active matrix tft lcd a color quotation

Looking for active matrix tft color lcd for your event or wholesale active matrix tft color lcd for your brand? Source from a wide selection on Alibaba.com and enjoy great variety as well as great deals.

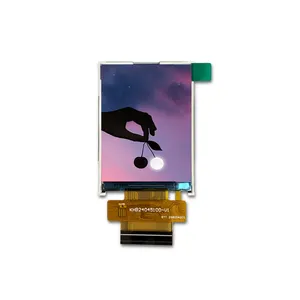

There are active matrix tft color lcd available in a variety of sizes (16x2, 16x4, 20x2, 20x4, 24x2, 40x2, and more) as well as many resolutions. Some of the modules allow for clear and colorful displays. You can find some modules that have integrated controllers, coloured and monochrome, and flat-screen and modules with SPI. For greater visibility outdoors, there are also super-bright modules with high luminance ranges.

Explore the extensive selection of wholesale active matrix tft color lcd LCD displays, TFT, and HMI that can be used across a range of industries, including domestic, medical, industrial, automotive, and many others. You can choose from a number of standard industry sizes and find the active matrier tft colors lcd that are applicable to your required use. If you would like options that allow a smaller environmental footprint due to low power consumption, you can browse the Chip-on-Glass (COG) LCDs. COGs are designed without PCBs so have a slimmer profile. For instance, the sling profile helps you to use the slink profile on your utility and grains when youing the plastic matings. Check out the Alibaba.com difference and when you shop from our wholesalers.

A wide variety of tft active matrix lcd options are available to you, You can also choose from original manufacturer, odm tft active matrix lcd,As well as from tft, ips, and tn.

Technology can be confusing because it evolves quickly, and there are complex acronyms for almost everything. If you are thinking ofbuildinga monitor or want to learn about the technology, you will encounter the term TFT Monitor at some point.

A lot goes on behind the glass surface, and we will look at this in comparison to other technologies to paint a clear picture of what TFT is and how it evolved.

TFT is an acronym for Thin Film Transistor, and it is a technology used in Liquid Crystal Display screens. It came about as an improvement to passive-matrix LCDs because it introduced a tiny, separate transistor for each pixel. The result? Such displays could keep up with quick-moving images, which passive-matrix LCDs could not do.

Also, because the transistors are tiny, they have a low power consumption and require a small charge to control each one. Therefore, it is easy to maintain a high refresh rate, resulting in quick image repainting, making a TFT screen the ideal gaming monitor.

The technology improved on the TN (Twisted Nematic) LCD monitor because the shifting pattern of the parallel, horizontal liquid crystals gives wide viewing angles. Therefore, IPS delivers color accuracy and consistency when viewed at different angles.

Both TFT and IPS monitors are active-matrix displays and utilize liquid crystals to paint the images. Technically, the two are intertwined because IPS is a type of TFT LCD. IPS is an improvement of the old TFT model (Twisted Nematic) and was a product of Hitachi displays, which introduced the technology in 1990.

The monitors can create several colors using the different brightness levels and on/off switches. But unlike OLED, both TFT and IPS do not emit light, so most have bright fluorescent lamps or LED backlights to illuminate the picture. Also, neither of them can produce color, so they have an RGB color filter layer.

Easy to Integrate and Update: By combining large-scale semiconductor IC and light source technology, TFTs have the potential for easy integration and updating/development.

Wide Application Range: TFTs are suitable for mobile, desktop screens, and large-screen TVs. Additionally, the technology can operate at a temperature range of -20°C to +50°C, while the temperature-hardened design can remain functional at temperatures not exceeding -80°C.

Impressive Display Effect: TFT displays use flat glass plates that create an effect of flat right angles. Combine this with the ability of LCDs to achieve high resolutions on small screen types, and you get a refreshing display quality.

High Resolution: The technology combines high brightness, color fidelity, contrast, response speed, and refresh rate to ensure you get a high resolution.

Good Environmental Protection: The raw materials used to make TFT displays produce zero radiation and scintillation. Thus, the technology does not harm the user or the environment.

Mature Manufacturing Technology: TFT technology came into existence in the 60s. Over time, its manufacturing technology has matured to have a high degree of automation, leading to cheaper, large-scale industrial production.

Wide View Angle: One of the main advantages of IPS screens is their wide viewing angle due to the horizontal liquid crystals. They do not create halo effects, grayscale, or blurriness, but these are common flaws with TFTs.

Better Color Reproduction and Representation: The pixels in TFTs function perpendicularly after activation with the help of electrodes. However, IPS technology makes the pixels function while parallel horizontally. Thus, they reflect light better and create a more original and pristine image color.

Faster Frequency Transmittance: Compared to TFT, IPS screens transmit frequencies at about 25ms, which is 25x faster. This high speed is necessary to achieve wide viewing angles.

Liquid Crystal Display (LCD) is a front panel display that utilizes liquid crystals held between two layers of polarized glass to adjust the amount of blocked light. The technology does not produce light on its own, so it needs fluorescent lamps or white LEDs.

As explained earlier, TFT improved on the passive-matrix LCD design because it introduces a thin film transistor for each pixel. The technology reducescrosstalkbetween the pixels because each one is independent and does not affect the adjacent pixels.

LED screens are like the new kids on the block in the display market, and they operate very differently from LCDs. Instead of blocking light, LEDs emit light and are thinner, provide a faster response rate, and are more energy-efficient.

Since IPS is a type of TFT, when comparing the two, we are essentially looking at the old Thin-Film Transistor technology (Twisted Nematic) vs. the new (IPS). Even though TN is relatively old, this digital display type has its advantages, a vital one being the fast refresh rate. This feature makes such screens the preferred option by competitive gamers. If you have any inquiries about the technology,contact usfor more information.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

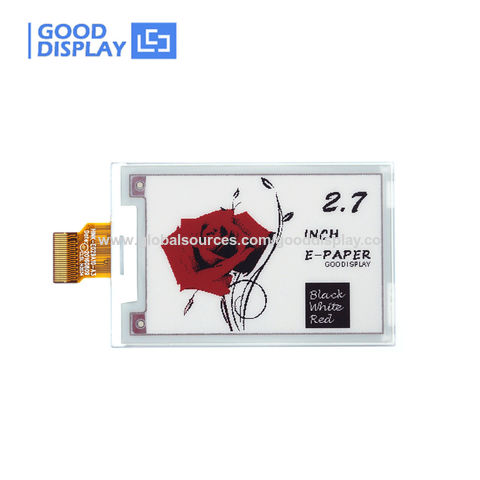

An AMLCD) is a type of flat-panel display, the only viable technology for high-resolution TVs, computer monitors, notebook computers, tablet computers and smartphones with an LCD screen, due to low weight, very good image quality, wide color gamut and response time.

The concept of active-matrix LCDs was proposed by Bernard J. Lechner at the RCA Laboratories in 1968.thin-film transistors was made by T. Peter Brody, Fang-Chen Luo and their team at Westinghouse Electric Corporation in 1972.

The most common type of AMLCD contains, besides the polarizing sheets and cells of liquid crystal, a matrix of thin-film transistors to make a thin-film-transistor liquid-crystal display.pixel on the display while all the other pixels are being updated. This method provides a much brighter, sharper display than a passive matrix of the same size. An important specification for these displays is their viewing-angle.

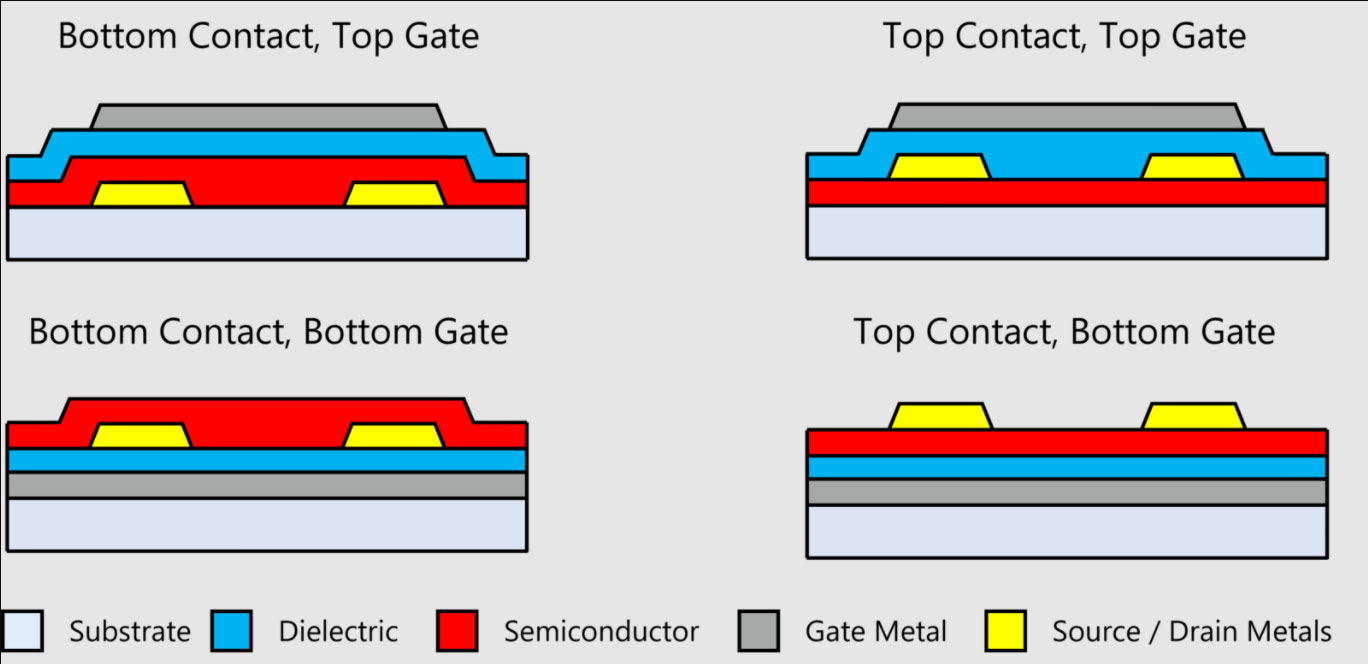

Thin-film transistors are usually used for constructing an active matrix so that the two terms are often interchanged, even though a thin-film transistor is just one component in an active matrix and some active-matrix designs have used other components such as diodes. Whereas a passive matrix display uses a simple conductive grid to apply a voltage to the liquid crystals in the target area, an active-matrix display uses a grid of transistors and capacitors with the ability to hold a charge for a limited period of time. Because of the switching action of transistors, only the desired pixel receives a charge, and the pixel acts as a capacitor to hold the charge until the next refresh cycle, improving image quality over a passive matrix. This is a special version of a sample-and-hold circuit.

Brody, T. P.; Fang Chen Luo; Szepesi, Z. P.; Davies, D. H. (1975). "A 6 x 6-in 20-lpi electroluminescent display panel". IEEE Transactions on Electron Devices. 22 (9): 739. doi:10.1109/T-ED.1975.18214. S2CID 1378753.

"History of TFT LCD". Archived from the original on 2013-08-23. Retrieved 2011-02-22. There are many kinds of AMLCD. For their integrated switching devices most use transistors made of deposited thin films, which are therefore called thin-film transistors (TFTs).

Liquid Crystal Pixels are transmission type pixels with a backlight, meaning that they are not emitting their own light. While there are many types of liquid crystal materials such as smectics, nematics and cholesterics, twisted nematic (TN) display mode is the most advanced and popular. A TN pixel cell consists of two glass substrates coated on their inner surfaces with transparent electrodes and separated by several millimeters from each other. A nematic liquid crystal material fills the space between the two substrates and two polarizers are attached on both sides of the pixel with their polarization axis crossed. The polarizer is a three-layer composite film with a stretched iodine doped polyvinyl alcohol (PVA) polarizing film in the center and two outer films for protecting the PVA film from the ambient. Since the two substrates, each having alignment layer, are oriented with their alignments perpendicular to each other, liquid molecule is twisted initially. In the voltage-off state, the polarizers are oriented perpendicular and the incoming light from a back light source, whose polarity is twisted by the liquid crystal, is transmitted through the output polarizer. When a voltage is applied to the electrodes, the director of the molecules tends to orient themselves parallel to the applied field, since liquid crystal materials have positive dielectric anisotropy. In this situation, the polarization of the light transmitted through liquid crystal is crossed to the output polarizer resulting in the cut off of the light and thus creating a black state for the display pixel. This operation is called normally white mode, while normally black mode can be achieved by changing the polarizers to a parallel orientation. Figure 10 shows the configuration a TN pixel cell in a normally white mode.

The transmission (luminance) versus the applied voltage characteristic is shown in Fig. 11. The shown characteristic is for normal viewing angle and indicates that grayscale levels can be achieved by varying the voltage across the LCD. Unfortunately, the transmission – voltage curve is viewing angle dependent, leading to grayscale errors and color shift in a display when it is viewed from significant angles to the display normal.

The equivalent circuit with the parasitic elements of a pixel cell and a typical TFT-LCD pixel layout are shown in fig. 12. The pixel consists of a switch TFT device, with the gate electrode connected to the row driver lines and the source electrode connected to the column driver lines. Furthermore, a storage capacitor is connected in parallel to the LC pixel capacitance.

The aperture part is the light transparent part and it is designated for the placement of the liquid crystal while the TFT, voltage lines and storage capacitor areas are non-light transparent. The ratio between the transparent portion of a pixel and its surrounding electronics is called aperture ratio or fill factor. Furthermore, in the shown layout design, the storage capacitor is connected to an adjacent row line resulting in the maximization of the aperture ration but the load capacitance of the row lines is, also, increased. The counter electrode of the LC pixel capacitor is the common ITO electrode on the opposite substrate (Den Boer, 2005). For large displays, this configuration is difficult to be used due to the large RC delay time of the row lines. In order to overcome this problem, a common storage bus can be placed in the aperture area which reduces the load capacitance of the row lines, but also reduces the aperture ration of the pixel.

The crosstalk effect is caused due to the column-line video-signal coupling during one frame and a DC component is being added to the AC data voltage. The DC component can not be entirely eliminated for all gray across the entire pixels matrix, resulting to slight difference in the pixel transmittance between the odd and even frames. A solution to this problem is the polarity inversion method. Apart from elimination of the DC component, the influence of the flicker on the display image quality is also eliminated with the use of a polarity inversion method. Four different polarity inversion methods have been widely used. Figure 13 shows the configuration of the four polarity inversion methods. The type of the polarity inversion method has an impact on the power consumption of the display. In the frame inversion method, all the pixels are driven to + Vp polarity in one frame period and then all of them are driven to – Vp polarity during the next frame period. This method is the most power-efficient method. However, this method is sensitive to the flicker and to vertical and horizontal crosstalk, meaning that this method can not be used in high image quality displays.

In the line and column inversion methods, the polarity of the pixels is alternated in the adjacent rows and columns, respectively. The line inversion method is compatible to the Vcom modulation (Den Boer, 2005) while column inversion method is not compatible. Furthermore, the line inversion method consumes more power than the column inversion method because the capacitance of all row busses is charged and discharged every row time. Finally, the column inversion method has better results to the compensation of the flicker.

In the pixel inversion method, the polarity of each pixel is inverted from the polarity of its neighbouring pixels, by a combination of simultaneous row and column inversions. This produces the highest quality images by total elimination of the flicker and crosstalk effect. This method is not compatible with the Vcom modulation and thus it requires high voltage column drivers leading to high power consumption.

A full color LCD display can be generated by incorporating red, green and blue color filters at the pixels. In order to produce the desirable color tone, the pixel is divided into three sub-pixels each one having red, green and blue color filter, respectively. The three sub-pixels have the same dimensions and the proper combination of each color tone; by applying the right voltages to the liquid crystals, the desired pixel emissive colour will be produced. The width of each sub-pixel is three times smaller than the sub-pixel length and when the three sub-pixels are very closely placed in parallel, a square full color pixel is produced. Figure 14 shows a full colour square pixel.

Offering you a complete choice of products which include Si TFT Active Matrix LCD, 3.5" Active Matrix LCD Panel, 7" Amorphous Transmissive Tft LCD Screen, 6.7" Amorphous Si TFT Color LCD Module, PQ 3Qi-01 is a 10.1" TFT Liquid Crystal Display and TFT LCD Panel 3.45.

A si TFT active matrix LCD of 7"(diagonal dimensions) with a resolution of 800*3(RGB)*480. Features include white LED backlight and VGA and Video input.The signal interface is parallel RGB(1ch,6-bit) with wide range of display colors of 262K.

It features Transmissive type and back-light with six LEDS(Serial type) with support resolution of n 320xRGBx240 (16.7M Color) which includes 24bit parallel RGB Interface (8bit x 3).

A070VW04_V1 is an amorphous transmissive type TFT (Thin Film Transistor) LCD (Liquid crystal Display). This model is composed of TFT-LCD, driver IC, FPC (flexible printed circuit), and backlight unit.

This color LCD module is composed of amorphous silicon thin film transistor liquid crystal display panel structure with driver LSis for driving the TFT array and a backlight.Color (Red,Green,Blue) data signals from a host system e.g. signal generator are modulated into the best form for active matrix system by signal processing board, and sent to the driver LSIs which drive the individual TFT arrays.

This 10.1” TFT Liquid Crystal Display module supports 1024 x RGB x 600 Wide-SVGA (WSVGA) mode and can display 262,144 colors.This module also supports two low power modes: a transflective mode with lower color and a reflective black and white (64 grayscales) mode. In reflective mode the screens shows higher resolution at 3072 x 600 pixels, in transflective mode the color resolution is 1024 x RGB x 600, while the black/white/grey resolution is 3072 x 600. The converter module for the LED backlight is built in.

3.45“ color TFT-LCD panel. The 3.45“ color TFT-LCD panel is designed for camcorder, digital camera application and other electronic products which require high quality flat panel displays. This module follows RoHS.Added features include High Resolution :230,400 Dots (320 RGB x 240) . Image Reversion: Up/Down and Left/Right.

T. Arai, H. Iiyori, Y. Hiromasu, M. Atsumi, S. Ioku, and K. Furuta,“Aluminium-Based Gate Structure for Active Matrix Liquid Crystal Displays,” IBM Journal of research and Development, Vol. 42, No. 3/4, pp. 491–499,1998.

Y.-F. Chen, C.-C. Chen, and K.-H. Chen “Mixed Color Sequential Technique for Reducing Color Breakup and Motion Blur Effects,” IEEE Journal of Display Technology, Vol. 3, No. 4, pp. 377–385, Dec. 2007.

W.C. Elmore, “The Transient Response of Damped Linear Networks with Particular Regard to Wideband Amplifiers,” Journal of Applied Physics, Vol. 19, No. 1, pp. 55–63, 1948.

D. Eliav, E.H.A. Langendijk, S. Swinkels, I. Baruchi, “Suppression of Color Breakup in Color-Sequential Multiple-Primary Projection Displays,” SID Digest, Vol. 36, No. 1, pp. 1510–1513, 2005.

N. Fisekovic, T. Nauta, N.J. Cornelissen, and J. Bruinink, “Improved Motion- Picture Quality of AM-LCDs Using Scanning Backlight,” Proceedings of International Display Workshops, pp. 1637–1640, 2001.

K. Fujimori, Y. Narutaki, and N. Kimura, “High-Transmissive Advanced TFT LCD Technology,” Sharp Technical Journal, No. 4, 2003. (sharpworld.com/corporate/info/rd/index.html).

H. Gleskova and S. Wagner, “DC-Bias Stressing of a-Si:H TFTs Fabricated at 150°C on Polyimide Foil,” IEEE Transactions on Electron Devices, Vol. 48, No. 8, p. 1667, 2001.

W.G. Hawkins, “Polycrystalline-Silicon Device Technology for Large Area Electronics,” IEEE Transactions on Electron Devices, Vol. 33, No. 4, pp. 447–450, 1986.

A. Hepburn, J.M. Marshall, C. Main, M.J. Powell, and C. van Berkel, “Metastable Defects in Amorphous Silicon Thin Film Transistors,” Physical Review Letters, Vol. 56, No. 20, pp. 2215–2218, 1986.

M. Hack and M.S. Shur, “Physicals Models for Amorphous-Silicon Thin Film Transistors and their Implementation in a Circuit Simulation Program,” IEEE Transactions on Electron Devices, Vol. 36, No. 12, pp. 2764–2769, 1989.

J. Hirakata, A. Shingai, Y. Tanaka, K. Ono, and T. Furuhashi, “Super-TFT-LCD for Moving Picture Images with the Blink Backlight System,” SID Digest, Vol. 32, No. 1, pp. 990–993, 2001.

Y. Igarashi, T. Yamamoto, Y. Tanaka, J. Someya, Y. Nakamura, M. Yamakawa, S. Hasegawa, Y. Nishida, and T. Kurita, “Proposal of The Perceptive Parameter Motion Picture Response Time (MPRT),” SID Digest, Vol. 34, No. 1, pp. 1039–1041, 2003.

M.D. Jacunski, M.S. Shur, and M. Hack, “Threshold Voltage, Field Effect Mobility and Gate-to-Channel Capacitance in Polysilicon TFT’s,” IEEE Transactions on Electron Devices, Vol. 43, No. 9, pp. 1433–1440, 1996.

Y. Kuo, “Amorphous Silicon Thin Film Transistors,” Thin Film Transistors: Materials and Processes, Vol. 1: Kluwer Academic Publishers, pp. 186–188, 2004.

M.-D. Ker, C.-K. Deng, and J.-L. Huang, “On-Panel Design Technique of Threshold Voltage Compensation for Output Buffer in LTPS Technology,” SID Digest, Vol. 36, No. 1, pp. 288–291, 2005.

Y. Kanemori, M. Katayama, N. Nakazawa, H. Kato, K. Yano, and Y. Fukuoka, “10.4 in.-Diagonal Color TFT-LCDs without Residual Images,” SID Digest, pp. 408–411, 1990.

K. Karim, A. Nathan, M. Hack, and W. Milne, “Drain Bias Dependence of Threshold Voltage Stability of Amorphous Silicon TFTs,” IEEE Electron Device Letters, Vol. 25, No. 4, pp. 188–190, 2004.

J.P. Krusius, D.P. Seraphim, R.G. Greene, D.S. Skinner, and B. Yost, “Approaches Toward Ultralarge FPDs,” Proceedings of IEEE, Vol. 90, No. 4, pp. 559–580, 2002.

S.-J. Kim, Y.-C. Sung, and O.-K. Kwon, “Pre-Emphasis Driving Method for Large Size and High Resolution TFT-LCDs,” SID Digest, Vol. 34, No. 1, pp. 1354–1357, 2003.

T. Krita, A. Saito, and I. Yuyama, “Consideration on perceived MTF of hold type display for moving images,” Proceedings of International Display Workshops, pp. 823–826, 1998.

S. Kawai, N. Takagi, T. Kodama, K. Asama, and S. Yanagisawa, “Amorphous Silicon Thin-Film Transistor for Liquid Crystal Display Panel,” SID Digest, pp. 42–43, 1982.

F.R. Libsch and S.-C.A. Lien, “Understanding Crosstalk in High-Resolution Color Thin-Transistor Liquid Crystal Displays,” IBM Journal of Research and Development, Vol. 42, pp. 467–479, 1998.

A.G. Lewis, D.D. Lee, and R.H. Bruce “Polysilicon TFT Circuit Design and Performance,” IEEE Journal of Solid-State Circuits, Vol. 27, No. 12, pp. 1833–1842, 1992.

B.-W. Lee, K. Song, D.-J. Park, Y. Yang, U. Min, S. Hong, C. Park, M. Hong, and K. Chung, “Mastering the Moving Image: Refreshing TFT-LCDs at 120 Hz,” SID Digest, Vol. 36, No. 1, pp. 1583–1585, 2005.

Z. Li, S. Venugopal, R. Shringarpure, D.R. Allee, and L.T. Clark, “An Analytical Lifetime Model for Digital a-Si:H Circuits,” SID Digest, Vol. 37, No.1, pp. 270–273, 2006.

M. Miyasaka and J. Stoemenos, “Excimer Laser Annealing of Amorphous and Solid-Phase-Crystallized Silicon Films,” Journal of Applied Physics, Vol. 86, pp. 5556–5565, 1999.

H. Nakagawa, “Current Trends of Flat Panel Displays Viewed from Applications,” Sharp Technical Journal, No. 4, 2003. (http://sharpworld.com/corporate/info/rd/index.html).

K. Ono, Y. Imajo, I. Mori, R. Oke, S. Kato, K. Endo, H. Ishino, and Y. Ooishi, “New IPS Technology Suitable for LCD-TVs,” SID Digest, Vol. 36, No. 1, pp. 1848–1851, 2005.

M.J. Powell, “Charge Trapping Instabilities in Amorphous Silicon-Silicon Nitride Thin Film Transistors,” Applied Physics Letters, Vol. 43, No. 6, pp. 597–599, 1983.

M.J. Powell, C.V. Berkel, and J.R. Hughes, “Time and Temperature Dependence of Instability Mechanisms in Amorphous Silicon Thin-Film Transistors,” Applied Physics Letters, Vol. 54, No. 14, pp. 1323–1325, 1989.

M.J. Powell and S.C. Deane, “Improved Defect-Pool Model for Charged Defects in Amorphous-Silicon,” Physical Review B, Vol. 48, No. 15, pp. 10815–10827, 1993.

K. Suzuki, “Compensative Addressing for Switching Distortion in a-Si TFTLCD,” Proceedings of 7th International Display Research Conference, pp. 107–110, 1987.

K.H. Shin, J.Y. Ahn, K.D. Kim, H.H. Shin, and I.J. Chung, “Acceptable Motion Blur Levels of a LCD TV Based on Human Visual System,” SID Digest, Vol. 37, No. 1, pp. 287–290, 2006.

H. Seetzen, W. Heidrich, W. Stuerzlinger, G. Ward, L.A. Whitehead, M. Trentacoste, A. Gosh, and A. Vorozcovs, “High Dynamic Range Display Systems,” ACM Transactions on Graphics, Vol. 23, pp. 760–768, 2004.

Y.-C. Sung and O.-K. Kwon, “Low-Cost TFT-LCDs with Pre-Emphasis Driving Method for Large-Size and High-Definition TVs,” IEEE Transactions on Consumer Electronics, Vol. 53, No. 4, pp. 1674–1681, 2007.

Y. Son, J. Kim, H. Cho, J. Hong, J. Na, D. Kim, D. Han, J. Hong, Y. Jeon, and G. Cho, “A Column Driver with Low-Power Area-Efficient Push-Pull Buffer Amplifiers for Active-Matrix LCDs,” Proceedings of IEEE International Solid- State Circuits Conference, pp. 142–143, 2007.

T. Shiga, S. Kuwahara, N. Takeo, and S. Mikoshiba, “Adaptive Dimming Technique with Optically Isolated Lamp Groups,” SID Digest, Vol. 36, No. 1, pp. 992–995, 2005.

J.H. Souk and J. Lee, “Recent Picture Quality Enhancement Technology Based on Human Visual Perception in LCD TVs,” IEEE Journal of Display Technology, Vol. 3, No. 4, pp. 371–376, 2007.

J.H. Stessen and J.G.R. vanMourik, “Algorithm for Contrast Reserve, Backlight Dimming, and Backlight Boosting on LCD,” SID Digest, Vol. 37, No. 1, pp. 1249–1252, 2006.

M.S. Shur, H.C. Slade, M.D. Jacunski, A.A. Owusu, and T. Ytterdal, “Spice Models for Amorphous Silicon and Polysilicon Thin Film Transistors,” Journal of Electrochemical Society, Vol. 144, No. 8, pp. 2833–2839, 1997.

E. Takeda, “Simplified Method of Capacitively Coupled Driving for TFTLCD,” Proceedings of 9th International Display Research Conference, pp. 580–583, 1989.

H. Takatsuji, E.G. Colgan, C. Cabral, Jr., and J.M.E. Harper, “Evaluation of Al(Nd)-alloy Films for Application to Thin-Film-Transistor Liquid Crystal Displays,” IBM Journal of Research and Development, Vol. 42, No. 3/4, pp. 501–508, 1998.

C.T. Angelis, C.A. Dimitriaids, M. Miyasaka, F.V. Farmakis, G. Kamarinos, J. Brini, and J. Stoemenos, “Effect of Excimer Laser Annealing on the Structural and Electrical Properties of Polycrystalline Silicon Thin-Film Transistors,” Journal of Applied Physics, Vol. 86, No. 8, pp. 4600–4606, 1999.

W.-C. Tsai, J.-Y. Lai, K.-Y. Tu, H.-T. Lin, and F.-Y. Gan, “A Novel Barrierless Cu Gate for TFT-LCD,” SID Digest, Vol. 37, No. 1, pp. 1181–1184, 2006.

E. Takeda, Y. Nan-no, Y. Mino, A. Otsuka, S. Ishihara, and S. Nagata, “Capacitively Coupled TFT-LCD Driving Method,” SID Digest, Vol. 31, No. 2, pp. 87–94, 1990.

S. Uchikoga, “Future Trend of Flat Panel Displays and Comparison of its Driving Methods,” Proceedings of 18th International Symposium on Power Semiconductor Devices & IC’s, pp. 1–5, 2006.

J.-S. Yoo, “A Novel Polysilicon TFT with Lateral Body Terminal for Driving Circuit Application of AMLCDs,” ITE Technical Report, Vol. 23, No. 67, p. 27, 1999.

Y.-S. Son, H.-H. Son, Y.-S. Kim, H.-S. Oh, and G.-H. Cho, “A Gray-Level Dependent Pre-Emphasis Column Driver with Fast Settling for Active-Matrix LCD Applications,” IEEE Transactions on Circuits and Systems - Part II, pp. 1057–1061, 2007.

Y. Yamada, K. Kimura, and Y. Ishii, “Technology Trend for High Quality Display Image of LC-TV,” Proceedings of International Display Workshops, Vol. 12, No. 1, pp. 227–230, 2005.

T. Yanagisawa, K. Kasahara, and M. Kajimura, “Compensation of the Display Electrode Voltage Distortion,” Proceedings of International Display Research Conference, pp. 192–199, 1986

N. Yamagishi, Y. Tanabe, H. Ishibashi, and H. Yamagami, “Moving Picture Simulations with OCB for Image-Blurring-Free LC TVs,” SID Digest, Vol. 37, No. 2, pp. 1804–1807, 2006.

Z. Yu and H.R. Wu, “Human Visual System Based Objective Digital Video Quality Metrics,” Proceedings of International Conference on Signal Processing, Vol. 2, pp. 1088–1095, 2000.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

Compared with ordinary LCDs, TFT LCDs provide very clear images/text with shorter response times. TFT LCDs are increasingly being used to bring better visual effects to products.

TFT stands for “thin film transistor”. The transistor of a color TFT LCD is composed of a thin film of amorphous silicon deposited on glass. It acts as a control valve to provide the appropriate voltage to the liquid crystal for each sub-pixel. This is why TFT LCDs are also known as active matrix displays.

TFT LCDs have a liquid crystal layer between a glass substrate formed by the TFT and transparent pixel electrodes and another glass substrate with a color filter (RGB) and a transparent counter electrode. Each pixel in the active matrix is paired with a transistor that includes a capacitor, which gives each sub-pixel the ability to retain its charge without sending a charge every time it needs to be replaced. This means that TFT LCDs are more responsive.

To understand how a TFT LCD works, we must first grasp the concept of a field effect transistor (FET), which is a transistor that uses an electric field to control the flow of current. It is a component with three terminals: source, gate and drain. fet controls the flow of current by applying a voltage to the gate, thereby changing the conductivity between the drain and source.

Using the FET, we can build a circuit as follows. The data bus sends a signal to the source of the FET, and when SEL SIGNAL applies a voltage to the gate, a drive voltage is generated on the TFT LCD panel. A sub-pixel is lit. A TFT LCD display contains thousands or millions of such driver circuits.

Color TFT LCD from 1.8 inch ~ 15 inch, there are different resolutions and interfaces. How to choose the right TFT LCD, you can refer to the previous article “LCD | How to choose a liquid crystal display module

Not EXACTLY what you need? We specialize in custom and semi-custom display solutions. Contact us about creating something that fits your exact specifications.

RPC Electronics engineers and manufactures LCD displays and embedded computing systems for OEMs in a wide variety of industries. As a single source vendor, RPC Electronics solves typical product development problems involved with hardware and software display systems.

This system level solution offers LCD hardware that includes graphics, controllers, cabling, LCDs with or without touch screens, and enclosures. Software is also provided. Hardware for embedded controls is inclusive with SBC boards, backplanes, chassis, power supplies, boards, modules, platforms, and HMIs.

Designed to meet a full range of display and embedded computing requirements, this capability also includes services and features such as kitting, touch screen installation, open frame, pixel screening, UL/CSA, and FCC class.

RPC’s ability to provide complete project planning assures product success, delivering the highest quality components in the industry along with dedicated service. For complete details, including full listings of system requirements, see the table below.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey