lcd touch screen monitors free sample

Established in 2010, Topfoison has devoted itself to the manufacturing and development of high-quality products for the Wearable device, Smart Watch, VR, Medical device, Industrial LCD display including Color LCD modules/OLED/LCD display/Round lcd screen/Round AMOLED/ Square transflective lcd screen/ IPS full wide display/ 1080p fhd AMOLED and 2K 1440p lcd. Topfoison focus on1.22-7.0 inch small size displays, all the products produced in our company enjoys the most advanced production craft and technology as well as the strictly ISO quality management system.

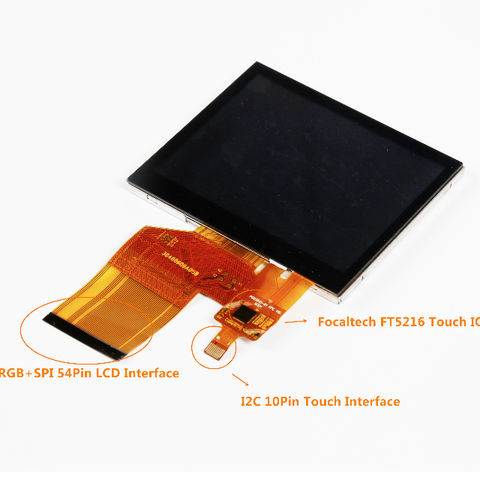

If using a High Brightness Display, you can choose the AD Board which have light sensor function that can adjust panel"s brightness automatically.PCAP touch supports 10-finger multi-touch capability, light gloves and stylus touch (need to adjust the firmware),

1. Details: length 230mm, width 180mm, thickness 4mm, physical tempering,rectangle shape, the black frame with a rectangle window for screen, with anti-glare coating for reducing the light glare, by quite special edge shaping technique . Welcome to custom your design.

2. Processing: From cutting raw material – glass sheet into little pieces to making physical tempering treatment, the processing procedures are done in our factory. And so is the screen printing step. The production volume reaches 2k – 3k per day. For customized request, that coating anti-fingerprint, anti-reflective (AR) and anti-glare (AG) on the clear surface is workable.

Be a protector for the screen and the touch panel. Different printed colors fit to electronics. There is a trend to apply this kind glass panel into the auto controller.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

See Permanently Germ-Free Touch Screen Monitors below. Impact Display Solutions specializes in developing customized display solutions to our clients’ exact specifications. Our design and engineering teams have the technical skill and experience to bring your LCD display plans to fruition. No matter what LCD panel types you need (customized or

Impact Display Solutions is a distributor of over 20 lines of touch screen manufacturers. Whether you need standard resistive and capacitive touch screens or have specialized requirements, we have your solution. Talk to our team about your specific application, such as use with gloves, rugged environments, clean rooms and more. Because we have the latest touch technologies including IR, SAW, and multi touch solutions, we are your one-stop-shop for the LCD touch screen monitor products you need. Don’t miss out on the new products based on latest technological advances in this field. Examples of unconventional options include:

PIT technology is a patented multi-touch technology. Based on the traditional infrared touch technology and the theory of total internal reflection (TIR), placing the infrared emission diode and reception diode on the lower surface of glass, the infrared beams generated by emission diodes are reflected through a prism light-guide specially designed and transmit across the front glass surface. Compared to traditional infrared touch technology, PIT touch screen has slimmer bezel, lower elevated height, and better multi-touch experience. Impact Display Solutions PIT touch screens have Win8 certification. PIT touch screens support multi-touch capability, allowing more people to touch the screen simultaneously. That allows users to have a better interactive experience. Compared to traditional infrared touch screen, 0.5mm ultralow elevated height enables PIT touch screen recognize human touch very accurately. Ultra-narrow bezel allows near-true flat appearance (as the touch transducers are placed under the screen). Protection performance enhancements are optional: waterproof or vandal-resistant.

As we all know, the biggest advantage of projected capacitive touch screens over other touch screen technologies is in the ease of implementation of feather-touch & multi-touch for gestures, but feather-style touching can lead to unintended activations in conventional projected capacitive touch screens. Adding force sensing overcomes that weakness of PCAPs. Force Sensing Touch Screens implement unintended touch rejection by ‘brushing off’ past accidents and it takes into account finger repositioning before selection. Force-sensing touch screen also enables new hand moves and menu-bringing features you can add to your product to enhance user experience.

Based on proven SAW touch technology, Impact Display Solutions has the capability of offering curved SAW touch screens in sizes of 21.5”, 27”, 32”, 35”, 42”. Furthermore, curved SAW touchscreens inherit and enjoy the benefits of SAW technology such as high reliability, protracted durability, sharp image clarity and vandal proofing. It’s the ideal touch solution for gaming and interactive kiosks.

Impact Display Solutions has extensive experience supporting projects in some of the harshest environments. Whether you are dealing with extreme temperatures, wet, oily or dirty conditions we have LCD panel types that will work for you. We can create shock, vibration and impact resistant solutions. We are experienced with Mil Spec standards and can meet your engineering specifications. Don’t miss out on the new products based on latest technological advances in this field. Examples of cover options include (stronger glass substrates in order of toughness):

Optical bonding can increase the brightness and contrast of a display. Typically, there are air gaps between the layers of the completed LCD assembly including the substrate, cover glass and touch screen. Optical bonding can be employed to strengthen the assembly and in most cases, to improve the overall brightness, contrast ratio and readability by mitigating the light reflection between the layers. We offer variety of bonding solutions to meet your LCD touch screen monitor requirements. Don’t miss out on the new products based on latest technological advances in this field. Examples of options include:

When you need to increase readability (especially in direct sunlight) by eliminating air gap between LCD and touch screen or protective lens, or both, Impact effectively achieves that goal with optical clear adhesive (OCA) lamination process. Dry bonding with OCA is an inexpensive bonding method with a reliable track record.

Performed in the U.S., Impact uses IR-curing process for optical bonding that involves infrared heat to bring optical silicone OCR material to gel state. Used to optically-bond touch screens of your choice or variety of lenses similar to options for UV curing listed above but excluding Micromesh option.

Because Impact specializes in LCDs, touch screens, computer motherboards, and value-added enhancements & assemblies, we are able to put all those products into convenient “all-in-ones” / AIOs, which include enclosures with either desktop mounts or backside VESA mounts. Click HERE for list of standard models of 15.6” to 21.5” diagonal, which consist of HD LCD, PCAP touch screen, internal computer motherboard, memory, and other components that encompass full computer functionality with convenient use interface. Please contact us to modify a standard model or make a custom-made AIO product from ground up.

For example, on a device that is stable at a single touch, it is also easy to check the phenomenon becomes unstable when it comes to three or more points.

1.5.1 Responding to pen pressure.I was wearing a subtle color for each touch ID. (Five or more are repeated the same color.) Modify additional bug at full screen.

Hope Industrial 12″ Panel Mount Monitors are designed to provide superior picture quality and state-of-the-art features in a rugged enclosure, ensuring years of reliable operation in any factory environment.

A unique single-cutout, stud-free design and 50 mm (1.98″) depth make installation a snap. Options like touch screens, DC or AC power input, and stainless steel make these displays highly versatile.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey