tft display layers made in china

In ruling NY N320557 (August 4, 2021), Customs and Border Protection (CBP) discussed the country of origin of five Thin Film Transistor – Liquid Crystal Display (TFT-LCD) modules. All five modules are virtually identical in composition, as they are all composed of a TFT-LCD cell, polarizers, a backlight, a driver and control printed circuit board (PCB), and a flexible PCB for connection. TFT display technology allows for the construction of high-resolution LCD displays, and the modules – once completed – can be incorporated into a variety of consumers display applications.

The manufacturing process for the five modules is also identical. The process begins in Japan where the TFT-LCD cell is manufactured. The TFT is created by depositing transistors onto a substrate through chemical vapor deposition, while the color filter is manufactured by building a color matrix on a glass substrate. The creation process of the cells is then completed when a layer of liquid crystal is deposited between the color filter and TFT as the two part are bonded together, creating a sheet of TFT-LCD cells. As next steps, the sheet of cells is delivered to China to be cut into individual cells. The cut-up cells are then bonded to the printed circuit board assembly (PCBA) – which contains the driver and control circuity – before the polarizers, backlight, and flexible connection PCBA are attached.

CBP also established that “substantial transformation” takes place when a particular product “emerges from a process with a new name, character or use different from that possessed by the article prior to processing.” The agency explained that the completed TFT-LCD cell is what imparts the essential function of the module and that the manufacturing process in Japan is what renders the end-use of the product. Despite the assembly that took place in China, the process did not substantially transform the cell into a new and different article. As such, CBP determined that the country of origin of the five modules is Japan.

Putting together a machine with a TFT LCD module requires immense accuracy and attention to detail. And this is indeed true if you’re a manufacturer of a crucial machine such as a ventilator.

Ventilators are essential medical equipment that can help save the lives of critically-ill patients. These machines are most needed nowadays, what with the increasing number of people getting sick from COVID-19 and other respiratory diseases. Hence, it’s important to use the best touch screen display module for ventilators to ensure that the machine works its best all the time.

This post is meant to raise awareness on why TFT-LCD modules are the best types of display panels for ventilators in china. We’ll also give you a brief preview of what ventilators are, how a TFT LCD display module works for a ventilator machine, and why a touch screen TFT LCD screen is the best choice for ventilator screens.

Ventilators are made up of many parts, all working together to provide life support to patients with breathing problems. Ventilators vary in designs depending on their manufacturer. However, the general parts of all ventilators include the following:Touch screen LCD display for patient monitoring and control settings

Modern ventilators in china now use TFT touch LCD display monitors. This is a big leap from the old ventilator models with minimum to no monitor displays.

A TFT color LCD display allows the ventilator to accurately display patient monitoring parameters and machine settings. This is possible because the combination of TFT-LCD technologies results in high-resolution images displayed on the screen. And since the ventilator is a critical life-saving machine, an accurate display is of tantamount importance.

Before the advent of the touch LCD module, ventilators use buttons and dials to operate various machine settings and control patient alarms. But with the use of a touch screen LCD display, it’s easier to silence alarms, adjust machine parameters, and check on a patient’s vital signs.

Now, using a TFT touch LCD display screen makes ventilator cleaning easier. This is because the screen is predominantly flat in a ventilator with a touch screen interface. Furthermore, there are fewer buttons and dials in such ventilators. A machine with plenty of buttons and dials makes for a good breeding space for harmful pathogens, as they’re harder to clean than those with flat touch screen interfaces.

As previously mentioned, a ventilator with a touch LCD display screen has fewer dials, knobs, and buttons than those who use a non-touch TFT LCD display. And this is because of a touch screen’s multifunctional nature. The screen can display content while acting as an interface device at the same time.

Machines meant to help patients breathe aren’t necessarily portable and lightweight. But using a touch TFT LCD display screen makes a full-blown ventilator significantly less bulky and more portable.

Imagine if you’d use an old display technology such as cathode ray tubes to power a ventilator’s display system. Now, that would be impractical and bulky.

TFT-LCD modules are made up of thin-film transistors built within the LCD-containing glass. Such a module makes the finished ventilator screen lightweight and thin.

A small TFT-LCD monitor with touch screen technology can also be used for ventilators that are meant to be portable. Examples of such portable breathing machines are those used on emergency vehicles and operating rooms.

There are several kinds of touch screen technologies that touch screen display suppliers and manufacturers use to power a ventilator screen. But the capacitive touch screen is the one that’s most widely used. Here’s an overview of what this touch screen technology is.

In this technology, the display panel is made up of a glass sheet with transparent electrode films embedded in it. An integrated circuit chip is added to create an electrostatic field that is three-dimensional.

Lots of industries use PCT in their machine displays, including the medical field. For instance, an increasing number of ventilators now use TFT LCD capacitive touch screens with PCT technology for their displays.

Rarely will you find a modern ventilator being powered by touch screen technologies other than capacitive ones? And this is for good reason! Here are the benefits clinicians can enjoy while using a ventilator with a TFT LCD capacitive touch screen:

Capacitive touch screen panels provide significantly better image clarity than other technologies. For instance, compare the output clarity of capacitive versus resistive technology (touch screens for ATMs and supermarket kiosks). Resistive touch screens have poorer clarity because the actual image display is right behind the protective glass layer. This isn’t the case in capacitive screens.

Furthermore, pairing up a capacitive touch screen with a TFT LCD module ramps up the output’s clarity. This is extremely needed in ventilator displays to ensure that clinicians and other health care workers clearly see the patient’s vital signs and machine parameters. This will eventually aid in better evaluation of the patient’s breathing status and general condition.

Capacitive touch screens are easier to use since they don’t require pressure to detect and respond to touch. A simple gentle touch is all you need to operate the ventilator’s display! Using a projective capacitive touch screen (PCT) makes a TFT LCDscreen even more friendly to the gloved fingers of health care workers and clinicians.

Capacitive touch screens are a perfect match for life-saving devices such as ventilators. This is due to its durability and extreme resistance to liquids and surface contaminants like grease and dust. A TFT LCD capacitive touch screen is also easy to disinfect once contaminated.

Most TFT LCD module manufacturers recommend disinfectant wipes with less than 70% alcohol for disinfecting touch screen ventilator screens. However, the disinfecting agent may widely vary amongLCD screen manufacturer guidelines or hospital protocol, so be sure to double-check them first.

To conclude, we’ve talked about touch screen display modules and why it’s the best choice to use for medical ventilators. We also tackled some facts about ventilators to further understand why touch screen LCD display modules are often used for their screens.

TFT-LCD display modules are good for ventilators because they make the machine lightweight, portable, easily cleaned, and easy to operate. Such modules also create clear and crisp screen displays.

If you are a ventilator manufacturer in china, consider using a touch screen LCD display for your next ventilator design. Look for a reputable touch LCD display manufacturer who can provide you with high-quality TFT LCD touch screen modules for your breathing machines. Remember, your ventilators will save patient lives, so choose the best TFT LCD modules with a touch screen display now!

The TFT LCD touch screen is a crucial part of the breathing machine. As a touch solution provider, Ever Glory has served many professional ventilator manufacturers all over the world in the past. We will provide effective guarantee and support to each ventilator manufacturer, ensure the smooth process of the whole ventilator production and rapid development, and do our best to alleviate the situation of ventilator shortage.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

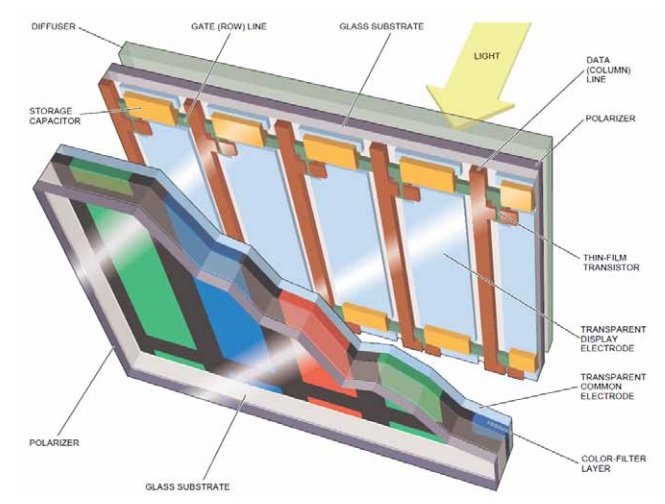

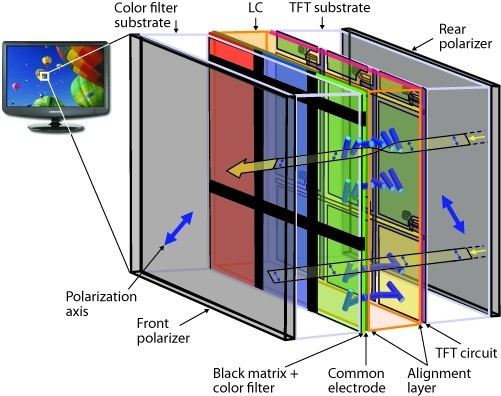

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

TFT displays have become increasingly common in our daily lives. They are used in cars, laptops, tablets, and smartphones, as well as in industrial applications and many more. But what are TFT displays and why are they so important?

A TFT (Thin Film Transistor) display is a type of display technology that uses a thin layer of transparent material to produce an image on the screen. The display is made up of thin layers of organic material called organic transistors, which are stacked together on a glass substrate and covered with a thin layer of plastic or metal oxide.

TFT displays are also used in many other industrial applications, such as industrial control systems, medical devices, automotive infotainment systems, and more.

The basic concept behind a TFT display is simple: it uses light to create an image on a screen. Light passes through the glass substrate and the organic transistors until it reaches the top layer of the display.

The number of pixels that can be displayed depends on how many organic transistors are used in each pixel or subpixel (a single-pixel is made up of multiple subpixels). For example, a 4-inch (10 cm) display has a pixel pitch of 0.0625 inches (1.57 mm).

The basic design of a TFT display has remained unchanged for more than 20 years. In this design, the sub-pixels are arranged in a grid pattern, with each subpixel connected to its neighbor by wires that form rows and columns.

The first large format TFT display was introduced in 1987 by NEC Corporation, which used a 1024×768 pixel screen for its PC monitor line, called CRT Professional Display System or “Videotronic” system. The technology was licensed to NEC’s competitors such as Hitachi and Toshiba for use in their own monitors and televisions. The system was marketed as “Super Video” and replaced the aging “Videotron” CRT monitors that were still being used at the time. The first LCD TV was also produced in 1987 by Sony.

In 1989, Sharp’s first TFT-LCD TV set was introduced with a resolution of 576×320 pixels, while the world’s first large format high definition screen with a resolution of 1024×768 pixels was introduced by NEC in 1994.

Over the years, TFT display technology has developed by leaps and bounds. It has been used in tablets, smartphones, notebooks, game consoles, and computer monitors. The technology is also used in digital cameras, camcorders, MP3 players, and GPS devices.

What does the TFT display technology comprise? From far, you can easily assume TFT to be a single unit. But in reality, it comprises different components that work together.

The backlight of the TFT display is a very important component. It provides the light for the pixels and is also responsible for illuminating the display. The light emitted by a backlight can be controlled by varying the amount of current running through it.

When it comes to LCD displays, there are two types of backlights; Active matrix and Passive matrix. Active matrix backlight has several layers of electrodes, which are used to control the amount of current flowing through them.

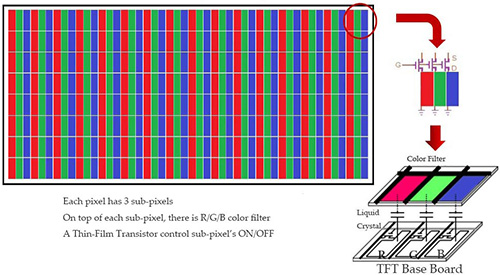

The pixel is the smallest unit in a TFT display. It is the basic unit of information that is displayed on the screen. The pixel consists of three sub-elements, namely; Red, Green, and Blue (RGB).

The number of sub-pixels that are used in each pixel varies with different display technologies. In full-color LCDs, there are three types of sub-pixel: red, green, and blue (RGB). Full color TFT displays use a combination of Red, Green, and Blue (RGB) sub-pixels to represent full color.

The light that is transmitted through each TFT is controlled by applying voltages of different values to each pixel in turn. To do this, a control circuit called a driver circuit is required. The driver circuit controls the voltage applied to each pixel with reference to a set of parameters known as “pixel information”.

This information includes color, brightness, and other characteristics that define how an individual pixel should be operated for display purposes. The parameters also include how many red, green and blue sub-pixels are used to produce each pixel.

The control system can be further divided into 3 sub-systems: the interface, the timing, and the data transfer system (DTS). These systems work together to provide all of the necessary functions for controlling TFT displays from external sources such as computers, printers, or TVs.

This is another component of a TFT display system. It consists of a liquid crystal material sandwiched between two glass plates. This material is responsible for controlling the light by changing its refractive index.

-Wide viewing angle: The viewing angle of the TFT display is larger than that of the CRT set. It is generally considered to be the best choice for applications requiring an extended viewing angle.

-Transparency: TFT display has better transparency than CRT set, which makes it more suitable for applications requiring high transparency such as window displays and computer monitors.

-High resolution: TFT display can produce higher resolution than CRT display. For example, the pixel density of TFT is about 3 million pixels per square inch (PPI), which is about three times that of conventional liquid crystal displays (LCDs) whose pixel density is about 100 ppi.

-Reliability: Since it uses no moving parts, the TFT screen does not need any maintenance or repair, and therefore the reliability is higher than that of LCDs and plasma displays.

-Power saving: TFT display consumes much less power than CRT. The power consumption of a mainstream TFT display is about 1/10 that of a typical LCD. In some applications, the power consumption can be reduced to 1/100 or less of that of a CRT.

-High brightness: The picture displayed on the screen can be bright enough to be seen in bright sunlight without any need for glare reduction filters.

-Compatibility: Since it uses no moving parts, the TFT screen does not have any mechanical problems such as screen flicker and image sticking problems found in plasma displays and LCDs.

-High resolution: Although the pixel density of TFT is about 3 million pixels per square inch (ppi), the resolution is more than 100 ppi which makes it more suitable for many applications where high resolution is needed.

-Consistency: Since it uses no moving parts, the image displayed on the TFT display is not affected by temperature and humidity, which makes it more consistent than LCDs and plasma displays.

-Cost: The cost of a TFT display is lower than that of LCDs and plasma displays. For example, in some applications where image quality is not critical, the cost of a TFT display may be only a few tens to a few hundreds of dollars while the cost of LCDs or plasma displays may be several thousand to several tens of thousands.

-Excellent color display: We can’t deny the fact that TFTs have a superior color display. This simply means that the color of pixels can be accurately reproduced.

-Very thin: When compared with LCDs and plasma displays, which are very thick, TFTs are very thin and lightweight. In addition, the cost of mounting a large size TFT screen to a wall panel is relatively low.

-No ghosting: ‘Ghosting’ refers to the fact that the display shows a bright spot on the screen when the screen is turned off. TFT screens do not show ghosting. TFTs produce a sharp image even when they are turned off.

-No geometric distortion: Geometric distortion refers to the shape of the display on a flat surface. TFTs produce a sharp image even when they are turned off.

-No radiation: TFTs do not emit any harmful radiation, and there is no need for shielding or shielding materials to protect people from harmful radiation.

Considering that TFTs use less power, it is possible to reduce energy consumption by up to 50% compared with LCDs. In addition, if you use LED backlights in TFT displays, you can reduce power consumption by up to 75% compared with conventional backlights.

If a product uses a backlight, there is a high possibility that the color of the screen will be affected after some time due to dust or dirt that comes into contact with it. But it is possible to prevent this problem by using TFTs with LED backlights, which have no problems such as those caused by dust and dirt.

Workability refers to the ease with which you can operate a product. When working with a screen that has TFTs, it is possible to increase the amount of information that can be displayed at one time. It is also possible to reduce the number of times you must change settings on a product by increasing its usability.

Design refers to what you can create with the use of a product. Using TFTs, it is possible to create products that have a thin profile and are lightweight, which makes them more convenient for transportation and storage.

Human interface refers to what you touch when using a product or what you see on the screen when using a product (e.g., buttons and other controls). By integrating the TFTs into the display part of a product, it is possible to make the human interface easier.

Amoled refers to a technology that replaces the traditional liquid crystal display (LCD) with an organic light-emitting diode (OLED). Modern TFTs are similar to Amoled in terms of their structure, but they differ from Amoled in terms of their performance.

The TFTs of the present invention have superior characteristics compared to Amoled, such as high contrast ratio and response speed. The TFTs also have superior characteristics compared to conventional display devices such as CRT and plasma display panels, which cannot be achieved by these conventional display devices.

IPS refers to a technology that replaces the traditional liquid crystal display (LCD) with in-plane switching technology. The IPS display has superior features to TFT due to its high contrast ratio, wide viewing angle, and high response speed.

There are certain limitations to TFTs. For example, there is a limit to the size of the display and the resolution of the image that can be displayed on a display. Also, because TFTs are considered to be a kind of organic semiconductor displays, they have a short life span and therefore need frequent replacement.

Because of their high resolution, TFT displays are used in display monitors. The type of TFT used in display monitors can be categorized as either active matrix or passive matrix. Active matrix TFTs use a thin film transistor (TFT) as its active component, whereas passive matrix uses a liquid crystal display (LCD).

TFTs are also being used in portable electronic devices such as mobile phones, personal digital assistants (PDAs), and cameras. These devices require high-resolution screens because the user must be able to view accurate images and text on the screen. TFTs are also being used in laptops, which have a much larger screen size than many other portable electronic devices.

Because of their size and high resolution, laptop computers use passive matrix TFT displays instead of LCDs for larger displays than those found on smaller-sized portable electronics devices that use LCDs for their displays (e.g., mobile phones and PDAs).

TFT displays are used in front-projection TVs. The type of TFT used in front-projection TVs can be categorized as either active matrix or passive matrix. Active matrix TFTs use a thin film transistor (TFT) as its active component, whereas passive matrix uses a liquid crystal display (LCD).

Head-mounted displays (HMDs) use liquid crystal on silicon technology to create small, inexpensive, low-power VR headsets that can be worn on the head. Some HMDs use active matrix TFT technology while others use passive matrix TFT technology. Active matrix HMDs use shorting bars or glass electrodes to control each pixel; passive matrix HMDs use a liquid crystal material that allows for the creation of an image by controlling the voltage applied to each pixel.

TFTs are used in projectors to create the on-screen image from the input signal. TFTs are used in both active matrix and passive matrix projectors. Active matrix projectors use shorting bars or glass electrodes to control each pixel, while passive matrix projectors use a liquid crystal material that allows for the creation of an image by controlling the voltage applied to each pixel.

CCDs are used in digital cameras and DV camcorders to capture still images and video, respectively. CCDs use a single array of photosites that each receives an electrical charge during exposure to light, resulting in an electrical signal that is output as an image. TFTs are used in CCDs as display circuits for previewing pictures.

TFTs are used in the display of gaming systems such as consoles, personal computers, and hand-held devices. TFTs are also used in the display of mobile telephones and in digital signs.

There are many factors to consider when buying a TFT display. The most important factors are the size of the display, the resolution of the display, and whether or not it is touch-sensitive.

It is also vital to consider where you are buying your TFT display system. A good place to buy a TFT display is from an authorized dealer or an online store. You should also consider whether or not the TFT display system you are looking for has a warranty.

At ICRFQ, we can connect you to the best TFT display suppliers and manufacturers in China. Just contact us and we will do what a reliable sourcing agent should do!

![]()

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp text/graphic with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The color TFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

Like an LED, an OLED is a solid-statesemiconductordevice that is 100 to 500 nanometers thick or about 200 times smaller than a human hair. OLEDs can have either two layers or three layers of organic material; in the latter design, the third layer helps transport electrons from the cathode to the emissive layer. In this article, we"ll be focusing on the two-layer design.

Inkjet printing- Withinkjet technology, OLEDs are sprayed onto substrates just like inks are sprayed onto paper during printing. Inkjet technology greatly reduces the cost of OLED manufacturing and allows OLEDs to be printed onto very large films for large displays like 80-inch TV screens or electronic billboards.

While continuously developing and absorbing advanced technology in the industry, App Based Elevator Call, Multimedia Display, Electric Lock also provides timely feedback on the latest industry information to customers, sharing information resources with customers.We make our customers better enjoy the Tft Display we provide through active cooperation, strict quality control and perfect after-sales service. We hold ourselves accountable for our business actions in the pursuit of sustainable development. We have paid attention to product quality for many years, and actively adopted domestic and foreign advanced technology and scientific management to ensure product quality. Welcome new and outdated consumers to call us for that upcoming long term small business associations. Our R&D team will follow the progress of science and technology and continue to use new technologies to design excellent products. We follow the rigorous concept of good quality, integrate the essence of technology and innovation, and integrate meticulous human nature functions into our products. We will build our own industry brand with a forward-looking vision and high-end positioning. With our professional team and top technology, we make our products perfect and beautiful and strive to be recognized by every customer.

WABON special shape screens is designed to satisfy the elevator indicator installed on the lintel. It is with rectangle display with the basic functions, as following.

TFT LCD Display (Thin-Film-Transistor Liquid Crystal Display) technology has a sandwich-like structure with liquid crystal material filled between two glass plates. Two polarizer filters, color ...

A TFT (Thin Film Transistor) display is a type of display technology that uses a thin layer of transparent material to produce an image on the screen. The display is made up of thin layers ...

TFT displays are used in home appliances, medical equipment, engineering instruments, airplanes, computer devices, TVs and more. We offer a wide range of embedded TFT touch ...

A TFT LCD , or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, ...

61 rows · US Micro Products manufactures a wide selection of TFT LCD (Active Matrix LCDs) displays to accommodate the needs of OEMs across many different industries, including ...

A TFT touch screen is a combination device that includes a TFT LCD display and a touch technology overlay on the screen. The device can both display content and act as an interface device for whoever is using it. TFTs make up the lion"s ...

Advanced quality enterprise equipment, large-scale production, fine technology, cast our Fingerprint Access Control, Access Control Touch Cop first-class quality. As one of the most professional Tft Display manufacturers and suppliers in China, we"re featured by quality products and good service. Please rest assured to buy customized Tft Display at competitive price from our factory.

Optical and SEM (scanning electron microscopy) images of fabricated (a, b) CL and (c, d) CLSE pixel structures. The five white line patterns in (d) are the ITO interdigitated pixel and common electrodes. (e) Images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel. (f) The three-black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM) and (g) optical images of pixels without BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines).

Figure 3e shows images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel fabricated in our laboratory, (f) the three black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM), and (g) optical images of panel areas without the BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines). As can be seen in the image from the normal direction, the brightness and contrast of the display area with the top BM and middle BM patterns are almost the same, but the contrast of the display area without the BM is relatively lower because of the lower darkness level of the LC off pixels indicating “HITACHI”. As shown in Fig. 3g, this is due to light leaking through the aperture between the data line and adjacent common lines. Therefore, in the CL structure, the BM on the drain line is necessary to obtain a high contrast ratio by shielding light leakage. This is the same as in the conventional structure. On the contrary, there is no light leakage along the gate line through the gaps between the gate line and edges of the pixel/common electrodes, as is clearly shown in Fig. 3g. This is a unique advantage of the CL structure because the conventional structure must shield these gaps with the BM to prevent light leakage. The suppression of light leakage along the gate line in the CL structure is due to the driving scheme (see Fig. 2b,a for a comparison with the conventional structure). During the holding period (tOFF) in the conventional structure, regardless of the pixel voltage, Vp (including Vp = 0), nonzero Vgp and Vgc are always applied to keep the TFT off, and these voltages are applied to the LC layer, inducing light leakage as reported in

Figure 4a shows the gate voltage (Vg) dependence of the panel brightness, while the inset shows that of the TFT current (transfer characteristics). The gray curves are for the conventional IPS TFT-LCD with the TFT before enhancement, the common line, and the matrix BM (MBM) shown at the top of Fig. 3f. The blue curves are for the proposed CL structure with the enhanced TFT and the stripe BM (SBM) shown in the middle of Fig. 3f. In this case, enhanced TFT characteristics were obtained by using an MNOS TFT without back-channel oxidation that was enhanced by the BTS process. In both structures, the threshold voltages for panel brightness, defined by extrapolating the straight part of the brightness curves, reflect those of the TFT transfer curves defined as Vg at a drain current of 10−12 A, and they are well matched to be 4 V and 9 V, respectively. The maximum brightness for the CL structure is 137% higher than that for the conventional structure, which is due to the increase in the aperture ratio from 38 to 52% that results from the elimination of the common line and the BM covering the gate line.

(a) Dependence of panel brightness and TFT current on gate voltage for the conventional pixel structure of 38% aperture ratio (AR) with matrix black matrix (MBM) over both drain and gate lines and proposed CL pixel structure of 52% AR with strip black matrix (SBM) over only the drain lines. Transfer characteristics before and after bias temperature stress (BTS) treatment are shown in the inset. (b) Charging and (c) holding characteristics of enhanced TFT of the CL structure with gate as a common line. Vg and Vd in the TFT ON state are 30 V and +/−7 V, respectively.

To estimate the charging and holding characteristics of the MNOS-enhanced TFT in the panel, the gate TFT ON and OFF time dependences of the panel brightness were measured (Fig. 4b,c). The charging characteristics in Fig. 4b are plotted as a function of tON at tOFF = 16.6 ms, Vg = 30 V, and Vd = ± 7 V. The holding characteristics in Fig. 4c are plotted as a function of tOFF at tON = 34 μs. 95.1% charging at tON = 34 μs and 95.3% holding at tOFF = 16.6 ms indicate that the enhanced TFT has sufficient charging and holding performance to drive a standard VGA (640 × 480 pixels) panel (the number of scanning lines is estimated as tOFF/tON = 16.6/0.034 = 488).

To confirm the driving conditions for the CL structure without the BM along the gate line (with the SBM), the tOFF dependence of the contrast ratio (CR) in the CL panel was further investigated as shown in Fig. 5a, where CR is plotted as a function of tOFF for the CL panels with the matrix BM (MBM) and the strip BM (SBM). The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. The SBM and MBM panels keep CR higher than 240 with tOFF > 16.6 ms, the frame period of a display panel without flicker being noticeable to the human eye. both panels decrease CR when tOFF is less than 16.6 ms; the CR of the SBM panel decreases faster than the CR of the MBM panel. As shown in the inset, the decrease in CR was due to the increase in dark-state brightness with decreasing tOFF as light leakage increases along the gate line. This light leakage is induced by the voltage Vgp = Vgc = VgON = 30 V applied only for 34 μs during the TFT ON (charging) state, which is 1/488th the duration, tOFF = 16.6 ms, of the TFT OFF (holding) state with Vgp = Vgc = VgOFF = 0 V, but the ratio increases with decreasing tOFF and becomes effective enough to switch on LC layer and induce light leakage. However, it should be stressed again that the CL panel with the normal holding (TFT OFF) time of 16.6 ms does not suffer from the light leakage along the gate line, so the aperture ratio can be increased by removing the BM along the gate line.

Figure 6 indicates the effect of bias temperature stress (BTS) on the TFT characteristics. As the stressing time, tS, of the positive gate stress voltage, Vst = + 77 V, increases from 0 to 3600 s, the transfer (Id-Vg) curve shifts in the positive direction (Fig. 6a). Vth is defined as Vg at which Id = 10−12 A and ΔVth is defined as the Vth shift from the initial value via BTS. As shown in Fig. 6b, ΔVth increases logarithmically with increasing tS: ΔVth = 2.17 + 4.93 × log (tS). The mechanism behind the gate-stress-induced Vth shift is electron tunnel injection from the a-Si:H semiconductor into the SiOx gate insulator. For confirmation, ΔVth of MNOS TFTs with different SiOx thicknesses is plotted as a function of the electric field applied to the SiOx layer in Fig. 6c. Here, the thickness of the SiOx was varied (5, 10, 20, 50 nm), while the SiN thickness was fixed at 200 nm. The electric field applied to SiOx, Eox, was calculated using the following equation,

Effect of bias temperature stress (BTS) on TFT characteristics. (a) The transfer (Id–Vg) curve shifts in the positive direction with positive gate bias stress of Vst = + 77 V over the duration of 0–3600 s. (b) ΔVth, defined as the Vth shift from the initial value via BTS, increases logarithmically with increasing tS, following ΔVth = 2.17 + 4.93 × log (tS). (c) ΔVth of MNOS TFTs with different SiOx thicknesses from 5 to 50 nm as a function of the electric field applied to the SiOx layer.

Figure 7a shows the effect of back-channel oxidation (BCO) and passivation (PAS) on the Id-Vg characteristics of the MNOS TFT. The Id-Vg curve with Vth = 5.1 V is further enhanced to Vth = 10.9 V after BCO, although there is a slight degradation of the slope of the current increase in the sub-threshold region. The slope recovers after PAS without any change to the enhanced characteristics

(a) Effect of back-channel oxidation (BCO) and passivation (PAS) on Id–Vg characteristics of MNOS TFT. (b) Vth and Vth standard deviation, σVth, after BTS and after BCO without BTS treatments and (c) SiOX thickness as a function of position along gate-line, x.

The advantage of BCO over BTS is the uniformity of the enhanced characteristics; Fig. 7b shows the distribution of the enhanced Vth as a function of position along gate-line, x, for the MNOS TFTs connected with a 90-mm-long gate line in the TFT substrate after BTS and BCO treatments. The average value of Vth and the standard deviation, σVth, for pristine TFTs before BTS or BCO, are 5.1 V and 0.35 V, respectively. After BCO, Vth is uniformly enhanced, with an average Vth = 11 V and σVth = 0.4 V without increasing σVth. On the other hand, after BTS, Vth is nonuniformly enhanced with an average Vth = 9.3 V and σVth of 1.4 V. In particular, Vth increases linearly as a function of position along gate-line, x. As the gate SiOx thickness linearly decreases, from (54 nm) to (47 nm) with increasing x as shown in Fig. 7c, the increase in ΔVth after BTS with x is due to increase in the electric field applied to SiOx as shown in Fig. 6c and Eq. 1.

It has been shown that the Vth of the MNOS TFT is independent of the gate SiOx thickness when the thickness is more than 5 nm8a, Vth of the MNOS TFT with the BCO treatment becomes almost independent of the BCO SiOx thickness. As shown in the inset, the thickness of BCO SiOx composed of oxidized a-Si:H linearly increases with BCO processing time, and the Vth increase almost saturates at a BCO SiOx thickness greater than 5 nm. Therefore, the enhanced MNOS TFT after BCO has a uniformly high Vth that is robust to thickness fluctuations of the gate and BCO SiOx layers. BCO also has an advantage over BTS in terms of the stability of Vth as shown in Fig. 8b, which plots the annealing time dependence of Vth for BCO and BTS. In this experiment, the stoichiometry (x) of the gate SiOx was 1.78 for BTS and 1.78 and 1.9 for BCO. The annealing temperature in the N2 atmosphere was 200 °C. In the case of BTS, Vth decreased to the pristine value after approximately 5 h of annealing, while Vth decreased more slowly in the case of BCO. In particular, the annealing time required for Vth to fall to 7 V was 7.5 times longer than that of BTS. Increasing the stoichiometry (x) of the gate SiOx dramatically improved the BCO-enhanced Vth to as much as 11 V, which was stably maintained after 24 h of annealing at 200 °C.

(a) Dependence of Vth on thickness of back-channel oxidized (BCO) SiOX. The inset shows the SiOx thickness dependence on the BCO process time for RF powers of 200 W and 500 W. (b) Stability of Vth as a function of annealing time for three different TFTs with gate SiOx stoichiometry, x = 1.78 and bias temperature stress (BTS), x = 1.78 and BCO, and x = 1.9 and BCO. The temperature of annealing in the N2 atmosphere was 200 °C. (c) Band diagram of back-channel oxidized MNOS TFT. The red arrows show the electric dipoles at the SiOX/a-Si:H and a-Si:H/BCO SiOX interfaces.

A schematic band model for the MNOS TFT with the BCO treatment and the sectional structure of the interface between the a-Si:H and gate and BCO SiOx are shown in Fig. 8c. The uniformly high Vth that is independent of SiOx thickness is due to the dipoles generated at the channel and back-channel interfaces between a-Si:H and SiOx8 of reference

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey