tft lcd failures manufacturer

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

For the first two situations, that’s because the circuit on the TFT and CF controlling that defective pixel point is shorted or broken. While the third situation is caused by damaged color pixel.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

The display LCD TFT is a kind of display screen that we are familiar with. Many intelligent terminal products use display LCD TFT. Liquid crystal is the most important part of display LCD TFT. Liquid crystal is a physical form, and this physical form can be used as a key factor in display by sorting. To understand the quality of display LCD wholesale tft module, we generally understand from the specific parameters. So what if the display LCD TFT is blurred? Now let Proculus introduce to you.

The LCD TFT display which becomes blurred and indistinct is divided into two cases: one is the display LCD TFT before installation, and the other is the display LCD TFT after a period of use. If you want to buy lcd module, you should the reasons for these two different time periods are also completely different.

Generally, the display LCD TFT is blurred before installation, which is likely to be the reason for the display LCD TFT itself. We generally check whether the driver is normal, and whether there is a problem with the chip and wiring. It is possible that there are some defects in the design of display LCD TFT, which leads to the blurred screen of display LCD TFT. This kind of situation needs to carry on the internal analysis to the TFT LCD display supplier and obtains the concrete solution.

There is another situation mentioned earlier, that is, it has been used for a period of time after installation, which leads to the blurring of the display LCD TFT. We need to check whether the connection with the motherboard is normal, whether the picture shows signs of jitter, whether the image can be seen clearly, and whether the tightness of the whole machine is poor, resulting in dust or water in the place where the motherboard is connected to the TFT LCD screen, all of which are likely to cause TFT LCD blurred screen. This kind of analysis should be combined with the TFT LCD screen itself, motherboard, structure and so on, and the steps are more complex.

The above content is the introduction to the treatment method of TFT LCD screen. With the continuous increase of TFT LCD display supplier, the competition in TFT LCD industry is becoming more and more fierce. The quality of many TFT LCD manufacturers is also uneven, and there is no lack of many black-hearted manufacturers to simplify the production process for profit, resulting in a lot of bad phenomena in the products. Therefore, we still have to pay more attention to the choice of TFT LCD suppliers.

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

Unfortunately, it is common for some failures to make it through final testing. After the vibration and thermal effects from the shipping process, these defects can be exposed and result in an out of box failure at the assembly line.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

It’s important to understand two things. The first is thatLCD display issues can be attributed to different parties and different circumstances. And the second and most important is, that the best results are obtained from a collaborative effort.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Thin-film transistor liquid-crystal display (TFT-LCD) manufacturing in Taiwan is booming; and the revenues from the TFT-LCD industry have grown significantly in recent years. One of the main problems in the TFT-LCD manufacturing process is to diagnose faulty products. This study employed support vector machines (SVM) with principal components analysis (PCA) to diagnose root causes in sputtering operations of the TFT-LCD industry. The PCA technique was used to transfer original manufacturing parameters into essential factors; and the SVM model was applied in classifying faulty products. Besides, the genetic and tabu (GA/TS) search algorithms were utilized to select SVM parameters. In terms of classification accuracy and efficiency, simulation results indicated that the SVM with PCA procedure is a feasible and promising way to diagnose faulty products in TFT-LCD manufacturing processes.

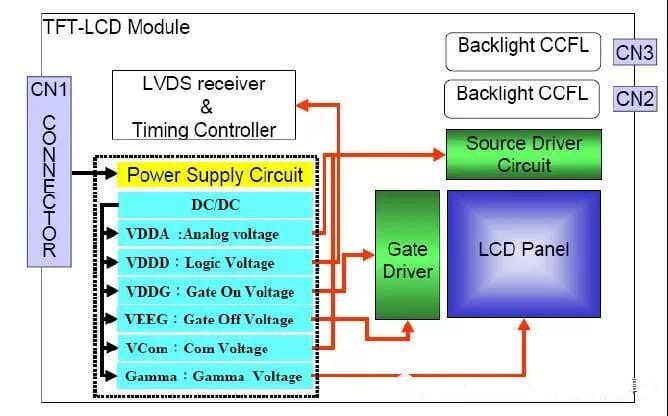

Vin: PWB input voltage (12V)VDD: ASIC, source IC, gate IC driving power (3.3v)VGH: TFT component switching voltage (~30V)VGL: TFT component turn-off voltage (~ -6v)VAA: step control voltage (~17V)VCOM: liquid crystal reversal reference voltage (~7V)

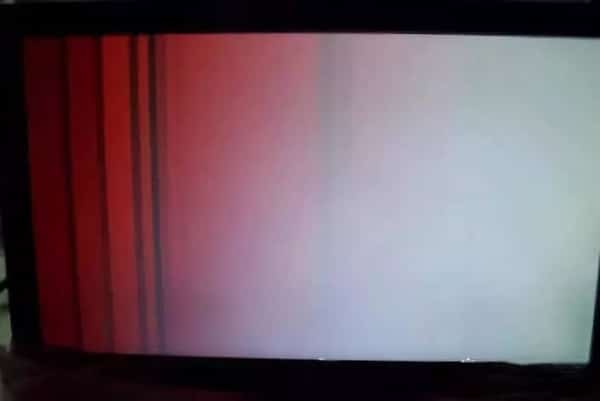

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

The most common display technology is liquid crystal displays (LCDs). Their applications include mobile phones, industrial meters, television, POS, smart homes, aerospace, automotive, military systems, gadgets, marine, etc.

If an LCD does have a white screen, it implies the backlight is working properly. Simply examine your signal input channels to determine the most likely causes.

It may also be affected by the display being completely disrupted by excessive heat, a shock that breaks the LCD controller, or a connection failure that requires professional repair.

Since LCD graphics are made up of RGB pixels, their display should not be as blurry as it was on old CRT displays. If you see blurry images, there are two possibilities;

§ The LCD"s surface is composed of a plastic film layer with maximum hardness. If you happen to clean the surface frequently or use the incorrect detergent or solvent, you will cause surface damage.

Others include a decline in screen or display contrast, broken glass, non-functioning pixel resolution or the entire display. Different types of LCD problems require different types of repair methods.

If you drop the LCD and discover it got broken on the surface but the display still works, you may have simply damaged the touch panel; you could replace it by finding a repair shop.

Backlight is used because LCD cannot emit light on its own. Usually, the backlight isn"t entirely driven; however, you can intensify the backlight to brighten a dim LCD screen.

To repair an LCD screen, you must first devise a way to fix the backlight. It is a simple task for some displays, although it can be challenging for others based on the process of manufacturing.

If you have any need for a stretched TFT LCD display, do reach out to a well-known manufacturer. Kindly contact us and we’ll be glad to partner with you for the best products.

According to real LCD manufacturing conditions, the number of normal LCD panels exceeds greatly the number of defective LCD panels. Therefore, the normal PRs greatly outnumber the defective PRs. As a result, the collected data set for training would be imbalanced if a two-class classification approach is adopted, the SVM by Vapnik [4] for example, the class imbalance problem occurs.

In practice, in addition to the class imbalance problem, the LCD defect detection also suffers from another critical problem resulting from the absence of negative information. To facilitate the following problem description, the normal PR class and the defective PR class are defined as the positive class and negative class, respectively.

The main difference between a normal PR and a defective PR is that their appearances are apparently different, as can be observed from Figure 4. The color (or gray level) of a normal PR is nearly uniform, implying that the variation of the gray-level distribution of normal PRs is very small. On the contrary, the surfaces of defective PR not only contain various kinds of textures, but also vary greatly in color, implying that the variation of the true distribution for negative class in the data space is very large. Collecting a set of positive training data that can represent the true distribution of positive class is easy, because: (1) the variation of positive-class distribution is very small; and (2) most of the LCD panels are normal (the number of normal PRs is considerably large). Therefore, the positive class can be well-sampled during the data collection stage in real practice. However, representative defective PRs are difficult to obtain in practice for several reasons. For example, there are numerous types of defects in array process, more than 10 types at least. However, not all the defects would occur frequently. Some of the defects seldom appear, for example the defect caused by abnormal photo-resist coating (APRC). The defect “APRC” seldom occurs, because equipment/process engineers maintain the coating machines periodically. Even so, the coating machines might still break down occasionally. As a result, the number of available images containing the APRC defects is quite limited. But, the APRC defect has a large variation in color and texture. Unfortunately, limited APRC examples cannot stand for all kinds of APRC defects. Therefore, the collected negative training data are most likely under-sampled. Here, the “under-sampled” means that the collected negative training set cannot represent the true negative-class distribution in the data space, which is the problem of absence of negative information. Due to this problem, numerous false positive (i.e., missing defects) will be produced if a two-class classification approach (e.g., a binary SVM) is applied to the LCD defect detection, which has been evidenced by the results reported in [7]. Compared with two-class classification approach, novelty detection approach is a better choice.

Novelty detection is one-class classification [10,35], which is to solve the conventional two-class classification problems where one of the two classes is under-sampled, or only the data of one single class can be available for training [5,6,9–11,35–40]. As analyzed above, for the LCD defect detection application, the normal PRs can be well-sampled, while the defective PRs are in general undersampled. Therefore, the LCD defect detection can be treated as a typical novelty detection problem. Accordingly, one-class classification is a better solution.

To summarize, it can be seen that the LCD defect detection suffers from two problems simultaneously: one is the class imbalance problem, and the other is the problem of the absence of negative information. For the first problem, there have been many sophisticated solutions, including sampling, cost-sensitive learning, SVM-based, and one-class learning approaches. However, the only solution to the second problem is the novelty detection approach (i.e., one-class classification approach). Therefore, one-class classification would be a more appropriate approach to the LCD defect detection application.

There are several approaches for one-class classification, such as density approach (e.g., Gaussian mixture model [5]), boundary approach (e.g., SVDD [9] and one-class SVM [40]), neural network approach [6,36], and reconstruction-based approach (e.g., the kernel principal component analysis for novelty detection [35]). It has been proven in [9] that when a Gaussian kernel is used, the SVDD proposed by Tax and Duin [9] is identical to the one-class SVM proposed by Schölkopf et al. [40]. This paper focuses on the SVDD since it has been applied to the same application in the works of [7] and [10], and has shown to be effective in detecting defective PRs. However, as discussed in Section 1, generalization performance of SVDD is limited. Therefore, the intent of this paper is on proposing a method to improve generalization performance of SVDD, and applying the improved SVDD to the LCD defect detection treated as a novelty detection problem. The improved SVDD is called quasiconformal kernel SVDD (QK-SVDD). Note that the QK-SVDD and SVDD are not two independent classifiers. To obtain QK-SVDD, one has to train an SVDD first, which will be introduced in Section 2.4. In the following part of the paper, we first introduce the defect detection scheme, and then derive the proposed method in details.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

LCD displays, especially older, mature display technologies such as segment and character LCDs have a very low fallout rate; so when we receive a request to return a large number of failures, we are concerned and want to solve the problem right away.

One percent failure is cause for alarm; after some investigation we found that the delaminating of LCD polarizers (or polarizers peeling away from the glass) was a result of excessive heat being applied to the display.

LCD displays, like microprocessors, are very sensitive to excessive heat and must be protected from exposure to high temperatures for long periods of time. In order to avoid the delaminating of LCD polarizers, the only time to expose the display to high heat is when it is being attached to the PCB (Printed Circuit Board).

When soldering a LCD, try to use hand soldering. If you do wave-solder, we recommend the display not be exposed to heat in excess of 300C (572 F) and then only for a few seconds.

There are two times when a display will face this extreme environment: manufacturing of the LCD and when being soldered to a PCB. Great care must be taken to avoid damage.

The entire LCD assembly is then "baked" to cure the adhesive with the temperature of the oven and the amount of time in the oven being critical. If the temperature is excessive, or the LCDs are left in too long, the polarizer will peel away from the glass.

All completed LCDs should be 100% visually inspected to identify the delaminating of LCD polarizer issue. If there is a problem, it should be pulled from the lot as defective. It should not reach the customers manufacturing location.

LCD Displays, like most electronic components are soldered to a PCB, either by wave or hand solder. When the temperature of the solder is excessive, or the heat source is kept in contact for an extended period of time, the polarizer will begin to peel away.

If you find that during your manufacturing process the LCD will be exposed to excessive heat, it is recommended to incorporate a heat shunt and divert the excessive heat away from the adhesive and polarizer.

LCD’s are manufactured with ROHS (Restriction of Certain Hazardous Substances) or non-RoHS (Lead based) solder with each type of solder having its own unique melting point.

Lead-based solder is mainly used in aviation, military and some medical industries with a melting temperature of 180C (356F). If requested, we are able to manufacture the LCD with non-RoHS solder.

The amount of pollutants produced during manufacturing processes of TFT-LCD (thin-film transistor liquid crystal display) substantially increases due to an increasing production of the opto-electronic industry in Taiwan. The total amount of wastewater from TFT-LCD manufacturing plants is expected to exceed 200,000 CMD in the near future. Typically, organic solvents used in TFT-LCD manufacturing processes account for more than 33% of the total TFT-LCD wastewater. The main components of these organic solvents are composed of the stripper (dimethyl sulphoxide (DMSO) and monoethanolamine (MEA)), developer (tetra-methyl ammonium hydroxide (TMAH)) and chelating agents. These compounds are recognized as non-or slow-biodegradable organic compounds and little information is available regarding their biological treatability. In this study, the performance of an A/O SBR (anoxic/oxic sequencing batch reactor) treating synthetic TFT-LCD wastewater was evaluated. The long-term experimental results indicated that the A/O SBR was able to achieve stable and satisfactory removal performance for DMSO, MEA and TMAH at influent concentrations of 430, 800, and 190 mg/L, respectively. The removal efficiencies for all three compounds examined were more than 99%. In addition, batch tests were conducted to study the degradation kinetics of DMSO, MEA, and TMAH under aerobic, anoxic, and anaerobic conditions, respectively. The organic substrate of batch tests conducted included 400 mg/L of DMSO, 250 mg/L of MEA, and 120 mg/L of TMAH. For DMSO, specific DMSO degradation rates under aerobic and anoxic conditions were both lower than 4 mg DMSO/g VSS-hr. Under anaerobic conditions, the specific DMSO degradation rate was estimated to be 14 mg DMSO/g VSS-hr, which was much higher than those obtained under aerobic and anoxic conditions. The optimum specific MEA and TMAH degradation rates were obtained under aerobic conditions with values of 26.5 mg MEA/g VSS-hr and 17.3 mg TMAH/g VSS

The amount of pollutants produced during manufacturing processes of thin-film transistor liquid crystal display (TFT-LCD) substantially increases due to an increasing production of the opto-electronic industry in Taiwan. This study presents the treatment performance of one aerobic and one anoxic/oxic (A/O) sequencing batch reactors (SBRs) treating synthetic TFT-LCD wastewater containing dimethyl sulfoxide (DMSO), monoethanolamine (MEA), and tetra-methyl ammonium hydroxide (TMAH). The long-term monitoring results for the aerobic and A/O SBRs demonstrate that stable biodegradation of DMSO, MEA, and TMAH can be achieved without any considerably adverse impacts. The ammonium released during MEA and TMAH degradation can also be completely oxidized to nitrate through nitrification in both SBRs. Batch studies on biodegradation rates for DMSO, MEA, and TMAH under anaerobic, anoxic, and aerobic conditions indicate that effective MEA degradation can be easily achieved under all three conditions examined, while efficient DMSO and TMAH degradation can be attained only under anaerobic and aerobic conditions, respectively. The potential odor problem caused by the formation of malodorous dimethyl sulfide from DMSO degradation under anaerobic conditions, however, requires insightful consideration in treating DMSO-containing wastewater. Copyright (c) 2010 Elsevier Ltd. All rights reserved.

Fluorinated greenhouse gases (F-GHGs) are among the most potent and persistent greenhouse gases contributing to global climate change. Learn about the manufacturing processes which release F-GHGs, and how LCD suppliers are working to reduce emissions.

This research is mainly to explore the treatment capacity for TFT-LCD industrial wastewater recycling by the processes combined with membrane bioreactor (MBR), reverse osmosis (RO) and ozone(O3). The organic wastewater from the TFT-LCD industry was selected as the target. MBR, RO and ozone plants were established for evaluation. An MBR plant consisted of a 2-stage anoxic/aerobic bioreactor and an immersed UF membrane unit was employed. The effluent of MBR was conducted into the RO system then into the ozone system. The RO system consisted of a spiral membrane in the vessel. One bubble column, 75 cm high and diameter 5 cm, were used as the ozonation reactor. On the bottom of ozonation reactor is a porous diffuser for releasing gas, with an aperture of 100 microm (0.1 cm). Over the whole experimental period, the MBR process achieved a satisfactory organic removal. The COD could be removed with an average of over 98.5%. For the TOC item, the average removal efficiency was 97.4%. The stable effluent quality and satisfactory removal performance were ensured by the efficient interception performance of an immersed UF membrane device incorporated with the biological reactor. Moreover, the MBR effluent did not contain any suspended solids and the SDI value was under 3. After the treatment of RO, excellent water quality was found. The water quality of permeate was under 5 mg/I, 2 mg/l and 50 micros/cm for COD, TOC and conductivity respectively. The treated water can be recycled and reused for the cooling tower make-up water or other purposes. After the treatment of ozone, the treated water quality was under 5 mg/l and 0.852 mg/l for COD and TOC respectively. The test results of MBR, MBR/RO and MBR/RO/ozone processes were compared as possible appropriate treatment technologies applied in TFT-LCD industrial wastewater reuse and recycling.

In TFT-LCD industry, water plays a variety of roles as a cleaning agent and reaction solvent. As good quality water is increasingly a scarce resource and wastewater treatment costs rises, the once-through use of industrial water is becoming uneconomical and environmentally unacceptable. Instead, recycling of TFT-LCD industrial wastewater is become more attractive from both an economic and environmental perspective. This research is mainly to explore the capacity of TFT-LCD industrial wastewater recycling by the process combined with membrane bioreactor and reverse osmosis processes. Over the whole experimental period, the MBR process achieved a satisfactory organic removal. The COD could be removed with an average of over 97.3%. For TOC and BOD5 items, the average removal efficiencies were 97.8 and 99.4% respectively. The stable effluent quality and satisfactory removal performance were ensured by the efficient interception performance of the UF membrane device incorporated with biological reactor. Moreover, the MBR effluent did not contain any suspended solids and the SDI value was under 3. After treatment of RO, excellent water quality of permeate were under 5 mg/l, 2.5 mg/l and 150 micros/cm for COD, TOC and conductivity respectively. The treated water can be recycled for the cooling tower make-up water or other purposes.

This study evaluated TMAH biodegradation under methanogenic conditions. Under methanogenic conditions, a sludge from a full-scale UASB treating TFT-LCD wastewater was able to degrade 2,000 mg/L of TMAH within 10 h and attained a specific degradation rate of 19.2 mgTMAH/gVSS-h. Furthermore, several chemicals including some surfactants, DMSO, and sulfate were examined for their potential inhibitory effects on TMAH biodegradation under methanogenic conditions. The results indicated that surfactant S1 (up to 2%) and DMSO (up to 1,000 mg/L) presented negligible inhibitory effects on TMAH degradation, while surfactant S2 (0.2-1%) might inhibit methanogenic reaction without any TMAH degradation for 3-5 h. At sulfate concentrations higher than 300 mg/L, a complete inhibition of methanogenic reaction and TMAH biodegradation was observed. Results from cloning and sequencing of archaeal 16S rRNA gene fragments showed that Methanosarcina barkeri and Methanosarcina mazei were the dominant methanogens in the UASB treating TMAH-containing TFT-LCD wastewater.

The objectives of this study are: (1) to determine the effect of pH, initial concentration of Fe(2+) and H(2)O(2) dosage on the removal efficiency of MEA by fluidized-bed Fenton process and Fenton process, (2) to determine the optimal conditions for the degradation of ethanolamine from TFT-LCD wastewater by fluidized-bed Fenton process. In the design of experiment, the Box-Behnken design was used to optimize the operating conditions. A removal efficiency of 98.9% for 5mM MEA was achieved after 2h under optimal conditions of pH3, [Fe(2+)]=5mM and [H(2)O(2)]=60mM. Copyright © 2011 Elsevier Ltd. All rights reserved.

This study evaluated biological treatment of TMAH in a full-scale methanogenic up-flow anaerobic sludge blanket (UASB) followed by an aerobic bioreactor. In general, the UASB was able to perform a satisfactory TMAH degradation efficiency, but the effluent COD of the aerobic bioreactor seemed to increase with an increased TMAH in the influent wastewater. The batch test results confirmed that the UASB sludge under methanogenic conditions would be favored over the aerobic ones for TMAH treatment due to its superb ability of handling high strength of TMAH-containing wastewaters. Based on batch experiments, inhibitory chemicals present in TFT-LCD wastewater like surfactants and sulfate should be avoided to secure a stable methanogenic TMAH degradation. Finally, molecular monitoring of Methanomethylovorans hollandica and Methanosarcina mazei in the full-scale plant, the dominant methanogens in the UASB responsible for TMAH degradation, may be beneficial for a stable TMAH treatment performance. Copyright © 2012 Elsevier Ltd. All rights reserved.

International Display Consortium (IDC) is the joining together of display companies to combined their buying power and obtained favorable terms with a major LCD manufacturer. Consolidating the buying power and grouping the demand enables the rugged display industry of avionics, ground vehicles, and ship based display manufacturers to have unencumbered access to high performance AMLCDs while greatly reducing risk and lowering cost. With an unrestricted supply of AMLCD displays, the consortium members have total control of their risk, cost, deliveries and added value partners. Every display manufacturer desires a very close relationship with a display vender. With IDC each consortium member achieves a close relationship. Consortium members enjoy cost effective access to high performance, industry standard sized LCD panels, and modified commercial displays with 100 degree C clearing points and portrait configurations. Consortium members also enjoy proposal support, technical support and long-term support.

Defect detection has been considered an efficient way to increase the yield rate of panels in thin film transistor liquid crystal display (TFT-LCD) manufacturing. In this study we focus on the array process since it is the first and key process in TFT-LCD manufacturing. Various defects occur in the array process, and some of them could cause great damage to the LCD panels. Thus, how to design a method that can robustly detect defects from the images captured from the surface of LCD panels has become crucial. Previously, support vector data description (SVDD) has been successfully applied to LCD defect detection. However, its generalization performance is limited. In this paper, we propose a novel one-class machine learning method, called quasiconformal kernel SVDD (QK-SVDD) to address this issue. The QK-SVDD can significantly improve generalization performance of the traditional SVDD by introducing the quasiconformal transformation into a predefined kernel. Experimental results, carried out on real LCD images provided by an LCD manufacturer in Taiwan, indicate that the proposed QK-SVDD not only obtains a high defect detection rate of 96%, but also greatly improves generalization performance of SVDD. The improvement has shown to be over 30%. In addition, results also show that the QK-SVDD defect detector is able to accomplish the task of defect detection on an LCD image within 60 ms. PMID:22016625

Defect detection has been considered an efficient way to increase the yield rate of panels in thin film transistor liquid crystal display (TFT-LCD) manufacturing. In this study we focus on the array process since it is the first and key process in TFT-LCD manufacturing. Various defects occur in the array process, and some of them could cause great damage to the LCD panels. Thus, how to design a method that can robustly detect defects from the images captured from the surface of LCD panels has become crucial. Previously, support vector data description (SVDD) has been successfully applied to LCD defect detection. However, its generalization performance is limited. In this paper, we propose a novel one-class machine learning method, called quasiconformal kernel SVDD (QK-SVDD) to address this issue. The QK-SVDD can significantly improve generalization performance of the traditional SVDD by introducing the quasiconformal transformation into a predefined kernel. Experimental results, carried out on real LCD images provided by an LCD manufacturer in Taiwan, indicate that the proposed QK-SVDD not only obtains a high defect detection rate of 96%, but also greatly improves generalization performance of SVDD. The improvement has shown to be over 30%. In addition, results also show that the QK-SVDD defect detector is able to accomplish the task of defect detection on an LCD image within 60 ms.

Green supply chain has become an important topic these days due to pollution, global warming, extreme climatic events, etc. A green product is manufactured with the goal of reducing the damage to the environment and limiting the use of energy and other resources at any stage of its life, including raw materials, manufacture, use, and disposal. Carbon footprint is a good measure of the impact that a product has on the environment, especially in climate change, in the entire lifetime of the product. Carbon footprint is directly linked to CO2 emission; thus, the reduction of CO2 emission must be considered in the product life cycle. Although more and more researchers are working on the green supply chain management in the past few years, few have incorporated CO2 emission or carbon footprint into the green supply chain system. Therefore, this research aims to propose an integrated model for facilitating the new product development (NPD) for green and low-carbon products. In this research, a systematic model based on quality function deployment (QFD) is constructed for developing green and low-carbon products in a TFT-LCD manufacturer. Literature review and interviews with experts are done first to collect the factors for developing and manufacturing green and low-carbon products. Fuzzy Delphi method (FDM) is applied next to extract the important factors, and fuzzy interpretive structural modeling (FISM) is used subsequently to understand the relationships among factors. A house of quality (HOQ) for product planning is built last. The results shall provide important information for a TFT-LCD firm in designing a new product.

This study investigated the linkage between performance of two full-scale membrane bioreactor (MBR) systems treating thin-film transistor liquid crystal display (TFT-LCD) wastewater and the population dynamics of dimethylsulfoxide (DMSO)/dimethylsulfide (DMS) degrading bacteria. High DMSO degradation efficiencies were achieved in both MBRs, while the levels of nitrification inhibition due to DMS production from DMSO degradation were different in the two MBRs. The results of real-time PCR targeting on DMSO/DMS degrading populations, including Hyphomicrobium and Thiobacillus spp., indicated that a higher DMSO oxidation efficiency occurred at a higher Hyphomicrobium spp. abundance in the systems, suggesting that Hyphomicrobium spp. may be more important for complete DMSO oxidation to sulfate compared with Thiobacillus spp. Furthermore, Thiobacillus spp. was more abundant during poor nitrification, while Hyphomicrobium spp. was more abundant during good nitrification. It is suggested that microbial population of DMSO/DMS degrading bacteria is closely linking to both DMSO/DMS degradation efficiency and nitrification performance. Copyright © 2013 Elsevier Ltd. All rights reserved.

... 42 Public Health 3 2010-10-01 2010-10-01 false LCD review. 426.425 Section 426.425 Public Health... PROGRAM REVIEW OF NATIONAL COVERAGE DETERMINATIONS AND LOCAL COVERAGE DETERMINATIONS Review of an LCD § 426.425 LCD review. (a) Opportunity for the aggrieved party, after his or her review of the LCD record...

This study investigated nitrification performance and nitrifying community in one full-scale membrane bioreactor (MBR) treating TFT-LCD wastewater. For the A/O MBR system treating monoethanolamine (MEA) and dimethyl sulfoxide (DMSO), no nitrification was observed, due presumably to high organic loading, high colloidal COD, low DO, and low hydraulic retention time (HRT) conditions. By including additional A/O or O/A tanks, the A/O/A/O MBR and the O/A/O MBR were able to perform successful nitrification. The real-time PCR results for quantification of nitrifying populations showed a high correlation to nitrification performance, and can be a good indicator of stable nitrification. Terminal restriction fragment length polymorphism (T-RFLP) results of functional gene, amoA, suggest that Nitrosomonas oligotropha-like AOB seemed to be important to a good nitrification in the MBR system. In the MBR system, Nitrobacter- and Nitrospira-like NOB were both abundant, but the low nitrite environment is likely to promote the growth of Nitrospira-like NOB. Copyright © 2012 Elsevier Ltd. All rights reserved.

The drive for larger size, higher spatial resolution, and wider aperture LCD has shown to increase the electrical crosstalk between electrodes in the driver circuit. This crosstalk leads to additivity errors in color LCD. In this paper, the crosstalk effect was analyzed with micrographs captured from an imaging colorimeter. The experimental result reveals the subpixel nature of color crosstalk. A spatial-based subpixel crosstalk correction algorithm was developed to improve the color performance of LCD. Compared to a 3D lookup table approach, the new algorithm is easier to implement and more accurate in performance.

Field sequential color (FSC) liquid crystal displays (LCD) using a high speed LCD mode and an R, G, B LED backlight, offers a significant potential for lower power consumption, higher resolution, higher brightness and lower cost compared to the conventional R, G, B color filter based LCD, and thus is of interest to various military and avionic display applications. While the DLP projection TVs, and Camcorder LCD view finder type displays using the FSC technology have been introduced in the consumer market, large area direct view LCD displays based on the FSC technology have not reached the commercial market yet. Further, large area FSC LCDs can present unique operational issues in avionic and military environments particularly for operation in a broad temperature range and with respect to its susceptibility for the color breakup image artifact. In this paper we will review the current status of the FSC LCD technology and then discuss the results of our efforts on the FSC LCD technology evaluation for the avionic applications.

In the field of Waste LCD disassembling and recycling, there are existing two major problems: 1) disassembling waste LCD mainly depends on manually mechanical crushing; 2) the resource level is not high. In order to deal with the above problems, in this paper, we develop an efficient, safe and automated waste LCD disassembling assembly line technology. This technology can disassembly and classify mainstream LCD into four components, which are liquid crystal display panels, housings and metal shield, PCB assembly. It can also disassembly many kinds of waste LCD. Compared with the traditional cooperation of manual labor and electric tools method, our proposed technology can significantly improve disassembling efficiency and demonstrate good prospects and promotional value.

... 42 Public Health 3 2013-10-01 2013-10-01 false LCD record furnished to aggrieved party. 426.418... COVERAGE DETERMINATIONS Review of an LCD § 426.418 LCD record furnished to aggrieved party. (a) Elements of a contractor"s LCD record furnished to the aggrieved party. Except as provided in paragraph (b) of...

... 42 Public Health 3 2014-10-01 2014-10-01 false LCD record furnished to aggrieved party. 426.418... COVERAGE DETERMINATIONS Review of an LCD § 426.418 LCD record furnished to aggrieved party. (a) Elements of a contractor"s LCD record furnished to the aggrieved party. Except as provided in paragraph (b) of...

... 42 Public Health 3 2012-10-01 2012-10-01 false LCD record furnished to aggrieved party. 426.418... COVERAGE DETERMINATIONS Review of an LCD § 426.418 LCD record furnished to aggrieved party. (a) Elements of a contractor"s LCD record furnished to the aggrieved party. Except as provided in paragraph (b) of...

... 42 Public Health 3 2010-10-01 2010-10-01 false CMS" role in the LCD review. 426.415 Section 426... Review of an LCD § 426.415 CMS" role in the LCD review. CMS may provide to the ALJ, and all parties to the LCD review, information identifying the person who represents the contractor or CMS, if necessary...

For the first time, an avionic grade MVA AM LCD with wide viewing angle has been developed for use in either landscape or portrait mode. The development of a high resolution Multi-domain Vertical Alignment (MVA) Active Matrix Liquid Crystal Display (AM LCD) is described. Challenges met in this development include achieving the required performance with high luminance and sunlight readability while meeting stringent optical (image quality) and environmental performance requirements of avionics displays. In this paper the optical and environmental performance of this high resolution 14.1" MVA-AM-LCD are discussed and some performance comparisons to conventional AM-LCDs are documented. This AM LCD has found multiple Business Aviation and Military display applications and cockpit pictures are presented.

Stereoscopic display technologies have been developed as one of advanced displays, and many TV industrials have been trying commercialization of 3D TV. We have been developing 3D TV based on LCD with LED BLU (backlight unit) since Samsung launched the world"s first 3D TV based on PDP. However, the data scanning of panel and LC"s response characteristics of LCD TV cause interference among frames (that is crosstalk), and this makes 3D video quality worse. We propose the method to reduce crosstalk by LCD driving and backlight control of FHD 3D LCD TV.

A new drive circuit for the liquid crystal display (LCD) of the InFocus TVT-6000 video projector is currently under development at the U.S. Army Missile Command. The new circuit will allow individual pixel control of the LCD and increase the frame rate by a factor of two while yielding a major reduction in space and power requirements. This paper will discuss results of the effort to date.

In this paper, the impact of display on quality assessment is addressed. Subjective quality assessment experiments have been performed on both LCD and CRT displays. Two sets of still images and two sets of moving pictures have been assessed using either an ACR or a SAMVIQ protocol. Altogether, eight experiments have been led. Results are presented and discussed, some differences are pointed out. Concerning moving pictures, these differences seem to be mainly due to LCD moving artefacts such as motion blur. LCD motion blur has been measured objectively and with psycho-physics experiments. A motion-blur metric based on the temporal characteristics of LCD can be defined. A prediction model have been then designed which predict the differences of perceived quality between CRT and LCD. This motion-blur-based model enables the estimation of perceived quality on LCD with respect to the perceived quality on CRT. Technical solutions to LCD motion blur can thus be evaluated on natural contents by this mean.

... Section 426.418 Public Health CENTERS FOR MEDICARE & MEDICAID SERVICES, DEPARTMENT OF HEALTH AND HUMAN... development of the LCD, including, but not limited to, the following: (1) The LCD being challenged. (2) Any... the draft LCD). (4) An index of documents considered that are excluded under paragraph (b) of this...

... Section 426.418 Public Health CENTERS FOR MEDICARE & MEDICAID SERVICES, DEPARTMENT OF HEALTH AND HUMAN... development of the LCD, including, but not limited to, the following: (1) The LCD being challenged. (2) Any... the draft LCD). (4) An index of documents considered that are excluded under paragraph (b) of this...

UV lamp systems have been used for cleaning of display panels of TFT LCD or Plasma Display Panel (PDP). However, the needs for high efficient cleaning and low cost made high voltage plasma cleaning techniques to be developed and to be improved. Dielectric-barrier discharges (DBDs), also referred to as barrier discharges or silent discharges have for a long time been exclusively related to ozone generation. In this paper, a 6kW high voltage plasma power supply system was developed for LCD cleaning. The -phase input voltage is rectified and then inverter system is used to make a high frequency pulse train, which is rectified after passing through a high-power transformer. Finally, bi-directional high voltage pulse switching circuits are used to generate the high voltage plasma. Some experimental results showed the usefulness of atmospheric plasma for LCD panel cleaning.

This study investigated the opinions of teachers about using interactive whiteboards with an LCD panel that was installed in classrooms within the FATIH educational project. The study was conducted at six high schools in which installation of interactive whiteboards with an LCD panel in classrooms was completed and teachers who received training…

The paper presents an objective lower bound for the discrimination of patterns and fine detail in images on a monochrome LCD. In applications such as medical imaging and military avionics the information of interest is often at the highest frequencies in the image. Since LCDs are sampled data systems, their output modulation is dependent on the phase between the input signal and the sampling points. This phase dependence becomes particularly significant at high spatial frequencies. In order to use an LCD for applications such as those mentioned above it is essential to have a lower (worst case) bound on the performance of the display. We address this problem by providing a mathematical model for the worst case output modulation of an LCD in response to a sine wave input. This function can be interpreted as a worst case modulation transfer function (MTF). The intersection of the worst case MTF with the contrast threshold function (CTF) of the human visual system defines the highest spatial frequency that will always be detectable. In addition to providing the worst case limiting resolution, this MTF is combined with the CTF to produce objective worst case image quality values using the modulation transfer function area (MTFA) metric.

Describes liquid crystal display (LCD) projectors and discusses their use in educational settings. Highlights include rear screen projection; LCD projectors currently available and the number of pixel elements in each; and examples of instructional applications, including portable setups, and use with videocassette recorders (VCRs), computers, and…

The year 2010 may be recorded as a first year of successful commercial 3D products. Among them, the 3D LCD TVs are expected to be the major one regarding the sales volume. In this paper, the principle of current stereoscopic 3D LCD TV techniques and the required flat panel display (FPD) technologies for the realization of them are reviewed. [Figure not available: see fulltext.

Marketing studies by EPIC show significant revenue opportunities by 2012 for UHB-LEDs in the automotive, LCD backlighting, and architectural lighting sectors. The goal of this workshop on manufacturing issues is to consider five key issues for UHB-LED manufacturing and to propose solutions that will pave the way to full exploitation of the opportunities.

In the automatic disassembly line of waste LCD displays, LCD displays are disassembled into plastic shells, metal shields, circuit boards, and LCD panels. Two industrial robots are used to cut metal shields and remove circuit boards in this automatic disassembly line. The functions of these two industrial robots, and the solutions to the critical issues of model selection, the interfaces with PLCs and the workflows were described in detail in this paper.

UNCLASSIFIED Defense Technical Information Center Compilation Part Notice ADPO113 31 TITLE: Are the Color Gamuts of CRT and LCD Triangular? An...ADP011297 thru ADP011332 UNCLASSIFIED Are the Color Gamuts of CRT and LCD Triangular? An Experimental Study Guan-wei Leea and Chao-hua Wenb aDepartment of...Tube) display. This study describes the difference of color gamuts in different luminance level and the accuracy of color between CRT and LCD. In the

We have combined a CMOS color camera with special software to compose a multi-functional image-quality analysis instrument. It functions as a colorimeter as well as measuring modulation transfer functions (MTF) and noise power spectra (NPS). It is presently being expanded to examine fixed-pattern noise and temporal noise. The CMOS camera has 9 μm square pixels and a pixel matrix of 2268 x 1512 x 3. The camera uses a sensor that has co-located pixels for all three primary colors. We have imaged sections of both a color and a monochrome LCD monitor onto the camera sensor with LCD-pixel-size to camera-pixel-size ratios of both 12:1 and 17.6:1. When used as an imaging colorimeter, each camera pixel is calibrated to provide CIE color coordinates and tristimulus values. This capability permits the camera to simultaneously determine chromaticity in different locations on the LCD display. After the color calibration with a CS-200 colorimeter the color coordinates of the display"s primaries determined from the camera"s luminance response are very close to those found from the CS-200. Only the color coordinates of the display"s white point were in error. For calculating the MTF a vertical or horizontal line is displayed on the monitor. The captured image is color-matrix preprocessed, Fourier transformed then post-processed. For NPS, a uniform image is displayed on the monitor. Again, the image is pre-processed, transformed and processed. Our measurements show that the horizontal MTF"s of both displays have a larger negative slope than that of the vertical MTF"s. This behavior indicates that the horizontal MTF"s are poorer than the vertical MTF"s. However the modulations at the Nyquist frequency seem lower for the color LCD than for the monochrome LCD. The spatial noise of the color display in both directions is larger than that of the monochrome display. Attempts were also made to analyze the total noise in terms of spatial and temporal noise by applying subtractions of

During the processes of TFT-LCD manufacturing, steps like visual inspection of panel surface defects still heavily rely on manual operations. As the manual inspection time of TFT-LCD manufacturing could range from 4 hours to 1 day, the reliability of time forecasting is thus important for production planning, scheduling and customer response. This study would like to propose a practical and easy-to-implement prediction model through the approach of Bayesian networks for time estimation of manual operated procedures in TFT-LCD manufacturing. Given the lack of prior knowledge about manual operation time, algorithms of necessary path condition and expectation-maximization are used for structural learning and estimation of conditional probability distributions respectively. This study also applied Bayesian inference to evaluate the relationships between explanatory variables and manual operation time. With the empirical applications of this proposed forecasting model, approach of Bayesian networks demonstrates its practicability and prediction accountability.

Cyclo Olefin Polymer (COP), which was developed by Zeon Corporation, is well known and used as an optical plastic in optical markets, having unique properties such as high light transmission, low water absorption, low birefringence etc. Optes Inc, who is ZEON CORPORATION"s affiliate optical parts manufacturer, has succeeded in the development of high performance optical base films. These are used for retardation and polarizing films in LCD"s (Liquid Crystal Displays), made from Cyclo Olefin Polymer with own film extrusion technologies. The Optical base film developed by Optes Inc has superior properties compared with those of existing products such as polycarbonate (PC), polyethylene terephthalate (PET) and Triacetate Cellulose (TAC) base in terms of low birefringence, high optical isotropy and high dimensional stability under high humidity and temperature conditions.

Color gamut as a significant performance index for display system describes the color reproduction ability IN real scenes. Liquid crystal display (LCD) is the most popular technology in flat panel display. However, conventional cold cathode fluorescent lamp (CCFL) backlight of LCD can not behave high color gamut compared with cathode ray tube (CRT). The common used method of color gamut measuring for LCD system is introduced at the beginning. According to the inner structure and display principle of LCD system, there are three major factors deciding LCD"s color gamut: spectral properties of backlight, transmittance properties of color filters and performance of liquid crystal panel. Instead of conventional backlight CCFL, RGB-LED backlight is used for improving color reproduction of LCD display system. Due to the imperfect match between RGB-LED" s spectra and color filter"s transmittance, the color filter would reduce the color gamut of LCD system more or less. Therefore, LCD system based on LED backlight with area-control technique is introduced which modifies backlight control signal according to the input signal After analyzing and calculating the spectra of LED backlight which passes through the color filters using method of colorimetry, the area sizes of color gamut triangles of RGB-LED backlight with area-control and RGB-LED backlight without area-control LCD systems are compared and the relationship between color gamut and varying contrast of liquid crystal panel is analyzed. It is indicated that LED backlight with area-control technique can avoid color saturation dropping and have little effects on the contrast variation of liquid crystal panel. In other words, LED backlight with area-control technique relaxes the requirements of both color filter performance and liquid crystal panel. Thus, it is of importance to improve the color gamut of the current LCD system with area-control LED backlight.

A new technique to fabricate arbitrarily shaped microstructures by using LCD (liquid crystal display) real- time mask is reported in this paper. Its principle and design method are explained. Based on partial coherent imaging theory, the process to fabricate micro-axicon array and zigzag grating has been simulated. The experiment using a color LCD as real-time mask has been set up. Micro-axicon array and zigzag grating has been fabricated by the LCD real-time mask technique. The 3D surface relief structures were made on pan chromatic silver-halide sensitized gelatin (Kodak-131) with trypsinase etching. The pitch size of zigzag grating is 46.26micrometers . The caliber of axicon is 118.7micrometers , and the etching depth is 1.332micrometers .

Many volatile organic compounds (VOCs) are emitted during the manufacturing of thin film transistor liquid crystal displays (TFT-LCDs), exposure to some of which has been reported to be associated with kidney dysfunction, but whether such an effect exists in TFT-LCD industry workers is unknown. This cross-sectional study aimed to investigate the association between exposure to VOCs and kidney dysfunction among TFT-LCD workers. The results showed that ethanol (1811.0+/-1740.4 ppb), acetone (669.0+/-561.0 ppb), isopropyl alcohol (187.0+/-205.3 ppb) and propylene glycol monomethyl ether acetate (PGMEA) (102.9+/-102.0 ppb) were the four dominant VOCs present in the workplace. The 63 array workers studied had a risk of kidney dysfunction 3.21-fold and 3.84-fold that of 61 cell workers and 18 module workers, respectively. Workers cumulatively exposed to a total level of isopropyl alcohol, PGMEA and propylene glycol monomethyl ether> or =324 ppb-year had a significantly higher risk of kidney dysfunction (adjusted OR=3.41, 95% CI=1.14-

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey