tft lcd failures supplier

The display LCD TFT is a kind of display screen that we are familiar with. Many intelligent terminal products use display LCD TFT. Liquid crystal is the most important part of display LCD TFT. Liquid crystal is a physical form, and this physical form can be used as a key factor in display by sorting. To understand the quality of display LCD wholesale tft module, we generally understand from the specific parameters. So what if the display LCD TFT is blurred? Now let Proculus introduce to you.

The LCD TFT display which becomes blurred and indistinct is divided into two cases: one is the display LCD TFT before installation, and the other is the display LCD TFT after a period of use. If you want to buy lcd module, you should the reasons for these two different time periods are also completely different.

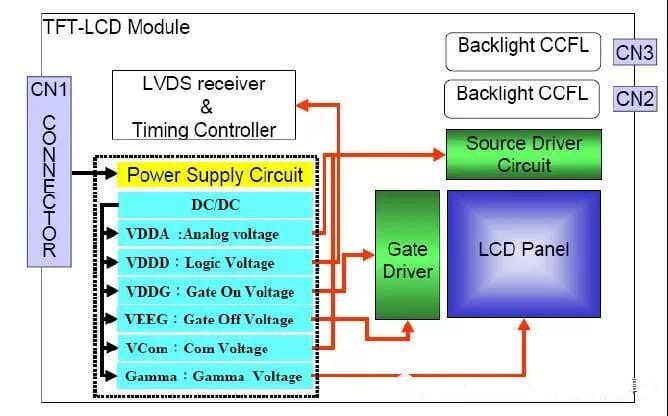

Generally, the display LCD TFT is blurred before installation, which is likely to be the reason for the display LCD TFT itself. We generally check whether the driver is normal, and whether there is a problem with the chip and wiring. It is possible that there are some defects in the design of display LCD TFT, which leads to the blurred screen of display LCD TFT. This kind of situation needs to carry on the internal analysis to the TFT LCD display supplier and obtains the concrete solution.

There is another situation mentioned earlier, that is, it has been used for a period of time after installation, which leads to the blurring of the display LCD TFT. We need to check whether the connection with the motherboard is normal, whether the picture shows signs of jitter, whether the image can be seen clearly, and whether the tightness of the whole machine is poor, resulting in dust or water in the place where the motherboard is connected to the TFT LCD screen, all of which are likely to cause TFT LCD blurred screen. This kind of analysis should be combined with the TFT LCD screen itself, motherboard, structure and so on, and the steps are more complex.

The above content is the introduction to the treatment method of TFT LCD screen. With the continuous increase of TFT LCD display supplier, the competition in TFT LCD industry is becoming more and more fierce. The quality of many TFT LCD manufacturers is also uneven, and there is no lack of many black-hearted manufacturers to simplify the production process for profit, resulting in a lot of bad phenomena in the products. Therefore, we still have to pay more attention to the choice of TFT LCD suppliers.

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

For the first two situations, that’s because the circuit on the TFT and CF controlling that defective pixel point is shorted or broken. While the third situation is caused by damaged color pixel.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

VISLCD has been engaged in LCD production and sales for 9 years, and we have met many customers who shared with us that they had encountered unreliable LCD suppliers.

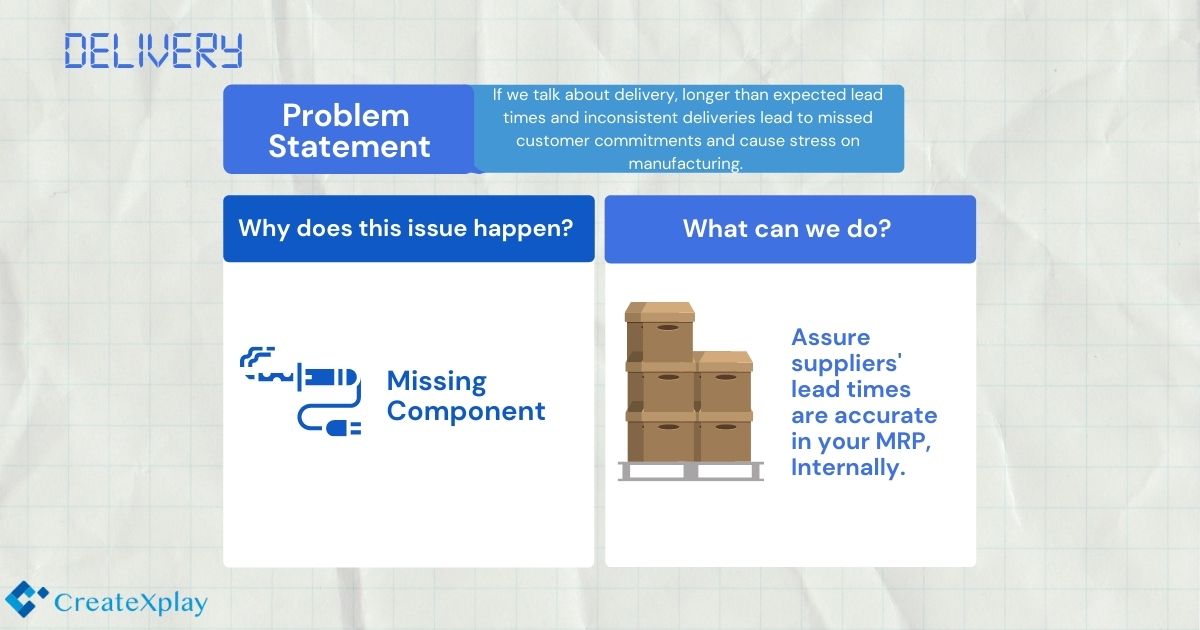

For example, the answer is not what you asked for, the LCD product cannot be delivered on time, the price of the LCD suddenly increases, the LCD module suddenly breaks down during the use of the product, or even the LCD is discontinued after less than 1 year of delivery…etc. In addition, there are many customers who are not sure what type of LCD supplier they are looking for.

In view of all the above, VISLCD has written this article to share knowledge about LCD suppliers and other issues related to LCD. We believe it will be helpful to LCD customers.

To understand LCD suppliers, we first need to know what kinds of LCD suppliers are available. Then LCD customers can find the right supplier based on information such as their product applications, LCD requirements and forecast volume.

LCD original manufacturer refers to the original manufacturer of LCD panel. Originated from the USA in the 1960’s, after more than 50 years of development, the manufacturers are now mainly located in China mainland, Korea and Taiwan. Among them, the Chinese manufacturers in recent years rely on the rapid scale, technology development and price advantage, has gradually occupied the main market share.

The video below is an official video presentation of the BOE display factory and Century Display (CTC), which will give you a more visual understanding of the original LCD manufacturer.

The 5.1 generation TFT-LCD line of Century Display in Shenzhen, China, for example, has been put into operation since 2008 with a cumulative fixed investment of more than $4 billion, and the cost of water, electricity, employee wages and equipment depreciation is as high as $0.5~100 million/month. The monthly production capacity is about 100,000 sheets ( 1300*1200mm/sheet). If all of them are used to produce 7-inch LCD panels, then the monthly shipment volume is up to 9,000,000 pcs. Therefore, a very large monthly shipment volume is required to meet the normal operation of the factory.

This is only the 5.1 generation TFT-LCD line, if it is 8.5 generation line or even 10 generation line or more, then the cost and shipment volume may be several times or even ten times more. It should be noted that the number of generations of LCD lines does not mean that the technology is high or low. The higher the generation, then the larger the size of the LCD can be put into production, of course, the greater the volume of shipments and investment amount.

LCD original manufacturers generally provide mainly LCD panels, but also provide COG (LCD + IC), FOG (LCD + IC + FPCA cable) and other kinds of LCD semi-finished products. Also includes a small amount of the original LCD module. But the original LCD factory will only deal with the famous brand companies directly (such as Apple, Dell, Xiaomi, etc.), or through agents to ship. And the MOQ quantity requirement is very high (generally 1,000,000 pcs/month or more), the unit price of original LCD module is also high and the degree of customization is low.

LCD original manufacturers usually have an order MOQ requirement for their agents, which translates into an LCD unit quantity of no less than 100,000pcs/month. When the LCD demand is high, this will not be a problem; but when the market is low, the agent must buy the agreed MOQ quantity of LCD from the original LCD manufacturer even if there is no customer demand for the time being. So when the low season, if your order quantity is large enough, then you may get a very good LCD panel price from the LCD agent, which may even be lower than the agent’s purchase price.

LCD module manufacturers is to purchase LCD semi-finished products (such as LCD panel, COG or FOG) from LCD agents, then purchase ICs from IC agents, produce or purchase backlight, FPCA cable and touch screen components, and then integrate all the above components into LCD module or touch LCD module. LCD module factories vary in size from tens of millions of pcs to hundreds of thousands of pcs shipped per month.

Medium and large size module factory generally get the semi-finished products are FOG LCD (also known as open cell LCD) from the original LCD manufacturers or LCD agents, and then add the backlight assembly into the finished LCD module. The advantage of doing so is that the quality is relatively stable, but the degree of customization will be much lower. Because FOG LCD already includes FPCA cable, generally speaking, the only thing that can be customized is the brightness of the backlight and the touch panel and cover glass (if needed). The rest are difficult to change, unless the customer’s LCD demand is very large.

The small and medium size module factory after years of mature development of the industry, the degree of customization will be much more flexible. The semi-finished products are mainly LCD panels, which means that the backlight size, backlight brightness, FPCA cable design, shape and PIN number, as well as the touch panel and cover glass can all be customized according to the customer’s requirements. But the MOQ requirement is higher for the backlight size. Other parts of the customization generally require LCD MOQ of at least 2,000~5,000 pcs, which varies depending on the LCD size.

Since LCD module manufactures vary in size and quality control(especially small and medium size LCD module factories), and most of the components are sourced, the selection of module factories is particularly important if customers want to buy LCDs with good quality and competitive prices.

For example, if the factory’s customers are mostly low-cost products or repaired product manufacturers, then it can be assumed that the quality of his products is not too good, LCD panels and some other components may be B-grade products, not A, can only meet short-term use.

This is essential to ensure supply. In case of supply shortage, many module factories with insufficient upstream channels sometimes cannot even start production. Because they can not buy raw materials such as LCD panels and ICs.

As the name implies, trading companies do not have their own factories, but directly sell finished LCD products from LCD resellers or LCD modules from module manufacturers. Generally speaking, the LCD prices of trading companies are relatively high and the quality and reliability are a little weaker. However, there is no shortage of good trading companies with good quality management teams and good upstream channel resources. The biggest advantage of trading companies is their flexibility, which can meet the diversified needs of customers.

2) Shenzhen has 3 types of buildings related to lcd (including other electronic products): office buildings, factories and markets. Almost all LCD panel and IC agents are located in various office buildings in Shenzhen, while component factories such as FPCA, Touch panel and backlight are located in various industrial parks in the suburbs. It is possible to find the right components and develop new products in the shortest time. Of course, there is also the famous Huaqiang bei(north) Electronic Market, a very complex place.

VISLCD was a trading company in the early days. But after nearly 9 years of development, it has developed into a combination of LCD module factory and LCD agent. The company is located in LCD base Shenzhen, China and operates in both Hong Kong and Shenzhen. We have our own module factory and have direct relationship with Century Display, LG, HKC and other LCD original manufacturers. Our main employees are also from these LCD manufacturers. We also accept all kinds of customized LCD business. Therefore, VISLCD is one of the best choices for medium-sized customers in terms of quality stability, semi-finished parts supply and customization.

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

Unfortunately, it is common for some failures to make it through final testing. After the vibration and thermal effects from the shipping process, these defects can be exposed and result in an out of box failure at the assembly line.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

Chances are you selected an LCD display supplier to work with your CM and now feel locked into the relationship. You’ve already gone through the qualification process, investing time and money. Not to mention approving the PO in good faith, believing the CM would be getting the right cost, on-time delivery, and high-quality components from your LCD supplier.

A CM had a quality issue with an LCD module. The CM felt comfortable notifying the LCD supplier of the problem. A comprehensive QA check at the supplier’s factory did not reveal any quality issues. The LCD supplier, taking accountability for their role in the end product, scheduled a visit to the CM’s factory. Working collaboratively with the CM, they discovered missing steps in the CM’s process that were compromising the quality of the displays. Quick and intelligent action meant the impact was negligible. The OEM, while informed, was not involved or burdened throughout this process.

Given the LCD supplier’s role and responsibilities, they should keep the OEM informed on aspects that pose a significant impact on products or customer perception:

Lead time: Contrary to the lines you may be fed, lead-time problems are not just part of doing business. Sure, uncertainty and circumstances happen, but an experienced LCD supplier will have safety nets in place to address this, like safety stock of the longest lead time component, multiple delivery options, and pull with their factory to increase or speed production.

Quality: Shoddy displays? Field failures? Dimensional tolerances not being met? These types of quality issues are a sure sign it’s time to start a new LCD supplier search.

For specialty components like LCD displays, it’s typical that you dictate to your CM the supplier they need to use. And if you are observing any issues with lead time, quality, performance, cost, or obsolescence, you should look for an alternate supplier.

Find an LCD display supplier that has experience dealing with a contract manufacturer. There are some items that are dealt directly with the CM, such as schedules, payments, and RMAs. But the supplier needs to know when to get the OEM involved, which is any time there may be a significant impact to your products or customer perception.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

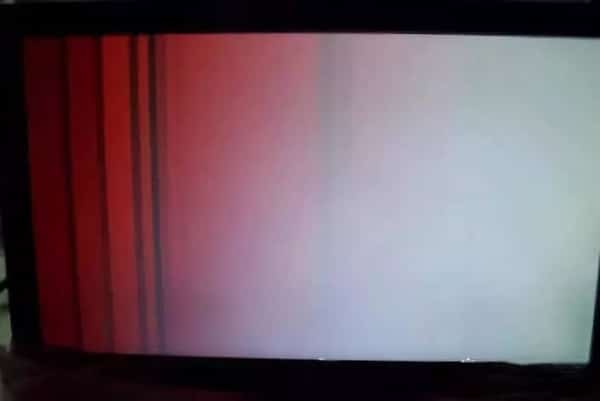

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

The main lines of LCD modules are size in 0.96-inch, 2-inch, 2.3-inch, 2.4-inch, 3-inch, 3.5-inch, 4.3-inch, 5-inch, 7-inch, 8-inch, 10.1-inch, 13.3-inch, 15.6-inch, and ancillary products.

Surprisingly cost issue is the least common. The pain of changing LCD suppliers is high, such that all the problems mentioned above end up costing more than a regular cost delta between competitive suppliers.

An LCD’s cost is an obvious challenge as it’s usually the most expensive component. The challenge is that cost is also difficult to quantify and properly understand. Determining the right price to pay depends on three main factors.

System-level manufacturability is another cost challenge where display integration improvements can reduce product complexity, improve manufacturing time, and reduce system-level manufacturing defects. For the most seamless LCD integration, additional components such as buttons, LEDs, PCB boards, and connectors are more efficiently integrated on display than a separately assembled component. Clearly, in this case, the LCD cost will go up, but when done right, the system-level cost is reduced to result in a net gain.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

According to real LCD manufacturing conditions, the number of normal LCD panels exceeds greatly the number of defective LCD panels. Therefore, the normal PRs greatly outnumber the defective PRs. As a result, the collected data set for training would be imbalanced if a two-class classification approach is adopted, the SVM by Vapnik [4] for example, the class imbalance problem occurs.

In practice, in addition to the class imbalance problem, the LCD defect detection also suffers from another critical problem resulting from the absence of negative information. To facilitate the following problem description, the normal PR class and the defective PR class are defined as the positive class and negative class, respectively.

The main difference between a normal PR and a defective PR is that their appearances are apparently different, as can be observed from Figure 4. The color (or gray level) of a normal PR is nearly uniform, implying that the variation of the gray-level distribution of normal PRs is very small. On the contrary, the surfaces of defective PR not only contain various kinds of textures, but also vary greatly in color, implying that the variation of the true distribution for negative class in the data space is very large. Collecting a set of positive training data that can represent the true distribution of positive class is easy, because: (1) the variation of positive-class distribution is very small; and (2) most of the LCD panels are normal (the number of normal PRs is considerably large). Therefore, the positive class can be well-sampled during the data collection stage in real practice. However, representative defective PRs are difficult to obtain in practice for several reasons. For example, there are numerous types of defects in array process, more than 10 types at least. However, not all the defects would occur frequently. Some of the defects seldom appear, for example the defect caused by abnormal photo-resist coating (APRC). The defect “APRC” seldom occurs, because equipment/process engineers maintain the coating machines periodically. Even so, the coating machines might still break down occasionally. As a result, the number of available images containing the APRC defects is quite limited. But, the APRC defect has a large variation in color and texture. Unfortunately, limited APRC examples cannot stand for all kinds of APRC defects. Therefore, the collected negative training data are most likely under-sampled. Here, the “under-sampled” means that the collected negative training set cannot represent the true negative-class distribution in the data space, which is the problem of absence of negative information. Due to this problem, numerous false positive (i.e., missing defects) will be produced if a two-class classification approach (e.g., a binary SVM) is applied to the LCD defect detection, which has been evidenced by the results reported in [7]. Compared with two-class classification approach, novelty detection approach is a better choice.

Novelty detection is one-class classification [10,35], which is to solve the conventional two-class classification problems where one of the two classes is under-sampled, or only the data of one single class can be available for training [5,6,9–11,35–40]. As analyzed above, for the LCD defect detection application, the normal PRs can be well-sampled, while the defective PRs are in general undersampled. Therefore, the LCD defect detection can be treated as a typical novelty detection problem. Accordingly, one-class classification is a better solution.

To summarize, it can be seen that the LCD defect detection suffers from two problems simultaneously: one is the class imbalance problem, and the other is the problem of the absence of negative information. For the first problem, there have been many sophisticated solutions, including sampling, cost-sensitive learning, SVM-based, and one-class learning approaches. However, the only solution to the second problem is the novelty detection approach (i.e., one-class classification approach). Therefore, one-class classification would be a more appropriate approach to the LCD defect detection application.

There are several approaches for one-class classification, such as density approach (e.g., Gaussian mixture model [5]), boundary approach (e.g., SVDD [9] and one-class SVM [40]), neural network approach [6,36], and reconstruction-based approach (e.g., the kernel principal component analysis for novelty detection [35]). It has been proven in [9] that when a Gaussian kernel is used, the SVDD proposed by Tax and Duin [9] is identical to the one-class SVM proposed by Schölkopf et al. [40]. This paper focuses on the SVDD since it has been applied to the same application in the works of [7] and [10], and has shown to be effective in detecting defective PRs. However, as discussed in Section 1, generalization performance of SVDD is limited. Therefore, the intent of this paper is on proposing a method to improve generalization performance of SVDD, and applying the improved SVDD to the LCD defect detection treated as a novelty detection problem. The improved SVDD is called quasiconformal kernel SVDD (QK-SVDD). Note that the QK-SVDD and SVDD are not two independent classifiers. To obtain QK-SVDD, one has to train an SVDD first, which will be introduced in Section 2.4. In the following part of the paper, we first introduce the defect detection scheme, and then derive the proposed method in details.

Apollo specializes in TFT-LCD flat panel technologies and supply chain solutions. We offer a huge selection of TFT-LCD monitors and touchscreens, as well as corresponding components. We also offer hardware and software solutions for all of our products and digital signage applications.

As a worldwide supplier of state-of-the-art TFT technologies and system solutions, Apollo Displays supports you in all project phases – 1 from construction of the metal housing and procurement of specific parts to in-house development of controller boards and touchscreen integration.

Let us start with the basics first; refresh the knowledge about TN and LCD displays in general, later we will talk about TFTs (Thin Film Transistors), how they differ from regular monochrome LCD displays. Then we will go on to the ghosting effect, so we will not only discuss the technology behind the construction of the TFT, but also some phenomena, like the ghosting effect, or grayscale inversion, that are important to understand when using an LCD TFT display.

Next, we will look at different technologies of the TFT LCD displays like TN, IPS, VA, and of course about transmissive and transflective LCD displays, because TFT displays also can be transmissive and transflective. In the last part we will talk about backlight.

Let us start with a short review of the most basic liquid crystal cell, which is the TN (twisted nematic) display. On the picture above, we can see that the light can be transmit through the cell or blocked by the liquid crystal cell using voltage. If you want to learn more about monochrome LCD displays and the basics of LCD displays, follow this link.

What is a TFT LCD display and how it is different from a monochrome LCD display? TFT is called an active display. Active, means we have one or more transistors in every cell, in every pixel and in every subpixel. TFT stands for Thin Film Transistor, transistors that are very small and very thin and are built into the pixel, so they are not somewhere outside in a controller, but they are in the pixel itself. For example, in a 55-inch TV set, the TFT display contains millions of transistors in the pixels. We do not see them, because they are very small and hidden, if we zoom in, however, we can see them in every corner of each pixel, like on the picture below.

On the picture above we can see subpixels, that are basic RGB (Red, Green, Blue) colors and a black part, with the transistors and electronic circuits. We just need to know that we have pixels, and subpixels, and each subpixel has transistors. This makes the display active, and thus is called the TFT display. TFT displays are usually color displays, but there are also monochrome TFT displays, that are active, and have transistors, but have no colors. The colors in the TFT LCD display are typically added by color filters on each subpixel. Usually the filters are RGB, but we also have RGBW (Red, Green, Blue, White) LCD displays with added subpixels without the filter (White) to make the display brighter.

Going a little bit deeper, into the TFT cell, there is a part inside well known to us from the monochrome LCD display Riverdi University lecture. We have a cell, liquid crystal, polarizers, an ITO (Indium Tin Oxide) layer for the electrodes, and additionally an electronic circuit. Usually, the electronic circuit consists of one transistor and some capacitors to sustain the pixel state when we switch the pixel OFF and ON. In a TFT LCD display the pixels are much more complicated because apart from building the liquid crystal part, we also need to build an electronic part.

That is why TFT LCD display technologies are very expensive to manufacture. If you are familiar with electronics, you know that the transistor is a kind of switch, and it allows us to switch the pixel ON and OFF. Because it is built into the pixel itself, it can be done very quickly and be very well controlled. We can control the exact state of every pixel not only the ON and OFF states, but also all the states in between. We can switch the light of the cells ON and OFF in several steps. Usually for TFT LCD displays it will be 8-bit steps per color, so we have 256 steps of brightness for every color, and every subpixel. Because we have three subpixels, we have a 24-bit color range, that means over 16 million combinations, we can, at least theoretically, show on our TFT LCD display over 16 million distinct colors using RGB pixels.

Now that we know how the TFT LCD display works, we can now learn some practical things one of which is LCD TFT ghosting. We know how the image is created, but what happens when we have the image on the screen for a prolonged time, and how to prevent it. In LCD displays we have something called LCD ghosting. We do not see it very often, but in some displays this phenomenon still exists.

Another issue present in TFT displays, especially TN LCD displays, is grayscale inversion. This is a phenomenon that changes the colors of the screen according to the viewing angle, and it is only one-sided. When buying a TFT LCD display, first we need to check what kind of technology it is. If it is an IPS display, like the Riverdi IPS display line, then we do not need to worry about the grayscale inversion because all the viewing angles will be the same and all of them will be very high, like 80, 85, or 89 degrees. But if you buy a more common or older display technology type, like the TN (twisted nematic) display, you need to think where it will be used, because one viewing angle will be out. It may be sometimes confusing, and you need to be careful as most factories define viewing direction of the screen and mistake this with the greyscale inversion side.

We know already that TN (twisted nematic) displays, suffer from grayscale inversion, which means the display has one viewing side, where the image color suddenly changes. It is tricky, and you need to be careful. On the picture above there is a part of the LCD TFT specification of a TN (twisted nematic) display, that has grayscale inversion, and if we go to this table, we can see the viewing angles. They are defined at 70, 70, 60 and 70 degrees, that is the maximum viewing angle, at which the user can see the image. Normally we may think that 70 degrees is better, so we will choose left and right side to be 70 degrees, and then up and down, and if we do not know the grayscale inversion phenomena, we may put our user on the bottom side which is also 70 degrees. The viewing direction will be then like a 6 o’clock direction, so we call it a 6 o’clock display. But you need to be careful! Looking at the specification, we can see that this display was defined as a 12 o’clock display, so it is best for it to be seen from a 12 o’clock direction. But we can find that the 12 o’clock has a lower viewing angle – 60 degrees. What does it mean? It means that on this side there will be no grayscale inversion. If we go to 40, 50, 60 degrees and even a little bit more, probably we will still see the image properly. Maybe with lower contrast, but the colors will not change. If we go from the bottom, from a 6 o’clock direction where we have the grayscale inversion, after 70 degrees or lower we will see a sudden color change, and of course this is something we want to avoid.

We will talk now about the other TFT technologies, that allow us to have wider viewing angles and more vivid colors. The most basic technology for monochrome and TFT LCD displays is twisted nematic (TN). As we already know, this kind of displays have a problem with grayscale inversion. On one side we have a higher retardation and will not get a clear image. That is why we have other technologies like VA (Vertical Alignment), where the liquid crystal is differently organized, and another variation of the TFT technology – IPS which is In-Plane Switching. The VA and IPS LCD displays do not have a problem with the viewing angles, you can see a clear image from all sides.

Apart from the different organization of the liquid crystals, we also organize subpixels a little bit differently in a VA and IPS LCD displays. When we look closer at the TN display, we will just see the subpixels with color filters. If we look at the VA or IPS display they will have subpixels of subpixels. The subpixels are divided into smaller parts. In this way we can achieve even wider viewing angles and better colors for the user, but of course, it is more complicated and more expensive to do.

The picture above presents the TN display and grayscale inversion. For IPS or VA technology there is no such effect. The picture will be the same from all the sides we look so these technologies are popular where we need wide viewing angles, and TN is popular where we don’t need that, like in monitors. Other advantages of IPS LCD displays are they give accurate colors, and wide viewing angles. What is also important in practice, in our projects, is that the IPS LCD displays are less susceptible to mechanical force. When we apply mechanical force to the screen, and have an optically bonded touch screen, we push the display as well as squeeze the cells. When we have a TN display, every push on the cell changes the image suddenly, with the IPS LCD displays with in-plane switching, different liquid crystals organization, this effect is lesser. It is not completely removed but it is much less distinct. That is another reason IPS displays are very popular for smartphones, tablets, when we have the touchscreens usually optically bonded.

Now, let us look at the backlight types. As we see here, on the picture above, we have four distinct types of backlight possible. The most common, 95 or 99 per cent of the TFT LCD displays on the market are the transmissive LCD display type, where we need the backlight from the back. If you remember from our Monochrome LCD Displays lecture, for transmissive LCD displays you need the backlight to be always on. If you switch the backlight off, you will not see anything. The same as for monochrome LCD displays, but less popular for TFT displays, we have the transflective LCD display type. They are not popular because usually for transflective TFT displays, the colors lack in brightness, and the displays are not very practical to use. You can see the screen, but the application is limited. Some transflective LCD displays are used by military, in applications where power consumption is paramount; where you can switch the backlight off and you agree to have lower image quality but still see the image. Power consumption and saving energy is most important in some kind of applications and you can use transflective LCD displays there. The reflective type of LCD displays are almost never used in TFT. There is one technology called Low Power Reflective Displays (LPRD) that is used in TFT but it is not popular. Lastly, we have a variation of reflective displays with frontlight, where we add frontlight to the reflective display and have the image even without external light.

Just a few words about Low Power Reflective Displays (LPRD). This kind of display uses environmental light, ambient light to reflect, and produce some colors. The colors are not perfect, not perfectly clear, but this technology is becoming increasingly popular because it allows to have color displays in battery powered applications. For example, a smartwatch would be a case for that technology, or an electrical bike or scooter, where we can not only have a standard monochrome LCD display but also a TFT LCD color display without the backlight; we can see the image even in

strong sunlight and not need backlight at all. So, this kind of TFL LCD display technology is getting more and more popular when we have outdoor LCD displays and need a low power consumption.

On the picture above, we have some examples of how transmissive and reflective LCD displays work in the sunlight. If we have a simple image, like a black and white pattern, then on a transmissive LCD display, even with 1000 candela brightness, the image probably will be lower quality than for a reflective LCD display; if we have sunlight, we have very strong light reflections on the surface of the screen. We have talked about contrast in more detail in the lecture Sunlight Readable Displays. So, reflective LCD displays are a better solution for outdoor applications than transmissive LCD displays, where you need a really strong backlight, 1000 candela or more, to be really seen outdoors.

To show you how the backlight of LCD displays is built, we took the picture above. You can see the edge backlight there, where we have LEDs here on the small PCB on the edge, and we have a diffuser that distributes the light to the whole surface of LCD screen.

In addition to the backlight, we have something that is called a frontlight. It is similar to backlight, it also uses the LEDs to put the light into it, but the frontlight needs to be transparent as we have the display behind. On the example on the picture above we can see an e-paper display. The e-paper display is also a TFT display variation, but it is not LCD (liquid crystal), it is a different technology, but the back of the display is the same and it is reflective. The example you see is the Kindle 4 eBook reader. It uses an e-paper display and a frontlight as well, so you can read eBooks even during the night.

The most common display technology is liquid crystal displays (LCDs). Their applications include mobile phones, industrial meters, television, POS, smart homes, aerospace, automotive, military systems, gadgets, marine, etc.

If an LCD does have a white screen, it implies the backlight is working properly. Simply examine your signal input channels to determine the most likely causes.

It may also be affected by the display being completely disrupted by excessive heat, a shock that breaks the LCD controller, or a connection failure that requires professional repair.

Since LCD graphics are made up of RGB pixels, their display should not be as blurry as it was on old CRT displays. If you see blurry images, there are two possibilities;

§ The LCD"s surface is composed of a plastic film layer with maximum hardness. If you happen to clean the surface frequently or use the incorrect detergent or solvent, you will cause surface damage.

Others include a decline in screen or display contrast, broken glass, non-functioning pixel resolution or the entire display. Different types of LCD problems require different types of repair methods.

If you drop the LCD and discover it got broken on the surface but the display still works, you may have simply damaged the touch panel; you could replace it by finding a repair shop.

Backlight is used because LCD cannot emit light on its own. Usually, the backlight isn"t entirely driven; however, you can intensify the backlight to brighten a dim LCD screen.

To repair an LCD screen, you must first devise a way to fix the backlight. It is a simple task for some displays, although it can be challenging for others based on the process of manufacturing.

If you have any need for a stretched TFT LCD display, do reach out to a well-known manufacturer. Kindly contact us and we’ll be glad to partner with you for the best products.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey