tft lcd driving circuit manufacturer

INT018ATFT is an embedded display driver board based on our 1.8 inch 128 x 160 RGB resolution TFT display module. Mounted on the embedded board is the RAIO RA8872 LCD controller that offers the following features and benefits:

INT028ATFT and INT028ATFT-TS are embedded display driver boards based on our 2.8 inch 240 x 320 RGB resolution TFT display module. Mounted on the embedded board is the RAIO RA8872 LCD controller that offers the following features and benefits:

TFT LCDs have become the norm for small-to-medium size displays in a variety of products within industrial, medical, POS and consumer applications. Compared to passive-addressed monochrome LCDs, TFT displays offer higher contrast, wider viewing angles, faster response time and full color. And, TFT LCDs are now on cost parity with similar size passive LCD displays.

A typical TFT LCD module product consists of a TFT LCD panel, one or more COG (chip-on-glass) driver ICs, a backlight unit, and an interface FPC. Several TFT display interface technologies coexist today. Picking the right technology depends on specific end-product concerns. Most often the display panel input will dictate that choice since TFT panels are designed to be COG bonding pad compatible with a very limited number of driver ICs. This article discusses the interfaces between TFT LCD modules and the typical CPUs found in embedded applications.

Typical TFT interfaces are determined by the particular TFT panel size and resolution, as shown in the below table. HDMI and eDP require interface converting boards and generally are not used for small to medium-size TFT LCDs.TFT LCD SizesResolutionsTypical Interfaces UsedUp to 3.5″128×160 to 240×320SPI, parallel MPU or RGB

The LCD controller signals are two types: data signals and control signals. The data signals are connected to the LCD data bus and depend on the LCD color depth (8-bit, 9-bit, 16-bit, 18-bit). The control signals are used to define the operation type (read or write), and whether the operation involves in addressing LCD registers or the display RAM.

LVDS interfacing has several benefits for TFT displays. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from the display. Also, LVDS generally consumes less power, pin counts are lower and there are far fewer worries about signal integrity.

Modern TFT driver ICs are highly integrated chips combining the source driver, gate driver and timing controller (TCON) – as well as other functional circuits such as memory, power circuit, and image processors – into one single IC die. Some driver ICs support multiple interfaces that are selectable on the module FPC or through initialization code firmware.

As a designer and manufacturer of custom LCD modules, New Vision Display works with customers to select the most appropriate and cost-effective TFT display and electronic interface solution for their particular requirement. New Vision Display has nearly 30 years of industry experience as one of the world’s leading TFT LCD screen manufacturers.

(Hong Kong – 08 Oct, 2004) – With respect to the increasing demand on TFT module for smart phone application, Solomon Systech Limited launched today their first single chip TFT LCD driver IC SSD1278 which supports 176×220 (QCIF+) resolution and 262K color smart phone system. SSD1278 is a single chip solution that includes gate/source driver blocks and power management circuit. SSD1278 with RGB interface, which is supported by common image processors/graphic controllers, is a perfect solution for speedy data transfer when using CMOS/CCD camera in the smart phone system.

SSD1278 is the smallest (with only 20.9 x 1.4mm² die size) and the simplest solution commercially available for QCIF+ resolution in the amorphous TFT display. The advantages of the small die size are not only in cost reduction of the module but also achievement of compact design of the phone. The smaller die allows thinner contact ledge at the LCD module and therefore smaller overall physical size. Besides, the advanced design technology from Solomon Systech achieves low power consumption in the TFT LCD module system. This is one of the essential factors in all portable systems. In an actual measurement of a 1.9″, 176×220 QCIF+ display module using Solomon Systech’s TFT driver SSD1278, the module power consumption at 262k color, 60Hz frame frequency and line inversion is only 8mW, while the power consumption at frame inversion is even 7mW. These low power consumption values enable Solomon Systech to become one of the most competitive TFT LCD driver suppliers in the market.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

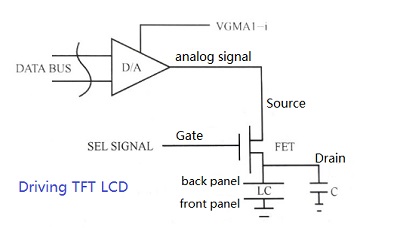

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp text/graphic with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The color TFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

The rapid progress of multimedia demands liquid crystal display (LCD) projectors that can display computer data, such as video-graphic arrays (VGA), super-video-graphic arrays (SVGA), extended-graphic arrays (XGA) and super-extended-graphic arrays (SXGA). One of the major challenges for poly-Si TFT drivers in such multi-scan LCDs is displaying as black in the peripheral region around the picture during a blanking period. Using conventional shift register driver circuits, the scanning speed in the up-and-down no-picture region is too high for pixel TFTs to write signals for black. Although decoder driver circuits for multi-scan operation have been introduced into an HDTV poly-Si TFT-LCD, they require many address signals and logic gates. These increase circuit area and thereby decrease the manufacturing yields. Poly-Si TFT drivers use a combination of bi-directional shift registers and decoder circuits to solve the above problems for a 2.7 in, 1.3 Mpixel TFT LCD light valve.

Panox Display`s 2.45 inch LCD is 240x432 pixel MP4 used TFT-LCD display with MIPI 1lanes interface, outstanding display quality, vivid color, super wide view angle, high brightness(500 nits) and easily controlled by MCU such as SSD2828, STM32, GD32, AVR, ARDUINO, ARM, and Raspberry PI.

It can be used in any iPod nano, Read scanning pen, Driving Recorder, Hand-held equipment, and dynamic information displays requires a display in high-quality and colorful images.

Panox Display values every opportunity to cooperate with clients, because TFT-LCD is very fragile, so we provide a solid package and the fastest way to ship. Panox Display has seven years experience of in international trade and served more than 1000 clients all over World.

To make your development of the TFT-LCD driver more smooth, Panox Display will provide free connectors and an adapter board, engineers can directly fly lines to the main board.

But Panox Display is not a school, if customers don`t know the basic knowledge to design circuit boards, we suggest using our controller board to drive the display.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey