lcd touch screen technology free sample

Touch screen technology is the direct manipulation type of gesture-based technology. Direct manipulation is the ability to manipulate the digital world inside a screen. A Touch screen is an electronic visual display capable of detecting and locating a touch over its display area. This is generally referred to as touching the display of the device with a finger or hand. This technology most widely used in computers, user interactive machines, smartphones, tablets, etc to replace most functions of the mouse and keyboard.

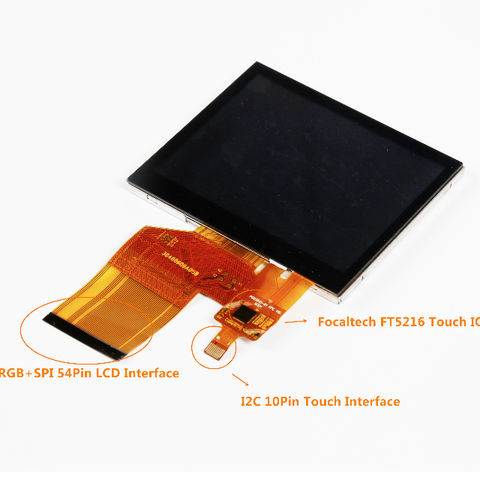

Touch screen technology has been around for a number of years but advanced touch screen technology has come on in leaps and bounds recently. Companies are including this technology in more of their products. The three most common touch screen technologies include resistive, capacitive, and SAW (surface acoustic wave). Most low-end touch screen devices contain a standard printed circuit plug-in board and are used on SPI protocol. The system has two parts, namely; hardware and software. The hardware architecture consists of a stand-alone embedded system using an 8-bit microcontroller, several types of interface, and driver circuits. The system software driver is developed using an interactive C programming language.

A touch screen technology is the assembly of a touch panel as well as a display device. Generally, a touch panel is covered on an electronic visual display within a processing system. Here the display is an LCD otherwise OLED whereas the system is normally like a smartphone, tablet, or laptop. A consumer can give input through simple touch gestures by moving the screen using a special stylus otherwise fingers. In some kinds of touch screens, some normal otherwise gloves are used which are coated to work properly whereas others may simply work with the help of a special pen.

The operator uses the touch screen to respond to what is displayed and if the software of the device permits to control how it can be exhibited like zooming the screen to enhance the size of the text. So touch screen allows the operator to communicate directly through the displayed information instead of using a touchpad, mouse, etc. Touch screens are used in different devices like personal computers, game consoles, EVMs, etc Touch screens are also essential in educational institutions like classrooms in the colleges.

The first concept of a touch screen was described & published in the year 1965 by E.A. Johnson. So, the first touch screen was developed in the 1970s by CERN engineers namely Bent Stumpe 7 Frank Beck. The first touch screen device was created & used in year 1973. The first resistive touch screen was designed in 1975 by George Samuel Hurst however wasn’t launched 7 used until 1982.

Different types of touchscreen technology work in different methods. Some can detect simply one finger at a time & get very confused if you seek to push in two positions at once. Other types of screens can simply notice and differentiate above one key push at once. There are different components used in touchscreen technology which include the following.

A basic touch screen is having a touch sensor, a controller, and a software driver as three main components. The touch screen is needed to be combined with a display and a PC to make a touch screen system.

The sensor generally has an electrical current or signal going through it and touching the screen causes a change in the signal. This change is used to determine the location of the touch of the screen.

A controller will be connected between the touch sensor and PC. It takes information from the sensor and translates it for the understanding of PC. The controller determines what type of connection is needed.

It allows computers and touch screens to work together. It tells OS how to interact with the touch event information that is sent from the controller.

Swiping a finger over the screen is used to type the letters using the keyboard on the screen. It is also used to move the pages from right to left and also close unwanted apps.

The Touch screen is a 2-dimensional sensing device made of 2 sheets of material separated by spacers. There are four main touch screen technologies: Resistive, Capacitive, Surface Acoustical wave (SAW), and infrared (IR).

The resistive touch screen is composed of a flexible top layer made of polythene and a rigid bottom layer made of glass separated by insulating dots, attached to a touch screen controller. Resistive touch screen panels are more affordable but offering only 75% of the light monitor and the layer can be damaged by sharp objects. The resistive touch screen is further divided into 4-, 5-, 6-, 7-, 8- wired resistive touch screen. The construction design of all these modules is similar but there is a major distinction in each of its methods to determine the coordinates of the touch.

A capacitive touch screen panel is coated with a material that stores electrical charges. The capacitive systems can transmit up to 90% of the light from the monitor. It is divided into two categories. In Surface-capacitive technology, only one side of the insulator is coated with a conducting layer.

Whenever a human finger touches the screen, the conduction of electric charges occurs over the uncoated layer which results in the formation of a dynamic capacitor. The controller then detects the position of touch by measuring the change in capacitance at the four corners of the screen.

In projected capacitive technology, the conductive layer (Indium Tin Oxide) is etched to form a grid of multiple horizontal and vertical electrodes. It involves sensing along both the X and Y axis using clearly etched ITO pattern. For increasing the accuracy of the system, the projective screen contains a sensor at every interaction of the row and column.

An infrared touch screen technology, an array of X and Y axis is fitted with pairs of IR LEDs and photodetectors. Photodetectors will detect any image in the pattern of light emitted by the Leds whenever the user touches the screen.

The surface acoustic wave technology contains two transducers placed along the X-axis and Y-axis of the monitor’s glass plate along with some reflectors. When the screen is touched, the waves are absorbed and a touch is detected at that point. These reflectors reflect all electrical signals sent from one transducer to another. This technology provides excellent throughput and quality.

A virtual touch screen is a user interface system that enhances essential objects into reality either using an optical display or projector using sensors to follow an interaction of a person through an object. For example, a person can create a rear projector system or a display to create three-dimensional images which come into view to float within midair.

The PCAP or Projected Capacitive touch screen technology provides the accessible multi-touch experience through tablets, smartphones to operate through extremely light touch using an extremely tough glass surface. These are strong and easily set with protecting glass & the main feature of this technology is a multi-touch function for up to ten fingers by enabling signal control.

These touch screens are equipped with a network of electrodes such as Silver Nanowire, Metal Mesh & ITO which project an electromagnetic field the passes throughout a protecting glass. Once the field alters at one end because of a touching finger, the position of touch can be designed as well as forward toward the controller.

The PCAP touch screens include a mainly scratch-resistant glass surface. Using optional protecting glasses, these screens are vandal-proof & can be utilized in public areas. But, the several touchpoints may change based on the force of the protecting glass used. These types of touch screens are ideal for recent True Flat designs like smartphones otherwise tablet PCs.

Optical sensors are used to identify the touch; so this technology is very popular because of scalability & versatility. This technology mainly depends on infrared lights. Two IR imaging sensors are arranged at the summit, which doubles up like emitters as well as retro-reflective tapes on the three sides. The produced lights are replicated back toward the imaging sensors, which turn into blocked at the end of touch & generate a shadow to place the touch.

An Acoustic Pulse Recognition Touch screen is designed with a glass cover & four transducers connected to the back exterior. Once the screen is stroked, the friction will create acoustic signals. The transducers notice the audio signal, and then it is changed into a signal. These screens are durable, scalable & water-resistant.

Transparent touch screens work by using two modern technologies to make a cutting-edge display that is tough to ignore. These touch screens deliver 4K images or HD based on the display size similar to a normal professional screen. The main difference between a transparent and normal touch screen is a clear screen substrate. White pixels appear completely transparent, black pixels not clear. The full variety of RGB colors has the properties of semi-transparent. Transparent touch screens are available in different types like transparent LCD screens and transparent OLED screens.

Once a bare finer is used to tap on the screen then it registers the commands. If you use a gloved finger otherwise a stylus pen then it doesn’t register the commands. So the main reason is conductive properties. There are different kinds of touchscreen technologies available in the market, but the capacitive type is more popular as compared to others because 90% of the touch screens sold and shipped worldwide are powered through capacitive technology.

These touchscreens depend on conductivity to notice touch commands. If you use a stylus or gloved finger to control them, then they won’t record the commands otherwise react to your commands.

The touch screen is one of the simplest PC interfaces to use, for a larger number of applications. A touch screen is useful for easily accessing the information by simply touching the display screen. The touch screen device system is useful in ranging from industrial process control to home automation.

At the transmission end using a touch screen control unit, some directions will send to the robot for moving into a specific direction like forwarding, backward, rotating left, and rotating right. At the receiving end, four motors are interfaced with the microcontroller. Two of them will be used for Arm and grip movement of the robot and the other two are used for body movement.

Some remote operations can be done with touch screen technology using wireless communication for answering calls, locating and communicating with staff, and operating vehicles and robots. For this purpose RF communication or infrared communication may be used.

It is possible to control the electrical appliances at home using touch screen technology. The whole system works by sending input commands from the touch screen panel through the RF communication which are received at the receiver end and control the switching of loads.

At the transmitter end, a touch screen panel is interfaced with the Microcontroller through a touch screen connector. When an area on the panel is touched, the x and y coordinates of that area are sent to the Microcontroller which generates a binary code from the input.

The applications of touchscreen technology include the following. Some of the examples of touchscreens like smartphones, a tablet or a computer & a point of sale device.

The touch screen supported most of the computers are Acer, HP, Dell, Microsoft, Lenovo, and other PC designers. And also, some high-end Google Chromebooks use touch screens.

Thus, this is all about an overview of touchscreen technology. The main reasons to choose this technology instead of physical buttons by the manufacturers are; these are instinctive, particularly to younger generations of users. By using this technology, the devices can make smaller. The design of these devices is cheaper. In touch screens, different technologies are used to let the operator operate a screen. Some technologies use a finger whereas others use tools such as a stylus. Here is a question for you, Do touch screens use a keyboard?

A touchscreen or touch screen is the assembly of both an input ("touch panel") and output ("display") device. The touch panel is normally layered on the top of an electronic visual display of an electronic device.

A user can give input or control the information processing system through simple or multi-touch gestures by touching the screen with a special stylus or one or more fingers.zooming to increase the text size.

The touchscreen enables the user to interact directly with what is displayed, rather than using a mouse, touchpad, or other such devices (other than a stylus, which is optional for most modern touchscreens).

Touchscreens are common in devices such as smartphones, handheld game consoles, personal computers, electronic voting machines, automated teller machines and point-of-sale (POS) systems. They can also be attached to computers or, as terminals, to networks. They play a prominent role in the design of digital appliances such as personal digital assistants (PDAs) and some e-readers. Touchscreens are also important in educational settings such as classrooms or on college campuses.

The popularity of smartphones, tablets, and many types of information appliances is driving the demand and acceptance of common touchscreens for portable and functional electronics. Touchscreens are found in the medical field, heavy industry, automated teller machines (ATMs), and kiosks such as museum displays or room automation, where keyboard and mouse systems do not allow a suitably intuitive, rapid, or accurate interaction by the user with the display"s content.

Historically, the touchscreen sensor and its accompanying controller-based firmware have been made available by a wide array of after-market system integrators, and not by display, chip, or motherboard manufacturers. Display manufacturers and chip manufacturers have acknowledged the trend toward acceptance of touchscreens as a user interface component and have begun to integrate touchscreens into the fundamental design of their products.

The prototypeCERNFrank Beck, a British electronics engineer, for the control room of CERN"s accelerator SPS (Super Proton Synchrotron). This was a further development of the self-capacitance screen (right), also developed by Stumpe at CERN

One predecessor of the modern touch screen includes stylus based systems. In 1946, a patent was filed by Philco Company for a stylus designed for sports telecasting which, when placed against an intermediate cathode ray tube display (CRT) would amplify and add to the original signal. Effectively, this was used for temporarily drawing arrows or circles onto a live television broadcast, as described in US 2487641A, Denk, William E, "Electronic pointer for television images", issued 1949-11-08. Later inventions built upon this system to free telewriting styli from their mechanical bindings. By transcribing what a user draws onto a computer, it could be saved for future use. See US 3089918A, Graham, Robert E, "Telewriting apparatus", issued 1963-05-14.

The first version of a touchscreen which operated independently of the light produced from the screen was patented by AT&T Corporation US 3016421A, Harmon, Leon D, "Electrographic transmitter", issued 1962-01-09. This touchscreen utilized a matrix of collimated lights shining orthogonally across the touch surface. When a beam is interrupted by a stylus, the photodetectors which no longer are receiving a signal can be used to determine where the interruption is. Later iterations of matrix based touchscreens built upon this by adding more emitters and detectors to improve resolution, pulsing emitters to improve optical signal to noise ratio, and a nonorthogonal matrix to remove shadow readings when using multi-touch.

The first finger driven touch screen was developed by Eric Johnson, of the Royal Radar Establishment located in Malvern, England, who described his work on capacitive touchscreens in a short article published in 1965Frank Beck and Bent Stumpe, engineers from CERN (European Organization for Nuclear Research), developed a transparent touchscreen in the early 1970s,In the mid-1960s, another precursor of touchscreens, an ultrasonic-curtain-based pointing device in front of a terminal display, had been developed by a team around Rainer Mallebrein[de] at Telefunken Konstanz for an air traffic control system.Einrichtung" ("touch input facility") for the SIG 50 terminal utilizing a conductively coated glass screen in front of the display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreenMagnavox Plato IV Student Terminal and thousands were built for this purpose. These touchscreens had a crossed array of 16×16 infrared position sensors, each composed of an LED on one edge of the screen and a matched phototransistor on the other edge, all mounted in front of a monochrome plasma display panel. This arrangement could sense any fingertip-sized opaque object in close proximity to the screen. A similar touchscreen was used on the HP-150 starting in 1983. The HP 150 was one of the world"s earliest commercial touchscreen computers.infrared transmitters and receivers around the bezel of a 9-inch Sony cathode ray tube (CRT).

In 1977, an American company, Elographics – in partnership with Siemens – began work on developing a transparent implementation of an existing opaque touchpad technology, U.S. patent No. 3,911,215, October 7, 1975, which had been developed by Elographics" founder George Samuel Hurst.World"s Fair at Knoxville in 1982.

In 1984, Fujitsu released a touch pad for the Micro 16 to accommodate the complexity of kanji characters, which were stored as tiled graphics.Sega released the Terebi Oekaki, also known as the Sega Graphic Board, for the SG-1000 video game console and SC-3000 home computer. It consisted of a plastic pen and a plastic board with a transparent window where pen presses are detected. It was used primarily with a drawing software application.

Touch-sensitive control-display units (CDUs) were evaluated for commercial aircraft flight decks in the early 1980s. Initial research showed that a touch interface would reduce pilot workload as the crew could then select waypoints, functions and actions, rather than be "head down" typing latitudes, longitudes, and waypoint codes on a keyboard. An effective integration of this technology was aimed at helping flight crews maintain a high level of situational awareness of all major aspects of the vehicle operations including the flight path, the functioning of various aircraft systems, and moment-to-moment human interactions.

In the early 1980s, General Motors tasked its Delco Electronics division with a project aimed at replacing an automobile"s non-essential functions (i.e. other than throttle, transmission, braking, and steering) from mechanical or electro-mechanical systems with solid state alternatives wherever possible. The finished device was dubbed the ECC for "Electronic Control Center", a digital computer and software control system hardwired to various peripheral sensors, servos, solenoids, antenna and a monochrome CRT touchscreen that functioned both as display and sole method of input.stereo, fan, heater and air conditioner controls and displays, and was capable of providing very detailed and specific information about the vehicle"s cumulative and current operating status in real time. The ECC was standard equipment on the 1985–1989 Buick Riviera and later the 1988–1989 Buick Reatta, but was unpopular with consumers—partly due to the technophobia of some traditional Buick customers, but mostly because of costly technical problems suffered by the ECC"s touchscreen which would render climate control or stereo operation impossible.

Multi-touch technology began in 1982, when the University of Toronto"s Input Research Group developed the first human-input multi-touch system, using a frosted-glass panel with a camera placed behind the glass. In 1985, the University of Toronto group, including Bill Buxton, developed a multi-touch tablet that used capacitance rather than bulky camera-based optical sensing systems (see History of multi-touch).

The first commercially available graphical point-of-sale (POS) software was demonstrated on the 16-bit Atari 520ST color computer. It featured a color touchscreen widget-driven interface.COMDEX expo in 1986.

In 1987, Casio launched the Casio PB-1000 pocket computer with a touchscreen consisting of a 4×4 matrix, resulting in 16 touch areas in its small LCD graphic screen.

Touchscreens had a bad reputation of being imprecise until 1988. Most user-interface books would state that touchscreen selections were limited to targets larger than the average finger. At the time, selections were done in such a way that a target was selected as soon as the finger came over it, and the corresponding action was performed immediately. Errors were common, due to parallax or calibration problems, leading to user frustration. "Lift-off strategy"University of Maryland Human–Computer Interaction Lab (HCIL). As users touch the screen, feedback is provided as to what will be selected: users can adjust the position of the finger, and the action takes place only when the finger is lifted off the screen. This allowed the selection of small targets, down to a single pixel on a 640×480 Video Graphics Array (VGA) screen (a standard of that time).

Sears et al. (1990)human–computer interaction of the time, describing gestures such as rotating knobs, adjusting sliders, and swiping the screen to activate a switch (or a U-shaped gesture for a toggle switch). The HCIL team developed and studied small touchscreen keyboards (including a study that showed users could type at 25 wpm on a touchscreen keyboard), aiding their introduction on mobile devices. They also designed and implemented multi-touch gestures such as selecting a range of a line, connecting objects, and a "tap-click" gesture to select while maintaining location with another finger.

In 1990, HCIL demonstrated a touchscreen slider,lock screen patent litigation between Apple and other touchscreen mobile phone vendors (in relation to

An early attempt at a handheld game console with touchscreen controls was Sega"s intended successor to the Game Gear, though the device was ultimately shelved and never released due to the expensive cost of touchscreen technology in the early 1990s.

Touchscreens would not be popularly used for video games until the release of the Nintendo DS in 2004.Apple Watch being released with a force-sensitive display in April 2015.

In 2007, 93% of touchscreens shipped were resistive and only 4% were projected capacitance. In 2013, 3% of touchscreens shipped were resistive and 90% were projected capacitance.

A resistive touchscreen panel comprises several thin layers, the most important of which are two transparent electrically resistive layers facing each other with a thin gap between. The top layer (that which is touched) has a coating on the underside surface; just beneath it is a similar resistive layer on top of its substrate. One layer has conductive connections along its sides, the other along top and bottom. A voltage is applied to one layer and sensed by the other. When an object, such as a fingertip or stylus tip, presses down onto the outer surface, the two layers touch to become connected at that point.voltage dividers, one axis at a time. By rapidly switching between each layer, the position of pressure on the screen can be detected.

Resistive touch is used in restaurants, factories and hospitals due to its high tolerance for liquids and contaminants. A major benefit of resistive-touch technology is its low cost. Additionally, as only sufficient pressure is necessary for the touch to be sensed, they may be used with gloves on, or by using anything rigid as a finger substitute. Disadvantages include the need to press down, and a risk of damage by sharp objects. Resistive touchscreens also suffer from poorer contrast, due to having additional reflections (i.e. glare) from the layers of material placed over the screen.3DS family, and the Wii U GamePad.

Surface acoustic wave (SAW) technology uses ultrasonic waves that pass over the touchscreen panel. When the panel is touched, a portion of the wave is absorbed. The change in ultrasonic waves is processed by the controller to determine the position of the touch event. Surface acoustic wave touchscreen panels can be damaged by outside elements. Contaminants on the surface can also interfere with the functionality of the touchscreen.

The Casio TC500 Capacitive touch sensor watch from 1983, with angled light exposing the touch sensor pads and traces etched onto the top watch glass surface.

A capacitive touchscreen panel consists of an insulator, such as glass, coated with a transparent conductor, such as indium tin oxide (ITO).electrostatic field, measurable as a change in capacitance. Different technologies may be used to determine the location of the touch. The location is then sent to the controller for processing. Touchscreens that use silver instead of ITO exist, as ITO causes several environmental problems due to the use of indium.complementary metal–oxide–semiconductor (CMOS) application-specific integrated circuit (ASIC) chip, which in turn usually sends the signals to a CMOS digital signal processor (DSP) for processing.

Unlike a resistive touchscreen, some capacitive touchscreens cannot be used to detect a finger through electrically insulating material, such as gloves. This disadvantage especially affects usability in consumer electronics, such as touch tablet PCs and capacitive smartphones in cold weather when people may be wearing gloves. It can be overcome with a special capacitive stylus, or a special-application glove with an embroidered patch of conductive thread allowing electrical contact with the user"s fingertip.

A low-quality switching-mode power supply unit with an accordingly unstable, noisy voltage may temporarily interfere with the precision, accuracy and sensitivity of capacitive touch screens.

Some capacitive display manufacturers continue to develop thinner and more accurate touchscreens. Those for mobile devices are now being produced with "in-cell" technology, such as in Samsung"s Super AMOLED screens, that eliminates a layer by building the capacitors inside the display itself. This type of touchscreen reduces the visible distance between the user"s finger and what the user is touching on the screen, reducing the thickness and weight of the display, which is desirable in smartphones.

In this basic technology, only one side of the insulator is coated with a conductive layer. A small voltage is applied to the layer, resulting in a uniform electrostatic field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. The sensor"s controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel. As it has no moving parts, it is moderately durable but has limited resolution, is prone to false signals from parasitic capacitive coupling, and needs calibration during manufacture. It is therefore most often used in simple applications such as industrial controls and kiosks.

This diagram shows how eight inputs to a lattice touchscreen or keypad creates 28 unique intersections, as opposed to 16 intersections created using a standard x/y multiplexed touchscreen .

Projected capacitive touch (PCT; also PCAP) technology is a variant of capacitive touch technology but where sensitivity to touch, accuracy, resolution and speed of touch have been greatly improved by the use of a simple form of

Some modern PCT touch screens are composed of thousands of discrete keys,etching a single conductive layer to form a grid pattern of electrodes, by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid, or by forming an x/y grid of fine, insulation coated wires in a single layer . The number of fingers that can be detected simultaneously is determined by the number of cross-over points (x * y) . However, the number of cross-over points can be almost doubled by using a diagonal lattice layout, where, instead of x elements only ever crossing y elements, each conductive element crosses every other element .

In some designs, voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. This is measurable as a change in capacitance. If a finger bridges the gap between two of the "tracks", the charge field is further interrupted and detected by the controller. The capacitance can be changed and measured at every individual point on the grid. This system is able to accurately track touches.

Unlike traditional capacitive touch technology, it is possible for a PCT system to sense a passive stylus or gloved finger. However, moisture on the surface of the panel, high humidity, or collected dust can interfere with performance.

These environmental factors, however, are not a problem with "fine wire" based touchscreens due to the fact that wire based touchscreens have a much lower "parasitic" capacitance, and there is greater distance between neighbouring conductors.

This is a common PCT approach, which makes use of the fact that most conductive objects are able to hold a charge if they are very close together. In mutual capacitive sensors, a capacitor is inherently formed by the row trace and column trace at each intersection of the grid. A 16×14 array, for example, would have 224 independent capacitors. A voltage is applied to the rows or columns. Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field, which in turn reduces the mutual capacitance. The capacitance change at every individual point on the grid can be measured to accurately determine the touch location by measuring the voltage in the other axis. Mutual capacitance allows multi-touch operation where multiple fingers, palms or styli can be accurately tracked at the same time.

Self-capacitive touch screen layers are used on mobile phones such as the Sony Xperia Sola,Samsung Galaxy S4, Galaxy Note 3, Galaxy S5, and Galaxy Alpha.

Self capacitance is far more sensitive than mutual capacitance and is mainly used for single touch, simple gesturing and proximity sensing where the finger does not even have to touch the glass surface.

Capacitive touchscreens do not necessarily need to be operated by a finger, but until recently the special styli required could be quite expensive to purchase. The cost of this technology has fallen greatly in recent years and capacitive styli are now widely available for a nominal charge, and often given away free with mobile accessories. These consist of an electrically conductive shaft with a soft conductive rubber tip, thereby resistively connecting the fingers to the tip of the stylus.

Infrared sensors mounted around the display watch for a user"s touchscreen input on this PLATO V terminal in 1981. The monochromatic plasma display"s characteristic orange glow is illustrated.

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any opaque object including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and POS systems that cannot rely on a conductor (such as a bare finger) to activate the touchscreen. Unlike capacitive touchscreens, infrared touchscreens do not require any patterning on the glass which increases durability and optical clarity of the overall system. Infrared touchscreens are sensitive to dirt and dust that can interfere with the infrared beams, and suffer from parallax in curved surfaces and accidental press when the user hovers a finger over the screen while searching for the item to be selected.

A translucent acrylic sheet is used as a rear-projection screen to display information. The edges of the acrylic sheet are illuminated by infrared LEDs, and infrared cameras are focused on the back of the sheet. Objects placed on the sheet are detectable by the cameras. When the sheet is touched by the user, frustrated total internal reflection results in leakage of infrared light which peaks at the points of maximum pressure, indicating the user"s touch location. Microsoft"s PixelSense tablets use this technology.

Optical touchscreens are a relatively modern development in touchscreen technology, in which two or more image sensors (such as CMOS sensors) are placed around the edges (mostly the corners) of the screen. Infrared backlights are placed in the sensor"s field of view on the opposite side of the screen. A touch blocks some lights from the sensors, and the location and size of the touching object can be calculated (see visual hull). This technology is growing in popularity due to its scalability, versatility, and affordability for larger touchscreens.

Introduced in 2002 by 3M, this system detects a touch by using sensors to measure the piezoelectricity in the glass. Complex algorithms interpret this information and provide the actual location of the touch.

The key to this technology is that a touch at any one position on the surface generates a sound wave in the substrate which then produces a unique combined signal as measured by three or more tiny transducers attached to the edges of the touchscreen. The digitized signal is compared to a list corresponding to every position on the surface, determining the touch location. A moving touch is tracked by rapid repetition of this process. Extraneous and ambient sounds are ignored since they do not match any stored sound profile. The technology differs from other sound-based technologies by using a simple look-up method rather than expensive signal-processing hardware. As with the dispersive signal technology system, a motionless finger cannot be detected after the initial touch. However, for the same reason, the touch recognition is not disrupted by any resting objects. The technology was created by SoundTouch Ltd in the early 2000s, as described by the patent family EP1852772, and introduced to the market by Tyco International"s Elo division in 2006 as Acoustic Pulse Recognition.

There are several principal ways to build a touchscreen. The key goals are to recognize one or more fingers touching a display, to interpret the command that this represents, and to communicate the command to the appropriate application.

Dispersive-signal technology measures the piezoelectric effect—the voltage generated when mechanical force is applied to a material—that occurs chemically when a strengthened glass substrate is touched.

There are two infrared-based approaches. In one, an array of sensors detects a finger touching or almost touching the display, thereby interrupting infrared light beams projected over the screen. In the other, bottom-mounted infrared cameras record heat from screen touches.

The development of multi-touch screens facilitated the tracking of more than one finger on the screen; thus, operations that require more than one finger are possible. These devices also allow multiple users to interact with the touchscreen simultaneously.

With the growing use of touchscreens, the cost of touchscreen technology is routinely absorbed into the products that incorporate it and is nearly eliminated. Touchscreen technology has demonstrated reliability and is found in airplanes, automobiles, gaming consoles, machine control systems, appliances, and handheld display devices including cellphones; the touchscreen market for mobile devices was projected to produce US$5 billion by 2009.

The ability to accurately point on the screen itself is also advancing with the emerging graphics tablet-screen hybrids. Polyvinylidene fluoride (PVDF) plays a major role in this innovation due its high piezoelectric properties, which allow the tablet to sense pressure, making such things as digital painting behave more like paper and pencil.

TapSense, announced in October 2011, allows touchscreens to distinguish what part of the hand was used for input, such as the fingertip, knuckle and fingernail. This could be used in a variety of ways, for example, to copy and paste, to capitalize letters, to activate different drawing modes, etc.

For touchscreens to be effective input devices, users must be able to accurately select targets and avoid accidental selection of adjacent targets. The design of touchscreen interfaces should reflect technical capabilities of the system, ergonomics, cognitive psychology and human physiology.

Guidelines for touchscreen designs were first developed in the 2000s, based on early research and actual use of older systems, typically using infrared grids—which were highly dependent on the size of the user"s fingers. These guidelines are less relevant for the bulk of modern touch devices which use capacitive or resistive touch technology.

From the mid-2000s, makers of operating systems for smartphones have promulgated standards, but these vary between manufacturers, and allow for significant variation in size based on technology changes, so are unsuitable from a human factors perspective.

Much more important is the accuracy humans have in selecting targets with their finger or a pen stylus. The accuracy of user selection varies by position on the screen: users are most accurate at the center, less so at the left and right edges, and least accurate at the top edge and especially the bottom edge. The R95 accuracy (required radius for 95% target accuracy) varies from 7 mm (0.28 in) in the center to 12 mm (0.47 in) in the lower corners.

This user inaccuracy is a result of parallax, visual acuity and the speed of the feedback loop between the eyes and fingers. The precision of the human finger alone is much, much higher than this, so when assistive technologies are provided—such as on-screen magnifiers—users can move their finger (once in contact with the screen) with precision as small as 0.1 mm (0.004 in).

Users of handheld and portable touchscreen devices hold them in a variety of ways, and routinely change their method of holding and selection to suit the position and type of input. There are four basic types of handheld interaction:

Touchscreens are often used with haptic response systems. A common example of this technology is the vibratory feedback provided when a button on the touchscreen is tapped. Haptics are used to improve the user"s experience with touchscreens by providing simulated tactile feedback, and can be designed to react immediately, partly countering on-screen response latency. Research from the University of Glasgow (Brewster, Chohan, and Brown, 2007; and more recently Hogan) demonstrates that touchscreen users reduce input errors (by 20%), increase input speed (by 20%), and lower their cognitive load (by 40%) when touchscreens are combined with haptics or tactile feedback. On top of this, a study conducted in 2013 by Boston College explored the effects that touchscreens haptic stimulation had on triggering psychological ownership of a product. Their research concluded that a touchscreens ability to incorporate high amounts of haptic involvement resulted in customers feeling more endowment to the products they were designing or buying. The study also reported that consumers using a touchscreen were willing to accept a higher price point for the items they were purchasing.

Unsupported touchscreens are still fairly common in applications such as ATMs and data kiosks, but are not an issue as the typical user only engages for brief and widely spaced periods.

Touchscreens can suffer from the problem of fingerprints on the display. This can be mitigated by the use of materials with optical coatings designed to reduce the visible effects of fingerprint oils. Most modern smartphones have oleophobic coatings, which lessen the amount of oil residue. Another option is to install a matte-finish anti-glare screen protector, which creates a slightly roughened surface that does not easily retain smudges.

Touchscreens do not work most of the time when the user wears gloves. The thickness of the glove and the material they are made of play a significant role on that and the ability of a touchscreen to pick up a touch.

Walker, Geoff (August 2012). "A review of technologies for sensing contact location on the surface of a display: Review of touch technologies". Journal of the Society for Information Display. 20 (8): 413–440. doi:10.1002/jsid.100. S2CID 40545665.

"The first capacitative touch screens at CERN". CERN Courrier. 31 March 2010. Archived from the original on 4 September 2010. Retrieved 2010-05-25. Cite journal requires |journal= (help)

Johnson, E.A. (1965). "Touch Display - A novel input/output device for computers". Electronics Letters. 1 (8): 219–220. Bibcode:1965ElL.....1..219J. doi:10.1049/el:19650200.

Stumpe, Bent; Sutton, Christine (1 June 2010). "CERN touch screen". Symmetry Magazine. A joint Fermilab/SLAC publication. Archived from the original on 2016-11-16. Retrieved 16 November 2016.

Technology Trends: 2nd Quarter 1986 Archived 2016-10-15 at the Wayback Machine, Japanese Semiconductor Industry Service - Volume II: Technology & Government

Biferno, M. A., Stanley, D. L. (1983). The Touch-Sensitive Control/Display Unit: A Promising Computer Interface. Technical Paper 831532, Aerospace Congress & Exposition, Long Beach, CA: Society of Automotive Engineers.

Potter, R.; Weldon, L.; Shneiderman, B. (1988). "Improving the accuracy of touch screens: an experimental evaluation of three strategies". Proceedings of the SIGCHI conference on Human factors in computing systems - CHI "88. Proc. of the Conference on Human Factors in Computing Systems, CHI "88. Washington, DC. pp. 27–32. doi:10.1145/57167.57171. ISBN 0201142376. Archived from the original on 2015-12-08.

Sears, Andrew; Plaisant, Catherine; Shneiderman, Ben (June 1990). "A new era for high-precision touchscreens". In Hartson, R.; Hix, D. (eds.). Advances in Human-Computer Interaction. Vol. 3. Ablex (1992). ISBN 978-0-89391-751-7. Archived from the original on October 9, 2014.

Apple touch-screen patent war comes to the UK (2011). Event occurs at 1:24 min in video. Archived from the original on 8 December 2015. Retrieved 3 December 2015.

Hong, Chan-Hwa; Shin, Jae-Heon; Ju, Byeong-Kwon; Kim, Kyung-Hyun; Park, Nae-Man; Kim, Bo-Sul; Cheong, Woo-Seok (1 November 2013). "Index-Matched Indium Tin Oxide Electrodes for Capacitive Touch Screen Panel Applications". Journal of Nanoscience and Nanotechnology. 13 (11): 7756–7759. doi:10.1166/jnn.2013.7814. PMID 24245328. S2CID 24281861.

Kent, Joel (May 2010). "Touchscreen technology basics & a new development". CMOS Emerging Technologies Conference. CMOS Emerging Technologies Research. 6: 1–13. ISBN 9781927500057.

Ganapati, Priya (5 March 2010). "Finger Fail: Why Most Touchscreens Miss the Point". Archived from the original on 2014-05-11. Retrieved 9 November 2019.

Beyers, Tim (2008-02-13). "Innovation Series: Touchscreen Technology". The Motley Fool. Archived from the original on 2009-03-24. Retrieved 2009-03-16.

"Acoustic Pulse Recognition Touchscreens" (PDF). Elo Touch Systems. 2006: 3. Archived (PDF) from the original on 2011-09-05. Retrieved 2011-09-27. Cite journal requires |journal= (help)

Hoober, Steven (2013-11-11). "Design for Fingers and Thumbs Instead of Touch". UXmatters. Archived from the original on 2014-08-26. Retrieved 2014-08-24.

Henze, Niels; Rukzio, Enrico; Boll, Susanne (2011). "100,000,000 Taps: Analysis and Improvement of Touch Performance in the Large". Proceedings of the 13th International Conference on Human Computer Interaction with Mobile Devices and Services. New York.

Lee, Seungyons; Zhai, Shumin (2009). "The Performance of Touch Screen Soft Buttons". Proceedings of the SIGCHI Conference on Human Factors in Computing Systems. New York: 309. doi:10.1145/1518701.1518750. ISBN 9781605582467. S2CID 2468830.

Bérard, François (2012). "Measuring the Linear and Rotational User Precision in Touch Pointing". Proceedings of the 2012 ACM International Conference on Interactive Tabletops and Surfaces. New York: 183. doi:10.1145/2396636.2396664. ISBN 9781450312097. S2CID 15765730.

Hoober, Steven (2014-09-02). "Insights on Switching, Centering, and Gestures for Touchscreens". UXmatters. Archived from the original on 2014-09-06. Retrieved 2014-08-24.

Brasel, S. Adam; Gips, James (2014). "Tablets, touchscreens, and touchpads: How varying touch interfaces trigger psychological ownership and endowment". Journal of Consumer Psychology. 24 (2): 226–233. doi:10.1016/j.jcps.2013.10.003. S2CID 145501566.

Zhu, Ying; Meyer, Jeffrey (September 2017). "Getting in touch with your thinking style: How touchscreens influence purchase". Journal of Retailing and Consumer Services. 38: 51–58. doi:10.1016/j.jretconser.2017.05.006.

"A RESTAURANT THAT LETS GUESTS PLACE ORDERS VIA A TOUCHSCREEN TABLE (Touche is said to be the first touchscreen restaurant in India and fifth in the world)". India Business Insight. 31 August 2011. Gale A269135159.

Sears, A.; Plaisant, C. & Shneiderman, B. (1992). "A new era for high precision touchscreens". In Hartson, R. & Hix, D. (eds.). Advances in Human-Computer Interaction. Vol. 3. Ablex, NJ. pp. 1–33.

Sears, Andrew; Shneiderman, Ben (April 1991). "High precision touchscreens: design strategies and comparisons with a mouse". International Journal of Man-Machine Studies. 34 (4): 593–613. doi:10.1016/0020-7373(91)90037-8. hdl:

AbraxSys explores the inustries utilizing industrial displays with touch screens and how these verticals bennefit from the various touch screen technologies.

When the touch technology is deposited on the cover glass using the sensor on lens approach, you end up with a separate touch module that can be sold to the LCD display assemblers. This would mean more revenues for the touch technology manufacturers who would supply these modules.

On the other hand, the on-cell alternative means that the LCD panel manufacturers can add these touch layers onto their own panels. The display assemblers would then just have to purchase a simple cover glass to complete the display. The touch module makers would be cut out of the process.

For now, it appears that the sensor on lens approach has an advantage over on-cell solutions. The on-cell approach means that LCD makers would have to make two separate models of each panel: one with touch and one without. This could add cost to an industry that is already running on razor-thin margins. Also, on-cell touch is limited to the size of the LCD panel; sensor on glass modules can be larger than the LCD panel, providing room for the dedicated touch points that are part of many smartphone designs.

In case you"ve been wondering where OLED displays fit into all this: An OLED display stack is somewhat different from an LCD stack. It only requires one substrate (glass) layer as opposed to LCD"s two, and the OLED material layer is much thinner than the LCD layer. As a result, the finished display can be half as thick as an LCD panel, saving weight and thickness -- which is important in a smartphone design.

In spite of all this, as far as touch screen technologies are concerned, OLEDs are more like LCDs than they are different: Both have active matrix TFT backplanes, and both tend to have a cover glass layer for protection. So essentially the same stack configurations are available to OLED panels.

No matter which solution wins out, it is clear that pro-cap technology is the best method for touch screens on mobile devices -- at least for the foreseeable future. Still, there are some changes already showing up in touch screen technology.

For example, some panel makers are creating "in-cell" touch panels, where one of the conductive layers actually shares the same layer as the thin film transistors (TFTs) used to switch the display"s sub-pixels on and off. (These transistors are fabricated directly on the semiconductor backplane of the display.) This approach not only reduces the electromagnetic noise in the system, but also uses a single integrated controller for both the display and the touch system. This reduces part counts and can make the display component thinner, lighter, more energy efficient and more reliable.

This approach only makes sense for very high volume products, such as a smartphone from a major vendor that is expected to sell millions of units, because the panel will have to be made specifically for that unique model. The first products using "in-cell" touch technology have already appeared on the market, such as the new , but it looks as though it will take years before this approach will become a widespread solution.Additional resources

Some device manufacturers are also adding stylus support to their products. The new higher-resolution displays make it useful for some users to have access to a pointing or writing device that has a finer tip than a finger. Some devices rely on an "active" stylus that can be sensed by the pro-cap system, such as the Samsung Galaxy Note. Others, such as the , are choosing single-point infrared optical sensing that can detect the position of any pointed object on the screen.

Meanwhile, system designers are developing new ways to interact with mobile devices via touch, such as and . Even as other modes of interaction -- such as speech recognition for voice input -- become more sophisticated, touch is likely to remain the primary way we control our devices.

is a speaker, writer, and display technology expert. He is a contributing editor with Information Display, the magazine for the Society for Information Display, and contributed to the Handbook of Visual Display Technology published 2010 by Springer-Verlag and Canopus Academic Publishing.

The structure of this technology consists of two layers, usually a deformable polyester film and a rigid glass substrate. The inner sides are each coated with a thin, translucent metallization (usually indium tin oxide). In order to avoid short circuits, both layers must be kept at an even distance with so-called spacers.

In contrast to PCAP (capacitive touch panels), resistive touch panels are much more reliable in their response behavior. Where with PCAP (cell phone etc.) you sometimes try a second or third time "to hit a key", the resistive touch panel reacts immediately - provided that the corresponding evaluation is done. We have summarized further differences in a table below.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

With capacitive touch, a conductive material is sandwiched by glass and placed over a display. When another electrical conductor, like a bare fingertip or a stylus, touches the surface, an electric circuit is completed at that location. Sensors embedded in the glass detect the location of the flow of current which is then registered as a touch event.

The most popular form of capacitive touch technology is known as projected capacitive and it can be found in all mobile phones and tablets. Project capacitive displays are considered the most precise touch technology and thus the gold standard if the target environment is protected from the weather.

PCAP displays work with any conductive material, meaning you can also use a charged stylus or wear thin gloves. On the other hand, PCAP displays can be fooled into thinking a touch has occurred if in humid, wet environments.

PCAP technology is also an expensive technology that is typically integrated with LED/LCD displays, meaning it is not possible to purchase PCAP technology as an overlay. (Well, unless you’re a display manufacturer with your own assembly line.)

Infrared technology works by emitting a grid of invisible infrared light across the face of an LED/LCD screen. When any object comes in contact with the screen, the infrared light will be disrupted, resulting in identification of the touch location.

Unlike project capacitive displays, which require conductive material to indicate a touch, infrared displays can work with any material. In addition, as there is no conductive matrix embedded above the display, infrared technology permits total clarity of the underlying picture. However, the exposure of the infrared emitting technology makes it susceptible to damage from grease, dust, and other external factors, which means you must be vigilant in keeping it clean. They are also not water-resistant and can malfunction if even the smallest amount of moisture gets on them. They can also record false touches since they will detect items that are close to but not actually touching the screen. For example, a second finger hovering just above a separate finger used to make selections.

Infrared touch technology is fairly inexpensive and can be purchased as an overlay, meaning it can be paired with any third party LCD/LED screen. Thus, for example, you may possess one overlay but rent LCD/LED displays as needed for each attended trade show.

Surface acoustic wave or SAW technology uses a series of transducers and receivers to produce and detect a grid of ultrasonic waves projected in front of a display. When the waves are disrupted, the location is identified.

Surface wave technology can detect the touch of any soft object as they absorb sound waves. On the other hand, use of hard items like pens won’t work as they will reflect sound waves and confuse the receivers. They are also susceptible to malfunction if exposed to the weather or other contaminants and thus should be kept clean and dry.

Resistive touch technology responds to the pressure generated the touch of an item. A protective glass screen covers a conductive layer and a resistive layer that have a small space between them. When the user presses on the screen, the conductive layer touches the resistive layer, closing an electric circuit and thus indicating the location of the touch.

The benefits of resistive technology include low cost, low power consumption, and resistance to moisture, dust, and debris, making it very good for weather-exposed use. Many consumers appreciate the tactile feel of these screens since they give the feeling that you are still pressing buttons, even if they are on a display monitor. Some of the downsides include maintenance costs since this screen has many moving parts and could be damaged by careless users. The image quality is also lower than with other touch technologies because of how much the conductive and resistive layers - plus the layer of air - block the display.

As with surface acoustic wave technology, resistive touch technology is typically limited to a single touch touchpoint. It is also uncommon to find displays larger than 22” as it is difficult to maintain the air gap beyond that size.

BCA and Brookfield have created the most advanced user experience in viscosity measurement by combining the ease of touch screen technology with the world-standard features of Brookfield’s series of DV-II Viscometers and DV-III Rheometers.

Brookfield is known for their superb work in mechanical design and production of their viscometers. Up until this point these designs included push button / character based LCD for the user interface. Brookfield came to us and wanted a modern color graphics LCD which would take their designs into the future. With a long list of requirements including touch screen technology and a tight deadline, BCA worked with the client to develop a program that established not only the right combination of electronics to drive their motor and torque analysis, but also a custom user interface. We had but one year to establish the product. We released the product on time. It was presented with great feedback at the Pittcon Conference 2013.

BCA worked on several pieces of the design in tandem to keep the project dates on target. The development of the electronics, firmware, and user interface occurred simultaneously. Additionally BCA was designing two models with different size touch screens and features. Code reuse was a must and the products today share the same compile.

There were some complex requirements on the electronics design. AD sample rates were specified in the 10 nanosecond range. The 7” LCD had specific speed requirements. The motor speed accuracy had to be 100%. We chose a Freescale IMX processor to handle the buck of this work. BCA has developed a royalty-free custom operating kernel which has been used in our product development for over 20 years. This finite state machine kernel was perfect for the over 200 states of this software. This allowed BCA to provide a royalty free option that already has support for system alarms, user interface screens with button input, event logging, protected memory access among many other modules.

The final product redesign enhanced the ease of use with adding popular features. DV-III has real-time on screen graphing that can be saved to the device, printed directly from the device, or viewed on a PC. Built into the system are math models that can provide rapid data analysis for selectable variables. Data can be transferred via flash drive or a computer can be hooked up directly.

A 10-point multi-touch screen refers to a touch screen that has the ability to recognise and respond to ten simultaneous points of contact. This allows you to easily zoom, flick, rotate, swipe, drag, pinch, press, double tap or use other gestures with up to ten fingers on the screen at the same time.

Initially, touch screen products could only recognise one point of touch and perform one touch movement at a time. The technology then advanced to two points of contact and many touch screens still use this older technology. But a screen that uses 10-point multi touch technology allows users to perform more complex actions on their touch screens than ever before. It also deals well with a shirt sleeve touching a screen, or a little droplet on the screen which can confuse two-point technology.

Some examples of where the 10-point multi-touch technology is best utilised is in product promotion and data visualisation situations. It allows businesses to tell their story and users can move seamlessly interact and browse through catalogues, data, images, simulations and 3-D presentations.

In presentation scenarios, large multi-touch monitors with 10-point multi-touch technology enable two or more people to operate the same monitor at once, performing independent functions. Applications of this can be in teaching, where a tutor can have two students making two separate input functions at the same time. Commercially, large displays can be used by multiple clients at the same time, either in retail or the hospitality sector. A good example is in a retail store, where a sales rep and a client can both collaborate and perform actions simultaneously on the same touch screen.

At InTouch Screens, we offer only the best in 10-point multi-touch technology, with a range in sizes from 10” to 55” screens. Our technology is the same technology used in most smartphones, so most users are comfortable with it immediately. Our driver-free plug-and-play operation for Windows touch screen solutions provides the simplest and fastest possible rollout. Simply plug the USB cable into your Windows PC and you are ready to flick the switch.

Additionally, our minimalist designs with flat bezel free screens and edge-to-edge glass make us a market leader in aesthetics and design. All of our touch screens are built with high-quality commercial grade components and toughened glass for projects where robustness and reliability are important. They are created to run 24 hours a day, 7 days a week, and we provide a 3-year warranty as standard.

When ordering any of our 10-point multi touch screen products, expect fast delivery across Australia. Contact us today and speak to one of our friendly sales team[email protected]or telephone 1300 557 219

Touch panel technologies are a key theme in current digital devices, including smartphones, slate devices like the iPad, the screens on the backs of digital cameras, the Nintendo DS, and Windows 7 devices. The term touch panel encompasses various technologies for sensing the touch of a finger or stylus. In this session, we"ll look at basic touch panel sensing methods and introduce the characteristics and optimal applications of each.

Note: Below is the translation from the Japanese of the ITmedia article "How Can a Screen Sense Touch? A Basic Understanding of Touch Panels"published September 27, 2010. Copyright 2011 ITmedia Inc. All Rights Reserved.

A touch panel is a piece of equipment that lets users interact with a computer by touching the screen directly. Incorporating features into the monitor like sensors tha

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey