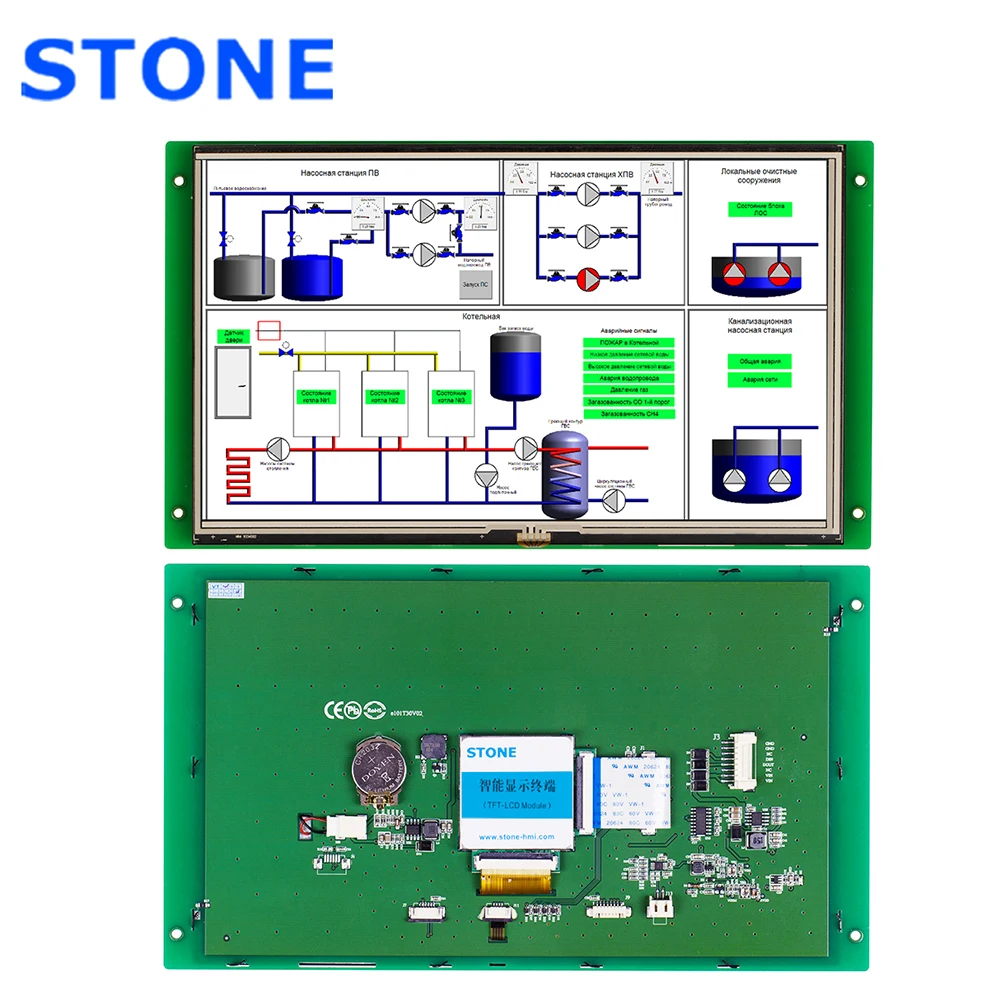

lcd display pic microcontroller supplier

Microchip"s LCD PIC microcontroller family is a Flash-based, power managed family of LCD-enabled microcontrollers. Microchips LCD PIC microcontroller family meets low power design requirements including driving the LCD display in sleep mode while maintaining desired functional features. With the ability to select from an array of available LCD PIC microcontrollers, a designer can provide additional value by creating scalable designs and products. This gives the designer flexibility to offer different solutions based on the demand of varying market segments all from a single design.

TV mounts provide consumers and businesses alike with stylish and easy-to-install options for monitor placement. Instantly transform a small space into a home theater or a modern and minimalist living room by adding a retractable pic microcontroller lcd or wall mount. These pieces of hardware provide a supportive, practical, and versatile piece of equipment to any home and the best part is they"re virtually invisible to the naked eye.

Flat-screen TVs opened new doors to innovative TV brackets and mounting displays many years ago. Today, standing TV mounts, ceiling TV mounts, and corner TV mounts are all great options for consumers who are looking to save space and add a modern touch to their environment. Full motion TV wall mounts and swivel mounts can provide anywhere from 45-degree to 360-degree motion for the ultimate viewing experience. Outdoor TV mounts and projector mounts are also convenient for outdoor events all year round. Browse a range of different material types on Alibaba.com to find everything from lightweight aluminum to heavy-duty steel pic microcontroller lcd depending on your customers" preferences and requirements.

A wide variety of lcd pic options are available to you, You can also choose from original manufacturer, odm lcd pic,As well as from tft, cog, and character.

A PIC Microcontroller can be easily made to communicate with LCD by using the built in Libraries of MikroC. Interfacing between PIC and LCD can be 4-bit or 8-bit. The difference between 4-bit and 8-bit is how data are send to the LCD. In the 8-bit mode to write an 8-bit character to the LCD module, ASCII data is send through the data lines DB0- DB7 and data strobe is given through the E line.

But 4-bit mode uses only 4 data lines. In this mode the 8-bit ASCII data is divided into 2 parts which are send sequentially through data lines DB4 – DB7 with its own data strobe through the E line. The idea of 4-bit communication is to save as much pins that used to interface with LCD. The 4-bit communication is a bit slower when compared to 8-bit. The speed difference is only minimal, as LCDs are slow speed devices the tiny speed difference between these two modes is not significant. Thus the 4-bit mode data transmission is most commonly used.

The above definitions tells the compiler, how LCD is connected to the microcontroller. The two set of definitions are used to provide Data (PORT) and Direction (TRIS) registers.

This function prints the text (string) in the current cursor position. When we write data to LCD Screen, it automatically increments the cursor position.

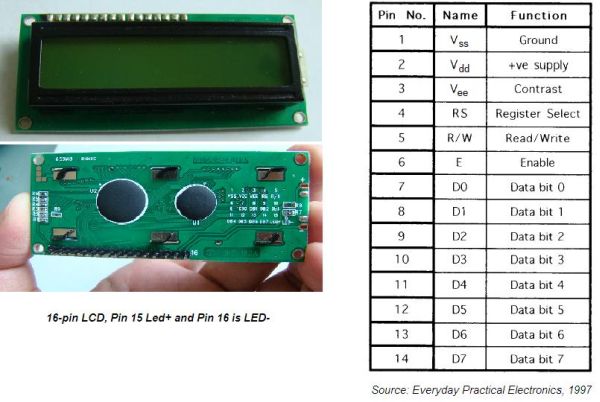

In this tutorial we will see How to Interface a 16×2 character LCD module with PIC 16F877A Microcontroller using MPLAB X IDE and MPLAB XC8 C Compiler. 16×2 Character LCD is a very basic and low cost LCD module which is commonly used in electronic products and projects. 16×2 means it contains 2 rows that can display 16 characters. Its other variants such as 16×1 and 16×4 are also available in the market. In these displays, each character is displayed using 5×8 or 5×10 dot matrix.

For controlling LCD using MPLAB XC8 compiler we need to know the hardware of LCD. These LCDs commonly uses HD44780 compliant controllers. So we need to learn HD44780 Dot Matrix LCD Controller Datasheet. Don’t worry we already developed an LCD library including commonly used functions, so you can use it without any hardware knowledge of LCD.

First two pins GND and VCC (VSS and VDD) are for providing power to LCD display. 3ed pin VEE is used to control the contrast of the LCD display. A 10KΩ preset whose fixed ends connected to VDD, VSS and variable end connected to VEE can be used to control contrast of the LCD. A microcontroller or microprocessor need to send 2 types of information for operating this LCD Module, Data Information and Command Information. Data Information is the ASCII value of the characters to be displayed in the LCD screen and Command Information determines other operations such as position to be displayed, clear screen, shift etc. Data and Command Information are send to LCD through same data lines (DB0 – DB7) which are multiplexed using RS (Register Select) pin of LCD. When RS is HIGH LCD treats DB0 – DB7 data pins information as Data to be displayed and when it is LOW LCD treats it as Command Information. Enable (E) input of the LCD is used to give Data Strobe. HIGH (5V) Voltage Level in the Enable (E) pin tells the LCD that DB0 – DB7 contains valid information. The input signal R/W (Read or Write) determines whether data is written to or read from the LCD. In normal cases we need only writing hence it is tied to GROUND in circuit shown below.

The interface between this LCD and Microcontroller can be 8 bit or 4 bit and the difference between them is in how the data or commands are send to LCD. In the 8 bit mode, 8 bit data and commands are send through the data lines DB0 – DB7 and data strobe is given through E input of the LCD. But 4 bit mode uses only 4 data lines. In this 8 bit data and commands are splitted into 2 parts (4 bits each) and are sent sequentially through data lines DB4 – DB7 with its own data strobe through E input. The idea of 4 bit communication is introduced to save pins of a microcontroller. You may think that 4 bit mode will be slower than 8 bit. But the speed difference is only minimal. As LCDs are slow speed devices, the tiny speed difference between these modes is not significant. Just remember that microcontroller is operating at high speed in the range of MHz and we are viewing LCD with our eyes. Due to Persistence of Vision of our eyes we will not even feel the speed difference.

Hope that you got rough idea about how this LCD Module works. Actually you need to read the datasheet of HD44780 LCD driver used in this LCD Module to write a MPLAB XC8 program for PIC. But we solved this problem by creating a header file lcd.h which includes all the commonly used functions using 4 bit mode. Just include it and enjoy.

Lcd_Set_Cursor(int row, int column) : This function is used to set row and column of the cursor on the LCD screen. By using this function we can change the position of the character or string displayed by following functions.

sprintf() can be used to write formatted string to a variable. It can be used with this LCD library to format displayed texts. This enables us to display integers and floating point numbers on the LCD very easily. You should include the header file stdio.h for using sprintf().

Custom Segment Liquid Crystal Displays are seen in products that measure the PH level of swimming pools, monitors used to measure specific gases in a mine, or in thermometers used to see if a child is running a fever. They are one of the oldest display technologies, but still one of the most popular.

Segment LCDs, also called static displays or glass-only displays, are constructed of two pieces of ITO (Indium tin oxide) glass with a twisted nematic fluid sandwiched in between. A static display is a segment display with one pin for every one segment.

These displays are still one of the most popular technologies in use and the majority of them are custom. Many people think the process of designing a custom segment liquid crystal display is complicated and too complex to be understood except for a few experienced people. But after designing custom LCDs for over 14 years, it can be said that just about anyone can select the best options for their product.

In other words, you don’t have to be an engineer, or have a PHD from MIT to design a custom LCD for your application. So instead of offering a list of technical terms and equations, these are the different options available.

Although Segment displays are an older technology, it is still one of the most popular. After all, they cannot display all the colors of a TFT or OLED like what can be seen on a cell phone and tablet.

The tooling fee for a custom display is the lowest of all the technologies and allows the customer to receive a LCD that is manufactured to the exact dimensions requested, including custom icons and segments.

Focus LCDs offers a one-time NRE (Non-recurring engineering) or tooling fee. This includes all design, technical support, and samples. A PDF showing an overview of our tooling process can be found by clicking here: Custom LCD flowchart

Segment displays require less power than other display technology such as TFT, OLED, and UWVD. This makes these LCDs ideal for applications that are battery powered or solar powered. They require the lowest power to drive, an estimated 2uA per centimeter squared. Glass only displays (no backlight and no controller) require an estimated 10% of the power that is required for a LED backlight. In other words, a static display without a backlight will draw around 1mA; the same display with a LED backlight will demand from 10mA up to 25mA. Most displays can be driven at 3.3V or 5V since microprocessors can operate at both voltages. 3.3V is becoming more popular since two double ‘AA’ batteries can produce between 3.0V and 3.3V.

A segment is any line, dot or symbol that can be turned on and off independently. The photo below is of a segment LCD that contains numbers, a small clock symbol, the word ‘Jul’, and the letters ‘PM.’

There are four numbers in the above LCD (0 8 4 7) all are seven segments. In other words the ‘0’ has seven segments, the ‘8’ has seven segments and so on. Each number has seven independent segments. Each segment can be turned on and off independently to create other numbers and some letters such as E, F C and others. This is an example of a ‘seven’ segment. But there are some letters that a seven segment cannot display such as the letter ‘M’ or ‘V’. In this case a fourteen segment configuration can be used.

An icon is a small symbol or set of words that is only one segment. In other words, when the segment is ‘on,’ the full word or symbol turns on. When it is “off,” the word or symbol turns off. In the photo above: the clocksymbol is one segment, the word ‘JUL’ is one segment, the letters FOCUSLCDS.COM are one segment and the letters ‘PM’ are one segment.

It is possible to burn a segment into the glass so that it is always “on”. In this case, the ‘FOCUSLCDS.COM’ has been burned into the glass and can always be seen by the customer even when the power is “off”. Some customers will have their company name burned into the glass.

Hence the display is called a segment display because each segment can be turned “on” and “off” individually. You choose the number of seven or fourteen segments and which icons you want on your custom display.

Segment displays earn the name ‘glass only display’ because the majority of them are glass with small metal leads attached to both sides of the display. However, it is possible to add a PCB (Printed Circuit Board) or a controller driver chip (IC). The construction of the display is similar to that of a sandwich. You take two pieces of glass, glue one piece on top of the other, than inject a fluid between the two pieces of glass. In the drawing below you see a side view of a segment display. The glass on top is smaller than the glass on the bottom. This is to allow room for the pins.

Segment LCDs, like all LCD display technologies, operate best between specific temperature ranges. You choose the temperature ranges that it will operate in. There are two standard configurations: normal temperature and wide temperature. The wider the temperature range, the more expensive the display.

The standard operating temperature range for a segment LCD is 0C to 50C. It is possible to build the display with a different fluid that will allow it to operate from -30C to 80C (F). With the addition of a heater, the display can operate down to -50C.

When the display becomes too cold, the fluid between the two layers of glass starts to freeze; when the display does freeze, the segments that were “on” when it froze will stay on. The display will not change until the temperature increases. When the display becomes too hot, a black spot will develop in the center of the glass. Basically the fluid is boiling. When the temperate comes down, the display will operate normally.

VATN (BTN) – Vertically Aligned Twisted Nematic is only available in negative mode (light colored letters on a dark/black background). VATN displays produce very bright segments and can be easily read.

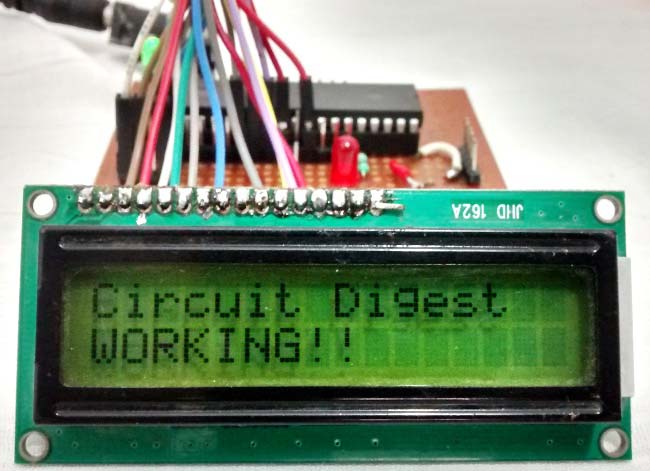

This is our sixth tutorial in our PIC Tutorial Series, in this tutorial we learn Interfacing of 16x2 LCD with PIC Microcontroller. In our previous tutorials we have learnt the basics of PIC using some LED blinking Programs and have also learnt How to use Timers in PIC Microcontroller. You can check here all the tutorials on Learning PIC Microcontrollers using MPLABX and XC8 compiler.

This tutorial will be an interesting one because we will learn How to Interface 16×2 LCD with PIC16F877A, check the detailed Video at the end this tutorial. Gone are the old days where we used LEDs for user indications. Let us see how we can make our projects look more cool and useful by using LCD displays. Also check our previous articles on Interfacing LCD with 8051, with Arduino, with Raspberry Pi, with AVR.

To make things easier we have made a small librarythat could make things easy while using this LCD with our PIC16F877A. The header file "MyLCD.h" is given here for download, which contains all the necessary function to drive the LCD using PIC MCU. Library code is well explained by comment lines but if you still have doubts reach us through the comment section. Also check this article for Basic LCD working and its Pinouts.

Now, there are two ways to add this code into your program. You can either copy all the above lines of code in MyLCD.h and paste them before the void main(). Or you can download the header file using the link and add them to the header file of your project (#include " MyLCD.h ";). This can be done by right clicking on the header file and selecting Add existing Item and browsing to this header file.

Here I have copied and pasted the header file code into my main C file. So if you are using our code, then you don’t need to download and add the header file into your program, just use the complete Code given at the end of this Tutorial. Also note that this library will only support PIC16F series PIC Microcontroller.

void Lcd_Start():This function should be the first function that has to be called to start working with our LCD. We should call this function only once to avoid lag in the program.

void Lcd_Set_Cursor(x pos, y pos):Once started, our LCD is ready to take commands, we can instruct the LCD to set its cursor in you preferred location by using this function. Suppose if, we need out cursor at 5th character of 1st row. Then the function will be void Lcd_Set_Cursor(1, 5)

Each time the Lcd_Print_Char(char data)is called, its respective character values is sent to the data-lines of the LCD. These characters reach the HD44780U in form of bits. Now this IC relates the bits to the character to be displayed by using its ROM memory as shown the below table. You can find bits for all the characters in the datasheet of HD44780U LCD Controller.

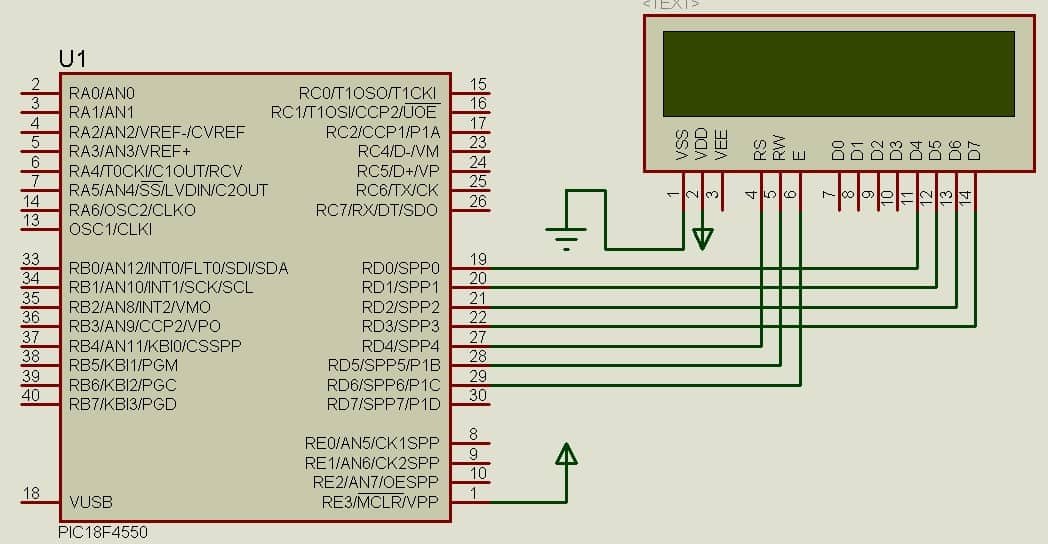

The hardware for this project is very simple. We are going to reuse the same PIC module that we used last time and connect the LCD module to our PIC using jumper wires.

Here we are discussing various aspects of 16*2 Character LCD Interfacing with PIC Microcontroller in 8-bit Mode. A character LCD is the most basic form of an electronic display device which is widely used. The module will consist of 2 rows each with 16 columns which can display 16 characters. Already discuss LCD in4-bit mode in the chapter 4-bit LCD interfacing with pic microcontroller

Several other LCD modules are also available like 20×4 dimension LCD which can display 20 characters per line and 4 such lines would be available. The choice for the module depends on the requirement.

The main advantage of using a character LCD instead of a seven segment display and other multi-segment LEDs is that there is no limitation in displaying special & custom characters animations and so on. All character LCDs will have 16 pins among which 8 are data pins through which data or commands are passed into the LCD registers. A character LCD can be configured in 8 bit or 4-bit mode in which 8 data pins and 4 data pins are used respectively. This feature allows efficient use of the digital I/0 pins of the microcontroller.

The features of a character LCD module make it more suitable as an electronic display than 7 segment displays and other multi-segment display modules. Most importantly the module can be interfaced much easily unlike other modules with no complexity in both hardware and software. The 4-bit mode interfacing of the LCD module enables an efficient method of saving the number of general purposes I/O pins which is a major criterion for an embedded system designer. There is no limitation in characters which can be displayed using the module. The contrast of the module can be adjusted using the VEE pin of the module and LED backlight which makes the display more bright can be enabled with LED+ and LED- pin.

The RS (Register Select) pin of the LCD module is used to select the specific register. When RS is low, the command register is selected and when RS is high, data register is selected. State of R/W pin determines the operation to be performed whether to read or write data.

All instructions to be executed by the LCD are latched into the command register of the LCD. LCD commands include a clear display, the cursor on/off, display shift and so on.

Commands are instructions given to the LCD module to perform a predefined task. The task to be performed is defined by the manufacturer. Some of the LCD commands are listed below.

The register select pin of the LCD module should be connected to a general purpose I/O pin and the corresponding pin should be made low. R/W pin should be grounded to select the write operation. The command register will not be accessed.

Enabling the LCD would latch in the value of the data port into the command register of the module. Enabling the module involves applying a high to low pulse to the Enable pin of LCD.

Data write operation involves the similar steps as that of a command write operation except data register should be selected by setting the RS pin and grounding the R/W pin. Enabling the module would then latch in the value in the data port to the data register of the module and corresponding character will be displayed on the LCD module.

First of all, it needs to be initialized before writing data into the character LCD. The initialization is done to configure the module for the specific use. It involves writing some initialization commands into the command register. Some of the initialization commands include a command to turn the display on and cursor off, the command to set cursor at the preferred position and the command to set the option for cursor increment or decrement and so on.

The user can also display custom characters on LCD. More Details of displaying of custom character on LCD is specified in the Chapter Display Custom Character on 16*2 LCD using PIC microcontroller

In this project i am going to interface 16×2 lcd display in 4-bit mode with Microchip Pic16f877 microcontroller. We can interface any size of character lcd display (8×1,8×2,10×1,10×2, 16×2,16×2,16×4,20×1,20×2,40×1,40×2 etc) in 4-bit mode with pic microcontrollers. In 4-bit interface mode only 4 lcd data lines are used to display data on lcd screen. Usually lcd is interfaced in 4-bit mode with microcontrollers to save I\O pins of microcontrollers. Before beginning any further i assume that you know difference between 4-bit and 8-bit lcd interfacing mode with microcntrollers. If not just take the below simple tutorial. Tutorial will help you in understating the basic difference, pros and cons of both the modes. It will also help you in understanding the code below easily.

In 4-bit mode only 4-bit data is send to lcd at a time. Since 8-bit microcontrollers contains data in 8-bit form so we divide our data in to two nibbles(1-nibble=4-bits). First higher 4-bits(nibble) is send to lcd and then the lower 4-bits(nibble) with enable stroke signal. Only D4,D5,D6,D7 data pins of 16×2 lcd are used in 4-bit interface mode. D1,D2,D3,D4 are left empty. D4 is our least significant bit and D7 is highest significant bit in 4-bit interface mode. A typical interfacing diagram is given at the right side.

Interfacing 16×2 lcd with Pic16f877 microcontroller is simple, if you have taken the above tutorial. The circuit of the project is also very simple. Port-B first 4 bits (RB0,RB1,RB2,RB3) of Pic16f877 microcontroller are used to send 4-bit data and commands to lcd. These four Pins(RB0,RB1,RB2,RB3) are Connected to four data pins of 16×2 lcd(D4,D5,D6,D7).Port-D pin# 5 is connected to rw(read-write) pin of lcd. Port-D pin# 6 is connected to rs(register select) pin of lcd. Port-D pin# 7 is connected to en(Enable) pin of 16×2 lcd. If you are newbie and have to idea about the working and pin configuration of lcd. Below is a good tutorial.

This function is separating four bits from our command and puts them on RB0,RB1,RB2,RB3 line and then sends them to lcd. The following instructions are separating four bits.

This function is separating four bits from our 8-bit data and puts the 4-bit data on RB0,RB1,RB2,RB3 pins and then sends them to lcd. Following instructions are separating four bits.

In the main function i first called lcdint() function. This function is initializing our lcd. Refer to the data sheet of lcd if you dont know what is lcd initialization. Then i am sending data to 16×2 lcd which i want to display on lcd screen. I am displaying word “Microcontroller” on lcd display screen.

LCD (20x4) Interfacing with PIC16F877A | Simulation | Liquid Crystal display---------------------------------------------------------------------------------...

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey