lcd panel test patterns supplier

In the past decade, LCD monitors have replaced CRT screens for all but the most specialist applications. Although liquid crystal displays boast perfect

Westar’s family of LCD Testers are supported by our Tooling Solutions. A tooling solution allows you, the customer, to use our LCD Tester to test a particular display. Tooling solutions are developed cost-effectively by our support staff, saving you time and money for your test functions.

For quickest delivery of tooling solutions, we ask that you supply a sample display, along with its specification or datasheet. Our tooling specialists will use this information to create a tooling solution. We have already developed hundreds of tooling solutions for many common LCD panels. Just ask our support staff if we have a solution already complete!

Our cabling solutions are delivered with schematics to allow you to repair your cables, or build more yourself. Our profiles are ready-to-use on your TFT Tester, already tested at our facility!

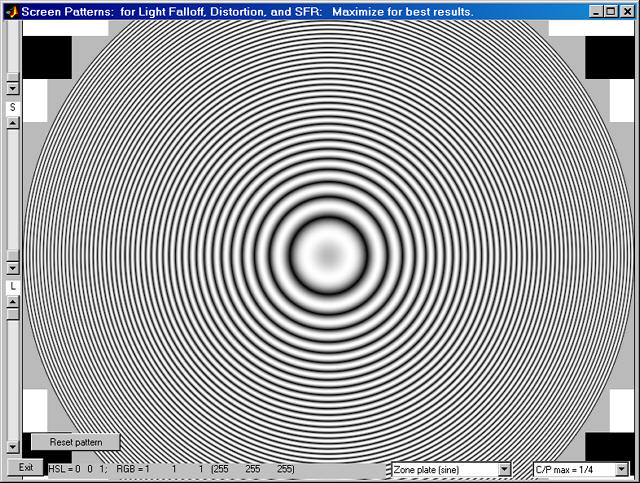

The EIZO monitor test lets you quickly and easily assess your monitor’s image quality. You can carry out 13 individual tests to check how uniform the image display is across the entire monitor, for example, or if the text is displayed sharply. You can check your monitor for defective pixels and get a sense of its viewing angle stability. Put your monitor to the test now!

The EIZO monitor test consists of various test scenarios that your monitor can handle to a greater or lesser extent, depending on the model. For example, gaming monitors are distinguished by particularly short response times, whereas graphic monitors impress with a particularly homogenous image display and smooth gradients. You should therefore always assess your monitor within the context of its respective device category. For this reason, please note the manufacturer specifications (especially for the defective pixel test). It is recommended that you carry out the monitor test in a dark room. This allows you to precisely assess even dark image areas.

In order to ensure meaningful test results, your monitor should already be warmed up prior to testing (ideally for 30 minutes). You should also clean the display prior to testing, since reflected light could cause dust particles to look like defective pixels.

Our integrated circuits and reference designs help you create high-density, high-performance, multi-channel flat panel display (FPD) test equipment that minimizes channel-to-channel variations due to reference voltage loading, clocking and power.

New generation flat panel display (FPD) test equipment often requires:Simultaneous high-precision, high-voltage, multi-channel measurement capabilities.

Also known as: 7RU rack mount monitor, rackmount lcd monitor, wall mount tft lcd monitor arm, monitor arm brackets, video test pattern generator, portable monitor tester

This report examines the gamma relationship between a display’s pixel input values and its luminance output values. We examine how a display’s gamma is specified and how it is normally measured. We see how a display’s gamma measurement and/or adjustment is complicated by dynamic luminance changes that are based on average picture level. We also examine the latest standard for measuring the gamma performance of these displays with dynamic luminance levels.

We then present a type of test pattern that maintains a constant APL, despite changes to its measurement stimulus level. We present an innovative method of maintaining constant APL at any desired window size or APL, as well as constant chromatic, to maintain accurate gamma measurements not only for grayscale levels, but for all colors.

Many display technologies dynamically adjust the luminance levels of the display, depending upon the average picture level (APL) of the currently displayed image. These displays include plasma panels with ABL, LCDs and PDPs with global and local dimming, and projectors with auto iris.

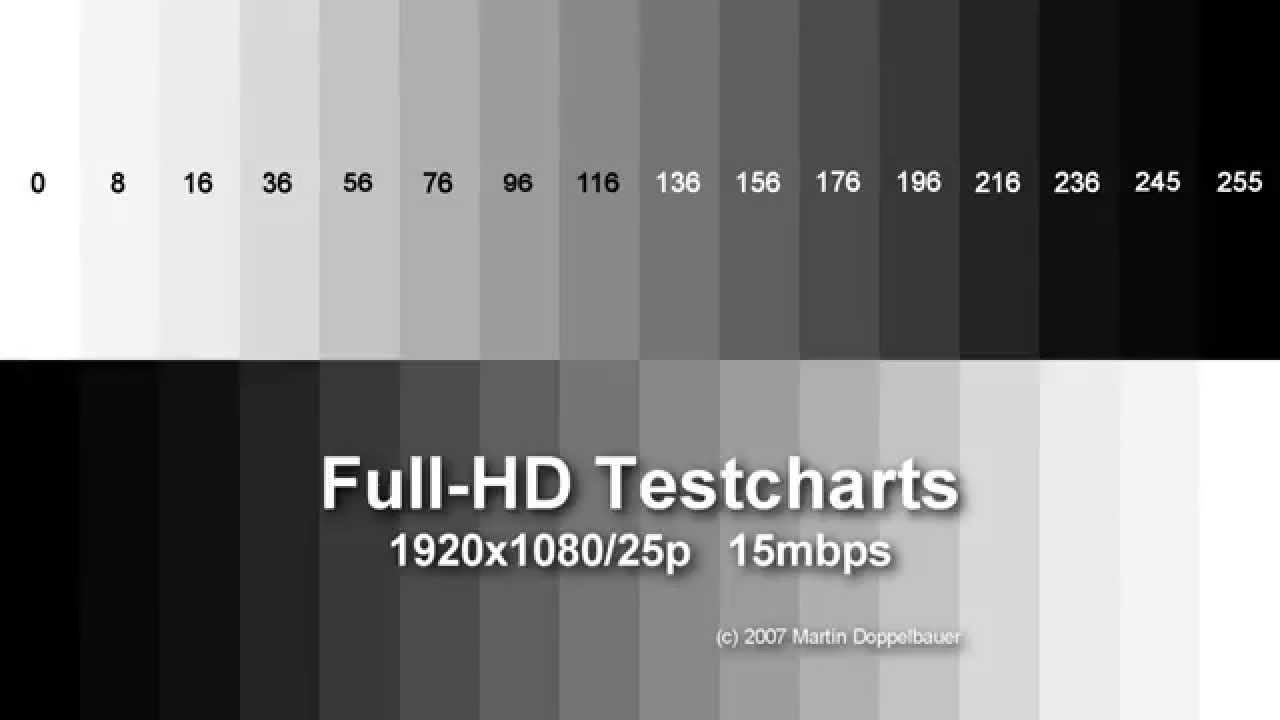

To measure a display’s gamma, we typically display ten or more test patterns, with the stimulus levels (pixel values) of the individual patterns distributed across the grayscale range of interest. We measure the luminance that the display produces with each test pattern and chart the results, to produce a visual representation of the display’s gamma performance (Figure 2).

For this type of display, the luminance of a full white area of the image dynamically changes as the average pixel level of the entire image changes (Figure 4). These displays, that dynamically change their luminance as the average pixel level changes, include all plasma display panels (PDPs), LCDs with global or local dimming enabled, and projectors with auto iris enabled.

Because plasma display panels generate significant heat and a high power supply load when producing high luminance across a significant area of a scene, all plasma displays include an Automatic Brightness Limiter (ABL) to protect their power supplies, to reduce phosphor aging, and to limit their energy consumption.

During a scene with a high proportion of bright elements, the ABL circuit limits the panel’s luminance (dims the entire picture) to limit power consumption. During a scene with a lower proportion of bright pixels there is less limiting effect. Depending upon the proportion of bright pixels in the entire image, this changes the amount of light a plasma panel produces at any particular pixel drive level (Figure 5).

Global or local dimming in LCDs and PDPs, and auto iris in projectors also have the effect of dynamically changing the luminance produced at a particular pixel drive level, depending upon the proportion of bright pixels in the rest of the image. This has the effect of dynamically changing the gamma performance of a display, depending upon picture content. So, what is an appropriate method to measure or adjust the gamma performance for a display that dynamically changes its luminance with picture content changes?

Both full field and window (partial field) test patterns have been used to test display gamma. The APL of both full field and window test patterns changes, though, as the measurement stimulus level changes.

A full-field test pattern produces 100% APL at 100% stimulus, with proportionally lower APLs at lower stimulus levels. The APL varies from 100% to 0%.

This extreme APL change is okay when testing LCD panels with dimming disabled or projectors with auto iris disabled, but is not appropriate for testing displays that dynamically change their luminance levels, depending upon the APL of the currently displayed image.

Window patterns with a black background have been in use for a long time for display measurements. These patterns minimize the APL change when switching between different stimulus levels, as compared to full field test patterns.

You can see that smaller size window patterns, with a black background, result in a smaller APL change as the measurement stimulus level is varied from maximum to minimum. But, any window pattern with a constant background level is not a constant APL test pattern.

Window test patterns have long been thought to be appropriate for measuring displays with dynamically changing luminance levels. However, a window pattern with any constant background level still has a changing APL as the measurement stimulus level changes. This still results in dynamically changing measurement conditions.

The International Committee for Display Metrology (ICDM), part of the Society for Information Display (SID) Definitions and Standards Committee, was charged with updating the Flat Panel Display Measurements Standard that had been used extensively by the industry since its publication by VESA in 2001. The ICDM published its Information Display Measurement Standard (IDMS) in May of 2012, with recommended procedures to quantify electronic display characteristics.

To measure the gamma of display technologies that dynamically adjust luminance based on image content, the IDMS standard specifies test patterns that maintain a fixed average pixel level (APL) (page 86). One IDMS implementation of fixed APL is a test pattern with a center stimulus window and a background that changes pixel level to counterbalance the luminance changes in the center window (Figure 10).

When you are measuring a display that dynamically adjusts its luminance based on image content, you don’t get meaningful gamma measurements with test patterns that each have a different APL. Each test pattern, each with a different APL, causes the display to exhibit a different dynamic luminance characteristic.

A constant APL test pattern maintains the same APL across the measurement stimulus range. As the stimulus level in the center window changes, the background level changes to compensate, keeping the total light output constant.

The center window for the four constant APL test patterns is at the currently selected stimulus level, ranging from 100% white to 0% black. The window size is approximately 5% of the area of the total image frame.

CalMAN also provides a Constant APL test pattern that can be user-defined. The user can select the Pattern Size, to select the size of the center stimulus window, and the Pattern APL, to set the APL of the overall pattern.

As well as maintaining a constant average pixel level for the Constant APL test patterns, CalMAN also maintains the test patterns as constant chromatic.

If you are unable to totally disable either dimming or auto iris, use a constant APL test pattern to minimize their effects on any display measurements.

For plasma panels, to constrain the effect of ABL to the average picture level of the expected content, use constant APL test patterns. We want to measure or adjust gamma in the picture condition that is most prevalent.

You don’t want a different APL for each different test pattern. That would mean that both the stimulus level and the APL are changing during the gamma measurement. We want to test gamma at one or more fixed APLs. Each gamma test will involve only one variable, the stimulus level.

If you want to test multiple variables (i.e. stimulus and APL), test only one variable at a time. Use a constant APL pattern (e.g. 50 APL) to test a display’s gamma at that APL across the stimulus range. Then, switch to another constant APL pattern (e.g. 25 APL) to test the display’s gamma at that APL.

Many display technologies produce different luminance at black, gray, and/or peak white levels, depending upon the average picture level (APL) of the image. These display types include plasma and LCD panels with global or local dimming, plasma panels with ABL, and projectors with auto iris.

A display’s gamma performance, which is critical to accurate image rendering, is determined by measuring test patterns at various stimulus levels. If the test patterns also change average picture level as they change stimulus levels, many displays produce a different luminance, not only in response to the changed stimulus level, but also due to the changed

Because a frame of picture content is always at a single APL and because most picture content averages out to an APL within a moderate range, we normally want to test at one, or possibly two different, APLs to accurately characterize a display’s gamma performance.

A constant APL test pattern allows us to stabilize the ABL effect in plasma panels, stabilize any dimming or auto iris action that can’t be disabled, and test at an APL that is representative of average program content. This allows a gamma test to measure only the effects of stimulus (picture) level changes.

CalMAN constant APL test patterns are available at a number of fixed APLs and at user-defined APLs. The CalMAN test patterns are also constant chromatic, minimizing any display changes due to any effect other than the desired stimulus level change. This enables the most accurate gamma measurements and adjustments that are possible, on any display type.

The correct set up and calibration of primary and secondary medical display devices is critical to acceptable use of mammographic systems. A set of test patterns has been developed by the AAPM and their application is described in the IAEA publication. These test patterns have been customised by Sunnybrook and Women’s Health Sciences Centre for the specific requirements of different equipment providers.

The test pattern code (with number of symbols) is [manufacturer code (2); size (1 or 0); test pattern type (2-5); left or right (1); number in series (1 or 2)].

Test patterns have been fabricated for the following manufacturer codes/models: Agfa (AG), Fuji Medical Systems (FM), General Electric 2000D/DS/Essential (GE), Giotto (GI), Hologic Selenia Dimensions (HI), Kodak / Carestream (KD), Konica Minolta (KM), Lorad Selenia (LO), Planmed Nuance (PM), Sectra Mamea(SE), Siemens Inspiration (SI), Siemens Novation (SN). An additional code “FS” is used for images that have hybrid header – CR modality but GE sizing.

The test pattern images can be loaded as patient images in the same manner that previous patient images would be reviewed on the system. This could be from the PACS, or from a CD that could be burnt to include downloaded image files. These images should be stored on the system and should not be deleted.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey