how to get cured resin off lcd screen pricelist

An animated explanation to “Why did this happen?” When you move up to larger resin 3d prints, you also start seeing failures. There’s no blanket answer for all print failures. But in this video, he explores a few reasons why resin 3d prints sometimes fail. And hopefully, show you how you can get better results.

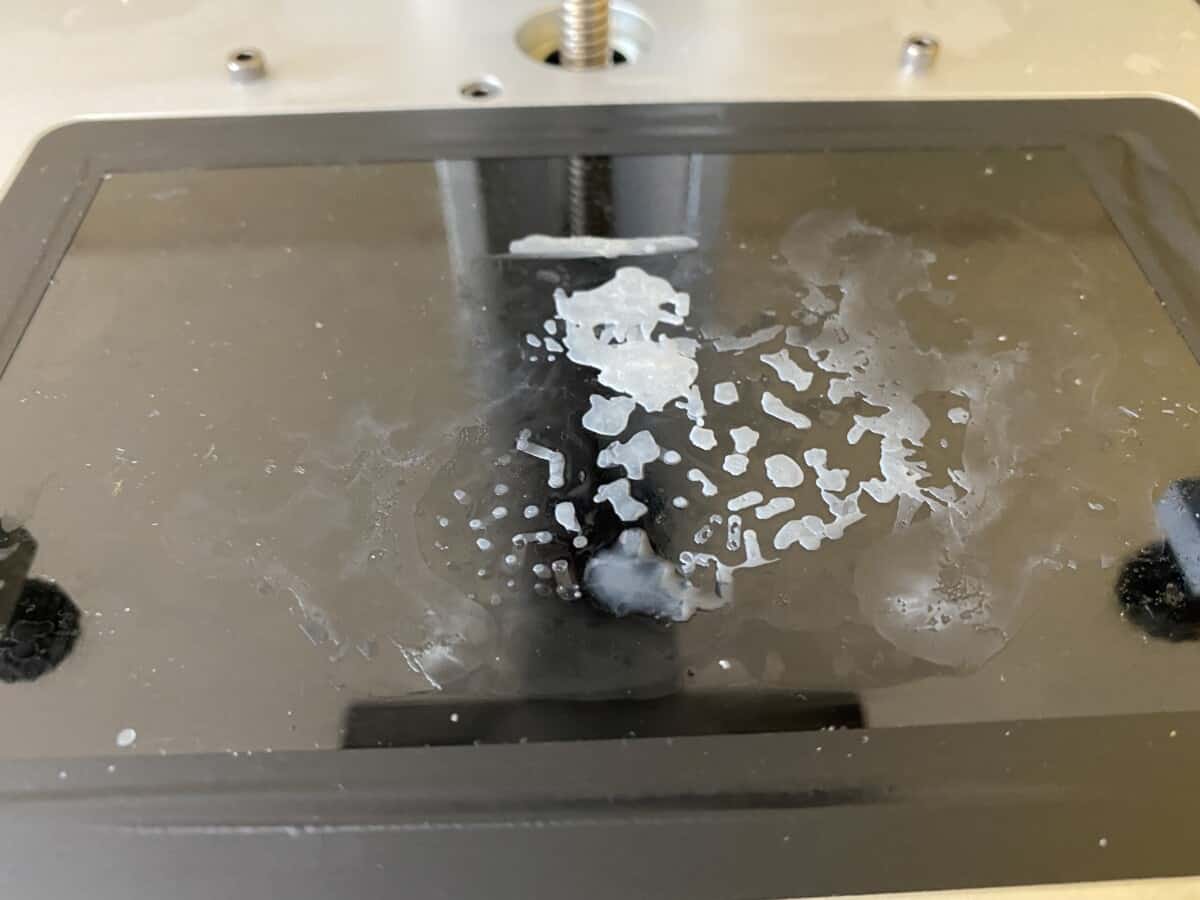

In that case, the Pendrive failed and the top pressed the failed print into the FEP perforating it. At the beginning, I wanted to cry, but I got my spatula and scrapped the shit out of the screen. I was able to remove most of it.

But I couldn’t scrap all. Do you see the top corner? I was not able to remove that little bastard. I poured alcohol and rubbed and rubbed and i was only removing the glue from the sealant. So I checked internet.

I promise that I will make a video with how I scrapped everything because I recorded it. But I wanted to let you know the solution right now before I forget to post.

The solution is a 10 dollar plastic shitty tool from Amazon. It is used for vinyl in cars and it is plainly a godsend tool. It does not damage the screen but it is enough sharp that it gets under the resin. It is plainly amazing. Best 10$ invested of my life.

Resin 3D printers are awesome, however, the whole process is extremely messy. Especially when an accident happens and the resin leaks from the vat all over the printer.

When this happens mid-print, it usually means one thing – the resin will leak onto the precious LCD of the printer and cure. This means one thing – the UV light will be blocked by the cured parts and you will probably experience holes in your printed parts.

Usually, the people on Facebook advise you to scrape the resin away with a plastic razor. This usually works for small leaks, but it doesn’t work well on large leaks.

I experienced a resin leak recently on my Elegoo Saturn. Scraping the resin was not leading anywhere and I managed to scratch the polarizer film on top of the LCD. Therefore I stopped and I decided to make a (successful experiment): use acetone to dissolve the cured resin. It worked flawlessly!

Let me start with a warning – if you decide to follow this guide, you will do it at your own risk. I tested the procedure on the pre-order batch of Elegoo Saturn with the TM089CFSP01 LCD. It is possible that later batches or different LCDs use a polarizer that is not acetone resistant. In that case, the procedure will damage your LCD! If you want to try it, try rubbing a corner of the LCD with acetone first to see if it is acetone resistant or not. On the other hand – if your LCD is ruined with resin, there is nothing you can lose.

The procedure is simple – soak the cured resin with acetone to soften it and scrape it away. However, the acetone evaporates quickly, so simply pouring it on the screen does not work (as it evaporates), nor rubbing an acetone-wet cloth over it. The solution is to soak a paper towel with acetone, put it on the LCD and cover it with plastic foil to prevent evaporation. After 10-15 minutes the resin softens and is easy to scrape off. You can also apply the same feature with IPA – it will just not make the resin as soft as acetone.

We’ll admit it. We like the results of resin 3D printing, but we don’t always care for the mess. We aren’t alone, and a common issue is to have drips of resin on your LCD screen — a potential disaster. You ought to have a screen protector, but yeah… you should back up hard drives, too. [Jessy] has the same problem and he has heard that you can easily clean cured resin from the screen using wood glue. Does it work? Check out the results of three glues in the video below.

We winced to see glue going on the screens. [Jessy] cured some resin on the screens deliberately for a test. He used Elmer’s wood glue, Gorilla wood glue, and Titebond II wood glue. While there is a bit of a price difference between the options, they are all fairly inexpensive.

After letting the glue cure for 24 hours, it should peel up and take the resin up with it. Getting under the corner to start peeling was challenging and the whole thing left a huge mess. In retrospect, [Jessy] mentioned it might be a good idea to put a tab under the glue while wet to provide a handle.

It probably doesn’t matter, though. Only the Gorilla glue grabbed any resin at all and even that wasn’t very effective. [Jessy] suggests using alcohol and a plastic scraper if you have this problem. We suggest a screen protector.

There are two upsides, though. First, the casting of some brands of wood glue made some interesting pieces that might have use in some other context. Second, the video comments have other ideas that might be worth trying including hot sponges and cheap material for screen protection.

Usually, we are more worried about getting resin to stick not unstick. If you are still on the fence about the mess versus rewards of resin printing, check out our overview.

As 3D printing continues to become cheaper and more accessible, resin 3D printers have become a popular choice for anyone interested in making highly-detailed models that wouldn’t be feasible using a filament-fed, FDM 3D printer. These MSLA (Masked Stereolithography) resin 3D printers typically have a single axis of motion, and this simple mechanical system means these machines can regularly be found for less than $300. With so many models on the market, we’ve made this list to help you find the best resin 3D printer for you.

The best resin 3D printers are capable of making high-resolution models by curing a liquid resin using a UV light source. This MSLA process uses a masking LCD to selectively block the UV light on a pixel-by-pixel basis, allowing these printers to create models that have a resolution of down to .035mm on the XY axes.

This high resolution comes at a price, as parts made on a resin 3D printer require post-processing after printing, and UV resin requires caution when handling. Because resin requires gloves and a mask to handle, we recommend beginners or anyone with young kids consider one of the FDM (fusion deposit modeling) printers on our overall best 3D printers page.

Why you can trust Tom"s HardwareOur expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.Mono or RGB LCD? The type of masking LCD on your resin 3D printer can have the single largest impact on your overall print speed. Because they are commonly used in other electronics, RGB masking LCDs are cheaper, but slower because they don’t allow UV light to pass through efficiently and need more exposure time per layer. For example, the RGB LCD on the Creality LD-002R requires 9 seconds per layer, while the Mono LCD on the Elegoo Mars 2 Pro requires only 2.2 seconds per layer.

How much build volume do you need?Most resin 3D printers have smaller build volumes than FDM 3D printers, so you may find yourself limited by this relatively small build volume. If you are interested in printing large parts, you’ll want to look at a large format resin 3D printer such as the Elegoo Saturn or theAnycubic Photon Mono X.

2K, 4K, or Beyond?A resin 3D printer that uses a 6.08-inch 2K screen like the Elegoo Mars 2 Pro is capable of an XY resolution of .05mm as well as a layer height of .05mm. For context, this means even a relatively low-resolution resin 3D printer is still capable of making extremely fine details that simply wouldn’t be possible on an FDM printer. If you need even more resolution, a 4K screen is capable of making finer features, but is typically more expensive.

Post Processing Equipment? Resin 3D printers create parts that require post-processing before they are completely finished. Typically, this workflow involves rinsing the parts in a solvent to dissolve any excess resin on the surface of the part, followed by a cure cycle that uses UV light to fully polymerize the part. This process can be done manually by submerging the part in a solvent and using an inexpensive UV light for curing, but some manufacturers have created post-processing equipment like the Elegoo Mercury X that automate the process and reduce the mess.

The Anycubic Photon M3 is the best all around resin 3D printer we’ve reviewed. It produces crisp details with 4K+ quality that rivals more expensive machines and has a wide build plate allowing it to make larger models than competitors in its class.

The etched build plate works really well at holding models tight during printing, but also allows for easy removal when they’re done. The metal vat has a convenient pour spout, and Anycubic includes a screen protector for the LED light source to prevent accidental drips from ruining your printer.

If you’re ready to throw some serious cash down for a decent-sized resin 3D printer with quality that will knock your socks off, the Phrozen Sonic Mighty 8K is here for you. Its roomy 218 x 123 mm build plate can accommodate an army of gaming miniatures or a gift-worthy superhero statue. Priced at around $600 at press time, this printer isn"t cheap. But in return for the premium, you get crispy details, prints that practically slide off the build plate, a built-in webcam and a machine that’s WiFi ready.

We enjoyed navigating through the Mighty 8K’s menus, thanks to its large and easy-to-use touch screen display. There’s little need to consult the manual – the printer walks you through an onboard tutorial to handle leveling and your first test print. Want to rerun a test file at a different exposure? No problem – the Sonic Mighty 8k will let you change exposure settings and more right inside the printer. I found this extremely helpful while dialing in a new resin.

The Phrozen Sonic Mighty 8K size is closer to what we see in FDM printers, without being so large that it dominates your workshop. The quality and extra wiggle room would be a worthwhile investment for someone running an Esty shop or an artist wanting to showcase their work. We were able to print 12 very-detailed gaming figures at once and the process only took 4 hours and 2 minutes.

The Creality Halot-One Plus is the flagship of the Halot line of MSLA resin 3D printers, offering an impressive set of features while still coming in at a prosumer-friendly price of $399. Unlike other printers in this price range, the Halot-One Plus includes Wi-Fi connectivity and a slicer app which allows users to quickly process models and prepare them for printing almost effortlessly.

The large 7.9-inch Mono LCD provides 4K resolution (4320 x 2560), fast per-layer cure times (3 seconds per layer), and a solid dual linear rail Z axis to allow for fast and accurate printing. The Halot-One Plus also includes an integrated air filtration system which reduces the amount of odor when printing, a surprising addition not typically seen at this price point. Finally, the 5-inch LCD interface allows users to adjust settings mid-print (including exposure time), and also provides an accurate estimate of remaining time during a print.

It’s only available for pre-order right now, but when it’s available, Elegoo’s Jupiter printer will offer a combination of great quality and a huge build volume. And, despite its $1,300 price, the Jupiter is actually a great deal for its size, given that competitors cost closer to $1,000.

Where the $499 Saturn provides a 192mm x 120mm x 200mm volume, the Jupiter provides a ton more, going all the way to 277.8mm x 156.3mm x 300mm. And the print quality is pretty good as we found when outputting a detailed model of the Notre Dame Cathedral.

The Anycubic Photon M3 Premium set an impressive standard. Offering both high resolution and large build volume in a single machine, it effectively does the work of two separate printers and still comes in cheaper than buying them individually.

The 10-inch 8K masking LCD provides an ultra-high 0.0285mm XY resolution which allows even the finest details to resolve on printed models. We were particularly impressed when we printed a model that had a tiny, open book on a pedestal; the words on the pages were sharp and legible (though one might need a magnifying glass to see them).

The 219mm x 123mm x 250mm build volume allows users to print large models with high resolution, or simply pack the oversized build platform with multiple small parts to produce many in parallel. Featuring integrated dual air filters, a laser-etched build platform, and a razor-thin NFEP vat film, the Photon M3 Premium is easily capable of handling anything you can throw at it.

If you’re looking for a reliable 3D printer to start your journey with resin printing, the Elegoo Mars 3 is a great place to start. The printer has outstanding 4K resolution for beautifully detailed models and a simple leveling system to get that first layer to stick perfectly.

Beginners should factor the high price of resin when considering their first printer, and the Elegoo Mars 3 only needs 350ml to fill its vat. The build volume is average for its class, with plenty of room for gaming miniatures and models.

If you’re looking to create small models for table-top gaming, or just display, the Elegoo Mars 3 Pro is a great choice, thanks to its great build quality and high resolution. The Mars 3 Pro has an XY resolution of 35 microns (0.035mm) which allows you to show intricate details in even small objects.

When we printed mz4250"s Red Dragon model, fine ridges on the tail and bones in the wing were sharp, without any visible splotching or errors. Even the spines and beard on the head were crystal clear. Its LCD screen provides a 4098 x 2560 resolution for prints, which is higher than the 4K resolutions of competitors like the Phrozen Sonic Mini 4K and AnyCubic Photon Mono 4K.

Unlike the Phrozen Sonic Mini 4K, which is very competitive in this area, the Mars 3 Pro doesn’t suffer from any build quality issues.It’s easy to level and even has a built-in air purifier that, in our tests, mitigated but did not completely remove the resin odor that all MSLA printers emit. With a price in the $300 - $350 range, this isn’t the cheapest resin printer on the market, but it offers great quality output and strong usability for the money.Round up of today"s best deals

Both DLP and LCD printers can print one full layer at a time, making them some of the fastest 3D printers available. An entry-level LCD printer costs $200 to $1,000. DLP printers start at $500 for entry-level printers and can go up to $100,000 for commercial use.

DLP is an older, more established technology than LCD printing. Though there are a lot of similarities between the two, the main difference is the light source used to cure the printing resin. DLP uses a high-intensity projector as a light source and directs it with thousands of tiny mirrors. LCD printers replace that setup with an LCD screen to mask the UV light which comes from an array of LED lights.

On the whole, LCD printers are constructed using cheaper components than DLP printers. However, LCD screens have shorter life spans than DLP mirror arrays. Plus, low-end screens tend to let light through in a less-than-uniform manner. This results in varying quality and precision from batch to batch and machine to machine.

DLP and LCD printers both employ liquid resin. DLP uses a high-power and higher-intensity light source that can operate on a wider range of resins. This gives DLP more options in terms of material quality. LCD printers, on the other hand, use low-intensity UV LEDs which require less viscous, fast-curing resins. This limits the types of material that can be used and impact the quality of the final product.

DLP is very accurate in narrow, small-scale prints. This makes it very useful for jewelry or dental implants, where precision is critical. LCD, on the other hand, is inexpensive and very accurate for the price point. This low price point makes it great for hobbyists. LCD is also ideal for when the price is more important than absolute precision. That can be valuable for industrial use, certain dental applications, and manufacturing.

DLP machines are available for hobbyists, professionals, and industrial applications that need large print volumes. LCD is a newer technology and has not caught on as much for industrial use. Therefore, large-volume LCD printers are not yet common, though this capability is gradually improving.

Less expensive versions of DLP and LCD systems can both have problems with surface finishes and print quality. DLP produces distortions on the edges of a print, especially in wide parts. LCD pieces can also come out imperfect due to inconsistencies in LEDs, especially with larger machines and larger prints. Both production methods must be followed by post-processing to finalize the parts’ surfaces. Generally, DLP parts come out with better surface finishes and print quality, especially with higher-end printers.

DLP and LCD are both available at affordable prices. An entry-level DLP printer can be purchased for as low as $500, while professional-grade types start at $2000. LCD printers, on the other hand, are available from $200 to $1,000.

There are a few technologies that are alternatives to both DLP and LCD printers. As an example:Stereolithography (SLA):SLA is a resin-based 3D printing technology known for its accuracy. It is similar to DLP and LCD in its use of photopolymer that is cured via UV light.

A 3D printing technology that is similar to DLP includes:DLP vs. FDM: FDM (Fusion Deposition Modeling) and DLP enable an on-demand manufacturing model for many products. They also have a similar pre-production workflow when preparing designs. For more information see our full article on FDM vs DLP 3D Printing.

A 3D printing technology that shares similarities with LCD includes:LCD vs. SLS: SLS uses a laser to fuse powder into a 3D printed object. This is an established industrial technology that compares to LCD in terms of accuracy and printing speed.

I have never seen my team take on to new equipment so happily. They love the print quality of the SOL unit and print speed averages at 50mins on fine setting if you lay the models flat. End to end time (including wash and curing) is 80-90 mins max. The team at Ackuretta was wonderful in accommodating my queries and concerns throughout.

Masked Stereolithography (MSLA) is a modified form of SLA printing. SLA uses a laser to trace the layers, and it is often reserved for industrial use since it is expensive.

MSLA uses an ultraviolet (UV) LED array and a LCD screen to selectively cure an entire layer of resin in seconds. MSLA resin printers utilize widely available and affordable components, which makes the technology available to consumers.

MSLA printers use a UV LED array underneath a LCD screen. The screen selectively turns pixels on and off, allowing UV light to cure the photopolymer resin in the vat. Budget resins often have cure times under 2.5 seconds, whereas the layer times for engineering resins can be 3 to 10 seconds.

When the layer has cured, the build plate lifts up, separating the print from the FEP or PFA film in the vat. The plate continues rising to a user-specified level then retracts down to start the next layer.

The FEP or PFA film will need to be replaced every few months or when indentions are made. The monochrome screens are degraded by the UV light, and their estimated lifespan is up to 2,000 printing hours. These should be considered a consumable.

Respirator($20-40) - Required - A respirator with activated carbon should be worn when interacting with resin and cleaning prints. These can also be used for sanding and painting.

UV Lamp($20) - Required - Portable UV LED array that can be used to post-cure prints, cure spills, cure resin in dirty IPA, and cure resin on reusable gloves after they are cleaned with IPA.

Metal Funnel ($12) - Optional - A metal funnel reduces waste, and it is used for filtering debris out of the resin as it is poured back into the bottle.

Flexible Plate ($15+) - Optional - Flexible plates can make removing prints easier, but they can cause failures on large prints that are printed directly to the build surface. The magnet adhesive will degrade over time.

Baster ($5) - Optional - Basters are recommended to remove resin from the vat. Typically, people would remove the vat and pour the resin out but this can drip resin on the screen, under the FEP film, and on your work space.

Screen Replacement ($50+) - Optional - Screens will need to be replaced months to years later, so we wouldn"t necessarily recommend holding onto spares.

Disclaimer: You assume all responsibility and risk for the use of, but not limited to, the resources, advice, and opinions of 4D Filtration or its employees. 4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon"s link redirect system will take you to a different product.

There are many ways you might get resin on the LCD screen of your resin 3D printer. You might have a print failure that causes a tear in your FEP and resin can leak through. You might get some on the bottom of your vat while changing resin types. If it gets exposed to UV light it will cure on and get stuck to your screen. Cured resin can be extremely difficult to remove from solid surfaces.

There are a few ways to get resin off of your screen. But it can be really easy to scratch your screen if you aren’t careful so here is how I have used to get it off of my screen.

The first thing that you need to do is clean the screen to remove any loose particles. I use a little bit of IPA and a clean microfiber cloth to get mine clean. This will not remove any of the cured resin but can help to get rid of any other particles that might cause scratches.

Plastic scrapers use “blades” that are plastic. They have the same form factor as double-sided razor blades but are much safer. They won’t scratch your screen nearly as easily as a traditional metal scraper. I still have some IPA on the screen that helps it to glide above the surface a little bit more and further reduce the possibility of scratches.

There is a reason that they give you a lot of different blades with these scrapers. The blades get nicked up and dull very quickly. Remember to change the blades often. To get the screen clean with the resin that is in the picture at the top of this article, It went through three different blades.

After much persistence, the screen is clean and functional again. Now is the time to add a screen protector to make this process much easier. because it isn’t if you will get more resin on your screen, but rather when will you get more resin on your screen.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Vat photopolymerization 3D printing technologies that use liquid resin as a base material offer numerous advantages. Laser-based processes like stereolithography (SLA) provide incredible resolution and are perfect for highly detailed models or jewelry casting, while projection processes like digital light processing (DLP) are lightning-fast — they can actually print entire layers of a part at once — and are therefore great for rapid prototyping.

That being said, newcomers to resin 3D printers might be unfamiliar with the liquid 3D printer resins used for the process and the safety considerations required to handle them. Liquid resins have virtually nothing in common with fused deposition modeling (FDM) materials like PLA, which are packaged as spools of solid filament, and they require proper care when loaded into a resin 3D printer.

One of the most important questions asked by resin 3D printing beginners is, “Is UV resin toxic?” The short answer is yes, they are, but there are many factors to consider when getting to grips with these printing materials. This article looks at the basics of UV resin safety, considering the toxicity of both liquid and cured resin and the steps required to protect oneself and the environment when deploying resin 3D printing processes.

Resin 3D printing technologies, sometimes called vat photopolymerization technologies, are a group of additive manufacturing processes that use resins as a printing material.

Resin 3D printers contain a tank of liquid resin (a kind of thermosetting photopolymer) and use a light source such as a laser (SLA) or a projector (DLP) to shine patterns of bright ultraviolet (UV) light onto the tank. When the light hits the liquid resin, it cures a thin layer of the material, turning it solid. This allows the resin printer to selectively cure a 2D pattern into a layer of the resin, then move its tank or light source incrementally to allow curing of the next layer.

The resin printing process offers numerous advantages, such as high resolution and a smooth, step-free surface. SLA is best for high-quality detailed parts, while DLP can be very fast, as the projector can cure a whole 2D layer with one flash of UV light. Resin printed parts are brittle and not particularly strong, but they are ideal for visual parts such as display prototypes. Resin printing is also one of the best ways to make transparent or translucent parts.

Although FDM 3D printing is now more common than SLA or DLP, resin 3D printing was actually the first form of 3D printing, patented in the 1980s by 3D Systems co-founder Chuck Hull. Formerly an expensive process reserved for professional users, resin printing is now widespread, with machines available at low prices from consumer stores like Amazon.

Without further ado, it is important to disclose at the outset that yes, UV resin is a toxic substance that requires strict safety precautions. In its uncured liquid form, UV resin contains irritants that can be harmful to humans, as well as pollutants that can be harmful to the environment and other living species.

Some of the potential harmful effects of resin are suspected but not confirmed due to lack of research. Long-term risks may include menstrual problems, altered sexual behavior or fertility, and damage to unborn children during pregnancy.

The chemical properties of liquid photopolymers make them poisonous if ingested and also a potential skin irritant and allergen. Furthermore, uncured resin is classified as hazardous to aquatic life. So why and how exactly is UV resin toxic?

Uncured liquid resin can irritate bare skin and can cause a rash called contact dermatitis. This can ultimately become more severe and cause an allergic reaction after prolonged skin contact. Several ingredients in common 3D printing resins can cause skin irritation. These include isooctyl acrylate, HDODA, HEMA, and epoxidized soybean oil.[1]

Resin should never be ingested in either its liquid or solid form. If 3D printing resin is accidentally swallowed, urgently seek assistance from poison control or a medical professional. Some photoinitiators in common 3D printing resins have a significant level of organ toxicity.

As with most FDM materials, resins are not food-safe even in their cured state, so processes like SLA and DLP should not be used to directly fabricate products like food containers, cookie cutters, or drinking vessels. However, to leverage the advantages of resin 3D printing for food parts, it is possible to make 3D printed resin casting molds or patterns which can then be used to make parts from genuinely food-safe materials. Note that these moldings should be thoroughly washed before use, as they will have been in contact with the resin mold.

Liquid 3D printing resins give off fumes or vapors containing volatile organic compounds (VOCs) that can be harmful to humans if inhaled into the throat or lungs. Short-term exposure to resin fumes can result in dizziness, headaches, and throat irritation. The long-term risks are unknown due to lack of research, but may include increased risk of cancer.

3D printing resins are harmful to the environment and should be classified as toxic waste. This means they should never be poured down the drain or directly into bodies of water, but should instead be safely bottled up and disposed of through dedicated toxic waste channels. Photopolymer resins are a pollutant that can kill marine life and destroy ecosystems.

Fully cured UV resin is less environmentally harmful than liquid resin and is therefore easier to dispose of. Alternatively, it is possible to use bio-based resins that are much less harmful to the environment, even in their liquid form.

Although liquid 3D printing resins are toxic, potentially irritating skin and giving off harmful fumes, they are safe to use if the appropriate safety precautions are taken. Such precautions include the use of personal protective equipment like safety glasses and nitrile gloves, as well as proper disposal containers.

Since liquid resins give off fumes that can harm the throat and lungs if inhaled, it is imperative to use resin 3D printers in a properly ventilated area.

The best solution when dealing with resin fumes is to have a ventilation hood over the work area to ensure that the harmful fumes are removed from the room as efficiently as possible. In environments where this setup is not possible — at home, for instance — then the work area should at least be positioned close to an open window.

Resin printer users should also create a non-porous workspace such as a glass table or a surface covered with a plastic sheet. This will prevent the harmful resin seeping into, for example, wooden surfaces.

All manufacturers of liquid resins for 3D printing must provide a safety data sheet (SDS) for each material. These documents provide information about the material’s ingredients (though sometimes to a limited extent due to trade secrets), its toxicity levels, and the appropriate safety measures that should be taken when working with the product.

When handling toxic UV resins, it is imperative to wear protective nitrile gloves, preventing potential skin irritation if small spillages occur. Though not as flexible, nitrile rubber offers superior chemical resistance to other forms of rubber.

In addition to creating a well-ventilated work area, operators of UV resin printers should wear a respirator to avoid inhaling fumes from the uncured resin. A suitable type of respirator is the 3M 60921, which is cheap and lasts several months.

As we will discuss in the following section, there are ways to safely dispose of uncured liquid resin. However, it is much easier and safer to dispose of hardened, fully cured resin, which is much less toxic and therefore less harmful to humans and the environment.

The unused resin does not have to go through the 3D printer to be cured. Instead, it can be left in a clear container in direct sunlight. The UV rays from the sun can carry out the resin curing process instead of the printer’s light source, and the container of hardened resin can then be disposed of as solid waste. Paper towels soiled with liquid resin should also be left in the sun (in a ventilated area) and left to harden before disposal.

Users of resin 3D printing equipment should consider the environmental impact of the printing process, disposing of resins safely in a way that does not pose a risk to aquatic life. Additionally, some material manufacturers offer bio-based resins that are much less harmful to the environment than ordinary synthetic resins.

Because uncured liquid 3D printing resins can kill marine animals, they cannot be poured down the sink, flushed down the toilet, or thrown out with regular garbage. Disposal of UV resins can be via a chemical waste stream (uncured liquid resin) or without (cured resin).

Uncured liquid resin can only be disposed of via a proper chemical waste stream organized by the local authority, typically by storing the material in a sealed container and delivering it to a waste management facility.

Disposing of UV resin without a regulated chemical waste stream requires curing of the resin until it is fully solidified. This involves pouring a small amount of liquid resin into a clear container, then leaving it in direct sunlight for up to 10 days until it is fully solidified. Handling the uncured resin requires the same safety procedures (gloves, eyewear, respirator) as when using a 3D printer. Resin-soiled paper towels should also be left in sunlight to cure.

Bio-based resins are derived from natural sources such as lignin, fatty acids, and camphor, and are not harmful to the environment like ordinary resins. Researchers have shown that bio-based resins can provide performance equivalent to ordinary epoxy resins during the SLA process.[2]

Currently available bio-based 3D printing resins include:eSun eResin-PLA: SLA resin made using PLA monomers (derived from corn starch, sugar cane, or other crop)

Is UV resin toxic? Yes, the liquid resins used in 3D printing processes like SLA and DLP are highly toxic and should be handled with due care: users should wear protective gloves, eyewear, and a respirator to minimize skin and eye contact and the possibility of ingestion, while ensuring that their work area is well-ventilated during printing and material handling.

Users must also consider the environment when using UV resins. Waste liquid resin should be disposed of via the proper channels — it should either be cured and hardened before disposal or sent to a chemical disposal facility — to avoid potential harm to marine wildlife.

If all these precautions are followed, resin 3D printing can be a highly valuable prototyping and production process capable of creating smooth, detailed parts such as intricate models, jewelry patterns, dental devices, and much more.

[2] Voet VS, Strating T, Schnelting GH, Dijkstra P, Tietema M, Xu J, Woortman AJ, Loos K, Jager J, Folkersma R. Biobased acrylate photocurable resin formulation for stereolithography 3D printing. ACS omega. 2018 Feb 2;3(2):1403-8.

This offer has expired!Be sure to follow us on Twitter for the latest deals and more. Sign-up for our newsletters and have our best offers delivered to your inbox daily.

The official ELEGOO storefront on Amazon is offering two of its resin 3D printers at discounts up to 27% off. The ELEGOO Mars 2 Pro Resin 3D Printer can be had for $219.99 shipped with the on-page coupon clipped. Normally listed for $300, this $80 in savings marks a new low price we’ve seen this printer listed for on Amazon. The Mars 2 Pro utilizes a 2K resolution monochrome LCD for an increased lifespan when compared to an RGB LCD. The screen resolution also has a direct effect on detail that is seen on prints. You get a 5.1×3.1×6.3 inch build volume with the Mars 2 Pro with an activated carbon filter to absorb the fumes from resin. When compared to a filament 3D printer, resin does require more work but the increase in detail is a nice progression for those already in the hobby. Keep reading for more.

The ELEGOO Saturn Resin 3D Printer is going for $439.99 with the on-page coupon clipped. This is 20% off the normal $550 retail price. When compared to the Mars 2 Pro, the Saturn is an overall upgrade. You’ll have the better 4K resolution monochrome LCD with the larger 7.55×4.72×7.87 inch build volume. The time per layer is roughly the same as the Mars 2 Pro at around 2 seconds per layer. The 4K LCD here has the same XY resolution as the Mars 2 Pro 2K LCD at 50 microns. ELEGOO not only makes these 3D printers, but you can also buy resin. They come in a variety of different colors and can be purchased at 100, 500, and 1,000-gram intervals. For instance, the Grey 1,000 gram 405nm curing resin can be purchased for $29.69 with the on-page coupon clipped.

Right now you can still save on the FlashForge Adventurer 3 3D Printer at $313.50. A resin printer is not recommended for those just getting started, but this filament printer is perfect. You get the ease of use of a fully integrated system while still being able to customize your printing experience. A built-in camera also allows you to monitor your prints. March 31 is World Backup Day so be sure to check out our roundup of deals on Synology storage solutions and more portable SSDs/HDDs.

Mars 2 Pro comes with a 6.08 inch monochrome LCD of 2K HD resolution and only takes 2 seconds per layer exposure to cure resin, which could significantly enhance your printing efficiency. Mono LCD has a much longer lifespan and stable performance during long term printing, thus saves your cost.

CNC machined aluminum body makes Mars 2 Pro a very formidable machine. Newly-designed sandblasted build plate has a much stronger adherence during printing and enables consistent printing success. Built-in active carbon could absorb the fume of resin and offer you a refreshing printing experience.

Brand new light source structure provides more even UV light emission and working together with 2K mono LCD, the printing details and precision are greatly improved and the 3D printed models are fascinating.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey