soldering lcd display brands

This Velleman soldering station is suitable for more intensive soldering work. The station has a manual temperature setting with an LCD on which the current set temperature can be read. The temperature range of the soldering iron is between 150 ° C and 450 ° C with a power of 48W. The included 1.6mm soldering tip (BITC10N1) is fine enough to solder small DIP components.

LCDs usually come without a microcontroller to control the display. To connect, you will need a strip of header pins, a potentiometer to adjust the contrast of the display, breadboard, and wires. Depending on the LCD, you may need a current limiting resistor to to limit the current to the LED backlight. You will need to solder the header pins of your choice to the display in order to plug it into your breadboard. If you have not soldered before, we recommend looking at our soldering tutorial.

While you can use any standard 16x2 alphanumeric LCD, the white on black display supplied with the kit looks übercool. The photographs in this guide are of a standard black on green display so yours may look different. The "16x2" refers to the display having two rows of sixteen characters each — other displays are available which are 8x1 or 20x4.

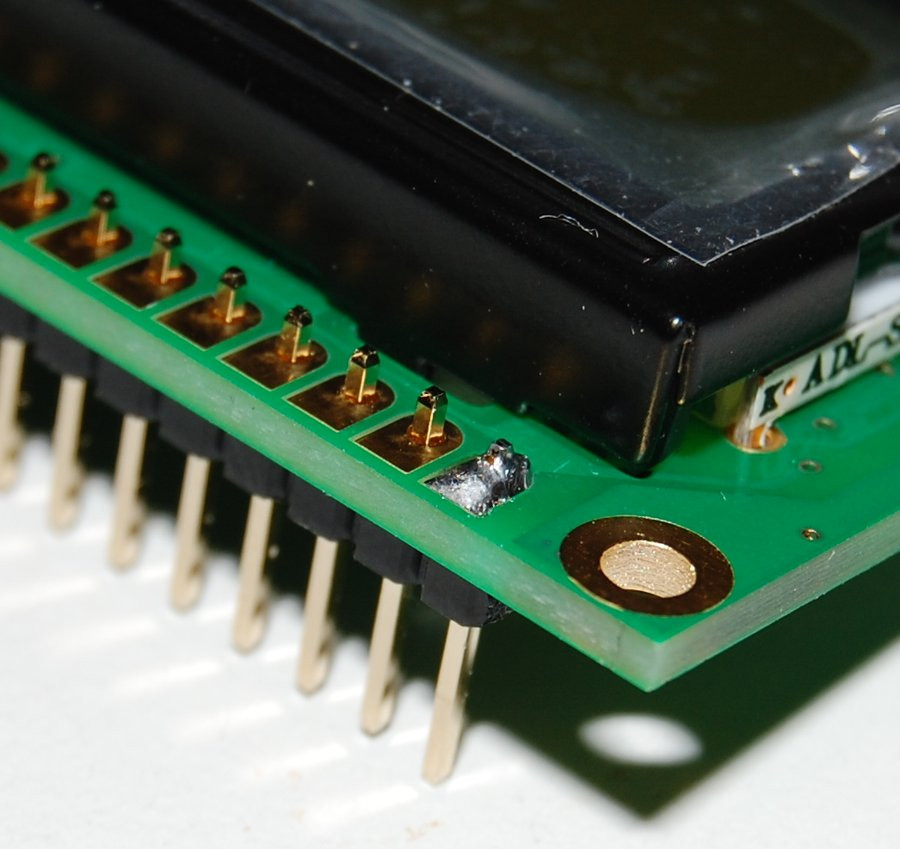

It is pretty straightforward to solder the header pins to the LCD module. Make sure to keep the soldering iron in contact with the joints for no more than about three seconds. There small risk of the damaging the existing components on the board with excess heat. You also need to be careful to keep the soldering iron away from the already soldered components on the board — you"re probably not yet ready to do surface mount soldering repair.

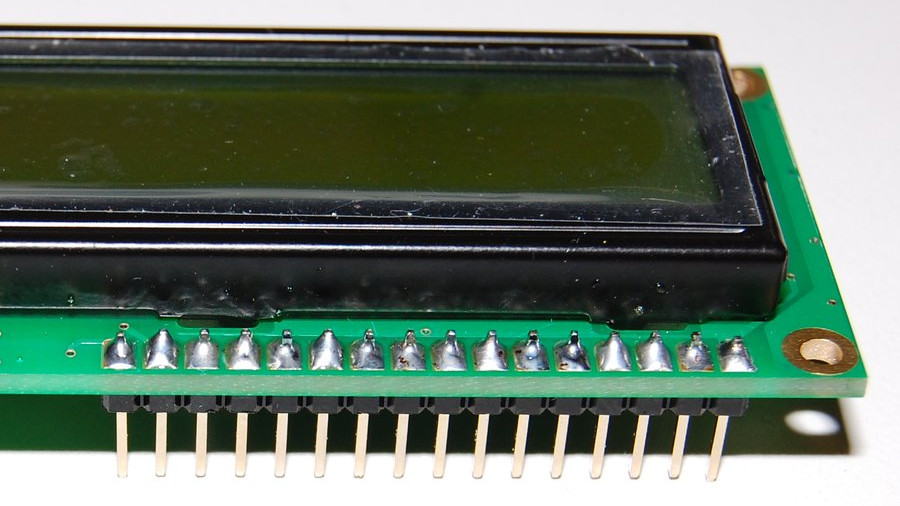

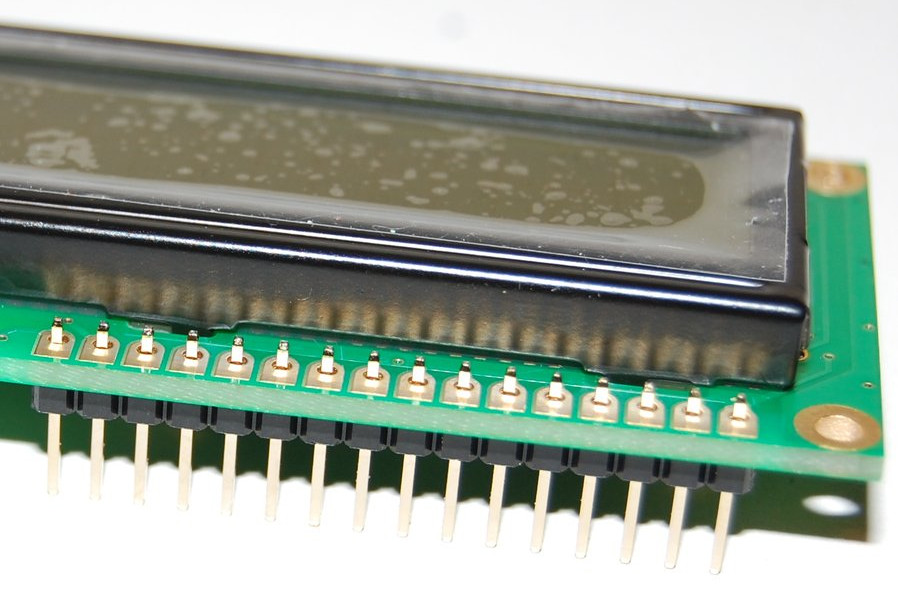

Before soldering, perform a "test fit" of parts. A test fit gives you a chance to double check if you"ve got the parts you need and ensures that they fit together. For this connection, break a row of 16x1 male headers and insert the header pins into the holes on the LCD module as shown in the image below. If you are using an RGB LED, you will need a row of 18x1 male headers.

Ensure that you don"t have one pin too many or too few in your header strip. Also make sure the black plastic strip of the header is positioned on the underside of the printed circuit board (PCB) so that you have plenty of pin length below the PCB to plug into your breadboard or a socket. The longest part of the pins should be below the PCB. The pin header provides connections that carry the data signals for controlling what the display... displays. They also carry power to the small microcontroller behind the black blob on the module and to the LED backlight if your display has one.

Because there"s not a lot of room it is easiest to feed the solder from behind pin while the soldering iron tip is between the pins, resting on the PCB pad with the side of iron against the side of pin you"re soldering. The reason we start with just one pin is because it makes it easier to obtain the correct alignment and fix any mistakes.

Once you"re happy with the alignment of the header you can solder another pin into place — we recommend soldering the pin at the opposite end of the header to the first pin you soldered. The reason for this is that once the two end pins are in place, the alignment won"t change.

Your display module should now look like the image below. One additional detail to note is that the pin header is usually at the "top" of the display — so keep that in mind if you plan to mount it anywhere. Remember to always test the display out before mounting to a project.

The 936H Digital Soldering Iron is made of iron plated tip and stainless steel which ensures reliable quality and stability. The solder iron has adjustable temperature range from 180-450 degrees centigrade and has a LCD for displaying temperature. The solder comes with a 1.5mm solder tip and is compatible with the Wellzion Ambrums tips.

This is an IIC Serial 1602 LCD module. With this I2C interface LCD module, you will be able to realize data display via only 2 wires. If you already have I2C devices in your project, this LCD module actually cost no more resources at all. It is fantastic for Arduino based project.

This article about soldering techniques is the second on a series written by Barbara Dutra, an exchange engineering student from Brazil, currently attending Arizona State University, college of electrical engineering. She is currently an intern at Focus Display Solutions.

The majority of Liquid Crystal Displays require electronic components to be attached to the LCD Glass via a printed circuit board. These components are permanently attached using solder via LCD soldering techniques.

The soldering of electronic components is the act of joining two pieces mechanically by melting a combination of metals that becomes a permanent adhesive once cooled.

There are many types of soldering tools and methods used depending on the application. For example, there is the soldering of mechanical parts with special materials in large equipment such as aviation, or solders used in very small scale applications such as in Surface Mount Devices (SMD) components, and finally there is one extremely delicate type of soldering processes used in the case of the amendment in optical fibers.

A poor solder connection can seriously reduce or cut the flow of current causing the circuit to fail in its operation. ( Note: A poor LCD solder connection increases the amount of resistance. The higher the resistance the more heat that is generated and the more power required to operate the device. This is a critical concern in battery powered applications that have a LCD and a Liquid crystal module with a backlight.)

The soldering station is used for SMD components in the industrial manufacturing of some PCB assemblies used in such products as display modules, cell phones and computer boards.

Soldering irons have a hollow base with a heating element located inside. Its tip, which is typically copper covered by another material that allows the transfer of heat, becomes heated when the iron is turned on.

The soldering gun contains an iron tip which heats almost instantaneously when the trigger is pressed. It also contains a small lamp to illuminate the place where soldering is taking place. This iron is suitable for heavier soldering applications or large components with thicker terminals that require more heat.

The majority of industrial countries now require ROHS approved solder and soldering techniques. The use of ROHS solder in Liquid crystal displays has not increased its cost or lead-time.

Before starting the soldering process, a bit of solder is applied to the tip of the soldering iron, this allows heat to be passed from the heating element to the copper contact.

The tip of the soldering iron is briefly placed simultaneously against both the leads of the component and the copper of the trace. The solder flows into the hole and forms a strong electrical bond as the solder cools down to room temperature.

Warning: This operation must be quick so that the soldering iron heat does not damage the track or electronic component. If there is excess solder or join is faulty, the solder can be reheated and removed with the use of the nozzle.

Soldering of SMD"s is more complex for a variety of reasons such as exposure to high temperatures and soldering conditions. The SMD components have very small terminals for soldering, and they are on the copper side of the board that will be exposed to heat. The risk of heat damages to the components is much higher than in a conventional method of mounting components with through-hole.

There are two welding processes: wave soldering and reflux soldering. The majority of Chip on Board (COB) LCDs contain a combination of both SMD (sometimes called SMT for surface mount technology) and through-hole.

In the wave solder process, the board should be reversed to receive the wave soldering, so it is required that the components are pre-pasted with an epoxy adhesive. On a conveyor belt, the board passes through a tub with solder alloy in liquid state.

In the case of reflux soldering, the components on the LCD are placed on the board that will be carried by a belt into an oven. A solder paste is applied to the plate and this paste is melted in the oven, soldering all components. This process will solder the components of the upper part of board. Then the plate goes to the soldering wave form, where the lower side components are soldered.

When a SMD component is defective or poorly welded, in some cases, the issue can be corrected using a soldering iron. However, an experienced person is required for this to be carried out due to the very precise work involved.

First remove the solder and then the soldering iron. Do not move the terminal until the solder cools and never "blow" on the solder. This may create air bubbles to form creating a poor solder joint and increasing resistance in the circuit or misalignment of the component.

Once the solder is cooled, tap the terminal with a wire cutter to make sure that soldering is secure and cut off the excess terminal with cutting pliers.

Note: "flow soldering" should not be used for soldering printed circuits due to their acidic nature which can corrode from their residues, thereby damaging the components.

A good LCD soldering joint will be shiny and even, a poor LCD soldering joint will have a dull appearance and be filled with holes or gaps that allow for the component to break free. Also, a poor solder joint will create more resistance.

The LCD soldering may have a good bond with the lead of the component, but a bad contact with the trace on the PCB. This can happen by insufficient heating of the lead, or the printed circuit board is dirty or rusty. Below is an image of this type of solder failure.

The image below shows a good LCD soldering contact with the trace, but little adhesion to the lead of the component. Note the lack of contact between the lead and the solder.

This can be a major headache since the LCD soldering will look good and you will have a difficult time locating which solder joint is causing the broken circuit.

The image below shows a poor LCD soldering weld that can occur on a solder joint for a LCD Display. The component will behave as if there is no connection at all.

Contact Focus Display Solutions for any questions or concerns you have regarding LCD soldering requirements for LCD displays. We are based in Chandler, Arizona and support customers in the US and Canada.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey