tft display vs tn manufacturer

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

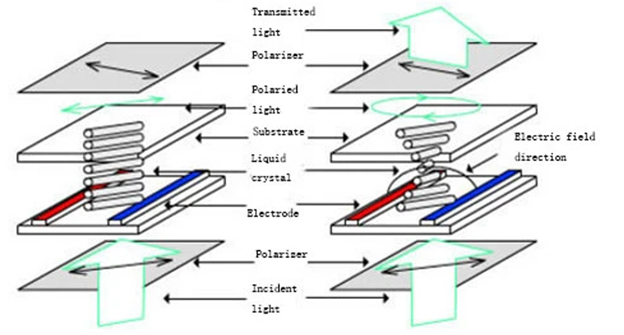

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

TN panels generally are good enough for most people especially if they do not want to spend a lot of money. Their colors are not as accurate as PVA / MVA / IPS panels, but for most people it"s a non factor unless what you do with your monitor absolutely requires accurate colors. Due to the nature of how TN panels work however, they are more prone to display video artifiact than other panel techs.

For example, in Batman: The Dark Knight DVD movie there is a scene where the Joker blows up a hospital and there"s lots of thick black smoke. On my Asus VK246H TN panel monitor the smoke is pixelated (blocky) and the Joker"s bare arms and leg also gets pixelated in that scene. I do not see those artifacts when viewing my the movie on my NEC LCD2690WUXi or Planar PX2611w monitors with H-IPS panels.

Go to a store and look at monitors there. 99% of then will be using TN panels. If you don"t like how any of them look, then it"s time consider the other more expensive types of LCD monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD or Liquid Crystal Display. It is also called Active Matrix LCD which differentializes from Passive Matrix LCD. A TFT substrate is composed of a matrix of pixels and ITO electrode (Indium Tin Oxide, a transparent electric conducting film) each with a TFT device and is so called array. Thousands or millions of these pixels together create an image on the display. The diagram below shows the simple structure of a pixel.

As long as there are TFT in the LCD, the LCD should be called a TFT LCD. But when the TFT LCD display was first commercialized, 100% TFT LCDs were TN (twisted Nematic) type TFT displays. As TN is a very technical term so most of the users ignored TN and named TN type TFT display as TFT display. While the newly developed TFT LCD display technologies such as IPS (in-plane-switching ) type TFT display, O-Film type TFT display (derived from TN type TFT display), MVA( Multi-domain Vertical Alignment) type TFT display, AFFS (Advanced Fringe Field Switching) type TFT display, they are widely call IPS display, O-Film display, MVA display and AFFS display. As the above terms have been used for long and widely accepted in the market, we will not try to correct the misunderstanding here. We will still use the TFT display (should be TN type TFT display) and IPS display (should be IPS type TFT display) in the following.

The twisted nematic effect (TN-LCD) was a main technology breakthrough that made LCDs practical. TN LCDs first make battery powered devices popular. TN-LCD displays led to the rapid expansion in the display field, quickly replacing other displays like LEDs, plasma, CRTs etc. By the 1990s, TN LCDs were widely used in portable electronics.

The TN display takes advantage of the ability of the nematic substance to rotate the polarization of light beams passing through it. Two polarizing filters, parallel planes of glass with their polarizing lines oriented at right angles with respect to each other, are positioned on either side of the liquid crystal. When light enters the display, it is polarized by the input filter. In the absence of an electric field, all the incoming light is transmitted. This is because the light polarization is rotated 90 degrees by the nematic liquid crystal, and the light therefore passes easily through the output filter, which is oriented to match the 90-degree shift. With the application of a voltage, an electric field is produced in the nematic liquid crystal. Under these conditions the polarization effect is reduced. If the voltage is large enough, the polarization effect disappears altogether, and the light is blocked by the output polarizing filter. The diagram below shows how a TN LCD works.

The best feature of TFT displays is the low cost due to a simpler manufacturing process, low-cost raw materials, and one of the oldest technologies for LCD displays. But they are not the best quality considering poor viewing angles, lower contrast ratio, slower response time, lower aperture ratio (each pixel not bright enough), and the worst is that there is one view angle with gray scale inversion (reversed image), see the below picture for reference.

IPS (in-plane-switching) technology is also one type of TFT LCD display. The basic LCD structure is similar to TN type TFT display but the inside display schematic is different.

In 1992, Hitachi researchers in Japan first developed details of the IPS technology. NEC and Hitachi became early manufacturers of active-matrix addressed LCDs based on the IPS technology. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and in-plane switching subsequently remained the dominant LCD designs through 2006. IPS technology is widely used in LCD panels for TVs, laptops, monitors, and smartphones. Apple Inc. products branded with the label Retina Display (such as iPhone 4 onward, iPad 3 on, iPad Mini 2 on, MacBook Pro with Retina display adopted IPS LCDs with LED backlighting.

An IPS LCD panel, when no electric field is applied to the liquid crystal cells, the cells naturally align in liquid crystal cells in a horizontal direction between two glass substrates which blocks the transmission of light from the backlight. This makes the display dark and results in a black display screen. When an electric field is applied, the liquid crystal cells are able to rotate through 90° allowing light to pass through resulting in a white display screen. IPS panels have superior image quality, good contrast ratio and wide viewing angles of up to 170°. IPS panels are well suited for graphics design and other applications which require accurate and consistent color reproduction.

In summary, normally high-end products such as Apple Mac computer monitors and Samsung mobile phones generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting-edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology. Of course, a TFT LCD display can always meet the basic needs at the most efficient price.

This article is an original piece of content written by Bill Cheung, a marketing manager who has an engineering and technical support background at Orient Display. We are a LCD and display technology provider with over two decades of industry experience in delivering cutting edge display solutions. Please browse our knowledge base if you would like to learn more about LCDs!

A TN-TFT display is a type of Liquid Crystal Displaywith thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

As with all our displays, a variety of customisation options are availableto bring you a unique design that meets your application requirements and satisfies environmental challenges, including:

Here at Anders we don"t just strive to design a best in class display solution for your product, but we also want to make sure the display is driven with the right embedded system. We can help achieve a hardware solution that ensures your display works perfectly within your application. Hardware solutions include:

With ever increasing pressure in all of our lives, having easy to use and reliable home appliances plays a key role in easing those stresses. A cost effective colour TFT display is ideal for demanding user expectations, available in a variety of shapes and sizes..

Residential and commercial metering solutions are changing from monochrome to colour with a TN-TFT display offering an ideal cost effective solution to give your product the uplift it deserves. We can optimise these to suit your application including mechanical integration, coverlens design and backlight enhancements.

TN-TFT Displays are ideal for medical and personal healthcare devices. Both low power consumption and low cost solutions, they are available with wide viewing angles for challenging medical situations where the user may be at an acute angle to the device.

Putting your own stamp on your product is more than a logo on the start-up screen. Discover how we can help you design a unique display solution with our customisation services:

We aim to offer reliable and long-term solutions to our B2B customers. If you would like to discuss your display and/or embedded system requirements please contact us below.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

When searching for a liquid crystal display (LCD), consideration of the device’s display technology is essential. Screen technology companies such as Apple and Samsung search for the best possible display panels and panel technology in order to offer their customers the best image quality. In competitive gaming, gaming monitors must be able to provide great image quality but also fast refresh rates so that gamers can play at a fast pace.

Before diving into how exactly liquid crystals affect display features, it is necessary to understand their general role in an LCD monitor. LCD technology is not capable of illuminating itself, so it requires a backlight. The liquid crystals are responsible for transmitting the light from backlight to the computer monitor surface in a manner determined by the signals received. They do so by essentially moving the light differently through the layer’s molecular matrix when the liquid crystals are oriented or aligned in a certain manner, a process which is controlled by the LCD cell’s electrodes and their electric currents.

The methods of alignment, however, can vary between panel types, offering different features and benefits. Two common and popular liquid crystal alignment techniques are twisted nematic (TN) and in-plane switching(IPS).

TN panels offer the cheapest method of crystal alignment. They also are the most common of the alignment methods and have been used for quite a long time in the display industry, including in cathode ray tubes (CRTs) that preceded the LCD.

In TN displays, the electrodes are positioned on either side of the liquid crystal layer. When a current is sent between the back and front electrode, something called an electric field is created that shifts and manipulates the orientation of the molecular matrix.

If no electric field is applied to the specific cell, the crystals experience a 90 degree twist in the alignment. As light from the backlight passes through this twist, the light waves are polarized, allowing them to pass through the polarizer that sits on the surface of the TN monitor.

If an electric field is applied, it can either untwist the TN liquid crystal layer partially or in full, depending on the strength of the field. The structure of TN crystals will typically straighten out when this happens, and some, if not all, light waves will not be polarized properly to pass through to the surface.

Each LCD cell composes a pixel of the display, and in each pixel are subpixels. These subpixels use standard red green blue (sRGB) colors to create a variety of colors to make the pixel display the necessary color to play its role in the overall display. If beneath the subpixel the liquid crystal fully polarizes the light, that subpixel’s specific color would be very bright in the pixel as a whole. But if the light is not polarized at all, then that color will not show up. If partially polarized, only a limited amount of that color is used in the mixture of RGB colors in the final pixel.

A more complex method of alignment is IPS. IPS monitors, unlike the TN, place both electrodes on the same level, behind the liquid crystal layer. When the electric field is applied, this forces the liquid crystal molecules to align themselves parallel to the IPS device layers instead of perpendicularly like the TN molecules.

Opposite of the TN, when the electric field is applied, IPS technology will polarize the light to pass, whereas when the electric field is not applied, the light will not be polarized to pass. Because of the orientation of the crystals, IPS displays require brighter, more powerful backlights in order to produce the correct amount of brightness for the display.

An important consideration is viewing angles. The TN offers only a limited viewing angle, especially limited from vertical angle shifts, and so color reproduction at these angles will likely not look the same as from a straight-on viewing; the TN’s colors may invert at extreme angles. The IPS counters that and allows for greater and better viewing angles that consequently offer better color reproduction at these angles than the TN. There is one issue with extreme viewing angles for IPS devices: IPS glow. This occurs when the backlight shines through the display at very wide angles, but typically is not an issue unless a device is looked at from the side.

In terms of color, as mentioned, TN devices do not have very strong color reproduction compared to other alignment technologies. Without strong color reproduction, color banding can become visible, contrast ratio can suffer, and accurate colors may not be produced. Color gamut, or the range of colors that the device can reproduce and display, is another feature that most TN displays do not excel in. This means that the full sRGB spectrum is not accessible. IPS devices, on the other hand, have good quality black color reproductions, allowing the device to achieve a deeper, richer display, but it is still not the best option if a customer is in search of high contrast (discussed further in a couple more paragraphs).

While TNs may not have the best color quality, they allow for high refresh rates (how often a new image is updated per second), often around 240 Hz. They also have the lowest input lag (receiving of signals from external controllers) at about one millisecond. TN panels often attract gamers because of the need for minimal lag and fast refresh rates in a competitive or time-sensitive setting. In consideration of moving displays like in video game displays, it is also important for fast response times (how fast a pixel can change from one amount of lighting to another). The lower the response time (the higher the response rate), the less motion blur will be shown as the display changes to show motion. TNs also offer these low response times, but it is important to remember that a powerful graphics processing unit, commonly called a GPU, is still needed to push these displays to meet the fastest refresh and response rates.

Oftentimes, refresh rates and frame rate of output devices (such as graphics cards) will not be synchronized, causing screen tearing when two different display images will be shown at once. This problem can be addressed through syncing technologies like Vsynch, Nvidia’s G-Sync, or FreeSync (a royalty-free adaptive synchronization technology developed by AMD).

Another common consideration of customers is the price of each display. TN, though it does not offer as high quality of a display, offers the lowest cost and best moving displays, making it useful if the intended use of the LCD monitor is simple and not too demanding. However, if you intend for something that calls for better color production or viewing angles, the IPS and other methods are viable choices, but at much higher costs. Even though IPS motion displays have reached the speed and rates of TNs, the price for such technology is much more expensive than the TN option.

There are other options besides the TN and IPS. One option is known as vertical alignment (VA) and it allows for the best color accuracy and color gamut. Compared to a typical IPS contrast ratio of 1000:1, VA panels can often have ratios of 3000:1 or even 6000:1. Besides improved contrast ratio, the VA is in between the TN and IPS. To compare the TN vs IPS vs VA, the VA does not have as great a viewing angle as IPS but not as poor as the TN. Its response times are slower than TN but faster than IPS (though at fast refresh rates, the VA displays often suffer from ghosting and motion blur). Due to the contrast ratio benefits, VA technologies are most often desirable for TVs.

And lastly, there is an option quite similar to IPS that is called plane to line switching (PLS). It is only produced by Samsung, who claims the PLS offers better brightness and contrast ratios than the IPS, uses less energy, and is cheaper to manufacture (but because it is only created by Samsung, it is hard to judge pricing). It also has potential in creating flexible displays.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

The two buzzwords the tech world has been chatting about for a number of years now is IPS, (In-Plane Switching) screen technology used for liquid crystal displays or LCD’s for short, and TFT (Thin-Film-Transistor) an active matrix screen technology, which is more expensive, but a sharper image.

Designed in the 1980’s, but not introduced until nearly a decade later, in 1996, by Hitachi, IPS technology is nothing new, and a type of LCD design that affords greater viewing angles and higher-quality color reproduction than the traditional TN or Twisted Nematic LCDs.

TFT (Thin-Film-Transistor) Liquid Crystal Display is a thin display type, where a transistor embedded into each crystal gate; these transistors are then printed on thin-transparent film. The technology was designed to improve image qualities, such as contrast and addressability.

Also designed in the late 1980’s, TFT display technologies is just another variation of LCD displays that offer greater color, contrast, and response times as opposed to available passive matrix LCD’s. One of the primary differences between IPS and TFT display technologies is the cost. IPS is more expensive than TN technology. However, there are some key differences between the two that should be noted.

Before we go into the differences, let’s talk about features of each technology. Note that we’re not talking TVs, computer, or tablets, but screens on a much smaller scale, (think 7” or smaller) which uses different rules to fit that scale. First, it’s interesting to discover that the TFT display technologies is the most common type of color display technology; more monochrome displays still out-sell color, due to lower cost and lower power consumption, however, the narrow poor visibility of TFTs in direct sunlight is their downside; but I’m getting ahead of myself here.

Brilliant color image – this is a huge advance in technology, from a Twisted Nematic (TN) display that only produced 6-bit color, to an 8-bit color display with the IPS technology

TFT display technologies have developed over the years and have become quite popular in tech circles. The features offered with this advancing technology are:Superior color display – for technology that requires it or for consumers that desire color screens

Features a longer half-life, (half-life is the amount of time in hours before the display is 50% as bright as when it was first turned on), than OLEDs and comes in varying sizes, from under an inch up to over 15 inches

Variety of displays, which can be interfaced through a variety of bus types, including 18 and 24 bit for red/green/blue, LVDS, and 8 bit and 16 bit for a CPU – many controllers allow for two or more different types of interfaces on the same TFT screen

Let me explain. As you can see, both have excellent color display and clarity; however, IPS screens offer greater color reproduction and viewing angles because of the way crystal orientation and polarizers are arranged. In a TFT screen, the structure of the crystals results in angular retardation in the light. The IPS screens thus offer less distortion properties. Other differences include power consumption and cost. With IPS screens, it takes more power (up to 15% more) than with a TFT screen. If you’re on a monitor, such as a computer screen that’s bigger than 7 inches, it will drain your battery faster than if you’re on a 3.5” screen. Regarding cost, IPS panels are more expensive to produce than TFT panels.

The color channels increase from 6 bits (TN displays) to 8 bits (IPS displays) to ensure the precision of shades per color channel, thus increasing manufacturing costs

If you want the benefits of having a Smartphone without a huge price tag, then TFT devices are your best bet. Another difference is that IPS screens have longer response times than TFT screens, so the lag output is greater. A few other key differences to be aware of are that with IPS panels, you get a bigger variety of panels, as was discussed above, with their super, advanced, and so forth developments, giving the consumer options, and IPS screens that can display 24-bit TrueColor; they also stay color-accurate and remain stable.

Now we will go over the downside of IPS screens, which we briefly touched on above, which includes a major disadvantage: cost. If you’re just looking for an average Smartphone or don’t need all the fancy coloring and clarity for LCD displays, then cost may not be a big factor; however, this is the main reason why IPS technology is beginning to come down. As with every new invention, discovery or technology, demand is everything. Another disadvantage is that colors may not always transcribe correctly or accurately, which may or may not be a deterrent. Also, high resolutions are not always readily available for personal applications. In certain circumstances, the brightness may not be enough, especially in darkness.

Steve Jobs said it best: “Design is not just what it looks like and feels like. Design is how it works.” I tend to agree with him. With TFT display technologies, less energy consumption is a big deal, especially when dealing with bigger screens, and of course less electricity means lower cost, overall. The visibility is sharper, meaning no geometric distortion, which is great for these tired, old eyes. The response time and physical design of the screens are also appealing. TFT displays can also save space and be placed virtually anywhere in an office or home, because of the brightly lit feature and crisp clear images.

Some cons of TFT screens deal with the viewing angle, which create distortion, resulting in a less-than-perfect image. Static resolution, meaning the resolution can’t be changed, may also cause a problem, but newer models seem to have tackled that issue. The accuracy of the display of colors is not perfect, specifically strong blacks and bright whites, so when printing an image, it may not display the spectrum of colors.

And there you have it. In the future, even this superb technology will change and new, more exciting technology will take its place. But until then, IPS & TFT screens are forging ahead with their own advances and improvements, so stayed tune. You don’t want to miss it.

Focus Display Solutions (www.FocusLCDs.com) offers off-the-shelf Color TFT display technologies in both TN and IPS. Many of the color modules contain built in touch panels.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. LCD screens have replaced heavy, bulky and less energy-efficient cathode-ray tube (CRT) displays in nearly all applications. The phosphors used in CRTs make them vulnerable to image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs do not have this weakness, but are still susceptible to image persistence.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

The origins and the complex history of liquid-crystal displays from the perspective of an insider during the early days were described by Joseph A. Castellano in Liquid Gold: The Story of Liquid Crystal Displays and the Creation of an Industry.IEEE History Center.Peter J. Wild, can be found at the Engineering and Technology History Wiki.

In 1888,Friedrich Reinitzer (1858–1927) discovered the liquid crystalline nature of cholesterol extracted from carrots (that is, two melting points and generation of colors) and published his findings at a meeting of the Vienna Chemical Society on May 3, 1888 (F. Reinitzer: Beiträge zur Kenntniss des Cholesterins, Monatshefte für Chemie (Wien) 9, 421–441 (1888)).Otto Lehmann published his work "Flüssige Kristalle" (Liquid Crystals). In 1911, Charles Mauguin first experimented with liquid crystals confined between plates in thin layers.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In 1964, George H. Heilmeier, then working at the RCA laboratories on the effect discovered by Williams achieved the switching of colors by field-induced realignment of dichroic dyes in a homeotropically oriented liquid crystal. Practical problems with this new electro-optical effect made Heilmeier continue to work on scattering effects in liquid crystals and finally the achievement of the first operational liquid-crystal display based on what he called the George H. Heilmeier was inducted in the National Inventors Hall of FameIEEE Milestone.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD televi

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey