how tft lcd works manufacturer

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

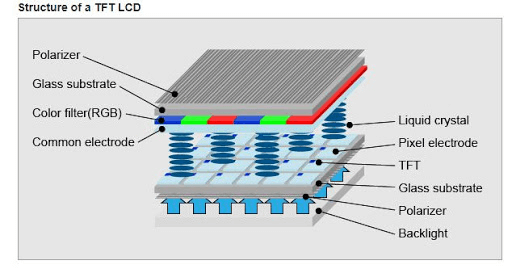

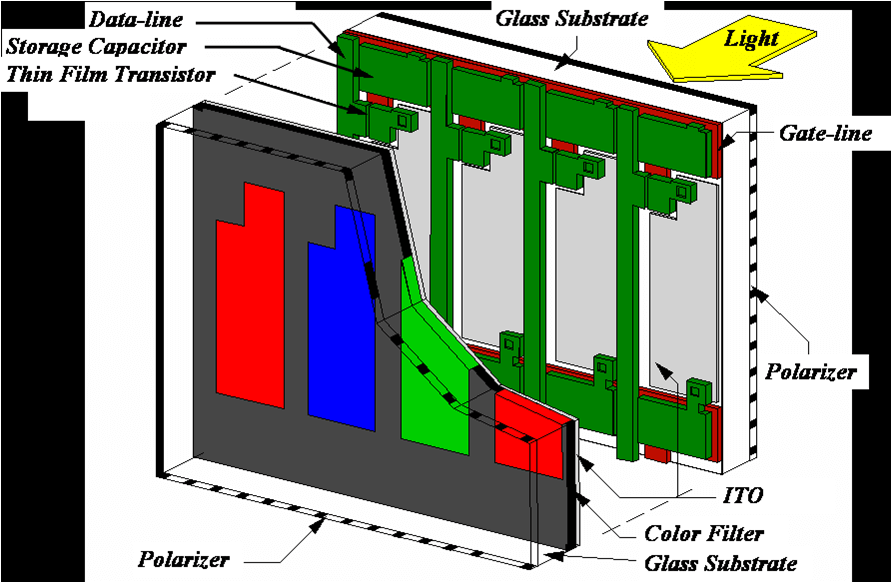

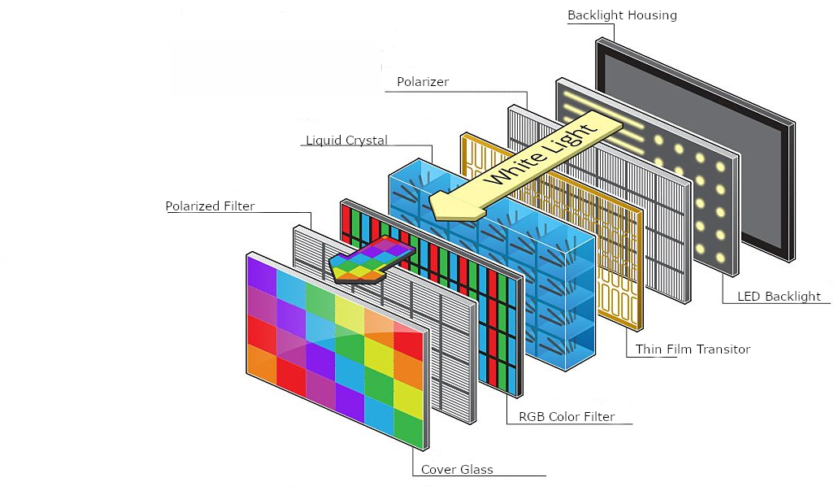

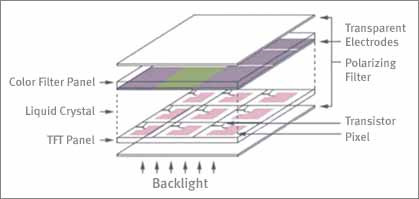

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

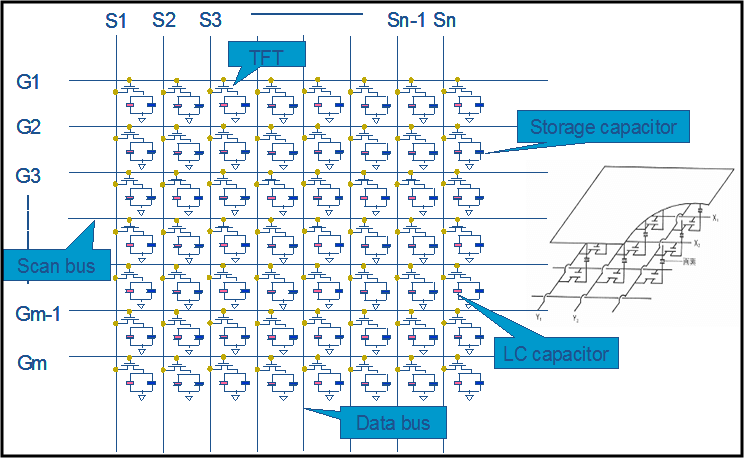

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

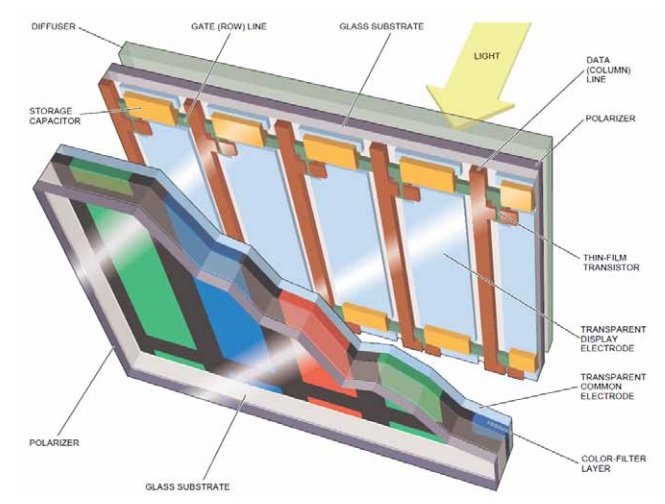

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

The twisted nematic effect is one of the cheapest options for LCD technology, and it also allows for fast pixel response time. There are still some limits, though; color reproduction quality may not be great, and viewing angles, or the direction at which the screen is looked at, are more limited.

Fig. 3:The top row characterizes the nature of alignment in using IPS as well as the quality of viewing angles. The bottom row displays how the twisted nematic is used to align the crystals and how viewing angles are affected by it.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

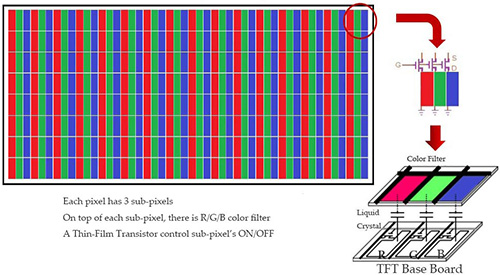

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

![]()

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

The TFT LCD screen display, for the general masses, is no longer a difficult noun. And it is another after semiconductor could create a large number of emerging technology products of the business turnover, more because of its features, thin so it than using the application scope of the cathode ray tube (CRT, cathode ray tube) display made by wider. Today, I’m going to talk about how the TFT LCD Touch Screen Display Works.

As I mentioned earlier, liquid-crystal displays (LCDs) refer to a bunch produced by using the TFT screen LCD display. Now for LCD displays the name is directed mostly used in notebook computers, or desktop computer applications display. Is the thin film transistor TFT LCD display. Abbreviation of TFT LCD. This kind of display form has two main characteristics, one is a thin film transistor, the other is TFT LCD itself. Let’s talk about the TFT screen itself.

This type of TFT LCD screen was first discovered, had been spent more than one hundred years ago. In 1888 AD, the Austrian botanist Friedrich Reinitzer, found in the observation from the plant refined out of benzoic acid cholesterol (cholesteryl benzoate) found that when the melting behavior of the compound heated to 145.5 ℃, Solid can melt, presents a kind of solid phase and liquid phase between the half gonorrhea melt flow of the liquid. This situation will always maintain ℃ temperature rise to 178.5 degrees, to form a clear isotropic liquid (isotropic liquid).

The next year, in 1889, the study of thermodynamic equilibrium and the phase transfer German physicist O.L Ehmann, compounds for a more detailed analysis of this. He found that under the polarizing microscope, half of the viscous liquid gonorrhea liquid compounds with different parts peculiar to the crystal birefringence (birefringence) of the optical properties, namely, optical interphase (optically anisotropic). It will be a name to this as the liquid crystal. Since then, scientists will be the nature of this new discovery, known as the fourth state material – LCD (liquid crystal). It at a specific temperature range can have the characteristics of the liquid and solid at the same time.

The liquid crystal state, as the name implies, will be a solid lattice and the liquid. When the liquid crystal was found, because of a lot of more phyletic, In 1922, the results observed by g. Friedel with a polarizing microscope divided liquid crystals into Nematic Smectic and Cholesteric categories. However, if they were classified according to the order of molecular arrangement (see figure 3), they could be divided into the following four categories:

Its structure is composed of TFT LCD molecules stick together, forming a layer structure. It’s every layer of the molecular long axis direction parallel to each other. And the long axis direction for each layer plane is vertical or a tilt Angle. Due to its structure is very similar to crystals, so they are called phase. The order parameter S (the order parameter) tend to be 1. Type in layered crystal layer and interlayer bonding can fracture because of temperature, so the layer and interlayer sliding more easily. But each layer within the molecular bonding is stronger, so it is not easy to be interrupted. Therefore in the context of the monolayer, Its arranged orderly and viscosity is bigger. If we use the macroscopic phenomenon to describe the physical properties of liquid crystal, we can make a group of regional average points as the liquid crystal molecules are pointing in the direction of the arrow (director), which is the direction of a group of liquid crystal molecules regional average. And with lamellar liquid crystal, because of its structure, the TFT LCD molecules will cambium-like so can point to a vector of different classification of the different lamellar liquid crystal again. When the long axis of the liquid crystal molecules are vertical stand, Call it “Sematic A phase.” if stand long axis direction of the TFT LCD molecules have some Angle of tilt (tilt), call it “Sematic C phase”. In A, C and other letters to name, which was discovered in accordance with the order to address, and so on, there should be A “Semantic phase B is.” but later found A deformation phase B is C phase, And the liquid crystal molecules in the structure layer by layer, in addition to each layer of TFT LCD molecules have tilt Angle, the tilt Angle between layer by layer will form a helical structure.

Nematic is a Greek word, the word mean in the thread is the same as in English. Mainly because with the naked eye to observe the liquid crystal, it looks like a silk pattern. The LCD screen molecules on the space of the regular arrangement of one dimension, all rod long axis of the liquid crystal molecules will choose a particular direction (that is, pointing vector) as the main shaft and arranged parallel to each other. And don’t like lamellar liquid crystal has a layered structure. Compared with the layer column type liquid crystal alignment is no order, That is to say, its order parameter S is smaller than the lamellar liquid crystal, and its viscosity is smaller, so it is easier to flow (its flow mainly comes from the free movement of molecules in the long axis direction). Linear liquid crystal is the common TFT LCD display screen TN(Twisted nematic) type liquid crystal.

Most of the sources of the name, because are generated by the derivative of the cholesterol. But some without cholesterol structure of LCD screen with this liquid crystal phase. This kind of liquid crystal as shown in figure 5, if it is a layer of a layer to separate, would very much like a linear LCD screen. But look at the Z-axis, may find it pointing in the direction of the arrow will with layers and layers of different distribution, like a spiraling when the pointing vector rotate 360 degrees for molecular layer thickness is called a pitch. Because of its every layer like linear LCD, so also known as Chiral nematic phase. In terms of cholesterol crystal, and pointing in the direction vector of the vertical distribution of LCD screen molecules, due to the different point to vector, will have the different optical or electrical differences, thus has produced different features.

If we are according to the molecular weight of high and low points can be divided into liquid crystal polymer (polymer liquid crystal, the polymer in many of the liquid crystal molecules) and low molecular liquid crystal. This kind of classification of TFT LCD belongs to the application of the low molecular liquid crystal. If the reasons for the formation of liquid crystal state, because it can be divided into type temperature formation of liquid crystal state to a liquid crystal (thermotropic), and because of the concentration and the formation of a liquid crystal state type lyotropic liquid crystal (lyotropic).

The solution so types lyotropic TFT screen molecules in the appropriate solvents reaches a certain critical concentration, the formation of liquid crystal state. Type lyotropic liquid crystal is one of the best examples that is soap. When soap bubbles in the water will not be at once into a liquid, and the bubble in the water for a long time, after the formation of white matter, is its liquid crystal state.

Our dielectric coefficient can be separated into two directions respectively is epsilon / / (and point to parallel component) and epsilon coming (a component perpendicular to the pointing vector). When the epsilon / / > epsilon coming then called the dielectric coefficient of different parts of LCD, can be used in parallel coordination. And epsilon / / < epsilon is called the dielectric coefficient of the different part coming negative type of TFT screen, only can be used in vertical coordination will need the photoelectric effect. When the applied electric field, the liquid crystal molecules will vary with dielectric coefficient is positive or negative, To determine whether the orientation of the liquid crystal molecules is parallel or perpendicular to the electric field, to determine whether the light penetrates. Now on most commonly used type TN LCD TFT LCD that belongs to the dielectric coefficient are type liquid crystal. When the dielectric coefficient of square difference Δ epsilon (= epsilon / / – epsilon) comes, the greater the LCD of the critical voltage (threshold voltage) will be smaller. So the LCD can be in the low voltage operation.

In accordance with the described above, the lamellar liquid crystal, linear liquid crystal, and LCD screen for cholesterol levels, because of its long liquid crystal molecules like a stick, so point to the direction of the vector and the molecular long axis parallel. To be defined with reference to the refraction coefficient of a single optical axis crystal, it will have two refractive indexes, respectively is perpendicular to the direction of the long axis of the liquid crystal n coming (= ne) and parallel to the long axis of the liquid crystal direction n / / (= no), so when the incident light liquid crystal, will be affected by two refractive indexes, cause in the vertical long axis of the liquid crystal and LCD long axis parallel to the direction of the speed of light will be different.

If with the molecular long axis parallel to the direction of light speed, when less than perpendicular to the speed of the molecular long axis direction, which means that parallel the molecular long axis direction of refractive index is greater than the vertical direction of the refractive index (because the refractive index is inversely proportional to the speed of light), is the one – no > 0. So the birefringence Δ n > 0, we think that it is called optics is a type of LCD, and lamellar liquid crystal and LCD are all belong to the optical is almost linear LCD. If the light of the parallel to the direction of the long axis was faster, On behalf of the flat to the governor of the axis of the refractive index is less than the vertical direction, so the birefringence Δ n < 0. We call it is the optical negative type of LCD. The cholesterol liquid crystal optical negative type of LCD.

For example, the elastic constant (kappa 11, kappa 22, kappa 33) contains the three most important constants: kappa 11 is the elastic constant at splay, kappa 22 is the elastic constant at the twist. Kappa 33 refers to predominating the elastic constants of bending (bend). The other as the coefficient of viscosity (viscosity coefficients and eta), will affect the rotational speed of the liquid crystal molecules with reaction time (response time), its value as small as possible. But this feature is affected by temperature is the largest. In addition to magnetic susceptibility (magnetic susceptibility), but also because of liquid crystals of different sex, Divided into c / / c coming. And the difference of magnetic susceptibility is defined as Δ c = c / / – c coming. In addition to the conductance coefficient (conductivity), and so on the photoelectric properties. Liquid crystal properties of the most important are the dielectric coefficient and refractive index of liquid crystal. The dielectric coefficient is determined liquid crystal under the influence of the electric field to the characteristics of the liquid crystal molecules, while the refractive index is liquid crystal in the light of its important parameters influencing the light path. The LCD is in using the liquid crystal itself of these features, the appropriate use of voltage, to control the rotation of the TFT LCD molecules, in turn, affect the direction of the light, to form different grayscale, a tool for displaying images. Of course, LCD itself is not alone as the monitor, also need other materials to help, Below, we will introduce the composition of various materials and operating principle of TFT LCD display.

The upper and lower two layers of glass are mainly to grip the LCD with. Below the glass layer with Thin film transistor (thin film transistor, TFT screen), while the layer above the glass with a Color filter (Color filter). If you notice (see figure 3), these two pieces of glass are in contact with the side of the LCD screen, not smooth, but with jagged grooves. The main purpose of the groove with the hope of a long rod, liquid crystal molecules will line up along the grooves. In this way, Liquid crystal molecules are arranged neatly. Because if it is smooth and flat, the arrangement of the liquid crystal molecules will not neat, causing light scattering, forming a light-leaking phenomenon. In fact, this is just a theory that told us to put the glass and LCD interface, complete processing so that the arrangement of liquid crystal has a certain order. But in the actual manufacturing process, and can not be with such a groove, the distribution of glass is made usually in glass coating on the surface layer of the PI (polyimide), and then a cloth to do the action of friction (rubbing), In order to make the surface molecules of PI no longer be scattered and arranged in a fixed and uniform direction, this layer of PI is called the coordination membrane, and its function is just like the grooves in the glass in FIG. 3, which provides the interface conditions for the uniform arrangement of liquid crystal molecules and allows the liquid crystals to be arranged in a predetermined order.

We can know from figure 10, when there is no applied voltage between the upper and lower two pieces of glass, the arrangement of LCD will be in accordance with the match to the membrane of the upper and lower two pieces of glass. For TN type of LCD, and match to the film’s point of view of the poor to 90 degrees. (see figure 9) so the liquid crystal molecules are arranged by the up and down automatically rotate 90 degrees when the incident light passes through the upper polarizing film, the polarization of light waves will only order direction. Through the liquid crystal molecules, the liquid crystal molecules rotate for 90 degrees, so when the waves reach the lower polarizing film, the polarization direction of the light just turned 90 degrees. The polarizing film of the lower and upper polarizing film, 90 – degree Angle is just the differences. (see figure 9) so can smoothly through the light, but if we applied voltage between the upper and lower two pieces of glass, because the type TN LCD for the dielectric coefficient of different sex more positive type of LCD (epsilon / / > epsilon coming, represent the parallel direction of the dielectric coefficient is larger than the dielectric coefficient of the vertical direction, so when the liquid crystal molecules are influenced by an electric field, will tend to be parallel to the orientation of the electric field direction.), so we can see from figure 10, At this time, the polarized light wave passing through the upper polarizer will not change the polarization direction when passing through the liquid crystal molecule, so it cannot pass through the lower polarizer.

The so-called NW (Normally white), is to point to when we don’t apply voltage on the LCD screen panel, we can see the panel is pervious to light, also is bright, so-called Normally white. But on the other hand, when we don’t apply voltage on the LCD panel if the panel is not pervious to light, the look is black, it’s called NB (Normally black). We have just mentioned in figure 9 and figure 10 all belongs to the configuration of NW, also we can know from figure 11, For type TN LCD, located in the upper and lower glass is perpendicular to the membrane, and the difference between NB and NW just lies in the relative position of the polarizing film is different. For NB, the fluctuation of the polarizing film polarity is parallel to each other. So when the NB no applied voltage, the light will be because the polarity of the LCD to rotate 90 degrees to be pervious to light. Why there are NW and NB these two kinds of a different configuration of the polarizing film? Mainly for different applications. Commonly used in a desktop computer or notebook computer, most of the NW configuration. That’s because, if you notice, generally the use of computer software environment, you will find that most of the entire screen is a bright spot, that is to say, computer software for the application of white background and black text. Since on the point of the majority, using NW is more convenient, of course. Also because the NW window does not need to add the voltage, the average will compare to save electricity. In turn, said that the application of the NB environment mostly belongs to the screen for the application of black.

The STN LCD and TN LCD are very similar in structure, the main difference between TN LCD, the arrangement of the liquid crystal molecules, the rotation angle from top to bottom. A total of 90 degrees and type the STN LCD liquid crystal molecules are arranged, the rotation angle will be greater than 180 degrees, usually is 270 degrees. (see figure 12) because of its rotation Angle is different, its characteristics different. We from figure 13 TN type and type the STN LCD voltage of the transmittance curve can know, when the voltage is low, the light penetration rate is very high. With a high voltage, the light of the penetration rate is very low. So they belong to the Normal White polaroids configuration. When the voltage in the middle position, the change of type TN LCD curve is flat, and the change of the STN LCD type curve is steep. So in TN type LCD, when transmittance change from 90% to 10%, corresponding to the voltage difference is larger than the STN LCD. We mentioned before, in the liquid crystal display, The different characteristics of TN and STN will result in TN type LCD, which has more grayscale changes than STN type LCD, so generally TN type LCD has 6~8 bits of changes. It is 64 ~ 256 gray-scale changes. Type the STN LCD for a maximum of 4 bits are only 16 orders of gray-scale changes. In addition, the STN type and TN LCD has a different place is the reaction time (response time) general type the STN LCD it’s response time to type in more than 100 ms and TN LCD its response time is 30 ~ 50 ms as shown in the image change quickly for the STN LCD type ghosting effect phenomenon is easy to happen.

TFT LCD Chinese translation of the name is called a thin film transistor liquid crystal display, from the beginning, we mentioned LCD voltage control is needed to produce gray. And the use of a thin-film transistor to generate the voltage, to control the transition of liquid crystal display, is called a TFT LCD. From the point of the cross-section structure of figure 8, between upper and lower two layers of glass, with LCD, will form a parallel plate capacitor, we call it the CLC (capacitor of liquid crystal). Its size is about 0.1 m3, But on the practical application, the capacitance and unable to keep the voltage to the next time to update the data in the picture.

That is to say, when TFT is good to the capacitor charging power, it is impossible to maintain voltage, until the next TFT this point charge again. (in general of 60 Hz screen update frequency, need time to keep about 16 ms.) as a result, there were changes in voltage, displayed gray scale is not correct. Therefore generally on the design of the panel, we will add a storage capacitor CS (storage capacitor is about 0.5 pF). So charged electric voltage can keep until the next update screen. But the right, long on the glass TFT itself, just use a transistor to make the switch. Its main work is to determine the LCD source voltage on the driver whether to charge to this point. As for this point more charge to high voltage, so as to show how the gray-scale. It is outside of the LCD source driver.

If you have a chance, take a magnifying glass, close to the LCD screen. You will find that as shown in figure 9 shows. We know that red, blue and green, are the so-called primary colors. That is to say, using the three kinds of color, can produce a variety of different colors. In a lot of flat-panel displays, this principle is used to show the color. We put the RGB 3 kinds of color, is divided into independent three points, each has different gray-scale changes, then the three neighboring RGB display point, as the basic unit of a display, Pixel is that this a pixel, and can have different color changes. Then for a need for a 1024 * 768 resolution display screen, we just let the composition of the flat panel display with 1024 * 768 pixels, can show a picture of the right. In figure 9, each point between the Black part of RGB is called the Black matrix. We can find that looking back on it in figure 8Black matrix is mainly used to cover do not intend to previous to light part. Such as some ITOs walk the line, or Cr/Al walk the line or are part of a TFT. This is why we in figure 9, the highlight of each RGB, it seems, is not a rectangle, and also on the top left corner is a piece of black matrix cover part, this part of a black missing Angle is the location of the TFT.

Figure 9 shows the common arrangement of color filters. Stripe is most commonly used in OA products, such as laptops, desktop computers, etc. Why is stripe used in this application? More often than not, the reason is now software is the Windows interface. That is to say, we can see the screen content, is composed of a pile of boxes of various sizes. The strips, just can make the edge of the box, look more straight, and there won’t be a straight line, look have the feeling of burrs or serrated. But if it is applied in the AV products, just not the same. Probably because the TV signal is a character, the character of the line is not straight, the contour is a mostly irregular curve. So in the beginning, the Use Mosaic arrangement used in AV products is (Mosaic, or called arranged diagonally). But the latest AV products, more have been improved to use triangle arrangement (triangle, or known as the delta). In addition to the above arrangement, still have a kind of arrangement, which is called a square arrangement. It is not the same as the first few, it is not three-point to as a pixel, but with four points as a pixel. And just four points are combined to form a square.

The CRT screen, it is using a high-speed electron gun that emits electrons, hits the phosphors on the silver screen, so as to produce the light, to show the picture. LCD itself, however, can only control the brightness of the light through, no glowing function itself. Therefore, a liquid crystal display must be combined with a backplate, to provide high brightness, brightness, and uniform distribution of the light source. We can see in figure 14, of the backplate of the main parts are CCFL (cold cathode tube), reflex plate, guide plate, prism sheet, Diffuser plate, and so on. Tubes are the main light-emitting parts, by a light guide, everywhere. The light distribution and baffle will be limited only to the TFT LCD light direction. Finally, by prism sheet and help diffuser, the light evenly distributed to all areas, provide TFT LCD a bright light. While TFT LCD is borrowed by the rotation of the voltage-controlled liquid crystal, control through the brightness of the light, so as to form different grayscale.

Another box in figure 14 glue and spacer structure of two kinds of ingredients. The box adhesive USES is to make the LCD panel in the upper and lower two layers of glass, to be able to stick close and to provide a panel of LCD screen molecules, cut off from the outside world, so the box plastic as its name suggests, is around and around in the panel to the liquid crystal molecules box limited to within a panel. The spacer is mainly provided two-layer glass support, it must be distributed evenly on the glass, or a part but uneven distribution cause spacer gathered together, it will block the light, It is also unable to maintain the appropriate gap between the upper and lower glass, which will lead to uneven distribution of electric field and affect the performance of the crystal grayscale.

A very important specification of LCD is brightness, and the most important factor to determine the brightness is the opening rate. What is the opening rate? Is simple light can pass through the effective area proportion. 17, let’s look at the picture to the left of figure 17 is an LCD display from directly above or below the past structure. When the light is emitted through the backplate, not all of the light can be through the panel, like for LCD source driver chip and the gate driver chip signal line, and TFT itself, the stored voltage is the use of storage capacity, etc. These places besides incomplete pervious to light, but also because the light through these places is not under voltage control, to display the correct gray-scale, so have to use the black matrix to cover, in order to avoid interference to other correct brightness of the light area. So the effective area of the previous to light, it’s just like figure 17 shows area on the right. This piece of the effective area of the previous to light and the ratio of the total area is called the opening rate.

When the light is emitted from the backlight plate, it will pass through the polarizer, glass, LCD screen, color filter, etc. It is assumed that the penetration rate of each part is as follows:

STONE is industrial screen manufacturers, provide a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, TFT screen module, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable forindustrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

The liquid crystal cannot emit light by itself, and the backlight should be added behind the LCD panel. A few years ago, CCFL cold cathode backlighting was the dominant market application, but with the development of technology, the LED backlight has gradually replaced the traditional CCFL backlight.

A thin-film transistor liquid crystal display, TFT LCD display for short, is a type of LCD display that uses thin-film transistor technology to improve image quality.

TFT LCD displays have many advantages over traditional LCD displays. While traditional LCDs use a single layer of transistors, TFT LCDs use a thin film of transistors. This allows for better image quality, as well as improved response time and lower power consumption. TFT LCDs are also thinner and lighter than traditional LCDs, making them ideal for use in portable devices.

When choosing a TFT LCD, it is important to consider the viewing angle and colour reproduction. While TFT IPS displays offer better image quality, they are also more expensive.

The colour filter array is the layer of the LCD that contains the colour filters. The colour filters are made of dyes or pigments and are arranged in a specific pattern. The most common patterns are RGB (red, green, blue) and CMYK (cyan, magenta, yellow, black).

TFT LCDs are used in a wide variety of industries, including consumer electronics, computing, telecommunications, automotive, and medical to name a few. Specifically, they are used in:Computers and laptop computers

The liquid crystal layer is the layer of the LCD that contains the liquid crystals. The liquid crystals are made of materials such as nematic or cholesteric.

TFT LCDs use two types of cover glass. Rigid cover glass is made of either soda-lime glass or Gorilla Glass. Flexible cover glass is used in some TFT LCDs, such as those used in mobile phones. The flexible cover glass is more resistant to breakage than rigid cover glass, making it ideal for use in portable devices.

The backlight is the layer of the LCD that emits light. Backlights can be made up of light-emitting diodes (LEDs), an electroluminescent panel (ELP), cold cathode fluorescent lamps (CCFLs), and hot cathode fluorescent lamps (HCFLs), or external electrode fluorescent lamps (EEFLs).

Nauticomp Inc. is a leading provider of industrial LCD displays. Our products are designed for use in a variety of industries, including maritime, aerospace, and military. We offer a wide range of LCDs, including TFT LCDs, OLEDs, and LEDs. Contact us today to learn more about our products and services.

![]()

Liquid crystal refers to the intermediate status of a substance between solid (crystal) and liquid. When crystals with a high level of order in molecular sequence are melted, they generally turn liquid, which has fluidity but no such order at all. However, thin bar-shaped organic molecules, when they are melted, keep their order in a molecular direction although they lose it in molecular positions. In the state in which molecules are in a uniform direction, they also have refractive indices, dielectric constants and other physical characteristics similar to those of crystals, depending on their direction, even though they are liquid. This is why they are called liquid crystal. The diagram below shows the structure of 5CB (4-pentyl-4’-Cyanobiphenyl) as an example of liquid crystal molecules.

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp text/graphic with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The color TFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

How does a TFT module operate? First, TFT stands for “Thin Film Transistor,” and it describes the control elements that actively control the pixels. Because of that, you hear a lot said about active matrix TFTs. How do the images get produced? It operates on a basic principle. You have the TFT LCD display, which has many pixels, and each pixel has the ability to reveal differing colors.

TFT displays also use a backlight that comprises fluorescent tubes to light a single pixel. When a small shutter gets opened, the light passes through. Of course, this technology is more detailed than what can fit in this article, but a simple explanation can give you an idea of how it works.

Ever heard of an LCD monitor? LCD stands for a monitor technology based on liquid crystals that change in molecular structure as it is used. As a result of the liquid crystal changing their molecular structure, they allow for varying levels of light to pass through them, which is what gives the picture.

Every pixel on any screen is made up of three components: Red, green and blue. You might also sometimes see this stated as RGB, which means the same thing. Twisted Nematic TFTs are the most common device that employ this tech. Without voltage applied, the molecular structure will be in its natural state, but twisted by 90 degrees, which is why they call it a Twisted Nematic TFT. When the light gets emitted by the backlight, it passes through the structure. Once the voltage gets applied, it creates an electric field, and the voltage twists the liquid crystals so that they align vertically.

To learn more about TFT LCD display or TFT technology, get in touch with manufacturers such as Microtips Technology. So Contact Microtips Technology Representative today to find out which LCD module is best for your needs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey