tft display driver circuit quotation

Since the reference voltages are connected to all channels, many DACs may use the same reference voltage. The more DACs there are connected to a single reference voltage, the larger the required C-DAC settling time. This study simulates the settling time for different numbers of connected DACs using a 0.35-μm 5-V CMOS model. Figure 11 shows the simulated results where the settling time is measured at 99.9% of its final voltage for a full swing (0.266 V ~ 4.75 V). The settling time is 5.2 μs when 200 DACs are connected to a single reference voltage. Although a column driver IC contains several hundreds or even up to a thousand DACs, these DACs are distributed to 256 (28) reference voltages. This means that not all the DACs are connected to a single reference voltage. A typical UXGA (1600×1200) display has a pixel clock frequency of 162 MHz and a horizontal scanning time of 9.877 μs [4]. Hence, the proposed column driver is suitable for UXGA displays.

Due to the limited silicon area, the proposed LCD column driver has only four channels. The 10-bit LCD column driver with R-DAC and C-DAC was fabricated using a 0.35-μm 5-V CMOS technology. Table I shows the device sizes used in the proposed column driver, where Rtop, Rmid, Rbot, and Ri are designated in Figure 7. Figure 12 is a photograph of the die. Except for the resistor string of the R-DAC, the die area is 0.2×1.26 mm2 for four channels. Each RGB digital input code is 10-bits wide.

The Differential Nonlinearity (DNL) and Integral Nonlinearity (INL) are typically measured for a DAC. However, it is difficult to determine these two specifications for a nonlinear DAC. To demonstrate the performance of the proposed circuit, the nonlinear gamma voltages are not applied to the R-string and the resistor values of the resistor string are made equal. Since an LCD panel needs several column drivers, the uniformity of different drivers is very important. Figure 13 shows the measured transfer curves of a DAC for eight off-chip column drivers. To show the deviation between different chips, Figure 14 provides an

enlarged view of the transfer curves, where the maximum deviation is 3.5 mV from the mean. This deviation is mainly due to process variations. The approach in this study uses no error correction. Hence, the deviation can be reduced by applying an offset canceling technique to the buffer amplifier. Figures 15(a) and (b) show the DNL values for positive and negative polarities, respectively. Figures 16(a) and (b) show the INL values for positive and negative polarities, respectively. The combination of R-DACs and C-DACs creates two groups of DNL values. The maximum DNL and INL values are 3.83 and 3.84 LSB, respectively. This study uses a 1-LSB voltage of 2.44mV to calculate the INL and DNL values. The linearity, however, is less important than the deviations between off-chip drivers for LCD drivers [2].

Figure 17 shows the measured output waveforms of two neighboring channels under dot inversion for the RGB digital inputs of ‘1111111111.’ Here, the voltage levels for negative and positive polarities are 0.266 V and 4.75 V, respectively. A load resistor of 5 kΩ and a capacitor of 90 pF were used. Figure 18 shows a similar waveform for ‘0000000000’ inputs, where the corresponding voltage levels for negative and positive polarities are 2.425 V and 2.598 V, respectively. These two figures show that the settling time is within 3 μs, which is smaller than that of previously published work [2] and standard UXGA displays [5]. Table II summarizes the performance of the proposed column driver IC. The average area per channel is 0.063 mm2, which is smaller than the reported areas of fully R-DAC-based column drivers [5, 8]. These experimental results show that the proposed column driver is suitable for UXGA LCD-TV applications.

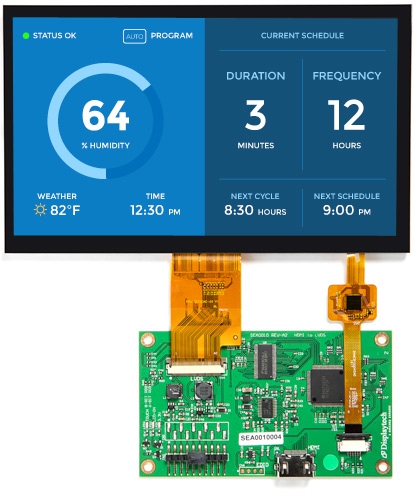

INT043BTFT and INT043BTFT-TS are embedded display driver boards based on our 4.3 inch 480 x 272 RGB resolution TFT display module. Mounted on the embedded board is the Solomon Systech SSD1961 LCD controller that supports common RAM-less LCD drivers and offers the following features and benefits:

INT028ATFT and INT028ATFT-TS are embedded display driver boards based on our 2.8 inch 240 x 320 RGB resolution TFT display module. Mounted on the embedded board is the RAIO RA8872 LCD controller that offers the following features and benefits:

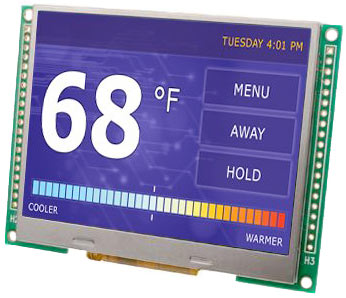

Display technology has moved forward at light speed. For years, even sophisticated equipment made do with numeric and alphanumeric display technology, buttons, and LEDs.

With mass production, manufacturing refinements, and competition, thin film transistor (TFT) displays have drastically dropped in price while dramatically improving in performance. They are the de facto standard to the point where it is not only expected, it is demanded that any modern user interface be full color, brightly backlit, touch sensitive, and have high video speeds and a good viewing angle.

While simple low-cost 8-bit microcontrollers could easily handle the multiplexed 7- and 14-segment LED and alphanumeric LCD displays, the memory, processor speeds, and peripheral resources needed to drive a TFT are more than most modest microcontrollers can handle. As a result, dedicated controller chips, embedded modules, or faster, denser, and more streamlined processor architectures are needed.

This article looks at the factors that make a good MCU-to-TFT interface. This includes memory depths and architectures, paging, data transfer, signaling levels, interfaces, and on-chip peripherals to look for when selecting a microcontroller for a TFT application. It examines the TFT technology and present day product offerings, which your designs will need to drive. It also looks at some microcontrollers that provide native support for color TFT displays, looking at their techniques, features, trade-offs, and limitations. All displays, microcontrollers, drivers, inverters, and development tools mentioned in this article are available from Digi-Key Corporation.

TFT displays are a type of liquid crystal display in which the transistor controlling the pixel’s crystal is etched into a layer of amorphous silicon deposited on the glass (see Figure 1). As in an IC process, very small transistors are geometrically formed. The small size of the transistor means it will not significantly attenuate the light passing through.

The advantage of TFTs is that they are fast enough for video, provide a large and smooth color palette, and are pixel addressable through an electronic two-dimensional control matrix (see Figure 2). Most low-cost displays use an amorphous silicon crystal layer deposited onto the glass through a plasma-enhanced chemical vapor deposition.

Figure 2: Electronically, a stable VCOM reference is used throughout the display, and the gamma corrected drive voltage passes through each transistor.

Many versions of TFT technologies have led us to the modern displays. Early complaints like poor viewing angles, poor contrast, and poor backlighting have been addressed. Better light sources, diffusers, and polarizers make many displays very vivid, some even claiming to be daylight readable. Modern day techniques like in-plane switching improve viewing angles by making the crystals move in a parallel direction to the display plane instead of vertically. Better speeds and contrasts of modern display make them high performance for a fairly low cost.

Since TFTs are not emissive devices, they require backlighting. The most commonly deployed backlight technology is cold cathode florescent lighting (CCFL). These devices were designed, chosen, and used because they are very efficient and have very long lives. Typically, a CCFL bulb is rated as having in the ball park of a 50,000 hour ‘half-life. ’ This means that after 50,000 hours, it still works, but with half the intensity when it was new.

Modern displays, especially the smaller ones, have transitioned to white LED-based backlights. These are easier to manufacture, do not require the high voltage inverter which CCFL bulbs need, and are approaching a lower cost point compared to CCFL technology. Both CCFL and LED technologies will use diffuser layers inside the stackup to evenly distribute light. LED-based backlights may actually be side lights and use a lightpipe structure to distribute the light.

Transflective technology is steadily improving and is available in some TFT displays. This is where both a backlight and ambient external light are used to make the display visible. Sunlight may make it viewable, but generally speaking the transflective displays are less transmissive. This means that the backlight will have to be brighter (and require more power) to be on par with a purely transmissive display that requires a backlight all the time.

With TFT and most color display technologies, an individual pixel contains a red, a green, and a blue picture element (pel). The relative intensity of each color will determine the resulting blended color.

Some displays will use dithering and alternating pixel colors to achieve a better blend of intermediate colors. Higher frame rates are also used since the persistence effect of phosphor-based displays does not carry over to LCDs. Determine the quality and smoothness of the display you will use. Not every frame rate control technique yields flicker- and jitter-free performance, especially at some resolutions. If you notice it, so will your customers and end users of your design.

The memory required to map the display image is key. While some micros will contain enough memory to hold a single page of display data (and not much else), you can see that a lot of memory is required for even a modest ¼ VGA display. This is more than what a typical microcontroller can house (see Table 1). As a result, an external bus interface to external RAM (SRAM, DRAM, or SDRAM) will be needed, especially if paging will be used.

Table 1: The memory required to map to a display is proportional to three times the square of the resolution because of the three color elements of each pixel.

Paging will allow better display quality since one page can be displayed while the next is being built in the background, then made live. This eliminates ghosting and image flicker when graphics are changing rapidly in effects like scrolling, moving sprites (graphical objects), color shade blending (for overlapping graphics as they move), etc.

A key feature when selecting a microcontroller for TFT interfacing is the DMA support. Multi-channel, flexible DMA will make a world of difference, especially when it comes to moving data between pages, character generator and rendering tables, animations and video. Along these lines, a preprogrammed and autonomous DMA functionality will allow you to refresh a display while the core microcontroller goes to sleep. This is a key power-reducing feature that can make a world of difference when operating from batteries.

Very high volume applications may justify using an OEM only for the glass and implementing your own control electronics from the glass up. This is especially true when designing a very small form factor device where the added flexibility of using your own PCB layout is critical to success. For those designing from the glass up, the primary interface will be drivers for the thin film transistors. The stable common voltage reference to which all pixels are referenced is key. This is called VCOM and several discrete and integrated solutions for generating a VCOM signal are available.

One effective solution is to use the National Semiconductor LMH6640MF/NOPB which is a rail-to-rail (up to 16 volts), voltage feedback, high output (up to 100 ma) amplifier optimized for TFT transistor driving. The fast 170 V/µS slew rate yields a 28 MHz full power bandwidth (at five volts) and its small SOT-23 package can be fit into tight spaces (see Figure 3).

The larger the panel, the more current will be required to operate the transistors. For larger panels, another contender is the Maxim MAX9550EZK+T which can drive up to 800 ma peaks up to 20 volts. It settles to within 0.1 percent in less than 2 µSec and features a soft start circuit to limit inrush current during startup. Note, the VCOM level is usually set between the upper voltage level and ground instead of being set to ground. This allows full scale alternating polarity to be driven to the pixels without the need for a negative power supply.

Also , the VCOM function and all its subtleties are often times integrated into more encompassing TFT driver chips like Texas Instruments’ LM8207MT/NOPB which combines an 18 channel gamma corrected driver with VCOM referencing buffer (see Figure 4). Note that the built-in VCOM buffer will allow a buffer tree to be created from a single reference for larger displays.

One approach to driving a TFT display without the need for a higher end processor is to use a discrete TFT controller chip that can be interfaced to a processor of lesser horsepower. An example is the Intersil TW8811-LD2-GR TFT controller chip (see Figure 5).

Aimed at a specific market segment, in this case automotive applications, the TW8811 combines control and even video standard (analog, RGB, S-Video, NTSC, PAL, and Secam) integration into a single chip controller. It supports and ties together different video sources to allow the same display to be used for navigation systems, engine displays, environmental control, in-car entertainment systems, backup cameras, etc.

The on-chip SDRAM interface provides the depth and cost-effective performance needed for displays up to WXGA resolutions, and the –40 to +85 degree temperature range makes this usable for a variety of harsh environment applications.

If a single microcontroller can control the task at hand as well as the embedded display, this is usually the most cost-effective solution. Most people will use a TFT module which already houses the VCOM, gamma correction, and TFT transistor drivers. As a result, the interface to the module is TTL, CMOS, or Low Voltage Differential Signaling (LVDS).

Thankfully, to help make TFT design tasks doable in a reasonable amount of time, the chip makers provide solutions targeted at display designs. Typically, these are higher-end, 32-bit, RISC-type processor architectures with streamlined peripherals and resources that handle both display-oriented and non-display-oriented functions such as communications, sensor interfacing, etc.

Devices like this need development environments and evaluation units and NXP is right there. The DK-57VTS-LPC2478 is a programmer’s development system that includes a 5.7 inch TFT with touch interface as well (see Figure 6). Note the 2M x 32 SDRAM for page buffering and graphic manipulations. NXP also offers the DK-57TS-LPC2478 which aims at sensor-based applications.

NXP Semiconductors is not alone by any means. Renesas Electronics America also provides processors with built-in support for TFTs. Take for example the DF2378RVFQ34V, an H8-based processor with advanced block transfer functionality built into the DMA. Like the NXP parts, it incorporates a slew of peripherals, Flash, memory interfaces, and I/O.

Not every processor needs to have a dedicated TFT interface to make it a viable candidate. For example, the TI TMS470R1B1MPGEA is a RISC-based 60 MHz ARM7 processor that can easily interface to a slew of TFT modules that are driven via a digital interface. While some modules need constant refreshing, others can be loaded with display data and generate all the timing and display data movement internally unburdening the host CPU. The CPU must be fast enough to keep up with any animations or video if this is the case.

Many displays are readily available as test vehicles. Many of these can be directly driven with the processors mentioned here. Many other processors can also be used, like offerings from Atmel (AT91SAM9261B-CU) and STMicroelectronics (STM32F107VBT6).

No matter how many data sheets you read, what it boils down to is this: a display is a visual device. What will ultimately make the decision is how it looks when you display your screens on it.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

Compared with ordinary LCDs, TFT LCDs provide very clear images/text with shorter response times. TFT LCDs are increasingly being used to bring better visual effects to products.

TFT stands for “thin film transistor”. The transistor of a color TFT LCD is composed of a thin film of amorphous silicon deposited on glass. It acts as a control valve to provide the appropriate voltage to the liquid crystal for each sub-pixel. This is why TFT LCDs are also known as active matrix displays.

TFT LCDs have a liquid crystal layer between a glass substrate formed by the TFT and transparent pixel electrodes and another glass substrate with a color filter (RGB) and a transparent counter electrode. Each pixel in the active matrix is paired with a transistor that includes a capacitor, which gives each sub-pixel the ability to retain its charge without sending a charge every time it needs to be replaced. This means that TFT LCDs are more responsive.

To understand how a TFT LCD works, we must first grasp the concept of a field effect transistor (FET), which is a transistor that uses an electric field to control the flow of current. It is a component with three terminals: source, gate and drain. fet controls the flow of current by applying a voltage to the gate, thereby changing the conductivity between the drain and source.

Using the FET, we can build a circuit as follows. The data bus sends a signal to the source of the FET, and when SEL SIGNAL applies a voltage to the gate, a drive voltage is generated on the TFT LCD panel. A sub-pixel is lit. A TFT LCD display contains thousands or millions of such driver circuits.

Color TFT LCD from 1.8 inch ~ 15 inch, there are different resolutions and interfaces. How to choose the right TFT LCD, you can refer to the previous article “LCD | How to choose a liquid crystal display module

In this paper, design for EMC of LCD driver IC is proposed. By the analysis with package parasitic parameters and EMC test pattern, local power/ground noise in LCD driver IC simulated. As a result of analysis, design for lower peak of EMI spectrum and design for lower mean level of that is proposed at the same time. In addition, decoupling cap with CMOS process can decrease EMI spectrum without any further mask. The analysis of the proposed design shows that LCD driver IC can be alternatives…Expand

In this work, we design and optimize a new amorphous silicon gate (ASG) driver circuit for GOP (gate-on-panel) application in medium size LCD. The circuit is composed of sixteen TFTs and one capacitor with distinct pre-charge nodes and dual low voltage levels. The design of distinct pre-charge nodes is conducive to the decrease of the charge time, and the dual low voltage level will stabilize the output waveform in off-duty periods. Biology-inspired global optimization technique is thus advanced to optimize circuit parameter for further improvement of dynamic characteristics. The optimization not only considers output characteristics but the pre-charge node voltage fluctuation, which may lead serious variation to output waveform when the temperature becomes higher. The results of our design including optimization indicate the achieved circuit performance is apparently better than an original design, where the associated sensitivity analysis is examined to assess the variation of optimized specification. The proposed new design is useful for manufacturing.

This paper proposes a new driving structure of the thin-film transistor liquid crystal display (TFT-LCD) that can yield a high image quality with a reduction in the number of source driver ICs for use in narrow-bezel notebook displays with ultra-high definition (UHD) and a high frame rate. The proposed driving structure improves the pixel charging ratio by reducing the RC loadings of TFTs of de-multiplexers on data lines and extending the available row-line time for pixel charging. A new gate driver circuit that generates two output waveforms in a single stage is presented to reduce the cost and occupied layout area of gate driver ICs, enabling the realization of high-resolution displays with a narrow bezel. To verify the feasibility of the proposed driving structure, a 12.3-inch panel with UHD (3840 × 2160) and a frame rate of 120 Hz is fabricated. Experimental results demonstrate that the proposed driving structure yields a measured pixel charging ratio of more than 97.09% for a heavy loading pattern with a gray level of 255. Following an accelerated lifetime test, the measured waveforms of the proposed gate driver circuit are stable without any malfunction, demonstrating its high reliability. Therefore, the proposed driving structure and the gate driver circuit are highly suitable for use in UHD TFT-LCD notebook applications.

ER-TFTV043-3 is 480x272 dots 4.3" color tft lcd module display with vga,video,av signal driver board,optional 4-wire resistive touch panel with USB driver board and cable,optional capacitive touch panel with USB controller board and cable,optional remote control,superior display quality,wide view angle.It can be used in any embedded systems,car,industrial device,security and hand-held equipment which requires display in high quality and colorful video.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey