lcd panel tape free sample

Our mission is to help companies create customized adhesive products. Our value is in our creative engineering solutions, our relationships with our partners and our expertise in the tape and flexible material world.

UltraTape’s unique tapes are designed specifically for Medical and Pharmaceutical applications. All tapes can be irradiated to meet the strict requirements of these industries.

UltraTape 1114P is a low adhesion, cuff sealing polyethylene tape used to ensure an effective seal between the glove and garment, protecting the product and worker. 1114P low adhesion tape is perforated at convenient 4-inch intervals to allow the operator to use one hand to apply the tape. Gamma irradiated version also available. Additional Product Specifications for 1114P.

UltraTape 7155 is a high tensile, premium grade, saturated crepe paper with a tinted stripe of color changing ink that produces a dramatic color change upon autoclave process completion. Autoclavable steam indicator paper is designed for high temperatures. Adhesion to non-woven and muslin fabric as well as plastic and metals. Additional Product Specifications for 7155.

UltraTape 7160 is a medium adhesion tape able to withstand 273° F (134° C) for +30 minutes, entire roll can be autoclaved. Medium adhesion vinyl tape is writable with a ball point pen. Vinyl tape is used for product labeling, color coding, and bag sealing during the autoclave process. 7160 medium adhesion vinyl tape is also available in gamma irradiated for use in a sterile environment. Additional Product Specifications for 7160.

UltraTape 7512 is a medium density polyethylene tape, excellent for gap sealing of doorways and pass-throughs. 7512 gap sealing tape offers excellent conformability, is removable and residue-free.

SEGDesign frames are high-quality silicone edge graphic (SEG) frames used to make fabric displays. With Banner Ups KederTape LITE and SEGDEsign you simply snap the frames, no tools needed! Create beautiful eye-catching fabric signs with Banner Ups SEG Kedertape system.

KederTape LITE is special because you don’t have to sew it into the fabric. The tape is coated with a unique adhesive that sticks to fabrics. No more barrier to entry for those who don’t have sewing capabilities. Jump into the profitable soft signage market today with KederTape LITE!

Gallery System Clear Tape picture hanging systems offer barely visible art hanging against light colored walls, using our economical Classic hooks that adjust with an included wrench — a great gallery hanging system for home use!

This example by Scotch Tapes shows how brands can use this full pallet display to its full effect. Since it occupies a lot of space inside a store, you can put as many products as you want of your brand. This way, you don’t have to stock them in the aisles along with the others.

Customizing your packing tape is a simple, cost-effective way to advertise your brand. With your logo emblazoned on every piece of tape your box has on it, each box becomes a miniature billboard promoting your business. Ensuring the packing tape is of good quality enhances the impact of the promotion. Custom-branded packing tape, made of premium material, proves your brand"s dedication to exceptional products delivered in distinctive packaging.

At Tape Jungle, we know that deciding which custom-printed tape to select can be challenging. First, packing tapes come in various sizes, and size is just one of our tape"s customizable features. The material, colors, font, and logo style are also customizable. All of this is great for creating unique and memorable packing tape, but it can be overwhelming if you"re unfamiliar with the process of customizing packing materials.

Second, when you place your order online, you can view a virtual copy of your custom tape. The virtual copy allows you to confirm all your choices before finalizing your order. However, the physical product will look slightly different than the computer mock-up, which can be frustrating if you"re not expecting those changes.

It can take testing to determine which tape or tapes will work best for your needs. Since you need a clear idea of what you want when you order custom logo tape, Tape Jungle is now offering custom-printed tape samples. Discover more about Tape Jungle"s customization process, how to order sample tape rolls, and everything you need to know about using tape to market your brand effectively.

With Tape Jungle, you can order sample rolls of our three most popular custom-printed tapes: polypropylene tape, PVC tape, and water-activated paper tape. When you select the packing tape, you can also choose a grade such as general purpose, heavy-duty, or industrial. The sample rolls display all available printing options to help you visualize the final product.

Standard bleed or full bleed. Bleed is the section of the print trimmed from the final product. With standard bleed, the printed material extends about 1/8 of an inch beyond the main printed design, while full bleed print extends from one edge of the paper to the other. If you have a large design printed on a small tape, full bleed minimizes the risk that part of your design will be accidentally cut off.

Polypropylene tape is also known as PolyPro. It is a low-cost, versatile tape made with an acrylic or rubber adhesive. Its high strength and low stretch properties make it a popular choice for packaging, especially when mailing those packages long distances. PolyPro tape has a glossy finish and is 85 to 90 percent opaque. It is a good, multipurpose tape that is useful for businesses of all sizes.

General Purpose: The general-purpose grade is excellent for everyday use. It is an effective sealant for packages weighing 1 to 30 pounds. With a glossy finish, the grade results in professional-looking packing tape for an affordable price.

Hi-Tak: Hi-Tak grade can withstand colder temperatures without losing its adhesion. We recommend Hi-Tak for sealing cartons with slippery surfaces, such as laminated boxes, recycled corrugated boxes, and even steel containers. Hi-Tak PolyPro tape has excellent edge tear and split resistance. The weight recommendation for this tape is also 1 to 30 pounds.

Industrial: Industrial grade is 20% thicker than heavy-duty grade, which gives it even more tensile strength. This tape can hold packages weighing 60 to 90 pounds. It"s perfect for shipping heavy items like machinery parts or large kitchen appliances.

Our polyvinyl chloride (PVC) custom tape is softer than standard polypropylene packing tape. Most PVC tapes use a natural rubber adhesive with a thin film backing made of polyvinyl chloride, hence the tape"s name. PVC tape has a flat finish and is 90-95% opaque. If you don"t have the budget for mechanized tape application, don"t worry; you can apply PVC tape with a handheld packing tape gun.

As the name implies, the adhesive on this tape activates by applying water to it. When activated, the adhesive bonds the tape to cardboard fibers, creating an impenetrable seal. It is impossible to open a box taped with water-activated tape without damaging the seal, making the tape a great theft deterrent. Water-activated paper tape is a simple and effective choice if you want tamper-evident packaging.

Another benefit of water-activated paper tape is its eco-friendliness. The packing tape, made from recycled materials, can be recycled after use. You can also advertise using this tape to promote your brand"s environmental responsibility.

Water-activated paper tape has a matte finish and is 100% opaque. Applying this tape requires a specialized dispenser, but you can easily purchase a high-quality tape dispenser online.

General-purpose works for packages weighing 0 to 30 pounds. This tape has 0% transparency, so no one will be able to see what"s inside your boxes even if the seal is applied unevenly.

Many of Tape Jungle"s customers are practical, business-minded people. They operate on an "I"ll believe it when I see it" basis. If this sounds like you, we have good news: you can test out a sample of our customizable tape whenever you want. Select any of the above packing tapes, pick a grade, width, and color, and choose how many rolls to order. You can order as little as a single roll or start with a dozen rolls to fully experiment with your new tape. The samples are just $1.00 per roll, so placing a sample order is a low-risk, high-reward investment.

Ordering sample custom-printed tape lets you test the material and its print quality. If you want a good logo tape, we recommend ordering a few rolls with slightly different variations of your logo so that you can pick the version that looks the best. We will keep your design plates on file, so you can easily re-order any custom packing tape designs.

Do you still have questions? We would love to answer them. Our support team is reachable via phone, email, or web chat. Additionally, you can schedule a 15-minute review session. We are committed to customer service that is just as reliable as our premium tapes. Join the Tape Jungle partnership and sample our custom-printed packing tape today.

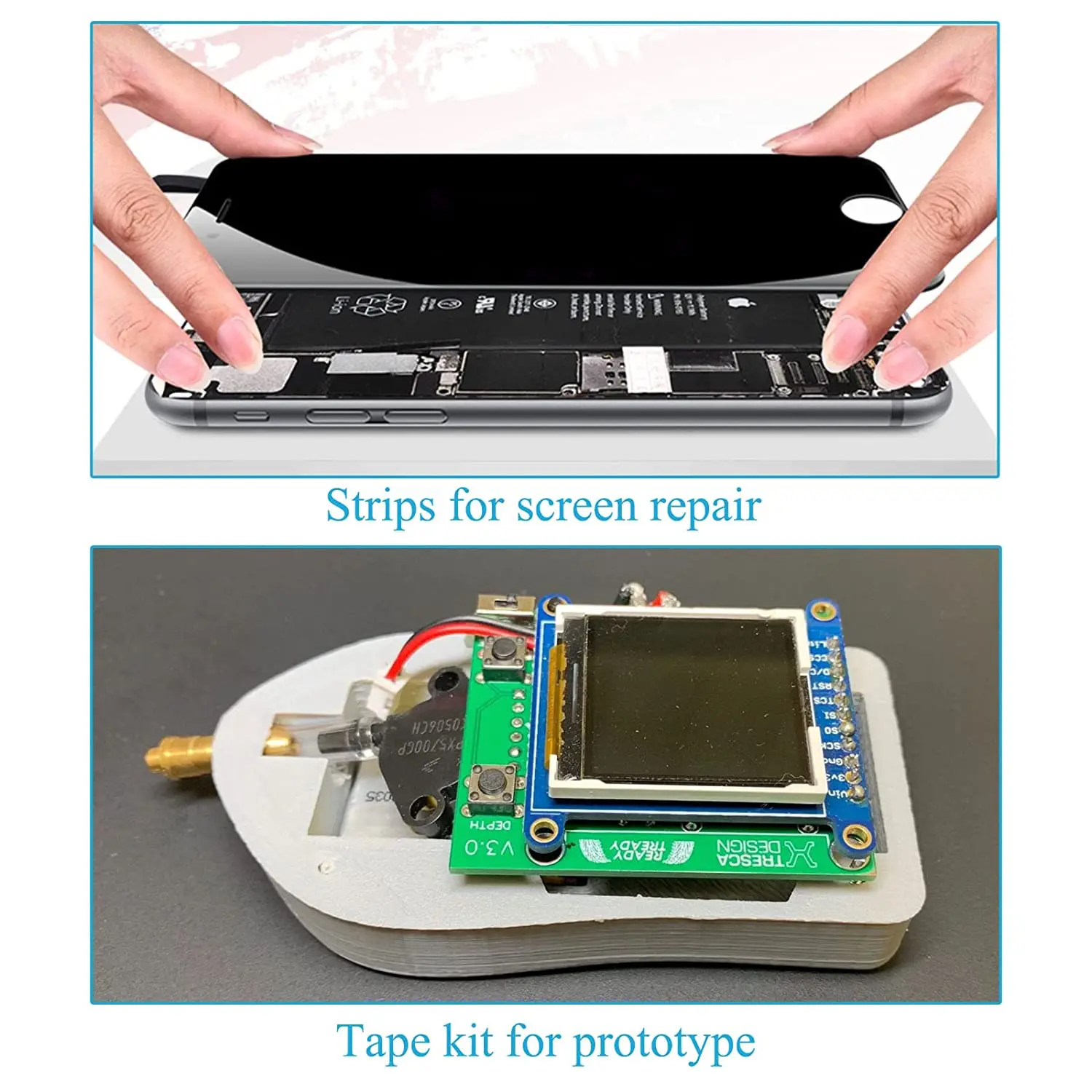

Displays and touch panels are at their best when they perform with highly transparent, low-haze, and UV-resistant features. Adding an optically clear adhesive to your LCD’s stack up promotes these features. Liquid optical bond can prove to be expensive. OCA bonding is considered a safe and effective alternative to the liquid optical bond method. Like liquid clear adhesives, OCA reduces the reflection layers in a panel. There are various advantages to choosing OCA bonding as your preferred integration method. OCA bonding is clean, which eliminates the need to clean up residuals after the bonding process is complete. The process produces high yield and is repairable.

OCA bonding is thin, making it an ideal choice for rigid bonding and small LCD frames. Our OCA adhesives are precisely adjusted to fit LCD panels 12” or smaller. The material is considered a dry film, its pressure-sensitive application allows for precise and unique processing in which it fits into your industrial LCD. Although thin, bonding protects the LCD against environmental factors as well as foreign contaminants and abrasive material. Applications include laminating films to rigid or flexible substrates; laminating together two rigid substrates; bonding touch panels and cover lenses; bonding displays to cover lenses or touch panels.

Our experienced team services each industrial panel model individually to diagnose cover glass irregularities. After ensuring repairability, our professional team uses an advanced optically clear adhesive to fuse the LCD and new cover glass, creating a blemish and scratch-free surface. Our advanced OCA prevents and protects end-user’s industrial panels from further damage due to natural wear and tear.

Lowered optical clarity due to increase in glare layers: the addition of a single piece of glass will create two additional reflective surfaces which trap glare, not only from ambient light but can even produce glare from the actual LCD. Adding an AR film does not match the level of clarity and visibility achieved with OCA bond.

Optical bonding is the process of adjoining the LCD and touchscreen or cover glass together to create a single optical index. Put simply, the air gap between the LCD and the cover glass is eliminated, therefore benefiting the LCD’s optical functionality and reducing the number of reflection points. Creating this singular optical index adds clarity and viewability to the display’s screen. Our bonding is performed with a proprietary adhesive, which is solidified with a quick but reliable curing method.

Why add an optical bond to your display? Besides creating a single optical index, there are other benefits to adding an optical bond to your LCD. Most LCDs have plastic surfaces that are not vandal or weatherproof. This component is called a cover lens. The material does not hold up well against scratches or damages, leaving your LCD with large vulnerabilities. To protect your LCD display, you will need to install a cover glass or other strengthened polycarbonate material to the LCD for protection. Adding this hardened substrate will require a bond. Adding an optical bond improves resistance against shock and vibration, which benefits those using their display in a volatile or rugged environment. Lastly, eliminating the gap prevents dust, moisture and condensation ingression, keeping your LCD readability and clarity at superior levels.

Our optical bonding service is the most robust ruggedized bonding service AGDisplays has to offer. Augmented optical performance including increased luminance, increased contrast, and reduced internal reflections. Optical bonding creates superior LCD strength and prevents a shattering screen and less vulnerable to contamination and moisture. Increase the quality and lifespan of your LCD while keeping replacement costs low with this service. AGDisplays is capable of low and high volume production. Full lamination may include outer substrates consisting of adhesive and elements such as mesh and other optical films.

Our optical bonding method is performed in-house by a skilled technician on any sized LCD. Each LCD is carefully handled throughout the technical process. Quality assurance measures and testing are performed on each LCD to guarantee your specifications are met. We strive to meet the needs of medical, military and other specialty markets and ensure that each product maintains high quality standards.

When optical bonding is not practical for your LCD, AGDisplays offers tape, or perimeter, bonding. Perimeter bonding helps your company save on costs while still ruggedizing your panels sufficiently. Our tape bond services provide a secure bond that increases productivity, long-term durability and improved appearance. The adhesive offers a wide temperature specification, allowing durable placement of the touch screen to the LCD in various environments.

Our technical experts use a class 1000 clean room to manually perform each bond with precision. Manufacturing yield for perimeter bond is high and is a cost-effective & common solution. AGDisplays offers tape perimeter touch screen and shield front perimeter bonding. Consult AGDisplays today to speak with a representative about which option is best for your project. AGDisplays supports virtually any manufacturer of LCD and touchscreen. For cover glass shield protection, AGDisplays can work with your requirements to offer products and glass materials to achieve your exact requirement.

Turn the panel over so that you"re working on the front of the panel. Place the panel on a book or the edge of the table, so that the pins hang over the edge and don"t get damaged while you"re working on the panel.

Select the top film and orient the film so that the arrow on the film label points to the side of the panel with the pins, then peel the protective film layer off the bottom film. This is the side with the sticker.

Peel the adhesive release film away from one edge and apply that edge of the film to the top of the panel panel and press it down with your finger. Gradually peel back the adhesive release film and use the card or roller to work the air out from under the film. If you see an air bubble form, gradually lift the film past the bubble and then reapply.

Use the razor blade to trim the film to the left and right sides and the bottom of the panel. If the film hangs over the top of the viewable area of the panel, that"s fine, but do not try to trim it from the top side, as the IC and conductive traces are easily damaged.

Remove the white backing from the factory graphics and align the bottom edge to the panel. Make sure that the graphics are evenly spaced on the polarizing film. There should be approx 1/32" gap between the bottom side of the panel and the start of the black border. There should be approx 1/32" gap between the left and right sides of the glass, and the black border of the graphics. Stick down the bottom edge of the graphics.

Over at my company we have been having issues with finding a secure and cost affective way to label our floors so that the drivers know which area they are in and the safe speed to proceed in that area. So far I have used this clear product in only 1 of our storage facilities. But because this tape is exactly the perfect fit I am thing to have it in all of our facilities by the end of next year.

Add a bit of string and tape to turn that fallen branch you found on your hike into unique decor. It’s the perfect way to bring in a natural element amongst your other photo display ideas. (Note: You can also use a hole puncher to string through holes in your prints... your call!)

Your walls will thank you for this one. Skip the nail holes for colorful borders by using washi tape to create makeshift frames. By leaving a little space between the prints and tape, you can give it a gallery effect and keep your prints from getting damaged. (This is where the poster tape comes in.)

Have a lot of prints to display? The more photos, the better the grid! We recommend using a ruler to space out your prints to keep your grid clean and consistent. Not to say you can’t also experiment with angles and spacing a bit to produce a more creative photo display. Just make sure you use poster tape so that you don’t damage your wall or prints.

We’re saying no to the stigma against tape. When used the right way, it’s a simple, tasteful shortcut to getting those prints up on the wall. You can use accent tape to add a little color or parchment tape to keep things classic.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey