lcd module technology comparison price

The display industry has come a long way in recent years. With so many competing standards on the market today, it’s often hard to tell if an emerging technology is worth paying extra for. OLED and QLED, for instance, sound similar enough on the surface but are, in fact, completely different display types.

LCDs, or liquid crystal displays, are the oldest of all display types on this list. They are made up of two primary components: a backlight and a liquid crystal layer.

Since liquid crystals don’t produce any light by themselves, LCDs rely on a white (or sometimes blue) backlight. The liquid crystal layer then simply has to let this light pass through, depending on the image that needs to be displayed.

You may have noticed that the term LCD has started to disappear of late, especially in the television industry. Instead, many manufacturers now prefer branding their televisions as LED models instead of LCD. Don’t be fooled, though — this is just a marketing ploy.

These so-called LED displays still use a liquid crystal layer. The only difference is that the backlights used to illuminate the display now use LEDs instead of cathode fluorescent lamps, or CFLs. LEDs are a better light source than CFLs in almost every way. They are smaller, consume lesser power, and last longer. However, the displays are still fundamentally LCDs.

Twisted nematic, or TN, was the very first LCD technology. Developed in the late 20th century, it paved the way for the display industry to transition away from CRT.

TN panels have been around for decades in devices like handheld calculators and digital watches. In these applications, you only need to power sections of the display where you don’t want light. In other words, it is an incredibly energy-efficient technology. Twisted nematic panels are also cheap to manufacture.

Instead of a twisted orientation, liquid crystals in an IPS display are oriented parallel to the panel. In this default state, light is blocked — the exact opposite of what happens in a TN display. Then, when a voltage is applied, the crystals simply rotate in the same plane and let light through. As a side note, this is why the technology is called in-plane switching.

Having said that, IPS displays do come with a few minor compromises. The technology isn’t nearly as energy-efficient as TN, nor is it as cheap to manufacture at scale. Still, if you care about color accuracy and viewing angles, IPS is likely your only option.

This default vertical arrangement blocks a lot more of the backlight from coming through to the front of the display. Consequently, VA panels are known for producing deeper blacks and offering better contrast compared to other LCD display types. As for bit-depth and color gamut coverage, VA is capable of doing just as well as IPS.

On the downside, the technology is still relatively immature. Early VA implementations suffered from extremely slow response times. This led to ghosting, or shadows behind fast-moving objects. The reason for this is simple — it takes longer for VA’s perpendicular arrangement of crystals to change orientation.

From this description alone, it’s easy to see how OLED differs from LCD and prior display types. Since the compounds used in OLEDs emit their own light, they are an emissive technology. In other words, you don’t need a backlight for OLEDs. This is why OLEDs are universally thinner and lighter than LCD panels.

Since each organic molecule in an OLED panel is emissive, you can control whether a particular pixel is lit up or not. Take away the current and the pixel turns off. This simple principle allows OLEDs to achieve remarkable black levels, outperforming LCDs that are forced to use an always-on backlight. Besides delivering a high contrast ratio, turning off pixels also reduces power consumption.

The contrast alone would make the technology worth it, but other benefits exist too. OLEDs boast high color accuracy and are extremely versatile. Foldable smartphones such as the Samsung Galaxy Flip series simply wouldn’t exist without AMOLED’s physical flexibility.

In summary, OLED subtypes aren’t nearly as varied as LCDs. Furthermore, only a handful of companies manufacture OLEDs so there’s even less quality variance than you’d expect. Samsung manufactures the majority of OLEDs in the smartphone industry. Meanwhile, LG Display has a near-monopoly on the large-sized OLED market. It supplies panels to Sony, Vizio, and other giants in the television industry.

In the section on LCDs, we saw how the technology can vary based on differences in the liquid crystal layer. Mini-LED, however, attempts to improve contrast and image quality at the backlight level instead.

The backlights in conventional LCDs have only two modes of operation — on and off. This means that the display has to rely on the liquid crystal layer to adequately block light in darker scenes. Failing to do that results in the display producing grays instead of true black.

This technique, known as local dimming, has become ubiquitous in higher-end LCD televisions. Until recently, though, it wasn’t viable for smaller displays like those found in laptops or smartphones. And even in larger devices like monitors and TVs, you run the risk of not having enough dimming zones.

Take the 2021 iPad Pro, for example. It was among the first consumer devices to adopt mini-LED technology. Even with 2,500 zones across 12.9 inches, however, some users reported blooming or halos around bright objects.

Still, it’s not hard to see how mini-LEDs can eventually deliver better contrast than conventional local dimming implementations. Furthermore, since mini-LED displays still rely on traditional LCD technologies, they aren’t prone to burn-in like OLEDs.

Quantum dot technology has become increasingly common — usually positioned as a key selling point for many mid-range televisions. You may also know it by Samsung’s marketing shorthand: QLED. Similar to mini-LED, however, it isn’t some radically new panel technology. Instead, quantum dot displays are basically conventional LCDs with an additional layer sandwiched in between.

When combined with traditional LCD color filters, quantum dot displays can cover a greater percentage of the visible light spectrum. Put simply, you get richer and ore accurate colors — enough to deliver a satisfactory HDR experience. And since the crystals emit their own light, you also get a tangible bump in brightness compared to traditional LCDs.

However, quantum dot technology does not improve other pain points of LCDs such as contrast and viewing angles. For that, you’d have to combine quantum dots with local dimming or mini-LED technologies. And until those mature, you’re unlikely to find a quantum dot display that can rival OLED in all aspects.

Quantum-dot OLED, or QD-OLED, is an amalgamation of two existing technologies — quantum dots and OLED. More specifically, it aims to eliminate the drawbacks of both traditional OLEDs and LCD-based quantum dot displays.

Modern OLED implementations combat this by leaving the fourth sub-pixel white (without any color filters) to improve the perception of brightness. However, they still usually fall short in terms of brightness, especially against high-end LCDs with larger backlights.

However, it’s still early days for the technology as a whole. Traditional OLEDs have enjoyed a nearly decade-long head start yet remain relatively unaffordable. It remains to be seen if QD-OLED televisions and monitors can compete in terms of price and durability, especially considering the risks of image retention or burn-in with organic compounds.

Their small size means that you can build an entire display out of microLEDs alone. The result is an emissive display — much like OLED, but without the drawbacks of that technology’s organic component. There’s no backlight either, so each pixel can be turned off completely to represent black. All in all, the technology delivers an exceptionally high contrast ratio and wide viewing angles.

Finally, MicroLED displays can also be modular. Even some of the earliest demonstrations of the technology had manufacturers creating giant video walls using a grid of smaller microLED panels.

Samsung offers its flagship The Wall microLED display (pictured above) in configurations ranging from 72 inches all the way to 300 inches and beyond. With a million-dollar price tag, though, it is clearly not a consumer product. Still, it offers a glimpse into the future of televisions and display technology in general.

And with that, you’re now up to speed on every display technology on the market today! Display types can vary significantly and the best option depends on the characteristics you deem important or require the most.

LCD modules are one of the most popular components and are great for users who are looking for a more natural LCD experience, even if it is just a small bit of light. high brightness will interfere with the display of others.

A LCD panel (LCD)) is one of the most popular electronic devices that have a lot of electronic components as well, a one-time wearable LCD module (LCD), is a popular choice because it provides more numerous features to the user. compact lcd modules allow for simple components and can be used with a higher amount of power. As a result, the lcd modules allow for simple components, such as gadgets, and are used to supplement the ones that are more important.

While there are a number of wholesale lcd modules available on Alibaba.com, one may be able to find a great variety of wholesale lcd modules and kits. For consumers who are looking for suitable lcd modules in bulk, a quick search on Alibaba.com for the lcd module wholesale that is suitable for a number of wholesale components. One of the most popular lcdds bulk assembly is the lcd module wholesale that is suitable for one of the most convenient components and wholesalers.

There are plenty of new and confusing terms facing TV shoppers today, but when it comes down to the screen technology itself, there are only two: Nearly every TV sold today is either LCD or OLED.

The biggest between the two is in how they work. With OLED, each pixel provides its own illumination so there"s no separate backlight. With an LCD TV, all of the pixels are illuminated by an LED backlight. That difference leads to all kinds of picture quality effects, some of which favor LCD, but most of which benefit OLED.

LCDs are made by a number of companies across Asia. All current OLED TVs are built by LG Display, though companies like Sony and Vizio buy OLED panels from LG and then use their own electronics and aesthetic design.

So which one is better? Read on for their strengths and weaknesses. In general we"ll be comparing OLED to the best (read: most expensive) LCD has to offer, mainly because there"s no such thing as a cheap OLED TV (yet).

The better LCDs have local dimming, where parts of the screen can dim independently of others. This isn"t quite as good as per-pixel control because the black areas still aren"t absolutely black, but it"s better than nothing. The best LCDs have full-array local dimming, which provides even finer control over the contrast of what"s onscreen -- but even they can suffer from "blooming," where a bright area spoils the black of an adjacent dark area.

One of the main downsides of LCD TVs is a change in picture quality if you sit away from dead center (as in, off to the sides). How much this matters to you certainly depends on your seating arrangement, but also on how much you love your loved ones.

A few LCDs use in-plane switching (IPS) panels, which have better off-axis picture quality than other kinds of LCDs, but don"t look as good as other LCDs straight on (primarily due to a lower contrast ratio).

OLED doesn"t have the off-axis issue LCDs have; its image looks basically the same, even from extreme angles. So if you have a wide seating area, OLED is the better option.

Nearly all current TVs are HDR compatible, but that"s not the entire story. Just because a TV claims HDR compatibility doesn"t mean it can accurately display HDR content. All OLED TVs have the dynamic range to take advantage of HDR, but lower-priced LCDs, especially those without local-dimming backlights, do not. So if you want to see HDR content it all its dynamic, vibrant beauty, go for OLED or an LCD with local dimming.

In our tests comparing the best new OLED and LCD TVs with HDR games and movies, OLED usually looks better. Its superior contrast and lack of blooming win the day despite LCD"s brightness advantage. In other words LCD TVs can get brighter, especially in full-screen bright scenes and HDR highlights, but none of them can control that illumination as precisely as an OLED TV.

The energy consumption of LCD varies depending on the backlight setting. The lower the backlight, the lower the power consumption. A basic LED LCD with its backlight set low will draw less power than OLED.

LG has said their OLED TVs have a lifespan of 100,000 hours to half brightness, a figure that"s similar to LED LCDs. Generally speaking, all modern TVs are quite reliable.

Does that mean your new LCD or OLED will last for several decades like your parent"s last CRT (like the one pictured). Probably not, but then, why would you want it to? A 42-inch flat panel cost $14,000 in the late 90"s, and now a 65-inch TV with more than 16x the resolution and a million times better contrast ratio costs $1,400. Which is to say, by the time you"ll want/need to replace it, there will be something even better than what"s available now, for less money.

OLED TVs are available in sizes from 48 to 88 inches, but LCD TVs come in smaller and larger sizes than that -- with many more choices in between -- so LCD wins. At the high end of the size scale, however, the biggest "TVs" don"t use either technology.

You can get 4K resolution, 50-inch LCDs for around $400 -- or half that on sale. It"s going to be a long time before OLEDs are that price, but they have come down considerably.

LCD dominates the market because it"s cheap to manufacture and delivers good enough picture quality for just about everybody. But according to reviews at CNET and elsewhere, OLED wins for overall picture quality, largely due to the incredible contrast ratio. The price difference isn"t as severe as it used to be, and in the mid- to high-end of the market, there are lots of options.

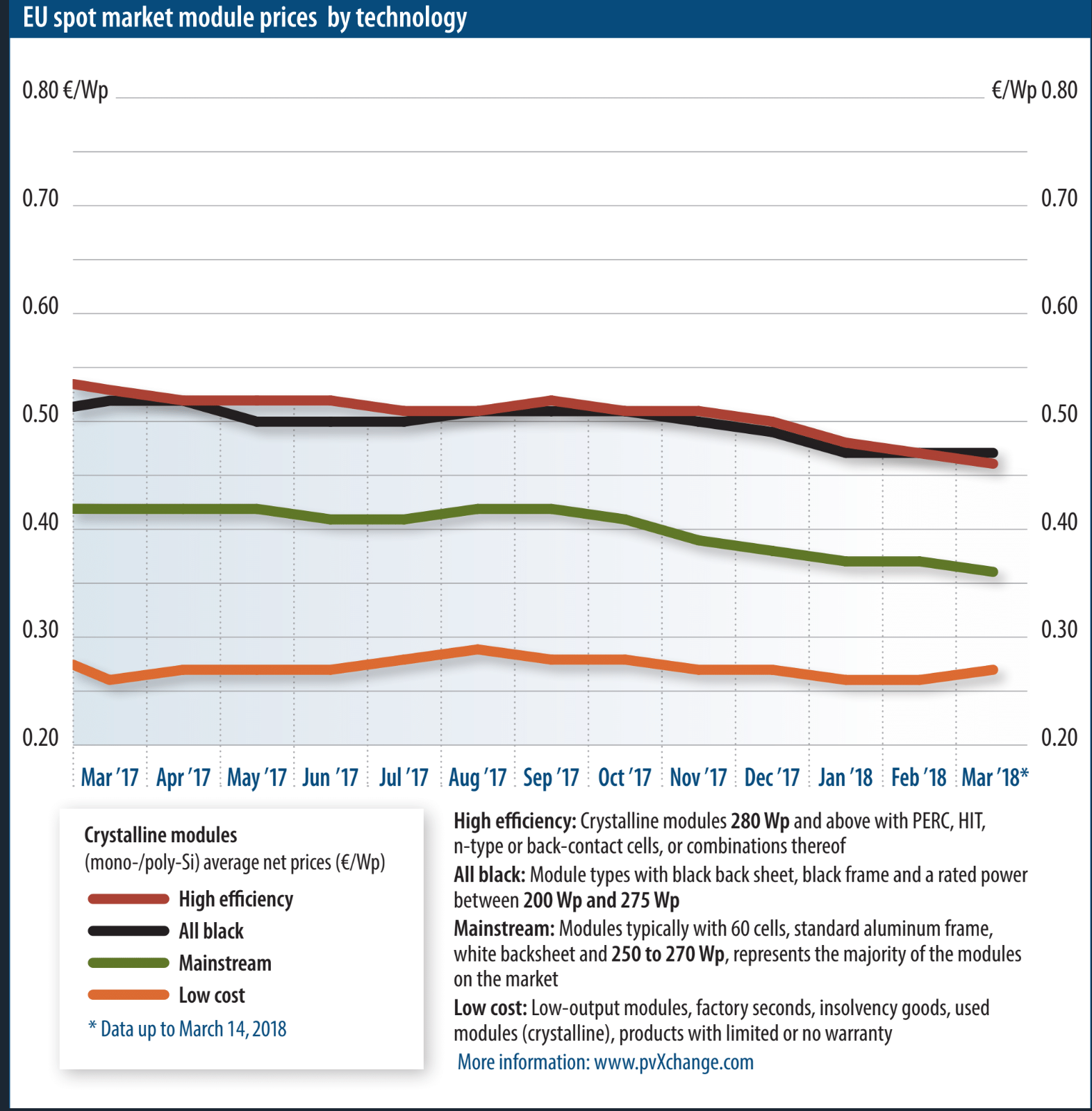

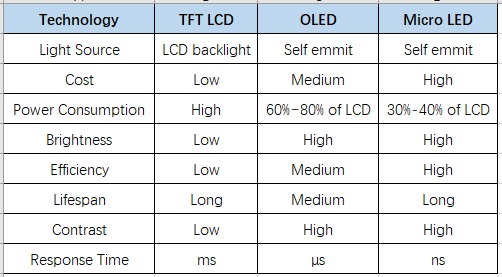

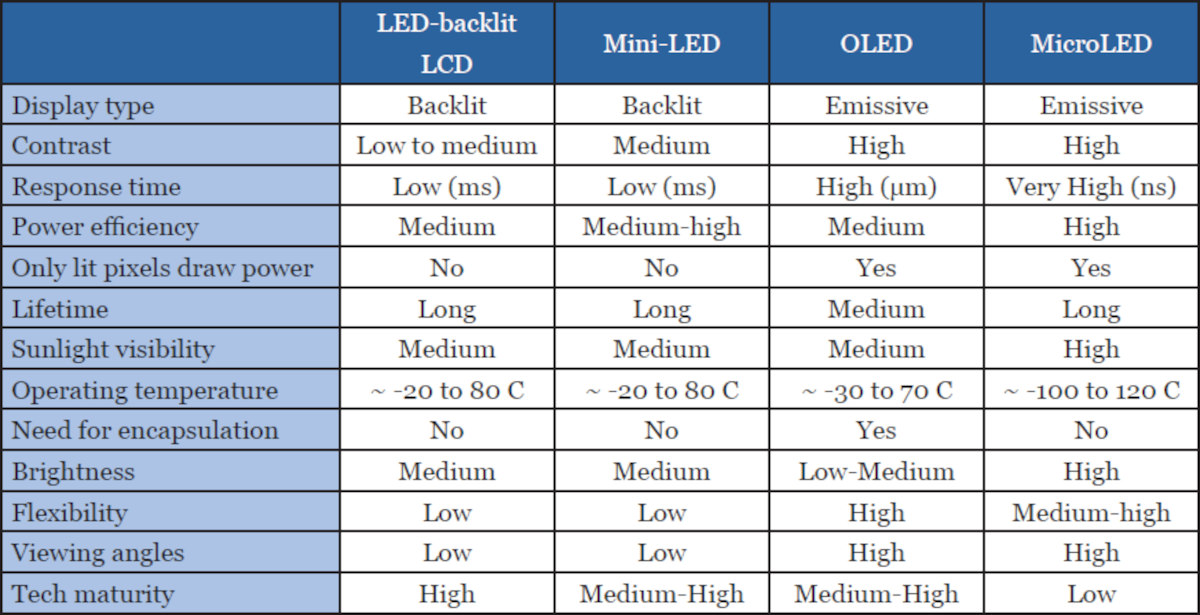

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Major technologies are CRT, LCD and its derivatives (Quantum dot display, LED backlit LCD, WLCD, OLCD), Plasma, and OLED and its derivatives (Transparent OLED, PMOLED, AMOLED). An emerging technology is Micro LED and cancelled and now obsolete technologies are SED and FED.

The Internet of Things (commonly known as IoT) is a network of physical "things" embedded with other technologies to connect and transfer data with devices on the internet. These devices can be everyday household objects or complex industrial tools. Since we can connect everyday things like thermostats, kitchen appliances and baby monitors to the internet, IoT has become an essential technology, transforming the way we live and work.

Besides enabling smart homes, automated IoT systems have become essential to business. IoT technology offers businesses real-time insight into how their systems work, right from the performance of machines to the supply chain and logistics processes. As a result, it helps monitor the overall business processes, improve productivity, generate more revenue, improve customer experience, and save time and money.

It’s likely that as the IoT market grows, there will be greater demand for displays catering to both commercial needs and consumers. Selecting the best display for your IoT device involves understanding the application requirements and then finding the IoT display technology that serves those needs the best. We’ve compared six display technologies suitable for integration with IoT devices.

TCT LCDs have seen improvements over the last decade. Some LCDs offer such high resolution that it is practically impossible to notice individual pixels with the naked eye. Moreover, movie enthusiasts and gamers have pushed display refresh rates to the stage of displaying even the fastest action clearly. LCDs can be used in applications needing a rich multimedia experience or in dimly lit places. However, LCDs are less readable in direct sunlight.

LCDs consume more energy than display technology such as EPD. Therefore, these are best suited for devices that can be charged regularly, like mobile phones or IoT devices that are continuously powered, such as thermostats and automotive displays. In addition, since LCDs require a backlight, the LCD module is thicker than the EPD module.

OLED technology has seen a rapid increase in mobiles, high-end TVs and smartwatches. It can display high contrast ratios as it can control the brightness of individual pixels. In theory, the power efficiency of OLED technology is better than TFT LCDs. This is because they use efficient organic light-emitting diodes, whereas LCDs use liquid-crystal materials to either block or show the backlight from each pixel. Moreover, the viewing angles are also much better than most LCDs.

Like many technologies, there are some disadvantages of OLEDs. For example, there are ageing issues with some electroluminescent materials, sensitivity to water, same daylight readability problems as with LCDs. Moreover, they are costly when compared to LCDs.

The evolution of IoT display technology is developing at a rapid pace. At present, some of the biggest manufacturers are testing newly emerging display technologies, such as electrochromic displays. As a result, the next generation of displays may look the same as today but function entirely differently as we push to more energy-efficient, flexible display designs.

LCDs were the only choice for low power until the arrival of two exciting options into the display market - E-ink display and Electrochromic display. This article will discuss these three low-power display technologies in brief and compare different features like power consumption, display quality, and more.

Reflective LCDs are prevalent in consumer electronics because of their low power consumption, ease of production, and cost-effectiveness. Low power seven segment display is widely used in calculators, digital clocks, radios, microwave ovens, and washing machines. It works by reflecting ambient light - such as natural light - from a reflective layer back to the viewer.

Electrophoretic display technology (which is used in E-ink displays) has a paper-like ultra contrast appearance that replicates the appearance of ordinary ink on paper. This display technology is popular because of its contrast, readability, thickness, low power consumption, and flexibility. It is widely used in e-readers like Amazon"s Kindle, real-time bus arrival information, electronic shelf label (ESL) segment, menu boards, etc. When the display is electrically charged, charged ink particles rise to the top of the display to create images.

An electrochromic display is the best low-power display technology in the market today. These ultra-low-power displays are lightweight, thin, energy-efficient, and cost-effective to produce and operate. They can also be bendable, meaning that they are easily customizable to individual business needs. As a result, these displays are widely used in logistics monitoring, consumer electronics, medical devices, smart cards, and more. Like the LCD, it works by reflecting ambient light. Using electrochromism, when a voltage is applied, the display will change color.

The electrochromic display is the most energy-efficient display technology for medium-frequency switching, i.e. if the display switches between 4-600 times a day.

There are two main competing display technologies in the market today: LCD and OLED. The mature and dominant technology is the Liquid Crystal Display (LCD), while the up-and-coming challenger is the Organic Light Emitting Diode Display (OLED display). The main difference between LCD and OLED displays is how they create the light and the colors of the image being displayed. This leads to application dependent strengths and weaknesses of either technology.

OLEDs operate via a solid-state technology, where the individual pixels can emit light in various colors and intensity without the need for an additional light source or color filter. The light-emitting portion of an OLED display is comprised of multiple layers of very specific organic semiconductor materials which can be adjusted to emit light in specific wavelengths. These organic layers have a typical thickness in the order of 100nm. In addition, no backlight is required, allowing for a very thin display module.

In LCD display technology, the individual pixels modulate light. An applied voltage changes the orientation of liquid crystal molecules that – in conjunction with a pair of polarizers – function as a light shutter by either blocking or allowing light to pass through. LCD displays, therefore, require an additional light source, either from reflected ambient light or more commonly from a “backlight” (an array of LEDs arranged behind or next to the LCD panel). LCD color can be created by adding color filters to the individual pixels. Because OLED displays don’t require the additional backlight, polarizers, or color filter components of an LCD module, they can be made much thinner than LCD displays of equivalent size and resolution.

OLED display technology can offer power-saving advantages over LCDs, which is important, especially for battery-powered applications such as mobile phones. An OLED’s power consumption will vary with image content and brightness, as light is generated only at the individual pixels needed to display the image. A dark image or a graphic on a black background will consume much less power than bright images or graphics. In contrast, LCD backlights must be ON while the display operates. It’s possible to control individual zones of the backlight separately to save power, but this added complexity is usually only applied in larger displays.

OLEDs can achieve a much higher contrast ratio if reflections from the front surface are carefully controlled. If no current flows through an OLED pixel, it does not emit any light. In contrast the shutter effect of an LCD pixel does not block 100% of the light. Depending on the specific LCD technology used and the angle of observation, a small percentage of the light generated in the backlight can escape. This can wash out dark areas of an image. It is possible but expensive to limit this light leakage to a point where the contrast of an LCD and OLED display become perceptually equivalent.

RGB OLEDs naturally generate a narrow bandwidth of light. This leads to very saturated primary colors and a wide color gamut. This enables OLED technology to display colors which are not easily accessible to LCDs unless RGB backlights or quantum dots are used. Often OLED colors are used “as is”, however, for very high image color fidelity, such high color saturation needs to be electronically ‘tuned down’, to match the color bandwidth of the rendering chain.

LCDs offer an advantage over OLEDs in applications where a continuous static image is required. The light emitting materials in OLEDs are affected by luminance decay as a function of the total amount of current that has passed through the pixel. This decay differs for red, green and blue. The dimming effect is subtle, but when adjacent pixels are illuminated at the same time it can become noticeable as an undesired brightness variation or color shift. LCDs don’t suffer from this dimming effect, which makes them a more suitable solution for applications with static images or images with static elements.

Another advantage of LCD technology is the wide variety of different variations to choose from. Depending on the application certain trade-offs can be very attractive. An example is much lower cost for a laptop display compared to a tablet. This is achieved by allowing poor image performance when viewed from the direction the is usually blocked by the keyboard. In a tablet where good viewing performance is required from any direction, much higher cost LCDs or OLEDs must be used.

They can be used to replace old TN LCDs or add dynamic push buttons on industrial equipment. They can be customized to various resolutions, FPC configurations, colors, custom shaped OLED displays (e.g. octagonal, round, etc.) and can even be made into flexible and transparent displays. Thanks to their versatility, OLED display panel suppliers can offer some exciting capabilities for their customers – things that were previously impossible with LCDs.

As an experienced LCD and OLED panel supplier, New Vision Display can help you find the right technology for your application. Contact us via the below form to discuss your project.

The most basic LCD introduced above is called passive matrix LCDs which can be found mostly in low end or simple applications like, calculators, utility meters, early time digital watches, alarm clocks etc. Passive matrix LCDs have a lot of limitations, like the narrow viewing angle, slow response speed, dim, but it is great for power consumption.

In order to improve upon the drawbacks, scientists and engineers developed active matrix LCD technology. The most widely used is TFT (Thin Film Transistor) LCD technology. Based on TFT LCD, even more modern LCD technologies are developed. The best known is IPS (In Plane Switching) LCD. It has super wide viewing angle, superior image picture quality, fast response, great contrast, less burn-in defects etc.

IPS LCDs are widely used in LCD monitors, LCD TVs, Iphone, pads etc. Samsung even revolutionized the LED backlighting to be QLED (quantum dot) to switch off LEDs wherever light is not needed to produce deeper blacks.

– Twisted Nematic Display: The TN (Twisted Nematic) LCDs production can be done most frequently and used different kinds of displays all over the industries. These displays are most frequently used by gamers as they are cheap & have quick response time as compared with other displays. The main disadvantage of these displays is that they have low quality as well as partial contrast ratios, viewing angles & reproduction of color. But, these devices are sufficient for daily operations.

– In-Plane Switching Display:IPS displays are considered to be the best LCD because they provide good image quality, higher viewing angles, vibrant color precision & difference. These displays are mostly used by graphic designers & in some other applications, LCDs need the maximum potential standards for the reproduction of image & color.

– Vertical Alignment Panel: The vertical alignment (VA) panels drop anywhere in the center among Twisted Nematic and in-plane switching panel technology. These panels have the best viewing angles as well as color reproduction with higher quality features as compared with TN type displays. These panels have a low response time. But, these are much more reasonable and appropriate for daily use.

– Advanced Fringe Field Switching (AFFS): AFFS LCDs offer the best performance & a wide range of color reproduction as compared with IPS displays. The applications of AFFS are very advanced because they can reduce the distortion of color without compromising on the broad viewing angle. Usually, this display is used in highly advanced as well as professional surroundings like in the viable airplane cockpits.

– Passive and Active Matrix Displays: The Passive-matrix type LCDs works with a simple grid so that charge can be supplied to a specific pixel on the LCD. One glass layer gives columns whereas the other one gives rows that are designed by using a clear conductive material like indium-tin-oxide. The passive-matrix system has major drawbacks particularly response time is slow & inaccurate voltage control. The response time of the display mainly refers to the capability of the display to refresh the displayed image.

– Active-matrix type LCDs mainly depend on TFT (thin-film transistors). These transistors are small switching transistors as well as capacitors which are placed within a matrix over a glass substrate. When the proper row is activated then a charge can be transmitted down the exact column so that a specific pixel can be addressed, because all of the additional rows that the column intersects are switched OFF, simply the capacitor next to the designated pixel gets a charge.

LCD technologies have great advantages of light, thin, low power consumption which made wall TVs, laptops, smartphones, pad possible. On its way to progress, it wiped out the competition of many display technologies. We don’t see CRT monitors on our desks and plasma displays TV at our home anymore. LCD Technologies dominant the display market now. But any technology has the limitations.

LCD technologies have slow response times especially at low temperature, limited viewing angles, backlighting is needed. Focus on LCD drawbacks, OLED (Organic Light Emitting Diodes) technology was developed. Some high-end TV and mobile phones start to use AMOLED (Active Matrix Organic Light Emitting Diodes) displays.

This cutting-edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology. Please note, OLED displays include AMOLED and PMOLED (Passive Matrix Organic Light Emitting Diodes). What you need to choose is AMOLED for your TV and mobile phones instead of PMOLED.

Liquid Crystal Display (LCD) screens are a staple in the digital display marketplace and are used in display applications across every industry. With every display application presenting a unique set of requirements, the selection of specialized LCDs has grown to meet these demands.

LCD screens can be grouped into three categories: TN (twisted nematic), IPS (in-plane switching), and VA (Vertical Alignment). Each of these screen types has its own unique qualities, almost all of them having to do with how images appear across the various screen types.

This technology consists of nematic liquid crystal sandwiched between two plates of glass. When power is applied to the electrodes, the liquid crystals twist 90°. TN (Twisted Nematic) LCDs are the most common LCD screen type. They offer full-color images, and moderate viewing angles.

TN LCDs maintain a dedicated user base despite other screen types growing in popularity due to some unique key features that TN display offer. For one,

Displays with VA screens deliver wide viewing angles, high contrast, and good color reproduction. They maintain high response rates similar to TN TFTs but may not reach the same sunlight readable brightness levels as comparable TN or IPS LCDs. VA displays are generally best for applications that need to be viewed from multiple angles, like digital signage in a commercial setting.

IPS (In-Plane Switching) technology improves image quality by acting on the liquid crystal inside the display screen. When voltage is applied, the crystals rotate parallel (or “in-plane”) rather than upright to allow light to pass through. This behavior results in several significant improvements to the image quality of these screens.

Based on current trends, IPS and TN screen types will be expected to remain the dominant formats for some time. As human interface display technology advances and new product designs are developed, customers will likely choose IPS LCDs to replace the similarly priced TN LCDs for their new projects.

... Specification TOPWAY HMT035ATA-1C is a Smart TFT Display Module with 32bit MCU on board. Its graphics engine provides numbers of outstanding features. It supports TOPWAY TML 3.0 for preload and pre-design display ...

TOPWAY Smart LCDs embed a display engine and a versatile range of TFT display module sizes and Touch-Panels to support a wide range of industrial and instrumentation application.The pre-loaded User Interface ...

TOPWAY HMT101ATA-C is a Smart TFT display module with 32bit MCU on board. Its graphics engine provides numbers of outstanding features. It supports TOPWAY TML for preload and pre-design display interface ...

A 13.3-inch touch display kit has a higher light transmittance and low light reflection, which can improve the brightness of the picture and clearly see the picture in the sun. With optical bonding technology, ...

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey