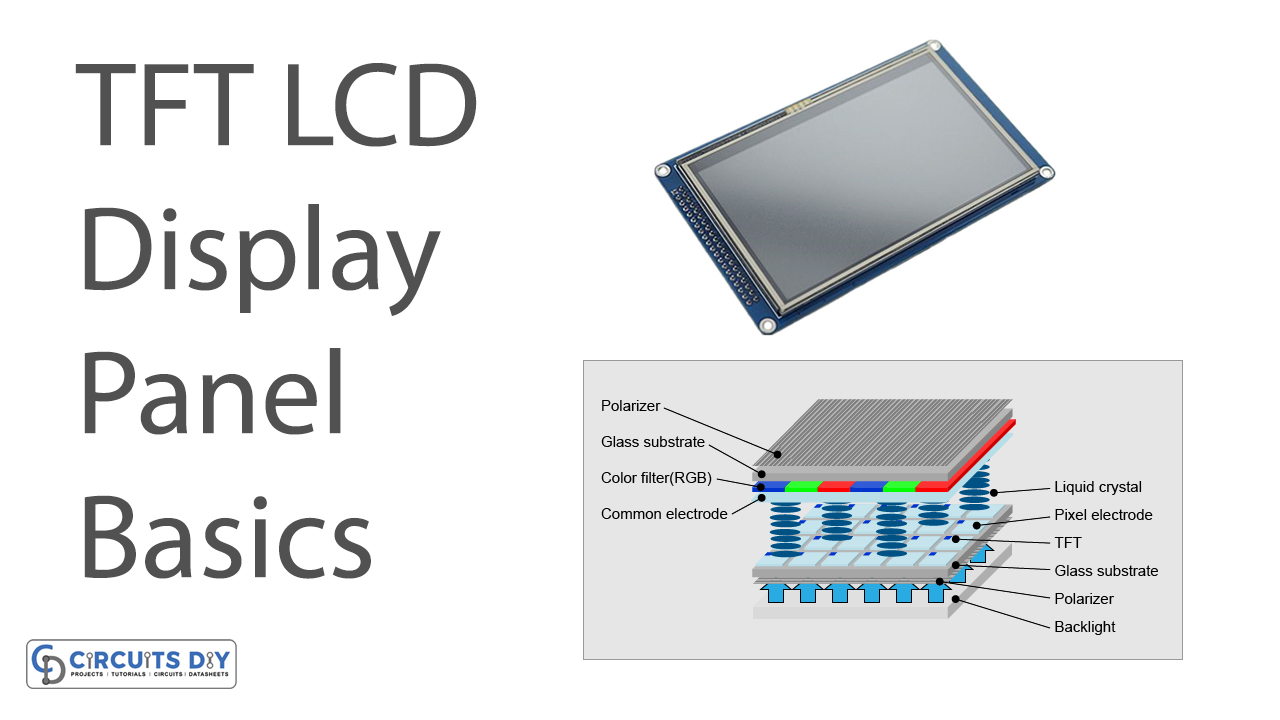

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

In order to enhance productivity, in this step we’ll do a series of procedure on a large glass, which will be cut into smaller pieces in the following step.

First, let me introduce a crucial material, ITO, to you. ITO, abbreviation of Indium tin oxide, has the characteristic of electrical conductivity and optical transparency, as well as can be easily deposited as a thin film. Thus it’s widely used to create circuit on glass.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

◇ Use glue to build a boundary for LC on both glass. And on CF glass, apply one more layer of conductive adhesive. This enable LC molecule link to the control circuit.

A TN-TFT display is a type of Liquid Crystal Displaywith thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

As with all our displays, a variety of customisation options are availableto bring you a unique design that meets your application requirements and satisfies environmental challenges, including:

Here at Anders we don"t just strive to design a best in class display solution for your product, but we also want to make sure the display is driven with the right embedded system. We can help achieve a hardware solution that ensures your display works perfectly within your application. Hardware solutions include:

With ever increasing pressure in all of our lives, having easy to use and reliable home appliances plays a key role in easing those stresses. A cost effective colour TFT display is ideal for demanding user expectations, available in a variety of shapes and sizes..

Residential and commercial metering solutions are changing from monochrome to colour with a TN-TFT display offering an ideal cost effective solution to give your product the uplift it deserves. We can optimise these to suit your application including mechanical integration, coverlens design and backlight enhancements.

TN-TFT Displays are ideal for medical and personal healthcare devices. Both low power consumption and low cost solutions, they are available with wide viewing angles for challenging medical situations where the user may be at an acute angle to the device.

Putting your own stamp on your product is more than a logo on the start-up screen. Discover how we can help you design a unique display solution with our customisation services:

We aim to offer reliable and long-term solutions to our B2B customers. If you would like to discuss your display and/or embedded system requirements please contact us below.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Backlight intensity is usually controlled by varying a few volts DC, or generating a PWM signal, or adjusting a potentiometer or simply fixed. This in turn controls a high-voltage (1.3 kV) DC-AC inverter or a matrix of LEDs. The method to control the intensity of LED is to pulse them with PWM which can be source of harmonic flicker.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

The North America TFT LCD panel market reached a value of US$ 52 Billion in 2020. Looking forward, IMARC Group expects the market to reach a value of US$ 64.4 Billion by 2026. Keeping in mind the uncertainties of COVID-19, we are continuously tracking and evaluating the direct as well as the indirect influence of the pandemic on different end use industries. These insights are included in the report as a major market contributor.

TFT (Thin Film Transistor) is an active-matrix liquid crystal display (LCD) panel that uses the TFT technology to improve image quality in terms of addressability and contrast. Every pixel on a TFT LCD panel has a separate transistor, which controls the display illumination while enabling an easy view even in bright environments. TFTs are gaining traction in nearly all the industries as they are lightweight, slim in construction, have high-resolution and offer low power consumption. They find major applications in various electronic goods such as televisions, mobile phones, tablets, laptops, desktops, portable video game devices, etc. Apart from these, they are also used in the automotive industry, navigation and medical equipment, laser pointer astronomy, SLR cameras and digital photo frames.

The North America TFT LCD panel market is currently being driven by several factors. TFT-LCD panels provide flexibility in presenting all types of data, including pictoral representation. On account of this, they are increasingly being employed not only in the consumer electronics but also in the aerospace sector as well to display aircraft altitude information, airframe parameters, warning messages and navigational data. Moreover, TFT LCDs are less prone to reflection, viewable from a wider angle and much lighter than traditional panels, thereby having wide applications in the electronics and automotive industry. Additionally, the rising demand for TFT-LCD display is catalyzed by the increasing consumption of flat panel TVs in households, smartphones and gaming industry.

IMARC Group provides an analysis of the key trends in each sub-segment of the North America TFT LCD panel market, along with forecasts at the regional and country level from 2021-2026. Our report has categorized the market based on size and application.

In this guide we’re going to show you how you can use the 1.8 TFT display with the Arduino. You’ll learn how to wire the display, write text, draw shapes and display images on the screen.

The 1.8 TFT is a colorful display with 128 x 160 color pixels. The display can load images from an SD card – it has an SD card slot at the back. The following figure shows the screen front and back view.

This module uses SPI communication – see the wiring below . To control the display we’ll use the TFT library, which is already included with Arduino IDE 1.0.5 and later.

The TFT display communicates with the Arduino via SPI communication, so you need to include the SPI library on your code. We also use the TFT library to write and draw on the display.

In which “Hello, World!” is the text you want to display and the (x, y) coordinate is the location where you want to start display text on the screen.

The 1.8 TFT display can load images from the SD card. To read from the SD card you use the SD library, already included in the Arduino IDE software. Follow the next steps to display an image on the display:

Note: some people find issues with this display when trying to read from the SD card. We don’t know why that happens. In fact, we tested a couple of times and it worked well, and then, when we were about to record to show you the final result, the display didn’t recognized the SD card anymore – we’re not sure if it’s a problem with the SD card holder that doesn’t establish a proper connection with the SD card. However, we are sure these instructions work, because we’ve tested them.

In this guide we’ve shown you how to use the 1.8 TFT display with the Arduino: display text, draw shapes and display images. You can easily add a nice visual interface to your projects using this display.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey