clear lcd screen free sample

Metal shields, blank silver or steel metallic screens with frames and rivets and reflection glow. award trophy front and side view isolated , realistic 3d vector illustration.

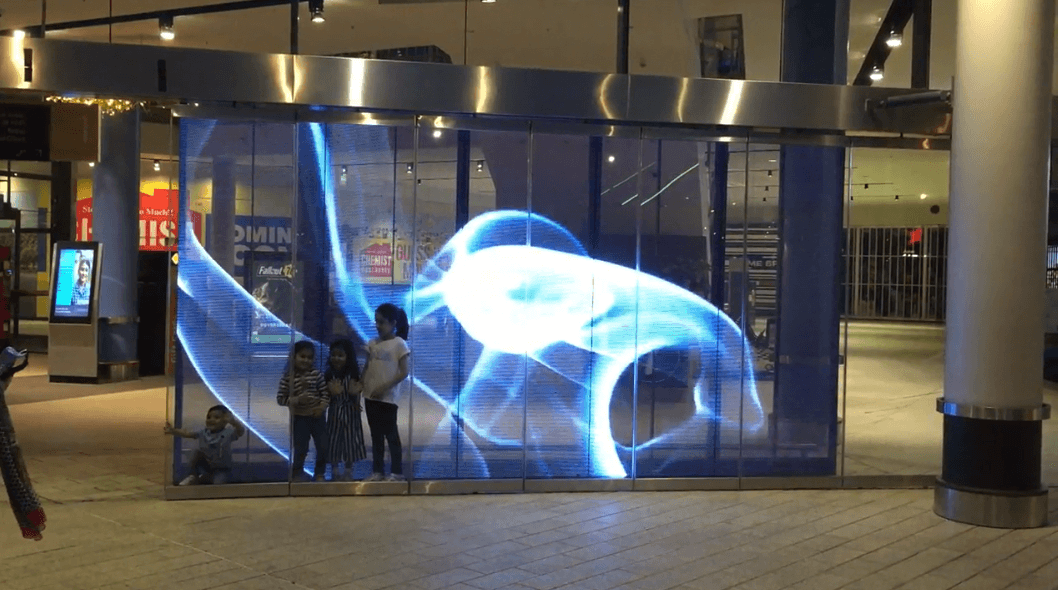

Transparent LCD’s provide an innovative display solution opening up new ways for brands to promote their products and services. Examples include retail stores looking to advertise a new fashion clothing or accessory, museums securely housing a precious artifact with information displayed on screen or brands looking to launch a new product at a live event or show. The opportunities are endless!

Our Transparent LCD Displays include a Grade A LCD panel with metal bezel protecting the edges / electronics and a media board supporting HDMI or VGA inputs from your PC, Laptop or Media Player.

Transparent screen technology offers intriguing ways to deliver visual information to your audience, being used to reveal or conceal products, objects or artefacts behind the screen.

The combination of HD LCD technology (4K on our 65″, 86″, 98″ version) with a transparent screen substrate opens up creative avenues that were previously closed with traditional LCD displays. Solid black pixels on a transparent background can be used in intriguing ways to hide (and gradually reveal) whatever is behind the screen.

Our Transparent LCD monitors are designed for integration into the customers own furniture housing or display case while our Transparent LCD showcases offer a complete solution including the display, housing and backlight with white or black options available on request. We can also offer custom freestanding options for POP / POS displays. Transparent LCD’s are predominantly fully housed however we’ve recently developed an innovative housing method using a high brightness LED panel which allows the display case sides to remain transparent for improved visibly into the display case.

Using their original design as a starting point, we worked closely with the team at Nike to adapt to the mechanical aspects of the design, the result was a sleek and minimalist set of nine Transparent LCD Display Screens, custom built to suit the applications requirements, bringing Nike’s original concept ideas to life.

These screens can also be granted multi-touch capability by combining them with infrared touch frames or PCAP touch overlays, to add an interactive element to your installation. This creates a very powerful impact when the content on screen integrates with real life objects behind the screen, encouraging viewers to interact on a level that will exceed expectations.

Transparent LCD’s comprise of an LCD panel without the backlight with white pixels appearing as transparent. In order to display an image, the Transparent LCD needs to be integrated into a housing with a high bright LED backlight.

We can also offer more complete solutions like our Transparent LCD Showcase that comes fully contained and ready to use with a powerful backlighting system to guarantee the best picture quality.

Yes in order to display an image Transparent LCD’s need to have a strong backlight. Notoriously Transparent LCD’s have also needed some form of housing to achieve optimum image quality, however, Nike’s House of Innovation paired our Transparent LCD’s with powerful, oversized backlights that allowed the screens to be mounted with no surround but still producing a high-quality image.

Transparent LCD’s are arguably the most popular transparent screens but are hindered by their need for a backlight to operate. For applications looking for a similar effect without the backlighting, Transparent OLEDs require no housing or surround but are only currently available in a 55″ screen size with HD quality. For larger transparent screen applications, Transparent LED’s are recommended with external and internal solutions usually installed to glass facades for the impact of an led screen without compromising the view from inside the building.

We also offer transparent projection technologies including our Clearview Rear Projection Film featured in Guardians of the Galaxy as well as at the 83rd Oscars celebration and MTV EMA awards.

Transparent LCD’s are a great way to combine physical and digital displays in one central place making them a popular choice for museums and exhibitions. Our transparent screens can also be integrated into display furniture and appliances & vending machines like freezer doors for supermarkets. Other uses include POS displays, store window displays, trade shows and product launches.

We manufacture in Britain and ship worldwide – if you need further information, a pricing quote, or want to discuss ideas for using our Transparent LCD Display click the link below to contact us, email us via info@prodisplay.com or call us on +44 (0)1226 361 306.

Screen Solutions offers complete solutions for transparent displays including standard and custom display cases. SSI has designed and built transparent displays for companies like Chrysler, Lockheed Martin, Mazda and many others over the last 15 years.

Standard Sizes start as small as 10″ and can get as big as 86″ Diagonal as seen in the video to your left. These complete displays include transparent panel, lighting, glass, display case and even a touch screen if you want.

Transparent display technology surrounds us, even if we aren’t aware of it. In this article we look at transparent head-up displays, LCDs, OLEDs and transparent electroluminescent technology and delve into the pros and cons of the four main transparent technology displays.

In this article, we’re looking at four types of transparent tech which include typical projection head-up displays (HUDs), LCDs, OLEDs, and transparent electroluminescent displays (TASEL). We’ll look at the pros and cons of each and show you how transparent display technology plays an essential part in our working lives and free time. An explanatory

Why have we included LCDs as a transparent display when, at first glance, they’re not truly transparent? In fact, we’re only able to see the information on our monitors, such as laptops, with the introduction of a backlight and a reflector shield.

Take these away and we see true transparency of the LCD display - which is something Samsung did in 2012 with the production of theirSamsung Transparent Smart Window.

LCDs are also one of the most popular screens on the market and this rise occurred early in the 21st century when liquid-crystal-display sets rocketed in popularity. In 2007, LCDs eclipsed sales of competing technologies like plasma, cathode ray tube, and rear-projection TVs.

They were thinner and lighter, easier to scale. And for the manufacturers, the cost of production was lower, so it’s easy to see how LCD displays quickly became a favorite with manufacturers and consumers.

Organic light-emitting diode displays, orOLEDsfor short, are a step up from LCDs when it comes to transparent technology. For starters, unlike LCDs, OLEDs do not require the use of a backlight or any other filters due to the use of pixels which produce their own light.

The organic materials used in OLEDs are affected by the environment, they’re sensitive to moisture and screen discoloration occurs if subjected to direct sunlight and heat

However, due to the limitation of monochromatic images, transparent electroluminescent displays shouldn’t be used as entertainment screens in vehicles - they should be used to display only the most critical information in the eye-line of the driver without distractions.

It takes the same time for the hardware to implement lcd.clear() for a 16x2 or a 20x4 screen. i.e. about 2ms whether by parallel or backpack. It also resets the cursor to 0, 0.

It takes the same time for the hardware to implement lcd.clear() for a 16x2 or a 20x4 screen. i.e. about 2ms whether by parallel or backpack. It also resets the cursor to 0, 0.

?>We provide a script that can be used to convert jpg images -> .c files, you can use it to convert some personal images and draw them on the screen using the following API.bin2code.py

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

I"m using serial communication to display the the data to my 4x20 lcd display. When I filled up all the lines of course I need to clear it. I"ve search over the net and found something like:

But it doesn"t work. I also found a solution like Serial.println(); but that solution (cheat as they called it) will only work on a serial monitor. So is there any possible solution to clear the display or delete a single character from the LCD?

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey