lcd panel test patterns quotation

In the past decade, LCD monitors have replaced CRT screens for all but the most specialist applications. Although liquid crystal displays boast perfect

Gray JE, Lisk KG, Haddick DH, Harschbarger JH, Oosterhof A, Schwenker R (1985) Test pattern for video displays and hard-copy cameras. Radiology 154(2):519–527

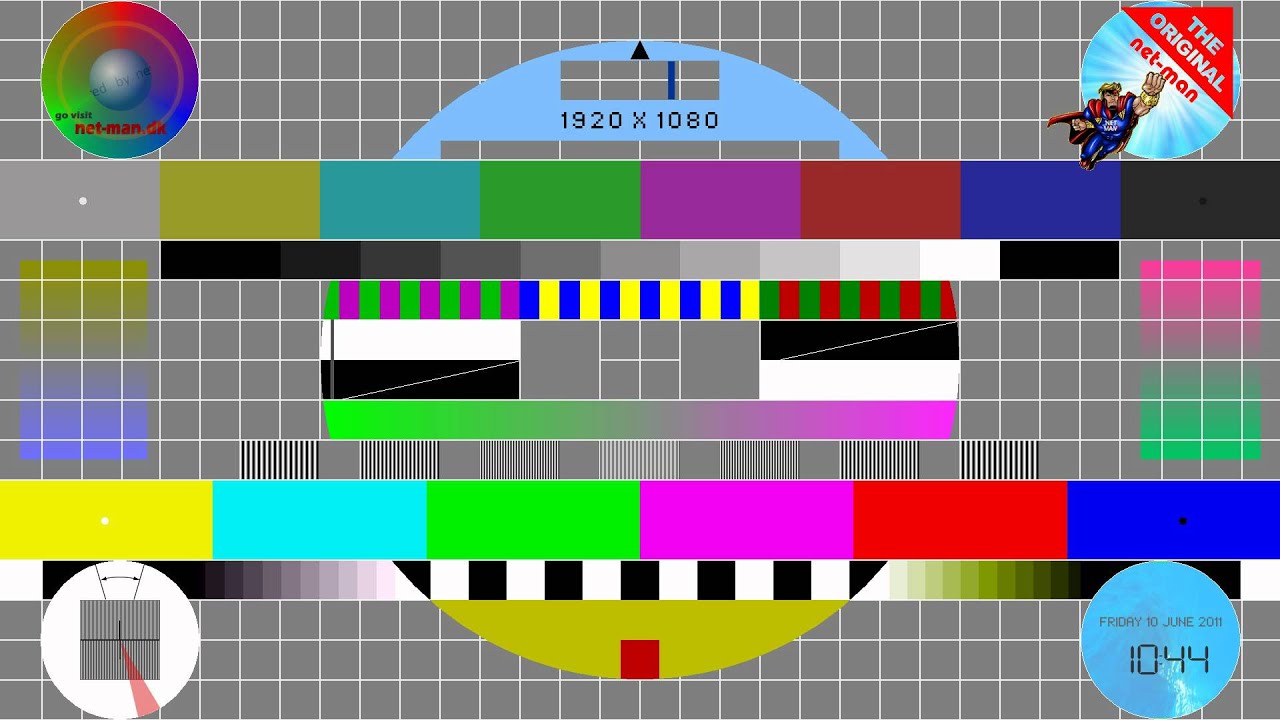

A test card, also known as a test pattern or start-up/closedown test, is a television test signal, typically broadcast at times when the transmitter is active but no program is being broadcast (often at sign-on and sign-off).

Used since the earliest TV broadcasts, test cards were originally physical cards at which a television camera was pointed, allowing for simple adjustments of picture quality.camcorders. From the 1950s, test card images were built into monoscope tubes which freed up the use of TV cameras which would otherwise have to be rotated to continuously broadcast physical test cards during downtime hours.

Electronically generated test patterns, used for calibrating or troubleshooting the downstream signal path, were introduced in the late-1960s. These are generated by test signal generators, which do not depend on the correct configuration (and presence) of a camera, and can also test for additional parameters such as correct color decoding, sync, frames per second, and frequency response.vectorscope, allowing precise adjustments of image equipment.

The audio broadcast while test cards are shown is typically a sine wave tone, radio (if associated or affiliated with the television channel) or music (usually instrumental, though some also broadcast with jazz or popular music).

Digitally generated cards came later, associated with digital television, and add a few features specific of digital signals, like checking for error correction, chroma subsampling, aspect ratio signaling, surround sound, etc. More recently, the use of test cards has also expanded beyond television to other digital displays such as large LED walls and video projectors.

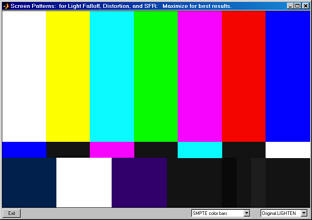

Test cards typically contain a set of patterns to enable television cameras and receivers to be adjusted to show the picture correctly (see SMPTE color bars). Most modern test cards include a set of calibrated color bars which will produce a characteristic pattern of "dot landings" on a vectorscope, allowing chroma and tint to be precisely adjusted between generations of videotape or network feeds. SMPTE bars—and several other test cards—include analog black (a flat waveform at 7.5 IRE, or the NTSC setup level), full white (100 IRE), and a "sub-black", or "blacker-than-black" (at 0 IRE), which represents the lowest low-frequency transmission voltage permissible in NTSC broadcasts (though the negative excursions of the colorburst signal may go below 0 IRE). Between the color bars and proper adjustment of brightness and contrast controls to the limits of perception of the first sub-black bar, an analog receiver (or other equipment such as VTRs) can be adjusted to provide impressive fidelity.

They are also used in the broader context of video displays for concerts and live events. There are a variety of different test patterns, each testing a specific technical parameter: gradient monotone bars for testing brightness and color; a crosshatch pattern for aspect ratio, alignment, focus, and convergence; and a single-pixel border for over-scanning and dimensions.

The famous RCA Indian-head test pattern used mainly in North America from 1940 to the 1970s with its elements labelled, describing the use of each element in aligning a black & white analog TV receiver.

Test cards are as old as TV broadcasts, with documented use by the BBC in the United Kingdom in its early 30-line mechanical Baird transmissions from 1934Occupied France during World War II.Radiodiffusion-Télévision Française 819-line test card introduced in 1953.

In North America, most test cards such as the famous Indian-head test pattern of the 1950s and 1960s have long since been relegated to history. The SMPTE color bars occasionally turn up, but with most North American broadcasters now following a 24-hour schedule, these too have become a rare sight.

With the introduction of color TV, electronically generated test cards were introduced. They are named after their generating equipment (ex: Grundig VG1000,Philips PM5544,Telefunken FuBK,BBC test card) or organization (ex: SMPTE color bars, EBU colour bars).

Formerly a common sight, test cards are now only rarely seen outside of television studios, post-production, and distribution facilities. In particular, they are no longer intended to assist viewers in calibration of television sets. Several factors have led to their demise for this purpose:

Modern microcontroller-controlled analogue televisions rarely if ever need adjustment, so test cards are much less important than previously. Likewise, modern cameras and camcorders seldom need adjustment for technical accuracy, though they are often adjusted to compensate for scene light levels, and for various artistic effects.

Use of digital interconnect standards, such as CCIR 601 and SMPTE 292M, which operate without the non-linearities and other issues inherent to analog broadcasting, do not introduce color shifts or brightness changes; thus the requirement to detect and compensate for them using this reference signal has been virtually eliminated. (Compare with the obsolescence of stroboscopes as used to adjust the speed of record players.) On the other hand, digital test signal generators do include test signals which are intended to stress the digital interface, and many sophisticated generators allow the insertion of jitter, bit errors, and other pathological conditions that can cause a digital interface to fail.

Test cards including large circles were used to confirm the linearity of the set"s deflection systems. As solid-state components replaced vacuum tubes in receiver deflection circuits, linearity adjustments were less frequently required (few newer sets have user-adjustable "VERT SIZE" and "VERT LIN" controls, for example). In LCD and other deflectionless displays, the linearity is a function of the display panel"s manufacturing quality; for the display to work, the tolerances will already be far tighter than human perception.

For custom-designed video installations, such as LED displays in buildings or at live events, some test images are custom-made to fit the specific size and shape of the setup in question. These custom test images can also be an opportunity for the technicians to hide inside jokes for the crew to see while installing equipment for a show.

Rather than physical test cards, which had to be televised using a camera, television stations often used a special purpose camera tube which had the test pattern painted on the inside screen of the tube. Each tube was only capable of generating the one test image, hence it was called a monoscope.

Monoscopes were similar in construction to an ordinary cathode ray tube (CRT), only instead of displaying an image on its screen it scanned a built-in image. The monoscope contained a formed metal target in place of the phosphor coating at its "screen" end and as the electron beam scanned the target, rather than displaying an image, a varying electrical signal was produced generating a video signal from the etched pattern. Monoscope tubes had the advantage over test cards that a full TV camera was not needed, and the image was always properly framed and in focus. They fell out of use in the 1960s as they were not able to produce color images.

There are also test patterns kits and software developed specifically for many consumer electronics. The B&K Television Analyst was developed in the 1960s for testing monochrome TV sets in the NTSC standard and was later modified for European and Australian PAL standards. Among other uses, it consisted of a flying spot scanner on which a test pattern printed on a cellulose acetate slide was shown.

When CRT monitors were still commonly used on personal computers, specific test patterns were created for proper calibration of such monitors in the cases whereby multimedia images could not be shown properly on said monitors.VCD and DVD lens cleaner discs, such as the Kyowa Sonic lens cleaning kits from 1997–2001, also included test patterns as well.

Test patterns are also used to calibrate medical displays for telemedicine and medical diagnostic purposes, such as the SMPTE RP-133 medical diagnostic imaging test pattern specification for medical and surgical displays, created around 1983AAPM in 2001.X-ray machines, in particular those manufactured by Leeds Test Objects in England, also exist as well.

Television has had such an impact in today"s life that it has been the main motif for numerous collectors" coins and medals. One of the most recent examples is The 50 Years of Television commemorative coin minted on 9 March 2005, in Austria. The obverse of the coin shows the centre portion of the Telefunken T05 test card, while the reverse shows several milestones in the history of television.

The Philips Pattern is widely recognised as one of the iconic popular culture symbols of the 1980s and 1990s. Numerous novelty and collectible items has been patterned after the famous test card, including wall clocks, bedsheets, wristwatches, and clothing.

In Britain, music - rather than radio sound - was usually played with the test card. The music played by the BBC, and afterwards ITV, was library music, which was licensed on more favourable terms for frequent use than commercially available alternatives. Later, Channel 4 used UK library LPs from publishers like KPM, Joseph Weinberger and Ready Music.

Until September 1955, the BBC used live playing 78 RPM commercial records as an audio background to the test cards. After that date, they switched to using recorded music on tape.celesta). ITV (which began its first trade transmissions in 1957) continued to use commercially available recordings until the late 1960s, when it also began to make specially produced tapes.

During the 1980s, the test card was gradually seen less and less - it was pushed out first by Teletext pages, then extended programme hours. The same tapes were used to accompany both the test card and Ceefax on BBC channels, but some fans argue that new tapes introduced after Ceefax became the norm in 1983 were less musically interesting.

Associated-Rediffusion–Marconi "diamond" monochrome test card versions 1, 2 and 3RTV in British Hong Kong, TVM in Crown Colony of Malta and WNTV in the western part of Colonial Nigeria

The Test Card Circle, a UK fan site: details of the UK"s Trade Test Transmissions including the history of the BBC and ITA Test Cards, a look at the music used and full details about the Trade Test Colour Films shown from the late fifties to 1973.

Some monitor calibrators have a uniformity testing function, and it’s not a bad idea to run it once in a while, if your screen is getting old. But not everyone has those calibrators, and anyway, they don’t always tell the whole story.

Of course this is NOT a very scientific testing method. Nerds will despair that I’m even suggesting it. But hey, I stand by it – it’s a good way to find little problems with your monitor before they become big problems.

I have a growing collection of old screens in my office (I’m a tech hoarder!) so I tested some more. One had some faint blurry vertical lines, like this:

Go ahead and test yours. I’m sure you’ll happily find that your screen is fine. But there might be a few people who discover a problem, and if so, it was definitely worth my while writing this article.

If you live in an urban area like I do, you’ll find that there are heaps of people selling second-hand monitors (eg on Facebook Marketplace). Potentially, a proportion of those would have been high-quality expensive screens in their day. (Remember to look for screens with IPS panels for photography). So you might find some genuinely good screens for sale at low prices, where the owners have upgraded to something bigger.

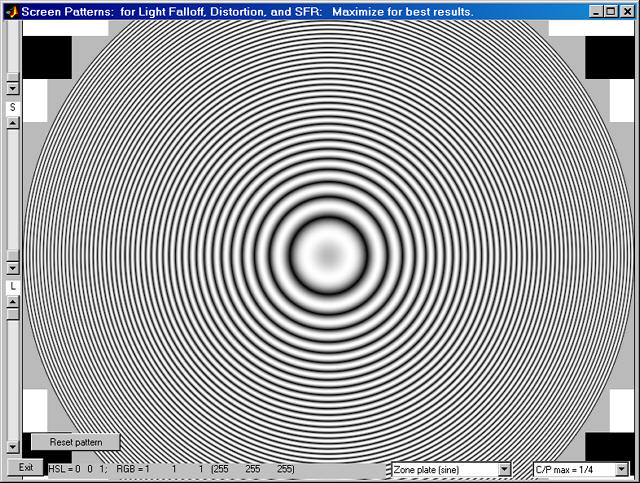

This selection contains several patterns that enable you to check your monitor’s calibration. The gamma patterns (left and middle) must be viewed on a monitor; they do not work in printed media. Reset pattern restores the default values, H = 0, S = 0, L = 1, and Gamma = 2.2.

This chart enables (shown below) you to set the black level (brightness) and estimate display gamma over a range of 1.2 to 2.8 with accuracy close to ±0.05. The gamma pattern is on the left; the black level pattern is on the right. Before using the chart, CRT monitors should be turned for on for at least 15 minutes. For flat screen (LCD) monitors, Screen resolution should be set to the monitor’s native resolution (right-click on the wallpaper, Properties, Settings).

Your monitor’s gamma should be set for 2.2 (for Windows systems).Gamma = 2.2 for the Internet-standard sRGB color space and the popular Adobe RGB (1998) color space. 1.8 was the standard for older Macintosh systems and prepress file interchange (Mac users, see Ian Lyons’ Mac Calibration page.). Many laptop LCD screens cannot be accurately calibrated because gamma is extremely sensitive to viewing angle (though my 2018 Asus Zenbook is better than I expected).You can adjust gamma using Quickgamma (a great free program) or a hardware calibrator (details here).

The image on the right shows the middle gamma pattern enlarged 4x. The upper part of this image, to the right of Standard, uses the same black-to-white sinusoidal variation as the Gamma and black level chart. The color patterns appear when the Alt pattern colors (T & B) box, located just to the right of the Gamma slider, is checked

When this image is displayed normal size (not enlarged; below) on a good quality monitor, the R-C, G-M, B-Y, and Standard patterns appear nearly identical.

Right: HSL rainbow patterns. These patterns are used for a rough visual estimate of the monitor’s color performance. They should appear well-saturated and have smooth color and tonal gradations (no abrupt changes). Laptops typically look very different from well-calibrated LCD or CRT monitors.

In order to perform motion pictures on the displays nowadays, the 2234 Video Pattern Generator has integrated the Multi-Media playback technology to provide versatile motion pictures for display quality evaluation test. It has high resolution test quality and multiple outputs support that can meet the requirements for multimedia video tests such as LCD Monitor / LCD TV / PDP / Projector of today and in the future.

This Video Pattern Generator provides both analog and digital signals, also supports multiple ports for independent output test and multimedia audio/video formats for play application. For the digital signal, the pixel rate of TMDS output is up to 330MHz and the test screen resolution is able to support beyond WQUXGA. Moreover, to cope with the higher frequency signal test for DVI Dual HDCP tests, it also supports dual link DVI test application.

In addition Chroma 2234 supports SSC (Spread Spectrum Clock, the technology to eliminate EMI) test that can significantly reduce the EMI problems occurred among displays and components, and simplify the product design.

For the application of multiple tests, Chroma 2234 supports a variety of audio/video and pattern file formats for play with the resolution up to 1080p. Meanwhile, to fulfill the test application for multi ports output, 3 HDMI and 2 DisplayPorts of which the output settings can be executed separately have been built in to reduce a great deal of test time and finish the tests in the fastest way possible.

For operation, Chroma 2234 has adopted full color graphic interface and built in memory for storage with the diversified special test patterns like xvYCC, HDCP&E-EDID, 8/10/12bit deep color, CEC, Lipsync and China high definition test patterns embedded for use. Tests can be performed easily and rapidly to save the time and control the cost.

A remote controller (optional) can be used to replace the direct panel editing for flexible practice in a large test area. It is suitable for mass application in the production line. In addition, various timing parameters and test patterns can be edited via the VPG Master application on PC site. The easy operating interface and complete test functions of Chroma 2234 are applicable for all video and related industries in R&D, production test and quality assurance.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Most panels also support true 8-bit per channel color. These improvements came at the cost of a higher response time, initially about 50 ms. IPS panels were also extremely expensive.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey