can lcd screen be fixed on iphone made in china

Mandy, ETS is obviously a company that you are connected to and this could easily be taken for spam. I think we can make an exception at this time since you are asking a good market research question that may be useful to many.

Having checked out your video, I personally will not use the aftermarket screen as a replacement for my X. It just doesn"t have what I expect for a $1000 USD phone. I recognize that $300 USD for a replacement is hefty but the aftermarket screen does not appear to have the quality that I would expect for my phone.

Since the iPhone 7/7 Plus has been released for quite a long time, finally the China made iPhone 7/7 Plus screen replacementscame out in the market. we’ve got some iPhone 7 series LCD screen replacements samples and done some tests on them, now let’s take a closer look at these new iPhone 7 series LCD screen replacements!(TianmaandLGsources for testing)

After installing all the sample screens to the iPhone 7/7 Plus rear housing assembly, we found that all the China made iPhone 7 series screen replacements are fitting well just like the original ones - the home button fits well, the screen assembly and the rear housing also fits well.

From the picture below, we can see that there is no difference between the China made iPhone 7 series display and the original ones, however, back to the rear side, we can easily figure out which one is which, cause the original one has Apple logo on it while the China made screen has none.

By comparing these two iPhone 7 screens, we can find that the screen flex cables are much different, there are extra IC on the China-Made iPhone 7 screen while the original one has none. And the original iPhone 7 series screen flex cable is integrated together while on the China-Made iPhone 7 series screen the touch function flex cable is soldered to the display and 3D touch flex cable.

Another difference between the original and China made iPhone 7 screen replacements is the exposed IC on the after-market iPhone screen, just like other China-Made iPhone 5 or 6 series screen replacement, which has more potential risk of electrostatic damage and more likely to get damaged and this problem needs to be improved.

During our test, we found that the display color between our after-market iPhone 7 screen and original screen seems a little different although they are not effecting the touch function. And to be honest, there may have some black dots on the screen because of impurities within the screen module when laminating the LCD and backlight together, without any doubt, this can be solved with technical improvement.

The screen touch sensitivity is another big concern for all of us, luckily, during our test, almost all home button and touch functionality on both iPhone 7 and 7 Plus works well, except one piece of iPhone 7, the 3D touch function is not acting so well on the central part of the screen.

The China-Made iPhone 7 series LCD screen assembly replacement still remains to be improved in quality and performance compared to the original ones, the exposed IC, heavier screen flex cable ribbon, and the screen color difference, the touch function stability, although the price is attractive. However, the China made iPhone 7 series screen replacement is under the improvement, and sooner or later their quality and performance can be quite close to original ones and acceptable, if you"re going to stock up some non-original iPhone 7 series LCD screen replacement, pay more attention and we’ll keep you updated with further information about after-market iPhone 7 series screen replacement!

“Original” screens are those containing LCDs manufactured for Apple. “Copy” screens are compatible replacements entirely designed and manufactured by third-party companies not associated with Apple.

LCD display panel can have poorer resolution (i.e. looks “coarser”), worse brightness, contrast and vibrancy and reduced refresh rate amongst other problems.

Changes in specification from original can result in battery and performance issues. Certain badly-engineered screens could even damage the backlight circuitry.

Customers who bring their iPhones to us for a screen repair are offered two choices of replacement- an original or a “copy” screen. The most common response is “Is there a difference- and which one would you recommend?”

Originals are those screens containing LCDs that were manufactured for Apple. So-called “copy” screens are compatible replacements, but designed and manufactured entirely independently by third-party companies, typically in China.

Our answer is simple- the original screen is the one we’d go for ourselves, every time. Some people think we make more money on them, but this isn’t the case. We recommend originals because they’re far higher quality and the price difference is fairly small.

We’d rather only fit original screens. The only reason we don’t is that many people will shop around and choose purely on price. As such, we need to offer the cheaper copy screens to remain competitive and avoid losing these customers. In some cases, they didn’t even know there was a difference in the first place- especially since it’s not in some shops’ interest to draw people’s attention to the issue!

This may well be the worst copy screen we’ve ever come across. As a result, the unfortunate customer has ended up paying twice to have their screen replaced- we’re sure that had they been properly informed, they would have chosen an original in the first place.

While the difference in price between copies and originals can vary across devices, it’s generally around £10 – £14 extra to have an original screen fitted. This really isn’t a lot considering the improved quality and reliability.

We compare our prices to our competitors- and we know that we come out of it favourably. While we have to offer copy screens to remain competitive, we always advise customers to go for the original.

When you’ve spent- directly or indirectly- several hundred pounds for an iPhone with a Retina display, it doesn’t make sense to replace it with a lower-quality screen that can make a £400 phone look like a £40 one! Not only that, but you’re likely to have fewer issues, and a longer-lasting screen.

There’s nothing stopping any random person without training or experience opening up a smartphone repair shop. As a result, the industry is full of companies with little skill or experience who are only interested in getting hold of your money and installing the cheapest parts they can find.

Many- if not most- don’t even acknowledge the existence of copy screens, let alone explain the difference to the customer. Hardly in their interest to do so if they only fit cheap, low-quality copies. Some of them can hardly be blamed- they know so little, they’re not even clear on the differences between OEM, non-OEM and copy displays themselves! Others can be more deliberately misleading… and some outright lie.

Generally, these shops are looking for the cheapest price on replacement screens.. When offered a copy at a half or a third of a price of the original, they’re going to go for that. That might be fine if they offered the customer a cheaper price- what we disagree with is selling “supermarket beans” (i.e. the copy screens) at “Heinz beans” prices!

Heading towards the “blatantly fraudulent”, we’re aware of companies that shamelessly fit copy screens while claiming them to be original. Worse, they’ll take your broken original screen and sell that to a recycler for more than they paid for your copy!

Obtained or manufactured “off the clock” via the same production line that produced them for Apple- in some cases, from the stockpile of parts that didn’t meet Apple’s standards, or

Apple tightened up their supply chain around 2015, which reduced the number of screens available for repairs and increased their price dramatically. A lot of companies went bankrupt, and Chinese manufacturers responded by making their own “copy” screens from scratch. At first, these weren’t much cheaper than the Apple ones, but the price soon fell.

We should be clear that- despite the name- “copy” screens aren’t direct copies of the Apple originals. Rather, they’re compatible replacements that have been designed from scratch and- as a result- vary in some respects that have an effect on usability and quality.

One of the most important differences between an original and a “copy” screen is how the digitizer (touch sensor) is designed. Apple has it manufactured as part of the LCD itself, whereas the copies have it on the glass.

Although there are only a small number of manufacturers of the bare LCDs themselves, these are then bought by countless other companies who add the remaining components needed to turn these into a complete working screen. As a result, you could easily end up with an LCD from the best “copy” manufacturer, but the digitizer/touch (as part of the separately-manufactured glass) from the worst.

There are countless digitizers out there, and you can only take the supplier’s word that the quality is good. Many ship good ones at first, then switch to cheaper parts to make more profit. This is particularly bad with the iPhone 6S and 6S+, since Apple moved the chips responsible for touch processing onto the LCD itself. As a result, you’re not just getting a copy screen- you’re getting copy chips too.

The performance specification (power drain, etc.) of most copy screens isn’t identical to the originals. As a result, they can drain the battery more quickly and mislead the operating system which was optimised for the original screen design.

It’s even possible that this mismatch could damage your backlight. We do a lot of subcontracted repairs for less-experienced shops, and get backlight repairs in almost every day. We’ve had cases where we fixed the circuit, fitted the new copy screen to test it, and had it break the circuit again!

Copy screens can disrupt the touch ID fingerprint reader. With the 6S, 6S+, 7 and 7+, the home button- part of the 3D touch- is part of the screen assembly. Frequently the home button flexes on aftermarket designs don’t work properly and stop the touch ID working- annoying if you use it to unlock the phone or log in to your bank.

We’ve seen many lift away from the frame that holds them in place. This usually results in the flex cable getting torn, and the screen needing replacing. You don’t even need to have dropped the phone- this often happens through general everyday wear and tear.

That brings us to another major issue with the copies. When you drop an Apple original, the glass often breaks, but if the LCD itself is intact, you can continue to use it until it’s fixed. With the copies, the touch/digitizer is on the glass and stops working when that’s broken. Even worse, the LCD itself is more likely to break due to the thinner and more fragile glass.

We’re not convinced this will happen, since Apple recently changed their repair policy to accept iPhones with third-party screens. However, it is possible that copy screens could be stopped from working via an iOS update, since those make a number of security checks.

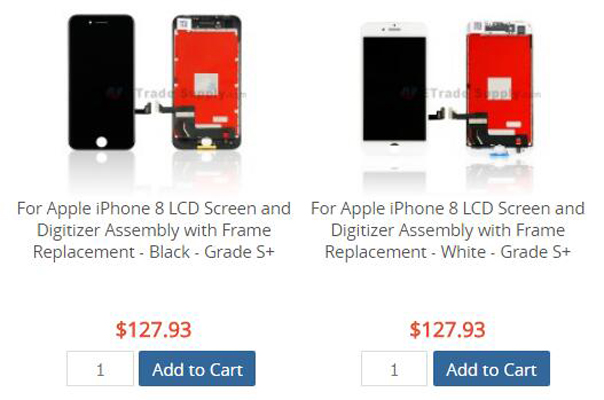

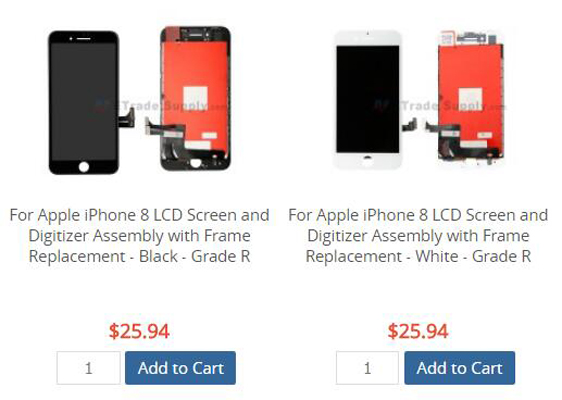

Broken screen replacement service is provided from thousands of repairs stores and phone parts wholesalers worldwide, iPhone of which are mostly engaged in. So how to purchase reliable LCD screens among so many quality grades from China suppliers? Let me firstly elaborate on the quality grades of the iPhone LCD digitizer assembly that most repair stores and traders used to replace the broken ones.

According to the investigation, 90% of the Chinese iPhone LCD screen suppliers are found selling third-party manufactured screens and seldom sell genuine original LCD screens. Therefore, if your phone screen is broken, there would be a high chance for your screen to be replaced with a non-original one. Why? Maybe the cost and quality are relatively competitive, so why not?

As known, Foxconn is authorized to assemble iPhone, so there are some original iPhone LCD screens leaked from the assemble factory. And there are brought out from the factory for replacement. However the price is definitely high and still, some people care more about the quality of the screen than how much they cost, so for this group of customers, the Original Quality of LCD digitizer assemblies are preferred.

For some LCD digitizers, the LCDs are still working while the front glasses are broken, which can be recycled. Some factories recycled these broken screens by removing the broken front glass and attach a new one, then the LCD digitizer assembly would be new again, which is what called refurbished. Brand new original LCD screens are limited, and the refurbished ones can replenish the shortage of the new original LCD digitizer assemblies, for their quality would be more stable than the third-party manufactured.

Some Chinese factories purchase the original single LCD display, not compete LCD screen from the original factory, and then attach high copy front glass, backlight, etc, materials into a complete LCD screen, which quality is not stable and the display color is slightly different from the ones with high copy backlight. Well, their price would be cheaper and loved by many repair shops and wholesalers.

Under the shortage of original LCD screens, many Chinese factories begin to produce the high copy LCD screen. The stock and supply are getting less and less since about 2015, which leads the price goes higher and higher. Therefore the Chinese manufacturer starts to produce LCD screens with high copy raw materials. With competitive prices and good quality that meet most iPhone users’ needs, they are also popular among many wholesalers and repair shops.

With the premium quality of LCD and OLED screens tested strictly, we’ve helped many clients enlarge their markets worldwide. If you wholesale the LCD digitizer assembly or retail them in your repair shop, more information and sample are supported for your reference, please do not hesitate to contact us or leave your comment to discuss more.

Die gewünschte Seite konnte leider nicht gefunden werden. Versuchen Sie, zur vorherigen Seite zurückzukehren, oder besuchen Sie unseren Hilfebereich, um mehr zu erfahren.

Vaya, parece que no podemos encontrar la página que buscas. Intenta volver a la página anterior o visita nuestro Centro de ayuda para más información.

Nous ne trouvons pas la page que vous recherchez. Essayez de retourner à la page précédente ou consultez notre assistance clientèle pour plus d’informations

Maaf, sepertinya kami tidak dapat menemukan halaman yang Anda cari. Coba kembali ke halaman sebelumnya atau lihat Pusat Bantuan kami untuk informasi lebih lanjut

De pagina waar u naar op zoek bent, kan niet worden gevonden. Probeer terug te gaan naar de vorige pagina of bezoek het Help Center voor meer informatie

Naku, mukhang hindi namin mahanap ang pahina na hinahanap mo. Subukang bumalik sa nakaraang pahina o tingnan ang aming Help Center para sa higit pang impormasyon

The rumor that the China made iPhone LCDs can’t survive the upcoming iOS updates existed for quite a long time which aroused panic among repair shops. Many repair shops who want to use/have already used these screens to compete with authorized repair are wondering, will Apple brick these iPhone to kill the third party repair? We ETrade Supply don’t think so and here is why:

Do you still remember that users sued Apple for bricked iPhone due to "error 53"? The situation is almost the same except only few people have let their home button be replaced by third party repair shops. How many China made iPhone LCDs have been sold? We don’t have the exact number. However, from what we know, the number should be over 1 million pieces at least. Will Apple brick millions of iPhones just to kill third party repairs?

Same rumors for the 4/4S screen before. The OEM LCDs for 4/4s died out for quite a long time, all screens supplied were China copy one since 2 years ago. Not a case of bricked phone/unusable have showed for the updating to the new iOS system.

The most possible reason that this rumor has been created—is just to cut the price of the China copy iPhone LCD and more possibly-- the demand for it.

A week before the Apple event in March 2016, the rumor was “China made iPhone LCDs can’t survive in the coming iOS 9.3 updates”, the price of these LCDs dropped significantly and everyone was holding their orders, waiting to see the result. Within one week, the price has dropped around $10/pc. After people found out that they did survive, the price increased again and here came the rumor “the China made iPhone LCDs won’t survive the iOS 10 updates”.

Since last June, more and more repair shops have accepted the China made iPhone LCDs because less OEM screens are supplied. A large certain amount of demand of OEM iPhone screens has been moved the China made ones. The rumor that “the China made iPhone LCDs won’t survive the newest iOS updates” will sure bring some demand back to those crappy OEM screen which have been used for quite a long time/ refurbished for multiple times.

The rumor is “ALL the China made iPhone LCDs won’t survive the iOS 10 updates”, not only for 5 series. As we all know, there are already China Made 6 screens in the market. Those who stocked large amount OEM 6 screens will be happy to see people still paying high price for the OEM 6 screens for quite a long time.

The supply chain of cell phone replacement parts is sophisticated, unclear and without any standards, which make it look more like gambling. Find a reliable long-term relationship partner who can grow with you is the key to success for repair shops. If you have any questions regarding the China made LCDs, please leave your comment below!

Since there are some differences in quality between the China-made iPhone screens and original iPhone screens, so you need to be careful when handling the new iPhone screen replacement, according to our test, the top corner of the screen is one of the key parts that should be gently treated. Don’t push these 2 corners with force when reassemble the phone.

After installing front camera and ear speaker, you’ll need to hold them with the metal bracket, there is another point you need to be carefully dealing with, please note that all the screws have unique positions, don’t mix them with wrong position, and what needs to be paid more attention to is the rightmost one with a red circle showed below, do not twist this screw too tight, or which can somehow cause the screen cracked after reassembling the screen.

After connecting the screen connectors, then you may need to test the screen functionality before totally installed. You’d better make the angle between the screen and body is less than 45 degree during the screen test. With screen test finished, then the last step, make sure the screen replacement is properly aligned with the housing edge.

Use our “Get an Estimate” tool to review potential costs if you get service directly from Apple. The prices shown here are only for screen repair. If your iPhone needs other service, you’ll pay additional costs.

If you go to another service provider, they can set their own fees, so ask them for an estimate. For service covered by AppleCare+, your fee per incident will be the same regardless of which service provider you choose.

Your country or region offers AppleCare+ for this product. Screen repair (front) is eligible for coverage with a fee by using an incident of accidental damage from handling that comes with your AppleCare+ plan.

The Apple Limited Warranty covers your iPhone and the Apple-branded accessories that come in the box with your product against manufacturing issues for one year from the date you bought them. Apple-branded accessories purchased separately are covered by the Apple Limited Warranty for Accessories. This includes adapters, spare cables, wireless chargers, or cases.

Depending on the issue, you might also have coverage with AppleCare+. Terms and Conditions apply, including fees. Feature availability and options may vary by country or region.

We guarantee our service, including replacement parts, for 90 days or the remaining term of your Apple warranty or AppleCare plan, whichever is longer. This is in addition to your rights provided by consumer law.

Replacement equipment that Apple provides as part of the repair or replacement service may contain new or previously used genuine Apple parts that have been tested and pass Apple functional requirements.

China-based display maker BOE (Beijing Oriental Electronics) has a complicated relationship with Apple. But despite some missteps, it looks like the two companies will be working together for a while longer, at least: a new report from The Elec (spotted by MacRumors) pegs BOE as the display supplier for the rumored iPhone SE 4. This latest report comes as Apple is allegedly working on its own display tech — and trying to lessen reliance on its main display maker and rival, Samsung.

Things got off to a rough start with Apple in 2020 when some of BOE’s screens for the iPhone 12 reportedly failed quality tests. Later, Apple caught BOE making unapproved changes to its iPhone 13 display design. And while BOE eventually secured a deal to make 6.1-inch OLEDs for the iPhone 14, the company has reportedly been unable to produce iPhone 15 screens to Apple’s specifications. Instead, it looks like BOE will be supplying 6.1-inch OLEDs for the next budget iPhone.

That’s good news for the bottom line — the SE will likely use an older OLED design, so BOE can use existing parts inventory. But it’s not great news, as Apple has been trying to reduce its dependence on Samsung for displays. A new report from The Informationdetails just how much power Samsung holds over Apple as one of the only manufacturers able to mass-produce high-end OLEDs to its specifications. Samsung Display reportedly gets away with things that no other Apple component supplier would dream of, like not letting Apple engineers into its facilities and refusing to replace a supply of screens when a minor flaw was identified.

As much as Cupertino would like to cut ties with Samsung, it’ll likely be quite a few years before that becomes a reality. If and when it gets its MicroLED production off the ground, Apple will likely start small and use the tech in watches first. In the meantime, Samsung probably isn’t losing any sleep over the iPhone SE order going to its competitor. As The Elec points out, the modern LTPO OLEDs that Samsung makes for the iPhone 14 (and likely 15) cost more than twice as much as the legacy OLEDs the SE will reportedly use. Maybe things will be different in a few years, but until then, it looks like Samsung’s display production lines will be plenty busy making OLED panels destined for high-end iPhones.

It"s no secret that Apple iPhones are made in China. This fact is written on the packaging, or directly on smartphones. However, in the territory of China, only the individual parts are assembled into the final equipment. It is much more interesting to watch where the iPhone camera, battery or processor is made.

Namely, if you start researching where spare parts and components for iPhone devices are made, you will find that they areoften produced by competitors. For example, Samsung. Parts for Apple smartphones come from various countries around the world and their development is in charge of well-known companies. Which specifically? We will tell you this in the following lines:

For many users, an amazing camera is a significant factor in which they prefer the iPhone over competing smartphones. Apple relies on several camera suppliers, but the largest is the Japanese company Sony. It makes rear cameras. The American company OmniVisiontakes care of the delivery of FaceTime cameras to Apple smartphones. Older iPhone models can still be equipped with cameras from the manufacturer Qualcomm.

The display is one of the most frequently ordered Apple spare parts. iPhone smartphone screens are characterized by their fantastic graphics and color. They are manufactured by several companies, the largest of which is the South Korean company LG.Some displays are supplied by Sharp.

The touch screen driver, manufactured by Broadcom for Apple, is also worth noting with the iPhone LCD. Last but not least, the surface of any iPhone screen must not lack durable Gorilla Glass. This is supplied by the American company Corning.

You might not expect it, but it really is. The Korean manufacturer Samsung has been supplying batteries for iPhones for more than 10 years. The paradox is that he is considered to be Apple"s biggest competitor.

Like cameras, processors are one of Apple"s largest smartphone domains. Thanks to their excellent performance parameters,the devices can operate extremely smoothly in all circumstances. And who is the supplier of these exceptional chips? The answer may surprise you again. There are two manufacturers, one of which is Samsung again. The second is the Taiwanese company TSMC.

Fortunately, if you"re looking for replacement parts for Apple smartphones, you don"t have to order them directly from individual manufacturers. You will find them all in our wide offer!

I built a like-new (but really refurbished) iPhone 6S 16GB entirely from parts I bought in the public cell phone parts markets of Huaqiangbei. And it works!I’ve been fascinated by the cell phone parts markets in Shenzhen, China for a while. I’d walked through them a bunch of times, but I still didn’t understand basic things, like how they were organized or who was buying all these parts and what they were doing with them.

So when someone mentioned they wondered if you could build a working smartphone from parts in the markets, I jumped at the chance to really dive in and understand how everything works. Well, I sat on it for nine months, and then I dove in.

You might wonder why I chose to make an iPhone 6s and not an iPhone 7. I had two reasons. The first was that I already own an iPhone 6s that I bought in an Apple store, and I thought I might end up needing to have an identical phone to the one I was trying to build that I knew was assembled by Apple to compare against. In the end, this was never really an issue, and I never ended up having to open it up. It is nice to be able to show people the phone I built side-by-side with a phone bought in an Apple store though.

However, the other reason, which turned out to be far more important, is that iPhone 7 parts are pretty hard to come by in the markets. It’s not totally clear why this is, but I have some ideas. A lot of the parts come from recycled/broken phones, and so it would make sense that there just isn’t that much supply yet. I also think there’s probably really high demand for iPhone 7 parts, so what parts are available may get traded before they make it out into display cases. In some cases, even iPhone 6s parts were a bit hard to come by (mostly the logic board). I keep asking people about this, and people keep saying things like “there should be more after Spring Festival” (which has come and gone) or “there should be more in a month or two – it’s just a temporary shortage right now”. I’ll keep my eyes out – it’ll be interesting to see how this evolves over time.

Logic board – This is like the motherboard in a computer. It’s the circuit board that has the processor, flash memory, wifi/cell chips, etc on it. Everything plugs into this. The one I bought is refurbished/repaired, almost undoubtedly from a real, legitimately purchased phone made by Apple that was recycled at some point.

It came with the touch id sensor, because the processor and touch id sensor are cryptographically paired. This means that touch id no longer works if you swap out the touch id sensor. This is for security reasons, to make it harder for someone to malicious bypass touch id to unlock your phone without your permission. But it’s a really crappy restriction when it comes to repairing/refurbishing phones.

Screen – I really wanted to assemble my own. But there were two issues – you need a bunch of bulky equipment and I had an incredibly hard time trying to buy a bare lcd/digitizer. You can get them apparently, but they don’t seem to be readily available over the counter in the markets. So instead, I bought a broken screen from a phone repair booth, and had them completely disassemble and then reassemble it with new parts, other than the lcd/digitizer.

Back/Shell – I originally wanted to make a gray phone with a black front, to match my everyday carry phone I bought in an Apple store. That way I would have something to compare against. But I ended up having a hard time finding a logic board with a black touch id button. However, there were lots of logic boards with white touch id buttons with rose colored rings, meant for a rose colored phone. So I ended up buying a second, rose colored back, hence the rose colored phone. The back I bought had an Apple logo, but zero laser markings inside or outside, so I’m pretty sure it’s not from a used phone.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

:max_bytes(150000):strip_icc()/where-is-the-iphone-made-1999503-48f09708f8af44f288c08ea09abddc04.jpg)

Apple is considered a sign of luxury and due to that its products have a huge demand. To meet this demand, Apple started to open factories in other countries. China is so far the largest producer of Apple products in the world.

Why is Apple using China as its source for iPhones and iPads? Well, in this chapter, we will try to explain in detail why Apple is doing so. These facts and figures will help in understanding what is going on.

See, the thing is that about 46 percent of Apple suppliers are Chinese manufacturers and firms. That means that over 360 suppliers from China are working for apple, creating every component required for building the iPhone/iPad.

Take a look at this that two cities nearby Chinese Delta rivers (Pearl River Delta and the Yangtze River Delta) have the most Apple suppliers that make components such as LCD screens, mics, sensors, cameras, RF readers, and every other component.

Whenever you get your new iPhone, you think that it is made in California. Well, if you look closely, it is written as “Designed by Apple in California, Assembled in China”.

Apple is considered as the symbol of luxury and that is why it has a huge demand all over the world. To meet the demand, Apple needs a workforce that can create thousands of iPhones in a matter of days.

And that is where Apple China comes in. Other than that, China has the skill set that is required to make complex components of the iPhone and other Apple products.

Why Apple is manufacturing products in China? Apple has the option to select countries such as India or Bangladesh. But why China is the only one that has this advantage? Well, here is why.

China has the power to meet the demand for Apple products and that can be defined in a number of ways. For instance, firstly, China has the skillset to develop new products for Apple.

As an example, last year, Apple iPhone 12 sales went beyond expectations. That was all because China helped Apple in making the iPhone 12 models at a very large scale. And that is how Apple China is meeting the demand.

The first one is that in China, the average working wage is relatively lower than in USA. Due to this, the Chinese firms are able to produce Apple products in lower cost and give more profit margins to Apple.

So, the making of components and assembling those components is straightway done in China (That is why you see “Assembled in China” at the back of the phone).

Another reason why Apple is manufacturing in China is the targeted audience. See, Apple is popular all over the world that includes regions such as UAE and Asia.

It is expensive to ship iPhones from the USA to these areas. So, with the help of China, Apple can lower that cost and can deliver phones to the vendors working in Asia and gulf countries.

The reason China is going with Apple products is that it has the resources that help Apple in meeting the demand. And by resources, we mean the workforce.

Actually, the thing is Chinese are considered hardworking people and that is true. Apple is taking the advantage of that because China has the capability of producing almost 100,000 iPhones every year.

Yes, mainly China handles the production of iPhones and new Airpods, people can also get their hands on items such as iMacs, iPods, iPads, and other related products at an optimum price.

However, there is a misconception that Apple products in China are cheap, compared to the rest of the world. Well, these prices are similar or differ a little bit to those you get in countries like the USA, UK, and Europe.

Now, let’s move towards the section that contains some of the key vendors of Apple that provide the components required for making the Apple products such as iPhones and iPads. This information is only provided to give you an idea of how Apple is working in China.

Foxconn is a contract manufacturer of Apple based in Taiwan. The company is famous for producing Iphones for the US-technology giant Apple. It is headquartered in Taipei, Taiwan.

They are have a giant Foxconn factory in Shenzhen, China. Foxconn brought revenues of around $175bn in 2018 and it was ranked 24t among the fortune 500 companies.

Foxconn manufacturers around 60-70% of the Iphones sold each year and Apple is by far Foxconn’s largest customer. Foxconn also developed some equipment for Iphone in order to increase their profit margins.

The first official vendor that is working for Apple is Bosch Sensortec. Bosch is a worldwide operating company based in Germany that provides components such as barometer, pressure, and humidity sensors.

The company’s Chinese firm is related to Apple and makes accelerometer sensors for Apple iPhones. Similarly, it also makes accelerometer modules for Apple iPad devices.

Cirrus Logic is a US-based technology company that makes audio components for various companies. They have factories in China that are producing audio chips for Apple.

The reason you get good battery timing on the iPhones is that the batteries are made by Sunwoda Electronics. Sunwoda is a maker of lithium-ion batteries that makes batteries for cars as well as phones.

Qualcomm China uses its resources to make camera modules for iPhones. These modules include the camera algorithm, chassis, lens, and focus sensor for the iPhone.

These devices include communication ICs, audio chips, current sensors, and compass modules. AKM, China makes compass sensors for all iPhones and it is doing that since the launch of the iPhone 6

Like Qualcomm, TSMC is another important partner of Apple that is working from China. TSMC is a Taiwan-based company that makes LCD/AMOLED screens for Apple as well as Samsung.

The Chinese branch of the company provides screens for Apple iPhones and iPads. Moreover, the company also makes the glass that is required for screens for Apple.

There are two terms that are required to be understood- Assembling and manufacturing. In this chapter, we are going to discuss and whether China is a manufacturer of Apple products or an assembler. Let move forward.

Before talking about assembling, let’s talk about the manufacturing term. Manufacturing means that a company makes the product from scratch using raw materials.

Talking about assembling, let’s take an example, suppose you are the assembler of a shoe company. You take the laces from another company, sole from another one; hire a firm that designs the logo and design of the shoe.

Then, you take all these parts and then join them together. Assembling is a cheap process when compared to manufacturing because there is no need to buy machines and spend money on designing the product.

In simple words, you can say that China is a manufacturer and the assembler of Apple. Some companies are just the manufacturer and some are just the assembler. Some may even do both like Foxconn.

Foxconn or also known as Hon Hai Precision Industry Co. Ltd is the longest partner of Apple that is giving its services in assembling Apple devices as well as producing some.

Foxconn is a Taiwanese-based company that designs and produces electronic components such as PCBs, computer chips. It is headquartered in New Taipei City, Taiwan, China. Foxconn also has its assembling facility in China.

Apple is linked with Foxconn China and for Apple, Foxconn is assembling the Apple products. Foxconn holds the assembly of the majority of Apple products because it is the first partner of Apple in China.

Pegatron is another Taiwan (China) based company that makes computing and consumer electronics for vendors. It also designs and manufactures computer peripherals.

The mainland China facility of Pegatron uses its resources for making Apple products. The company has new ties with Apple. However, it is playing an important role in assembling Apple products.

The company currently assembles the majority of iPhones, Ipads and MacBooks in its Shenzhen assembly plant. Foxconn also operates in countries like Thailand, South Korea, Czech Republic.

Similarly, Foxconn also assembles iPads for Apple. It has worked on iPads series such as iPad generation 3, 4, 5, and 6. Currently, it is also assembling the latest iPad.

Pegatron is the second assembler of Apple that uses its resources to assemble iPhones. Pegatron has a new partnership with Apple. At the launch of the iPhone 6, Pegatron assembled almost 30% of the phones to meet the demand.

Goertek uses its HQ (Head Quarter) facility to assemble Apple Air pods. The newest Apple headphones (Air Pods Max) are assembled with the resources and knowledge of Goertek.

Like Goertek, Luxshare is another Chinese company that assembles consumer electronics, telecom equipment, and audio parts for automobiles. Luxshare is a key assembler of Apple Air Pods and it has assembled both Air Pods 1 and 2 for Apple.

Apple does not have own factory and make products in China. It has given a contract to multiple Chinese companies that make and produce Apple products.

Apple entered China in 2001 and due to the high demand, Apple partnered with Foxconn and China to assemble the iPhones and iPads in the production facility of Foxconn in Zhengzhou. Later the production and assembling shifted to Shenzhen facility of Foxconn.

There is a misconception that China is the center of Apple so the products here are cheaper than the rest of the world. Well, that is not true. In fact, Apple products in China are a little bit expensive when compared to the rest of the world.

There are no Apple-owned factories in China. However, we can say that Foxconn and Pegatron and others are the companies in China that is making the product and assembling it as well. Plus, Apple is using the help of various Chinese companies to make its components.

Till now, Apple has not stopped the manufacturing of its products in China. However, it is planning to move its assembling factories to India and Vietnam because of low assembling costs. This is also due to the trade war during Donald Trump presidency between China and USA.

Apple has gained a lot of attention due to the fact that it is considered a sign of luxury. Apple products have a huge demand and there is no way to meet this demand unless there is a huge workforce present with Apple. That is where China comes in.

We hope that this blog has provided you all the information of what kind of products are being made in China for Apple company and which companies and Manufacturing it and which are Assembling it.

Apple’s iPhone X is notoriously hard to repair. Its screen and back are made of glass, and dropping the $1,000 iPhone will often break an unprotected device. Users who want to repair a cracked screen with Apple will have to pay upwards of $279 for the service.Users who want to go another way and pay a third party repair store for a replacement have thus far been out of luck—aftermarket parts for the new wave of Apple devices simply didn’t exist. Worse, iOS software updates can cause problems with phones repaired with aftermarket parts.AdvertisementBut there’s a new wave of replacement screens coming out of China that promise to make repairing the iPhone X a little cheaper and easier if they can work out their own unique kinks. The first is a liquid crystal display (LCD) screen, first spotted by Mobile Defenders.

The existence of aftermarket LCD iPhone X displays is surprising, because the iPhone X ships with an organic light-emitting diode (OLED) screen. That means third-party screen manufacturers have found a way to make an entirely different technology (which is used in other versions of the iPhone) work with the iPhone X.Mobile Defenders tested out the screens and found a couple of quirks. They have a red shift when viewed from an angle, are thicker than the OEM OLED screen, and run hotter than an original iPhone X screen. Repair experts who have tested the screens say that it uses the iPhone X’s battery faster than expected.“This is not a proper solution, and is almost guaranteed to be blocked by Apple in the near future,” Kev Notton—founder of San Diego-based RepairMapr, a diagnosis tool repair shops can use to annotate repairs—told me on Facebook. “We wanted to warn anyone that may purchase them off eBay/Amazon thinking that they"re the real thing.”There are listings for the screens on eBay, though a lot of repair professionals are getting them direct from suppliers in China. Confusingly, many of the listings refer to the screens as both LCD and OLED. They also tend to cost more than the $279 Apple charges for replacing the screen. “The term LCD is so loosely interchanged with "display" these days, kinda like Kleenex to tissues, so I can certainly see average consumers being confused by it,” Notton said.For Notton, even if a person who gets an LCD to replace their OLED is informed, the next person who uses the phone might not be. “Most of these devices have 3 or more owners in their lifetime,” he said. “Even if a single customer wants a cheaper repair, the next owner of that device won"t know they"re receiving a device with a lower quality technology inside.”Aftermarket OLED screens have hit the market too. A video uploaded by REWA Technology—a Hong Kong based wholesaler—showed off the differences between the OEM screen, the LCDs, and the new OLED.

The aftermarket OLED screens had normal touch functionality and ran a little thinner than the OEM screens, but the sample REWA used in its video had a glitch that caused bright pink lines to run across the whole screen. Despite that, REWA and other third-party repair stores are hopeful that the new batch of screens from China will soon be provide customers a cheap and easy alternative to Apple’s official repair process. “It’s a start,” Michael Oberdick, founder of the Ohio-area repair store iOutlet, told me over Facebook. “I obviously wouldn’t put on a customer’s phone yet but I’m sure there is cases out there that the consumer is informed by a repair shop about the difference and possible issues and will put it on their device as it may be their only / quickest option.”

There are several display panel manufacturers in mainland China of which JDF(BOE) and TM(Tianma) stand out noticeably. JDF has gradually transformed its 6th production line into small-to-medium-size displays since 2014 and now JDF proceeds this plan and concentrates production capacity in this field in an all-around way.

As a matter of fact, TM(Tianma) has already transformed its display size and capacity altogether in late 2013 in prior of JDF(BOE), focusing on small-to-medium-size displays.

In addition to this, though SC which was vigorously supported by Foxconn had been performing mass production for LTPS, TFT, LCD displays at the beginning of 2012, did not make a great progress for the reason that SC failed to neither win over the Apple iPhone orders and nor get authorization in CG Si and IGZO technology of Sharp.

But do you know which iPhone 6 LCD made by these three display penal manufacturers is more cost-effective? Let’s go on with this article and sort things out. Not too long ago, REWA has analyzed the JDF(BOE) and LT(IVO) China made iPhone 6 LCDs in some ways. After several months’ development, how is the situation now? We have tested 3 mainstream China-made iPhone 6 LCDs by JDF(BOE ), TM(Tianma) and SC from aspects of “Appearance” and “Function” in order to make a comparison with OEM ones and give us clarity of thought.

After installed in the mobile devices, it’s much easy for us to find that all these three China made LCDs have a small gap between the LCD and device body, especially SC.

It can be observed visually that LCD Display and Touchscreen digitizer flex cable made by JDF, TM and SC are different in texture. 5) Structure Generally speaking, there are two kinds of mainstream cell phone display constructions of formation, “G+G” and “In-cell”.

Compared with the In-cell structure of OEM LCD, JDF, TM and SC which use G+G touch screen display technology thus cause their overall thickness greater than the OEM ones.

Testing Touch screen digitizer by moving the app icon in all directions including swiping from the edge of the screen, JDF, TM and SC display have no problems with touch function.

Testing LCD display in the pure color of gray, white and black, a part of JDF, TM and SC LCDs have somewhat degree problems of backlight leakage, but it does not affect the normal use and can be ignored in a certain sense. Note: The severity of this problem in the actual situation is a lot more slight than the captured pictures above.

After playing video for 72 hours, JDF, TM, SC have no obvious differences with the OEM ones. CONCLUSION From a series of tests we can find there are only a few differences between OEM display and China made LCDs. In terms of quality, JDF & TM are better than SC. For Price, JDF is more favorable than TM. Therefore, on the market condition that OEM LCDs being out of stock, JDF LCD is the most cost-effective choice for you. Want to order our products? Please contact us: PRE-SALES Skype: rewatech Email: service@rewa.tech AFTER-SALES Skype: support-rewatech Email: support@rewatechnology.com And you can also check our repair guides:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey