tft lcd driving circuit supplier

There are other types of Tft lCD driver, such as amber tft stick driver, battery tft lcd driver, and strip sticks for battery tft drivers. In this type, the sticks are free of the battery and can be used into many other if as is the case. Moreover, the tft lcd driver vary in its aspects as it is powered and can be used with many others.@@@@@

There are two types of Tft lCD driver for 12v and one such is the Tft LCD driver 12v. In this case, the Tft LCD driver for 12v is also called the Tft LCD driver from 12v to 24v. It is essential to know that a tft lCD driver is 12v or 24v. And in this case, a tft lcd driver with 12v power supply can be obtained.

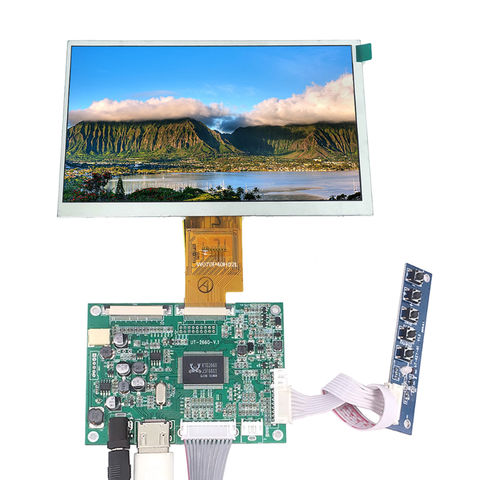

A wide variety of driver board for tft lcd options are available to you, such as original manufacturer, odm.You can also choose from datasheet, driver board for tft lcd,As well as from tft, ips, and standard.

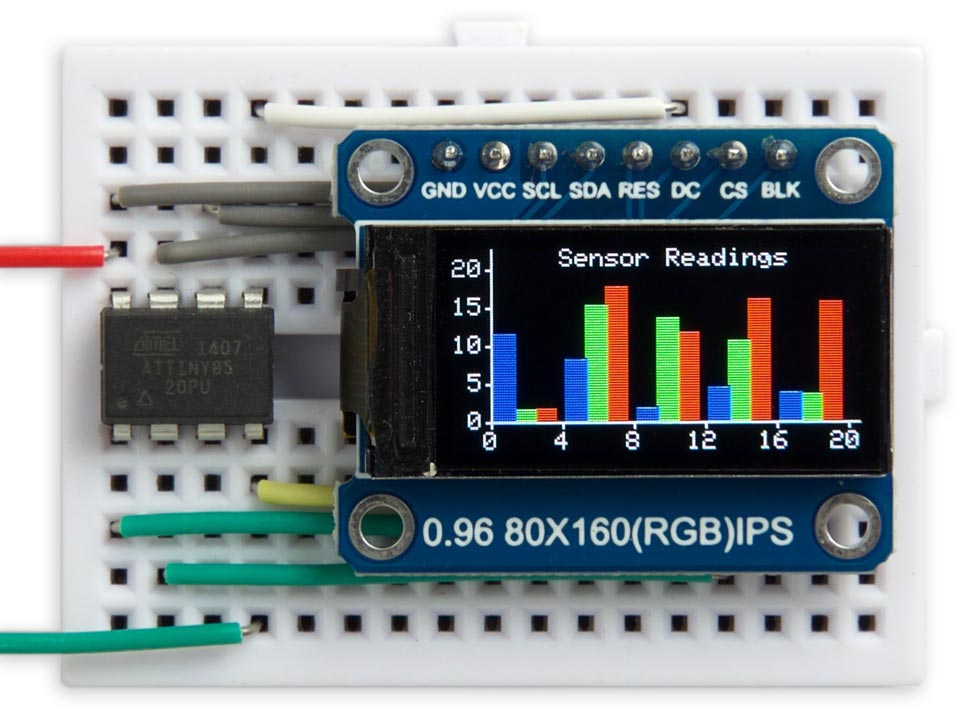

Panox Display`s 2.45 inch LCD is 240x432 pixel MP4 used TFT-LCD display with MIPI 1lanes interface, outstanding display quality, vivid color, super wide view angle, high brightness(500 nits) and easily controlled by MCU such as SSD2828, STM32, GD32, AVR, ARDUINO, ARM, and Raspberry PI.

It can be used in any iPod nano, Read scanning pen, Driving Recorder, Hand-held equipment, and dynamic information displays requires a display in high-quality and colorful images.

Panox Display values every opportunity to cooperate with clients, because TFT-LCD is very fragile, so we provide a solid package and the fastest way to ship. Panox Display has seven years experience of in international trade and served more than 1000 clients all over World.

To make your development of the TFT-LCD driver more smooth, Panox Display will provide free connectors and an adapter board, engineers can directly fly lines to the main board.

But Panox Display is not a school, if customers don`t know the basic knowledge to design circuit boards, we suggest using our controller board to drive the display.

(Hong Kong – 08 Oct, 2004) – With respect to the increasing demand on TFT module for smart phone application, Solomon Systech Limited launched today their first single chip TFT LCD driver IC SSD1278 which supports 176×220 (QCIF+) resolution and 262K color smart phone system. SSD1278 is a single chip solution that includes gate/source driver blocks and power management circuit. SSD1278 with RGB interface, which is supported by common image processors/graphic controllers, is a perfect solution for speedy data transfer when using CMOS/CCD camera in the smart phone system.

SSD1278 is the smallest (with only 20.9 x 1.4mm² die size) and the simplest solution commercially available for QCIF+ resolution in the amorphous TFT display. The advantages of the small die size are not only in cost reduction of the module but also achievement of compact design of the phone. The smaller die allows thinner contact ledge at the LCD module and therefore smaller overall physical size. Besides, the advanced design technology from Solomon Systech achieves low power consumption in the TFT LCD module system. This is one of the essential factors in all portable systems. In an actual measurement of a 1.9″, 176×220 QCIF+ display module using Solomon Systech’s TFT driver SSD1278, the module power consumption at 262k color, 60Hz frame frequency and line inversion is only 8mW, while the power consumption at frame inversion is even 7mW. These low power consumption values enable Solomon Systech to become one of the most competitive TFT LCD driver suppliers in the market.

TFT LCDs have become the norm for small-to-medium size displays in a variety of products within industrial, medical, POS and consumer applications. Compared to passive-addressed monochrome LCDs, TFT displays offer higher contrast, wider viewing angles, faster response time and full color. And, TFT LCDs are now on cost parity with similar size passive LCD displays.

A typical TFT LCD module product consists of a TFT LCD panel, one or more COG (chip-on-glass) driver ICs, a backlight unit, and an interface FPC. Several TFT display interface technologies coexist today. Picking the right technology depends on specific end-product concerns. Most often the display panel input will dictate that choice since TFT panels are designed to be COG bonding pad compatible with a very limited number of driver ICs. This article discusses the interfaces between TFT LCD modules and the typical CPUs found in embedded applications.

Typical TFT interfaces are determined by the particular TFT panel size and resolution, as shown in the below table. HDMI and eDP require interface converting boards and generally are not used for small to medium-size TFT LCDs.TFT LCD SizesResolutionsTypical Interfaces UsedUp to 3.5″128×160 to 240×320SPI, parallel MPU or RGB

The LCD controller signals are two types: data signals and control signals. The data signals are connected to the LCD data bus and depend on the LCD color depth (8-bit, 9-bit, 16-bit, 18-bit). The control signals are used to define the operation type (read or write), and whether the operation involves in addressing LCD registers or the display RAM.

LVDS interfacing has several benefits for TFT displays. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from the display. Also, LVDS generally consumes less power, pin counts are lower and there are far fewer worries about signal integrity.

Modern TFT driver ICs are highly integrated chips combining the source driver, gate driver and timing controller (TCON) – as well as other functional circuits such as memory, power circuit, and image processors – into one single IC die. Some driver ICs support multiple interfaces that are selectable on the module FPC or through initialization code firmware.

As a designer and manufacturer of custom LCD modules, New Vision Display works with customers to select the most appropriate and cost-effective TFT display and electronic interface solution for their particular requirement. New Vision Display has nearly 30 years of industry experience as one of the world’s leading TFT LCD screen manufacturers.

(Hong Kong – 08 Oct, 2004) – With respect to the increasing demand on TFT module for smart phone application, Solomon Systech Limited launched today their first single chip TFT LCD driver IC SSD1278 which supports 176×220 (QCIF+) resolution and 262K color smart phone system. SSD1278 is a single chip solution that includes gate/source driver blocks and power management circuit. SSD1278 with RGB interface, which is supported by common image processors/graphic controllers, is a perfect solution for speedy data transfer when using CMOS/CCD camera in the smart phone system.

SSD1278 is the smallest (with only 20.9 x 1.4mm² die size) and the simplest solution commercially available for QCIF+ resolution in the amorphous TFT display. The advantages of the small die size are not only in cost reduction of the module but also achievement of compact design of the phone. The smaller die allows thinner contact ledge at the LCD module and therefore smaller overall physical size. Besides, the advanced design technology from Solomon Systech achieves low power consumption in the TFT LCD module system. This is one of the essential factors in all portable systems. In an actual measurement of a 1.9″, 176×220 QCIF+ display module using Solomon Systech’s TFT driver SSD1278, the module power consumption at 262k color, 60Hz frame frequency and line inversion is only 8mW, while the power consumption at frame inversion is even 7mW. These low power consumption values enable Solomon Systech to become one of the most competitive TFT LCD driver suppliers in the market.

Please see the DT028CTFT for reference designs. The schematics between the B and the C are the same with the exception that the B does not have the IPS interface.

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

Edge Electronics provides LCD backlighting solutions for Active (TFT) LCDs. From power products like CCFL inverters, to LED driver boards and LED rails from top manufacturers, to fully custom high bright LED backlighting enhancements, we can help with all of your LCD backlight needs.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

The field of large-sized LCD drive IC is quite difficult to enter. Besides the high technical requirements, large sized drive IC manufacturers must obtain the cooperation of large size panel manufacturers and top wafer OEM. There are only two panel production lines in China mainland, and the purchasing right of drive IC is controlled has to be obtained abroad. Magnachi, the associated company of Hydis, is one of top five global large-sized drive IC manufacturers. NEC, the associated company of Shanghai SVA-NEC, is the third largest global large-sized drive IC manufacturer.

The field of medium and small sized LCD drive IC is comparably easier to enter considering factors such as a fewer connections between LCD Panel manufacturers, a large number of medium and small LCD module manufacturers in China mainland with a self-purchase right. However, the high technical requirements for medium and small LCD drive IC can not be ignored.

Like large sized TFT-LCD drive IC, the medium and small sized TFT-LCD drives IC also need high pressure techniques. Source drive and gate drive separately needs 6V and 20V-40V. And medium and small sized TFT-LCD drives IC need to be as concentrated as possible, while large sized TFT-LCD only needs 0.35 micron.

Thanks to its rich experience, UMC is able to provide high pressure technique of 0.25 micron and 0.18 micron aiming at STN and TFT drive IC. TSMC has also declared that it had begun mass production with 0.18 micron technique, with a low power consumption of 40V. But TSMC and HJTC in China mainland are not able to do it yet.

TFT-LCD drive IC for mobile phones has the highest concentration degree as well as the highest technical requirements. Source drive IC and gate drive IC of large sized TFT-LCD drive IC are separate. Sometimes, the control part of digital clock control, power supply and cache memory are also separate. But the development trend of TFT-LCD drive IC for mobile phone is totally integrated, meaning that not only initiative drive IC, gate drive IC, clock control, power supply but also the cache memory should be integrated in one single chip. Only a few manufacturers are able to do so : NEC, TOMATO, and LEADIS etc, and especially Renesas, which is the largest medium and small sized TFT-LCD drive IC manufacturer in the world. While all Taiwan manufacturers produce source drives and gate drives separately.

Medium and small sized LCD drive IC manufacturers all have their own technical background or obtain technologies by purchase. The founder of LEADIS was once the manager of Samsung drive IC department. Solomon Systech was once LCD department of Motorola, and MANANCHIP entered this field after had purchased ISRON.

There is a long-term development for companies once the technical barrier has been crossed. Solomon Systech is a good example. Currently, it is the largest IC design corporation in China (except Taiwan). In 2005, the sales of Solomon Systech exceeded USD $400 million with a profit of USD $76 million. Its market share of color STN-LCD drive IC and OLED drive IC ranked first in the world. Especially in the field of OLED, its market share exceeds 60% with a gross profit margin maintains at 20%.

This article will take you through a high level overview of all of the parts of a TFT LCD display. The vast majority of what I have read on the internet makes this whole issue massively complex. I’m quite sure that this complexity problem is a real reflection of the serious design and manufacturing complexity in these displays and drivers. That being said, to get a conceptual understanding is much simpler, and is the point of this article.

A significant amount of my learning about this subject came from a 195 page powerpoint presentation by Dr. Fang-Hsing Wang entitled “Flat Panel Display : Principle and Driving Circuit Design“. He has graciously allowed me to reproduce a few of his images. This dude knows way way more about these circuits than I do and I would encourage you to read his work.

The fundamental element in a TFT display is the liquid crystal. These elements have the property that the crystals will align from horizontal (which blocks the light) to vertical (which lets most of the light through) based on the electric field applied to them. Basically, you shine light through the liquid crystal, which blocks some or all of the light, the remainder of the white light then goes through a color filter to make red, green, or blue. It works like this:

What does the schematic for one element in a pixel look like? And where is the T(transistor) in the TFT? The three letter acronym TFT stands for a thin film transistor that is physically on the top of the LCD matrix right next to each liquid crystal element. Here is a schematic model for one element in the array. C-LC represents the capacitance of the liquid crystal. CS is a storage capacitor that is used to hold the electric field across the liquid crystal when the transistor is OFF. To apply a voltage across the LC you just turn on the gate and apply the correct voltage to the column commonly known as the source.

You should notice that the “back” terminal of the two capacitors is called “VCOM” and is physically on the other side of the liquid crystal matrix from the TFT. All of the liquid crystal backsides in the display are connected to the same VCOM. A bit of painfulness in this system is that the CS capacitor leaks, which means that the LCD changes state which means that each pixel must be updated, properly called refreshed, on a regular basis.

If you have been thinking about this system you might have done a little bit of math and figured out that you are going to need an absolute boatload of source and gate driver signals. And you would be right! For example, a 4.3″ screen with 480×272 will require 480x272x3 elements which are probably organized into 480 rows by 816 columns. This would require a chip with at least 480+816=1296 pins, that is a lot. It turns out that for small screens <=3.5″ there are chips with enough pins to do the job. But, for larger screens, it requires multiple chips to do the job. The “…” in the picture above shows the driver chips being cascaded. The next thing to know is that “TFT Glass” usually has the driver chip(s) embedded into the screen at the edge (you can see that in the picture from Innolux above).

However, a 3.3v logic 1 is not anywhere high enough to drive the gate so that it can pass the much higher source voltage. So, you need to level shifter and a buffer to get the “right” voltage. On page 15, Dr. Wang made a nice picture of this circuit as well.

It turns out that this picture is conceptually correct, but the exact implementation has “a lot going on”. You can read about the next layer of circuit design in his presentation on pages 15-35.

In its most basic form, the TFT source driver is responsible for taking an 8-bit digital input value representing the value of an individual LCD element and turning it into a voltage, the driving the voltage. Like this:

The last issue that I will address in TFT LCD drivers is called Gamma Correction or more simply Gamma. Gamma is an intensity adjustment factor. For any given digital intensity input, you will need a non-linear translation to a voltage output on the source. For example a doubling of digital input (so that a pixel appears twice as bright) you will not double but instead will have some non-linear translation of the output voltage.

The good news is that this gamma correction is built into the display drivers. From my reading, this is sometimes done with digital processing, and sometimes done with an analog circuit. But in general, it appears to be tuned and programmed into the driver by the panel vendor for these smaller display.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey