tft lcd failures made in china

The display LCD TFT is a kind of display screen that we are familiar with. Many intelligent terminal products use display LCD TFT. Liquid crystal is the most important part of display LCD TFT. Liquid crystal is a physical form, and this physical form can be used as a key factor in display by sorting. To understand the quality of display LCD wholesale tft module, we generally understand from the specific parameters. So what if the display LCD TFT is blurred? Now let Proculus introduce to you.

The LCD TFT display which becomes blurred and indistinct is divided into two cases: one is the display LCD TFT before installation, and the other is the display LCD TFT after a period of use. If you want to buy lcd module, you should the reasons for these two different time periods are also completely different.

Generally, the display LCD TFT is blurred before installation, which is likely to be the reason for the display LCD TFT itself. We generally check whether the driver is normal, and whether there is a problem with the chip and wiring. It is possible that there are some defects in the design of display LCD TFT, which leads to the blurred screen of display LCD TFT. This kind of situation needs to carry on the internal analysis to the TFT LCD display supplier and obtains the concrete solution.

There is another situation mentioned earlier, that is, it has been used for a period of time after installation, which leads to the blurring of the display LCD TFT. We need to check whether the connection with the motherboard is normal, whether the picture shows signs of jitter, whether the image can be seen clearly, and whether the tightness of the whole machine is poor, resulting in dust or water in the place where the motherboard is connected to the TFT LCD screen, all of which are likely to cause TFT LCD blurred screen. This kind of analysis should be combined with the TFT LCD screen itself, motherboard, structure and so on, and the steps are more complex.

The above content is the introduction to the treatment method of TFT LCD screen. With the continuous increase of TFT LCD display supplier, the competition in TFT LCD industry is becoming more and more fierce. The quality of many TFT LCD manufacturers is also uneven, and there is no lack of many black-hearted manufacturers to simplify the production process for profit, resulting in a lot of bad phenomena in the products. Therefore, we still have to pay more attention to the choice of TFT LCD suppliers.

In this article, we are looking at the benefits of looking for Chinese TFT LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with STONE Tech.

Handbags, wallets, phone cases, and other similar items have become the favorites of wholesalers and bulk buyers. These products are directly sold to end consumers. However, the fascinating thing about the Chinese production and manufacturing business is that it does not only cover the end-consumer products. Rather, you can also acquire raw and basic materials needed for the further manufacturing of goods and products. One such product is LCD displays.

LCD displays have become something of a necessity in today’s world of tech advancement. Many things in our daily life have been automated, and are operated using an interactive user interface. For these kinds of machines and gadgets, LCD displays are typically necessary.

In this article, we are looking at the benefits of looking for Chinese LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with Stoneitech.com.

STONE Tech is an LCD manufacturer located in Beijing, China. It was founded back in 2010, and it has been developing TFT LCD display modules ever since. These modules can be used for a variety of different machines including electric equipment, precision instruments, and civil electronics etcetera.

The same applies to LCD displays. When you save up on costs when buying LCD displays, you can set a lower price for the whole machine or gadget that you are producing.

When it comes to LCD modules, the orders are not received by the hundreds or thousands as is the case with other smaller products such as handbags and wallets etcetera. One module can cost around $250, and it is for this reason that the dynamics are a little different with this business. That is why STONE offers single pieces for sale as well as multiple pieces. This encourages smaller businesses to make their purchases since they can easily purchase as many modules as they like. As long as you meet the limit stated by the supplier, you are good to go.

In the case of LCD modules, this benefit relates to a reselling business. For example, if you are planning on buying some modules to use in your machines etcetera, then there is not a very suitable opportunity for you to expand. If you want to start a business in another country, you will have to open a manufacturing unit there so that your products can be produced and then get sold. Or, you will have to transport your final products to the other country in order to run your business.

However, if you are buying the LCD modules to resale at a profit, you can use the Chinese markets to grow your business. You can buy the modules at a reduced price and then sell them at a profit in a different area or city where the people will be willing to pay more.

Now that we have seen the benefits of choosing Chinese manufacturers for LCD modules, let us narrow it down a bit and look at why you should choose STONE specifically.

One of the main things that you have to look at in any supplier is the level of reliability and trust. This is usually determined by the level of experience and the time that the supplier has spent in the market. STONE was founded in 2010 and has been producing LCD modules for the past 10 years.

If you are looking to buy LCD modules in bulk, look no further than the Middle Kingdom. China has become the hub of mass manufacturing and is the favorite spot for wholesalers and business owners.

In case you need some convincing about buying from the Chinese, we have compiled a list of benefits that you can enjoy when looking for TFT LCD manufacturers in China.

LCD device is made of two pieces of glass made of liquid crystal box, only 5 ~ 10um between them, and the inner surface of the glass is also coated with a layer of orientation layer, it is easy to destroy, so the assembly, use should pay attention to.

LCD surface can not be pressurized too much, so as not to destroy the orientation layer, in case the pressure is too large, or pressed by hand in the middle of the LCD, need to be placed at least 1 hour before powering up. Assembly remembers to pressure evenly, only the edge of the device, not the middle of the pressure, and not uneven force.

Because the LCD is made of glass, if lost, the impact will certainly cause rupture, so the design of the whole machine must be considered when the assembly method, assembly of vibration and impact resistance performance.

As the LCD is low-voltage, micro-power, liquid crystal material resistivity is very high (up to 1010Ω.cm or more), so the glass surface conductivity due to moisture is enough to affect the display. Between segments will produce a “crosstalk” display. Therefore, the entire machine design should be considered moisture-proof, the chassis is well sealed, and even the use of laminated conductive rubber strip.

If the pin is TFT LCM, the LCD should be installed 2mm or more away from the line board, and can not be too much force, heat too high, so as not to destroy the connection. The maximum temperature resistance of the connection shall not exceed 80℃. No detergent shall be used at the tube foot because the detergent will decompose Cl2 in daylight and form hydrochloric acid after absorbing water thus corroding the electrode.

Liquid crystal and polarizer are organic, the photochemical reaction will be produced under UV light irradiation, so it should be considered according to the LCD use conditions and the environment whether the device needs to prevent UV light filter.

Because the surface of the LCD device is a plastic polarizer, so the assembly, use should absolutely avoid hard object scratches, staining, TFT LCM on the surface of the polarizer have a layer of protective film, so as not to cause scratches, staining. When assembling, the protective film should be removed at the end of the assembly. Even so, it is best to wear cotton gloves during installation and operation to avoid staining by hand sweat, oil, cosmetics, etc. If it has been stained, it should be promptly treated with a fine cloth, cotton ball wipe; if the stain is too heavy and must be cleaned with solvents, only with isopropyl alcohol (glycerin), alcohol, Freon wipe, and quickly dry, but never with acetone, aromatic solvents (such as toluene and water scrubbing), otherwise it will damage the LCD surface polarizer.

Because the LCD working voltage is very low, the internal resistance is very large, so when using a multimeter (× 10K file) check, sometimes there will be a “string” phenomenon, which is due to electrode overhang, which is a normal phenomenon.

After a few hours or days of use, the electrode discoloration appears black, brown “handwriting”, liquid crystal box bubbles, resulting in the inability to display. This is due to the drive voltage DC component being too large, thus causing the electrochemical reaction caused. Check the circuit to exclude excessive DC components, and then replace the LCD with a new one. When the “word” just appeared, the LCD can be heated to above the temperature, that is, when the display surface of the display device all changes color, stop heating, natural cooling, generally can be removed from the “word”.

The causes of the chaotic TFT LCM display may be: back electrode overhang, drive for DC, power fluctuations, poor contact, battery depletion, etc. can be excluded according to different reasons.

According to real LCD manufacturing conditions, the number of normal LCD panels exceeds greatly the number of defective LCD panels. Therefore, the normal PRs greatly outnumber the defective PRs. As a result, the collected data set for training would be imbalanced if a two-class classification approach is adopted, the SVM by Vapnik [4] for example, the class imbalance problem occurs.

In practice, in addition to the class imbalance problem, the LCD defect detection also suffers from another critical problem resulting from the absence of negative information. To facilitate the following problem description, the normal PR class and the defective PR class are defined as the positive class and negative class, respectively.

The main difference between a normal PR and a defective PR is that their appearances are apparently different, as can be observed from Figure 4. The color (or gray level) of a normal PR is nearly uniform, implying that the variation of the gray-level distribution of normal PRs is very small. On the contrary, the surfaces of defective PR not only contain various kinds of textures, but also vary greatly in color, implying that the variation of the true distribution for negative class in the data space is very large. Collecting a set of positive training data that can represent the true distribution of positive class is easy, because: (1) the variation of positive-class distribution is very small; and (2) most of the LCD panels are normal (the number of normal PRs is considerably large). Therefore, the positive class can be well-sampled during the data collection stage in real practice. However, representative defective PRs are difficult to obtain in practice for several reasons. For example, there are numerous types of defects in array process, more than 10 types at least. However, not all the defects would occur frequently. Some of the defects seldom appear, for example the defect caused by abnormal photo-resist coating (APRC). The defect “APRC” seldom occurs, because equipment/process engineers maintain the coating machines periodically. Even so, the coating machines might still break down occasionally. As a result, the number of available images containing the APRC defects is quite limited. But, the APRC defect has a large variation in color and texture. Unfortunately, limited APRC examples cannot stand for all kinds of APRC defects. Therefore, the collected negative training data are most likely under-sampled. Here, the “under-sampled” means that the collected negative training set cannot represent the true negative-class distribution in the data space, which is the problem of absence of negative information. Due to this problem, numerous false positive (i.e., missing defects) will be produced if a two-class classification approach (e.g., a binary SVM) is applied to the LCD defect detection, which has been evidenced by the results reported in [7]. Compared with two-class classification approach, novelty detection approach is a better choice.

Novelty detection is one-class classification [10,35], which is to solve the conventional two-class classification problems where one of the two classes is under-sampled, or only the data of one single class can be available for training [5,6,9–11,35–40]. As analyzed above, for the LCD defect detection application, the normal PRs can be well-sampled, while the defective PRs are in general undersampled. Therefore, the LCD defect detection can be treated as a typical novelty detection problem. Accordingly, one-class classification is a better solution.

To summarize, it can be seen that the LCD defect detection suffers from two problems simultaneously: one is the class imbalance problem, and the other is the problem of the absence of negative information. For the first problem, there have been many sophisticated solutions, including sampling, cost-sensitive learning, SVM-based, and one-class learning approaches. However, the only solution to the second problem is the novelty detection approach (i.e., one-class classification approach). Therefore, one-class classification would be a more appropriate approach to the LCD defect detection application.

There are several approaches for one-class classification, such as density approach (e.g., Gaussian mixture model [5]), boundary approach (e.g., SVDD [9] and one-class SVM [40]), neural network approach [6,36], and reconstruction-based approach (e.g., the kernel principal component analysis for novelty detection [35]). It has been proven in [9] that when a Gaussian kernel is used, the SVDD proposed by Tax and Duin [9] is identical to the one-class SVM proposed by Schölkopf et al. [40]. This paper focuses on the SVDD since it has been applied to the same application in the works of [7] and [10], and has shown to be effective in detecting defective PRs. However, as discussed in Section 1, generalization performance of SVDD is limited. Therefore, the intent of this paper is on proposing a method to improve generalization performance of SVDD, and applying the improved SVDD to the LCD defect detection treated as a novelty detection problem. The improved SVDD is called quasiconformal kernel SVDD (QK-SVDD). Note that the QK-SVDD and SVDD are not two independent classifiers. To obtain QK-SVDD, one has to train an SVDD first, which will be introduced in Section 2.4. In the following part of the paper, we first introduce the defect detection scheme, and then derive the proposed method in details.

I recently got a new LCD TFT Display Shield and when I try anything it only shows white! I can use the touchscreen library with no problems and can get coordinates but i can"t show anything on the display! I just tried with the ADAFRUIT library and another one called TFTLCD.

Many LCD technologies, such as monochrome character, dot matrix and segment displays, make use of ITO glass. Even though ITO glass has been in existence for some time, it is still an important aspect in LCD designs and will be covered in the article below.

The article about ITO glass was written by Barbara Dutra, an exchange engineering student from Brazil, who is currently an intern at Focus Display Solutions. Her current job responsibilities include ISO certification, Test and quality insurance of inbound LCD displays and writing technical articles.

But that does not rule out this option because the processing power is in expansion. Anyway these free indium techniques do not solve a fundamental problem: with or without touch, the electrodes that provide power to the pixels on the LCD screen depend on the ITO glass. This will be solved only with the development of new materials that emulate the highly desirable ability of the ITO glass to combine transparency and conductivity.

It is safe to say that the cost of LCD displays does not look to be decreasing any time soon, if at all. Part of the reason for higher cost displays is not only the potential cost increase due to an ITO shortage. But a labor shortage that is taking place in many LCD manufacturing locations.

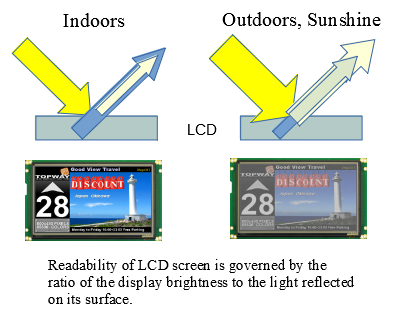

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

Because every point on the TFT LCD screen maintains that color and brightness after receiving the signal, it glows at a constant rate, rather than constantly refreshing the bright spots as the cathode ray tube display (CRT) does. As a result, the TFT LCD is of high quality and does not flicker, reducing eye fatigue to a very low level.

For displays of the same size, the visual area of the TFT LCD screen is larger. The visible area of the TFT LCD is the same as its diagonal size. Cathode ray tube display screen picture tube front panel around an inch or so of the border can not be used for display.

The original LCD screen is usually used in electronic watches and calculators because it is unable to display delicate characters. With the continuous development and progress of liquid crystal display technology, character display begins to be exquisite, but also supports the basic color display, and gradually used in liquid crystal TV, camera liquid crystal display.

The subsequent DSTN and TFT were widely made into liquid crystal display devices in computers, and DSTN LCD screens were used in early notebooks. TFT is used not only on laptops (most laptops now use TFT displays), but also on mainstream desktop displays.

The display material of the traditional display screen is phosphor, which is shown by the impact of the electron beam on the phosphor. The electron beam produces strong electromagnetic radiation in the moment it hits the phosphor. Although there are many display products in dealing with the radiation problem more effectively, as far as possible to reduce the amount of radiation to a very low, but to completely eliminate it is difficult. Relatively speaking, the TFT LCD screen has an innate advantage in preventing radiation because it does not exist at all.

In the aspect of electromagnetic wave prevention, TFT LCD screen also has its own unique advantages. It uses strict sealing technology to seal a small number of electromagnetic waves from the driving circuit in the display, while ordinary displays in order to emit heat. The internal circuit must be in contact with the air as much as possible so that the electromagnetic waves generated by the internal circuit "leak" outward in large quantities.

TFT LCD screens are digital and do not use analog interfaces like cathode ray tube color displays. In other words, with the TFT LCD, the graphics card no longer needs to convert the digital signal into an analog signal and output it as usual. In theory, this would make the color more accurate and perfect.

A traditional cathode ray tube display is always dragged behind a bulky ray tube. The TFT LCD breaks through this limit and gives a whole new feel. The traditional display screen emits electron beam to the screen, so the neck of the picture tube can not be very short, when the screen increases, it is necessary to increase the size of the whole display.

On the other hand, the TFT LCD screen controls the liquid crystal molecular state through the electrode on the display screen to achieve the display purpose. Even if the screen is enlarged, its volume will not increase in direct proportion, and its weight is much lighter than the traditional display with the same display area.

Compared with the traditional display screen, the TFT LCD screen starts with a pure flat glass panel, and its display effect is flat at right angles, giving people a refreshing feeling. And it is easier for LCD to achieve high resolution on a small screen. For example, a 17-inch LCD can achieve a good resolution of 1280 × 1024. On the other hand, the effect of using a resolution of more than 1280 × 1024 on an 18-inch CRT color display is not entirely satisfactory.

The traditional display screen is composed of many circuits. When these circuits drive the cathode ray picture tube, they need to consume a lot of power, and with the continuous increase of the volume, the power consumed by the internal circuit will certainly increase. In contrast, the power consumption of TFT LCD is mainly consumed by its internal electrode and driver IC, so the power consumption is much smaller than that of traditional display.

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Tft Lcd Screen, Touch Screen, Touch Screen Monitor With Stylus, Round Tft Lcd Display Panel,Curved Lcd Panel. All of the time, we have been paying attention on all information to insure each product or service glad by our customers. The product will supply to all over the world, such as Europe, America, Australia,Ethiopia, Greek,Netherlands, Nepal.The quality of our products is equal to OEM"s quality, because our core parts are the same with OEM supplier. The above products have passed professional certification, and we not only can produce OEM-standard products but we also accept Customized Products order.

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Industrial Tft-Lcd Panel, Lcd Monitor, Medical Tft-Lcd Panel, Face Recognition Tft-Lcd Panel,Touch Displays/Screen. As an experienced group we also accept customized orders. The main goal of our company is to build up a satisfying memory for all customers, and establish a long-term win-win business relationship. The product will supply to all over the world, such as Europe, America, Australia,Russia, Holland,Boston, Qatar.Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don"t hesitate to contact us. We will do our best to meet your needs.

China"s first 8.5-generation TFT-LCD production line was launched in Bengbu, East China"s Anhui province, on June 18, 2019, representing a breakthrough in the production of high-definition LCD screen, Science and Technology Daily reported.

TFT-LCD, or Thin Film Transistor Liquid Crystal Display, is key strategic material of the electronic information display industry. The Gen 8.5 TFT-LCD production line, launched by the Bengbu Glass Industry Design and Research Institute of the China National Building Material Group, will produce high-definition LCD screens of 55 inches, the report said.

According to the Liquid Crystal Branch of the China Optics and Optoelectronics Manufactures Association, the demand for TFT-LCD in the Chinese mainland was about 260 million square meters in 2018, including 233 million square meters" Gen 8.5 TFT-LCD. However, the annual supply of domestically made TFT-LCD is less than 40 million square meters, with all of them Gen 6 or below, which cannot meet the demand in scale and quantity.

The association predicted that China"s market demand for Gen 8.5 TFT-LCD or above will exceed 300 million square meters by 2020, accounting for 49.6 percent of the total global demand.

The production and control precision of Gen 8.5 TFT-LCD is comparable to that of the semiconductor industry, representing a higher level of large-scale manufacturing of modern glass industry.

The institute in Bengbu, with 60 years of expertise in glass, has finally made a breakthrough in the production of Gen 8.5 TFT-LCD, and will provide key raw material guarantee for China"s LCD panel industry after it goes into mass production in September, the report said.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey