tft display layers for sale

TFT LCD Monitors are primarily discussed in our previous blogs. TFT LCDs are an everyday landscape, with TFT LCD being an extensively used display in different ways looking, from medical equipment, automobiles or advertisements, and smartphones.

One of our blogs, TFT LCD MONITOR: WHAT YOUR BUSINESS NEEDS TO KNOW, clearly mentioned how customers value Liquid Crystal Display (LCD) for the clear, high-quality images it produces. However, industry professionals are increasingly incorporating new technology into creating LCD screens. New inventions have recently taken the tech world by storm, replacing outdated LCD versions, such as the TFT LCD Monitor.

An open frame monitor is one of the most cost-effective and practical solutions available. It is the most versatile way to utilize your computer, yet it is significantly less expensive than a standard PC. Furthermore, the display will last for a long time. It’s an excellent choice for companies looking to increase their image quality.

For businesses, open frame displays are a wonderful option. They are long-lasting and simple to install. Open frame displays can be available in a wide variety of sizes.

Open frame monitors are devices without bezels located mainly in bare metal enclosures. These are ideally used in kiosks, ATMs, point-of-sale terminals, marine, medical, transportation, industrial automation, commercial display, and outdoor use.

Compared to CRT (cathode ray tube) monitors, flatscreen monitors are much thinner and lighter. The technology also enables more transparent images, higher resolutions, and flicker-free displays, which are easier on the eyes, require less energy, and emit no electromagnetic radiation.

In today’s cars, there are a growing number of displays. This article explains the most important trends in automotive displays that you must know in 2022.

Nowadays, electromechanical switches and controls are being increasingly replaced by electronic controls, which include touchscreen displays. Even smaller controls, such as those to control the air conditioning, the position of a car’s exterior mirrors, or the buttons on the multifunction steering wheel, are involved.

The terms reflective, transmissive, and transflective describe how LCD modules illuminate. Compared to emissive display technologies such as OLED displays (organic light-emitting diode) and VFDs (vacuum fluorescent displays), LCDs need an ambient light source like the sun, artificial light, or a merged backlight.

Some displays use ambient lighting instead of backlights. This mode of operation is termed reflective. A mirror is installed behind the liquid crystal layer in this mode, which is either on the LCD cell or the rear polarizer...Read More

Display interfaces are used to exchange information across different components. It operates over three primary functions, i.e., image decompression, image assembly, and communication to and from the display daemon.

LVDS signaling is considered ideal for large displays, e.g., TV, laptops, and other computers. Its capability of transferring large pixels in less time makes it a popular and favorable choice for developing PMOLED, AMOLED, TFT, and different types of displays.

Today, there is a high demand for electronic devices featuring high brightness displays. Liquid Crystal Display Technology (LCD) is one of the most popular display technologies in use today. They are found in various electronic devices right from mobile phones, computer monitors, tablets, touchscreen displays, tablets, television sets, and more. Over the years, there have been variations to these displays. TFT LCDs have gained immense popularity in recent years. These are thin-film-transistor liquid-crystal displays, which utilize thin-film transistors to optimize image qualities. These LCD displays are nowadays available in different configurations. Of these, 10.25 inch TFT LCD displays offered by Microtips USA have gained popularity in recent years due to various reasons...Read More

TFT, which stands for thin film transistor, is an advanced offshoot of the LCD technology. These are active matrix LCDs, which immensely improve the quality of color, contrast, image clarity, and more. This is one reason why TFTs are used in displays of many electronic devices, along with capacitors. The 3.9-inch bar type color TFT LCD display comes with such amazing quality and features in terms of the resolution, size, interface, and so on. This display finds applications in many industrial equipment, marine equipment, point of sale (POS) terminals, automobiles, advertising displays, server systems, and so on. There are many 3.9-inch TFT LCD module manufacturers making this display although features may slightly differ based on the manufacturer...Read More

TFT or thin film transistor is a variant of the LCD technology. TFTs are active matrix LCDs, which help improve contrast, color, and picture quality. Thin film transistors are used along with capacitors to improve image quality in many electronic devices. Owing to their several advantages, these TFT displays are available in various specifications. The 4.3 inch TFT display is one of the most popular among them. The 4.3-inch TFT LCD display module touch screen has a resolution of 480X272 with an RGB interface. This display finds applications in mobile phones, cars, embedded systems, and certain industrial equipment among others. There are many 4.3-inch TFT LCD module manufacturers making this display; however, certain features may slightly differ based on the manufacturer...Read More

Over the years, various display technologies have gained popularity across the world and the liquid –crystal display technology, abbreviated as LCD, stands tall among them. This technology has become a choice for manufacturers of electronic devices such as mobile phones, televisions, computers, and more, owing to several advantages offered by them. However, the advances in this technology have opened new options for device manufacturers. Thin-film-transistor is one of the most popular types of LCDs used by electronics manufacturers all over the world. Today, it is produced in various specifications to meet your application requirements. However, the 12.3 inch TFT LCD display by Microtips Technology has gained the attention of electronic device manufacturers...Read More

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

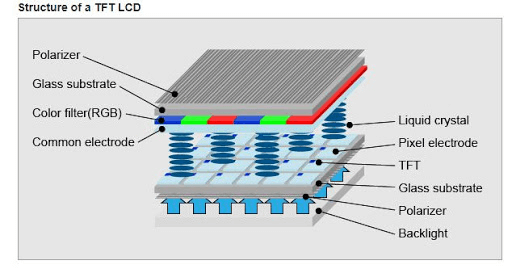

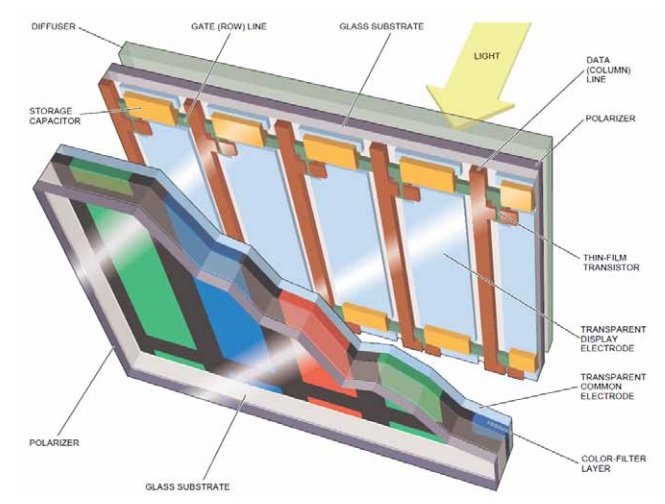

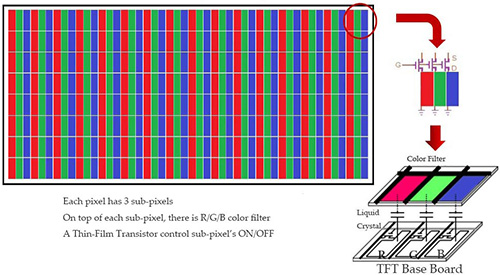

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

NEW YORK, March 13, 2015 (GLOBE NEWSWIRE) -- via PRWEB - ICAP Patent Brokerage announces for sale multiple patent portfolios disclosing methods of improved thin-film transistor (TFT) semiconductor manufacture, polynucleotide sensing and detecting, and lithium-ion battery and bioethanol production. These portfolios will be offered in an exclusive corporate auction featuring assets from Third Patent Portfolio Investment Company and Patentfonds, with a bidding deadline of March 26th, 2015.

"This auction contains valuable portfolios for companies producing solar cells and flat panel displays, as well as manufacturers of organic detection equipment, lithium-ion batteries, and bioethanol," says Dean Becker, CEO of ICAP Patent Brokerage.

Lot 1: Polycrystalline layering, or deposition, is an essential step in the production of spatially extended circuit elements, in particular solar cells and monitors based on thin-film transistor (TFT) technology. This portfolio discloses methods for the production of polycrystalline layers with a lower density of impurity than the precursor material, resulting in decreased display switching times and improved solar cell efficiency.

Lot 2: Traditional polycrystalline deposition methods require material to be grown on substrate, produced under vacuum. This portfolio discloses a novel component which allows for simple industrial production of semiconductor layers via liquid or gas suspension. Importantly, application of the layer is not required to be performed under vacuum, utilizing a protective gas atmosphere instead. Semiconductor sales are expected to reach $358 billion in 2015.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey