que significa tft lcd factory

Las pantallas de cristal líquido normales, como las de las calculadoras, presentan elementos de imagen excitados en forma directa –se puede aplicar una tensión a través de un segmento sin que interfiera con otros segmentos de la pantalla. Esto no es posible en pantallas grandes con un gran número de píxeles, puesto que se requerirían millones de conexiones -conexiones en la parte superior e inferior para cada uno de los tres colores (rojo, verde y azul) de cada píxel. Para evitar esto, los píxeles son direccionados en filas y columnas, lo que reduce el número de conexiones de millones a miles. Si todos los píxeles de una fila son excitados mediante una tensión positiva y todos los píxeles de una columna son excitados con una tensión negativa, entonces el píxel que se encuentra en la intersección tiene el voltaje aplicado más elevado y es conmutado. El inconveniente de esta solución es que todos los píxeles de la misma columna reciben una fracción de la tensión aplicada, como ocurre con todos los píxeles de la misma fila, así a pesar de que no sean conmutados completamente, tienden a oscurecerse. La solución al problema es proporcionar a cada píxel su propio transistor conmutador, esto permite controlar a cada píxel por separado. La baja corriente de fuga del transistor implica que la tensión aplicada al píxel no se pierde durante las actualizaciones de refresco de la imagen en la pantalla. Cada píxel es un pequeño condensador con una capa transparente de óxido de indio y estaño en el frontal, una capa transparente en la parte posterior, y entre medio una capa aislante de cristal líquido.

La distribución de los circuitos en un TFT-LCD es muy similar a la utilizada en la memoria DRAM. Sin embargo, en vez de realizar los transistores usando obleas de silicio, estos son fabricados depositando una película delgada de silicio sobre un panel de vidrio. Los transistores ocupan sólo una pequeña fracción del área de cada píxel y la película de silicio de la superficie remanente es eliminada permitiendo que la luz pase a través de ella.

La capa del silicio para TFT-LCD se deposita generalmente usando el proceso denominado PECVD (Plasma Enhanced Chemical Vapor Deposition) de un precursor de gas silano (SiH4) para producir una película amorfa de silicio. El silicio policristalino también se utiliza en algunas pantallas donde se requieren TFTs con un rendimiento más alto, típicamente en pantallas donde se requiere una resolución muy alta o en aquellas donde se desea realizar algún procesamiento de datos en sí mismo. Ambos tipos de TFTs, los de silicio amorfo y los de silicio policristalino presentan una prestación muy pobre frente a los transistores fabricados a partir de cristales de silicio simples, normalmente durante la construcción quedan residuos que posteriormente con el tiempo pueden presentar píxeles apagados y se pueden propagar en líneas horizontales y verticales de manera progresiva.

TN+Film (Twisted Nematic + Film, Torsión Nemática + Película) o TN, es el tipo de visualización más común, atribuible a su coste de producción bajo y amplio desarrollo. El tiempo de respuesta de un píxel en los paneles TN modernos, es lo suficientemente rápido para evitar rastros de sombras y efecto fantasma (problemas de refresco), que eran un problema de los monitores LCDs de tecnología pasiva. Los tiempos de respuesta rápidos han sido la virtud más importante de esta tecnología, aunque en la mayoría de los casos este número no refleja el rendimiento a través de las transiciones de los posibles colores. Los tiempos de respuesta tradicionales fueron dados acuerdo a un estándar ISO como la transición desde el negro hacia el blanco y no reflejaron la velocidad de las transiciones de los tonos grises (una transición mucho más común para cristales líquidos en la práctica). El uso moderno de tecnologías RTC (Response Time Compensation - Overdrive) han permitido que los fabricantes reduzcan el tiempo de las transiciones de gris (G2G) significativamente, mientras que el tiempo de respuesta ISO queda casi igual. Los tiempos de respuesta son dados ahora en las cifras de G2G, con 4ms y 2ms como valores comunes para los modelos fundamentados en la tecnología TN+film. Esta estrategia de mercadotecnia, combinado con el coste relativamente más bajo de la producción para pantallas TN, ha resultado en el dominio de TN en el mercado del consumidor.

Una de las desventajas de las pantallas basadas en TN es su escaso ángulo de visión, especialmente en la dirección vertical, siendo la mayoría incapaces de mostrar los 16,7 millones de colores (color verdadero de 24 bits) disponibles de las tarjetas de gráficas modernas. Estos paneles especiales, con 6 bits por canal de color en lugar de 8, puede acercarse al color de 24 bits usando un método de tramado que combina píxeles adyacentes para simular el tono deseado. También pueden usar FRC (Frame Rate Control, control de tasa de tramas), el menos conspicuo de los dos. El FRC cicla muchas veces rápidamente sobre los píxeles para simular un tono en particular. Estos métodos de simulación de color son perceptibles para la mayoría de las personas y angustiosos para otros. FRC tiende a ser más notable en los tonos más oscuros. El motivo de tramado tiene la tendencia de hacer visibles los píxeles del LCD. En general, la reproducción de color y el ángulo de visión de los paneles de tipo TN son pobres. Los defectos en la amplitud de color (a menudo referenciados como unos porcentajes de la gama de colores de 1953 de la NTSC) también pueden atribuirse a la tecnología de retroiluminación. Para las pantallas con retroiluminación por CCFL (lámparas fluorescentes de cátodo frío) son comunes gamas de color del 40% a 76% respecto de la gama de color de NTSC, mientras que las pantallas retroiluminadas por LED blanco pueden extenderse al 100% de la gama de color de NTSC - una diferencia poco perceptible al ojo humano.

IPS (In-Plane Switching, Alternancia en el plano) fue desarrollado por Hitachi en 1996 para superar los pobres ángulos de visión y reproducción de color de los paneles TN. La mayoría también soporta 8 bits de color reales. Estas mejoras vinieron con una pérdida de tiempo de repuesta, que estaba inicialmente en el orden de los 50ms. Los paneles de IPS eran también sumamente costosos.

IPS desde entonces ha sido reemplazado por S-IPS (Super-IPS, Hitachi en 1998), que tiene todos los beneficios de la tecnología de IPS más un tiempo de refresco de píxel mejorado. Aunque la reproducción de color se acerca a la de los CRTs, el contraste es relativamente pobre. La tecnología S-IPS es ampliamente usada en los paneles de 20" y más. LG y Philips permanecen como dos de los fabricantes principales de paneles basados en S-IPS.

AS-IPS (S-IPS Avanzado), también desarrollado por Hitachi en 2002, mejora considerablemente el contraste de los S-IPS tradicionales al punto de ser superados solo por algunos S-PVAs. AS-IPS es también un término usado por monitores NEC (por ejemplo, NEC LCD20WGX2) basados en tecnología S-IPS, en este caso, desarrollada por LG.Philips

A-TW-IPS (IPS Blanco Real Avanzado), desarrollado por LG.Philips LCD para NEC, es un panel S-IPS personalizado con un filtro TW (Blanco Real) para hacer que el blanco se vea más natural e incrementar la gama de color. Esto se utiliza en LCDs profesionales o de fotografía.

H-IPS Lanzado a finales de 2006, es una evolución del panel IPS que mejora a su predecesor, el panel S-IPS. El panel H-IPS puede verse en el NEC LCD2690WUXi, Mitsubishi RDT261W 26"LCD y en el más reciente Apple iMac de aluminio de 24".

Otro contra de la tecnología IPS es que puede verse afectada por un problema de trasluz, debido a sus características. Deja pasar más luz en las zonas oscuras del que debería, por lo que en algunos ángulos de visión agudos, sobre todo verticales, puede verse que las zonas negras dejan de serlo, transformándose en un brillo que el mismo monitor genera. Se creó un filtro de polarización para solucionarlo, que es incorporado en los IPS de elevado coste.

Los analistas predijeron que MVA sería la tecnología a seguir, pero sin embargo TN ha dominado el mercado. Un factor contribuyente era el mayor costo de MVA, conjuntamente con un tiempo de respuesta más lento (que aumenta considerablemente cuando se dan cambios pequeños en la luminosidad). Los paneles de MVA más económicos también pueden usar tramado y FRC.

PVA (Alineación Vertical por Patrones) y S-PVA (Super Alineación Vertical por Patrones) son las versiones alternativas de la tecnología de MVA ofrecidas por Samsung. Desarrollado por separado, padece del mismo problema que el MVA, pero a cambio ofrece contrastes muy altos como 3000: 1. Los paneles PVA económicos también usan tramado y FRC. Todos los paneles S-PVA son de 8 bits de color reales y no usan ningún método de simulación de color. PVA y S-PVA pueden brindar una buena profundidad de negro, amplios ángulos de visión y S-PVA puede ofrecer además tiempos de respuesta rápidos gracias a modernas tecnologías de RTC.

PLS (Plane Line Switching) y S-PLS Es una tecnología actualmente en desarrollo por Samsung que permite ángulos de visión totales. Se puede considerar una mejora del panel IPS consistente en mejores ángulos, mejor calidad de imagen, mejor brillo y un precio más bajo. Los primeros monitores con esta tecnología son los modelos S27A850 y S24A850 de Samsung, salidos a finales de 2011.

Los dispositivos de visualización exteriores como un LCD TFT usan generalmente una conexión analógica VGA, mientras que la mayoría de los nuevos modelos disponen de una interfaz digital, como DVI o HDMI.

Dentro de un dispositivo de visualización externo hay una tarjeta controladora para convertir VGA, DVI, HDMI, CVBS, etc. a la resolución nativa digital RGB que el panel de pantalla pueda usar. En un portátil, el chip de gráficos producirá directamente una señal adecuada para la conexión del TFT incorporado. El mecanismo de control de la luz de fondo se incluye normalmente en la misma tarjeta controladora.

La interfaz de bajo nivel de STN, DSTN o paneles de pantalla TFT usan tanto TTL 5V como TTL 3,3V que transmiten reloj de píxeles, sincronización horizontal, sincronización vertical, rojo digital, verde digital y azul digital en paralelo. Algunos modelos también tienen señales de pantalla activa, dirección de barrido horizontal y vertical.

Las nuevas y grandes pantallas TFT (> 15 ") suelen utilizar señalización LVDS o TMDS que transmiten los mismos contenidos que la interfaz paralela, pero pondrá la señal de control y datos RGB en un determinado número de líneas de transmisión en serie que son sincronizadas con un reloj a la tasa datos de píxeles.

La intensidad de la luz de fondo se controla normalmente por variación de unos pocos voltios CC que es transformado a alto voltaje (1,3 kilovoltios) usando un convertidor AC-DC y enviado a la luz de fondo. También puede ser controlado por medio de un potenciómetro o, puede ser fijo. En algunos modelos usan una señal PWM para el control de la intensidad.

El panel de la pantalla sólo aceptará una señal de vídeo en la resolución determinada por el panel de matriz de píxeles que es determinado en el momento de fabricación. Algunos paneles de pantalla ignorarán los bits de color LSB para simplificar los interfaces de conexión (8bit -> 6bit/color) si tienen una resolución de color menor.

Los cristales líquidos del interior de la pantalla son extremadamente tóxicos. No deben ser ingeridos, o tocados por la piel o la ropa. Si se producen derrames debido a que la pantalla se agrieta o hace añicos, lávese inmediatamente con agua y jabón.

Debido al alto coste de construcción de las fábricas de TFT, son pocos los principales proveedores de paneles OEM para grandes paneles. Las principales proveedoras de paneles de cristal son:

Los paneles LCD TFT son habitualmente clasificados en las fábricas en tres categorías, en relación con el número de píxeles muertos, luz de fondo y la uniformidad de la luz de fondo y la calidad de los productos en general. Además, puede haber un máximo de ± 2ms de diferencia de tiempo de respuesta entre los paneles individuales que llegaron a la misma línea de montaje en el mismo día. Las pantallas con menor calidad se venden a los vendedores sin nombre o utilizando un «valor» de los monitores TFT (a menudo marcadas con la letra V detrás del tipo de número), las que se encuentran en medio se orientan a los juegos o a la oficina en casa (a veces marcadas con la letra S), y las mejores pantallas suelen estar reservadas para un uso «profesional» (marcado con la letra P o S después de su tipo de número).

El mercado del CRT fue desplazado por las pantallas TFT, LCD y LED, las cuales han sido sustitutas en monitores y televisores. Para comienzos de 2012, es prácticamente imposible encontrar monitores de un tamaño inferior a 17", además de haber pasado de formato 4:3 a formato panorámico 16:10 y posteriormente al formato cinematográfico 16:9. Las conexiones digitales desplazaron el analógico VGA para abrir paso al DVI, DVI-D, HDMI y al DisplayPort. Pese a ello, VGA continua integrándose en algunos monitores, televisores y tarjetas gráficas dado que se sigue utilizando de forma minoritaria.

El inconveniente actual es que la tecnología aún no permite alcanzar la calidad de imagen (existe una sensación de arenilla borrosa o pixelado en los TFT, LCD y LED) y velocidad de respuesta de los viejos CRT (2 ms). Aunque a favor hay una interesante cantidad de mejoras, como son un menor daño a la vista (mirar un CRT es comparable a observar una bombilla incandescente), resoluciones de imagen superiores (como FULL HD 1080p/1080i, XHD de 2560x1600 o incluso 4K) y lo que siempre clamó a su éxito, un peso y volumen considerablemente pequeños. Además de un consumo reducido, en especial si utiliza retroiluminación LED.

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

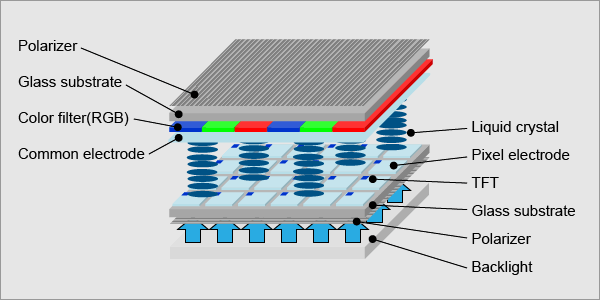

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

The TFT panel is composed of millions of TFT devices and ITO (In TI Oxide, a transparent conductive metal) regions arranged like a matrix, and the so-called Array refers to the region of millions of TFT devices arranged neatly, which is the panel display area. The figure below shows the structure of a TFT pixel.

No matter how the design of TFT display board changes or how the manufacturing process is simplified, its structure must have a TFT device and control liquid crystal region (if the light source is penetration-type LCD, the control liquid crystal region is ITO; but for reflective LCD, the metal with high reflection rate is used, such as Al).

The TFT device is a switch, whose function is to control the number of electrons flowing into the ITO region. When the number of electrons flowing into the ITO region reaches the desired value, the TFT device is turned off. At this time, the entire electrons are kept in the ITO region.

The figure above shows the time changes specified at each pixel point. G1 is continuously selected to be turned on by the driver IC from T1 to TN so that the source-driven IC charges TFT pixels on G1 in the order of D1, D2, and Dn. When TN +1, gATE-driven IC is selected G2 again, and source-driven IC is selected sequentially from D1.

Many people don’t understand the differences between generations of TFT-LCD plants, but the principle is quite simple. The main difference between generations of plants is in the size of glass substrates, which are products cut from large glass substrates. Newer plants have larger glass substrates that can be cut to increase productivity and reduce costs, or to produce larger panels (such as TFT display LCD TV panels).

The TFT-LCD industry first emerged in Japan in the 1990s, when a process was designed and built in the country. The first-generation glass substrate is about 30 X 40 cm in size, about the size of a full-size magazine, and can be made into a 15-inch panel. By the time Acer Technology (which was later merged with Unioptronics to become AU Optronics) entered the industry in 1996, the technology had advanced to A 3.5 generation plant (G3.5) with glass substrate size of about 60 X 72 cm.Au Optronics has evolved to a sixth-generation factory (G6) process where the G6 glass substrate measures 150 X 185 cm, the size of a double bed. One G6 glass substrate can cut 30 15-inch panels, compared with the G3.5 which can cut 4 panels and G1 which can only cut one 15-inch panel, the production capacity of the sixth generation factory is enlarged, and the relative cost is reduced. In addition, the large size of the G6 glass substrate can be cut into large-sized panels, which can produce eight 32-inch LCD TV panels, increasing the diversity of panel applications. Therefore, the global TFT LCD manufacturers are all invested in the new generation of plant manufacturing technology.

The TRANSISTor-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

The organic light display can be divided into Passive Matrix (PMOLED) and Active Matrix (AMOLED) according to the driving mode. The so-called active driven OLED(AMOLED) can be visualized in the Thin Film Transistor (TFT) as a capacitor that stores signals to provide the ability to visualize the light in a grayscale.

Although the production cost and technical barriers of passive OLED are low, it is limited by the driving mode and the resolution cannot be improved. Therefore, the application product size is limited to about 5″, and the product will be limited to the market of low resolution and small size. For high precision and large picture, the active drive is mainly used. The so-called active drive is capacitive to store the signal, so when the scanning line is swept, the pixel can still maintain its original brightness. In the case of passive drive, only the pixels selected by the scan line are lit. Therefore, in an active-drive mode, OLED does not need to be driven to very high brightness, thus achieving better life performance and high resolution.OLED combined with TFT technology can realize active driving OLED, which can meet the current display market for the smoothness of screen playback, as well as higher and higher resolution requirements, fully display the above superior characteristics of OLED.

The technology to grow The TFT on the glass substrate can be amorphous Silicon (A-SI) manufacturing process and Low-Temperature Poly-Silicon (LTPS). The biggest difference between LTPS TFT and A-SI TFT is the difference between its electrical properties and the complicated manufacturing process. LTPS TFT has a higher carrier mobility rate, which means that TFT can provide more current, but its process is complicated.A-si TFT, on the other hand, although a-Si’s carrier movement rate is not as good as LTPS’s, it has a better competitive advantage in cost due to its simple and mature process.Au Optronics is the only company in the world that has successfully combined OLED with LTPS and A-SI TFT at the same time, making it a leader in active OLED technology.

The LTPS membrane is much more complex than a-SI, yet the LTPS TFT is 100 times more mobile than A-SI TFT. And CMOS program can be carried out directly on a glass substrate. Here are some of the features that p-SI has over A-SI:

LCD screens are backlit to project images through color filters before they are reflected in our eye Windows. This mode of carrying backlit LCD screens, known as “penetrating” LCD screens, consumes most of the power through backlit devices. The brighter the backlight, the brighter it will appear in front of the screen, but the more power it will consume.

1971 – Lechner, F. J. Marlowe, E. O. Nester, and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs

2020 – TFT LCD display technology dominants the display market now. Within the last 20 years, it has wiped out the market of CRT (cathode-ray tube) and Plasma. The only challenges are OLED (organic light-emitting diode)and Micro LED (Maybe, still in lab).

TFT LCD Display (Thin-Film-Transistor Liquid Crystal Display) technology has a sandwich-like structure with liquid crystal material filled between two glass plates. Two polarizer filters, color filters (RGB, red/green/blue) and two alignment layers determine exactly the amount of light is allowed to pass and which colors are created.

Each pixel in an active matrix is paired with a transistor that includes a capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. The TFT layer controls light flow a color filter displays the color and a top layer houses your visible screen.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available.Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available. Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The TFT screen itself can’t emit light like OLED display, it has to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light emitting diodes) to generate their light and therefore utilize less power and require less depth by design.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

ZY utiliza material de retroiluminación ESR y pantalla Retina de densidad de píxeles ultra alta, que tiene las ventajas de una alta gama de colores, brillo y una pantalla delicada.

La pantalla LCD TFT Samsung A30s es demasiado gruesa y hay espacios después de la instalación. El grosor de la pantalla LCD ZY Incell se reduce a la mitad.

ZY adopta la tecnología avanzada TDDI IN-CELL, que es más liviana y delgada, con luz de fondo de alta gama de colores y brillo de alta definición, mostrando colores.

The thin film transistor liquid crystal display (TFT-LCD) is currently the most widely used liquid crystal display. This article introduces the basic information of TFT-LCD from its structure, principle, manufacturing process, characteristic index, research progress, and application.

TFT-LCD technology is a high technology that combines microelectronics technology and LCD technology. By using microelectronic fine machining technology and Si material processing technology, people have developed the technology of growing Si materials on large-area glass plates and TFT planar array technology. Combined with the increasingly mature LCD manufacturing technology, product quality can be continuously improved, and the automatic large-scale production capacity can be enhanced. In addition, the qualified rate can be improved, the cost can be reduced, and its performance/price ratio can be closer to CRT.

A thin film transistor (TFT) liquid crystal display is an active matrix display formed by integrating a TFT switch into a twisted nematic (TN) liquid crystal display. This way, the shortcomings of passive matrix display, such as cross-interference, less information, and slow writing speed, can be overcome. And the display quality is greatly improved so that it can be applied to the high-resolution panchromatic display of computers and other fields.

The main component of the finished TFT-LCD is an LCD display module (LCM), which is composed of a Panel and a Backlight. As the core part of the whole liquid crystal display, the Panel has the most complicated manufacturing process. What people usually call bright spots are generated during the manufacturing process of the Panel. The quality of the backlight can directly influence the display effect, and it is usually the key factor influencing the life of TFT-LCD.

A TFT array is built on the glass substrate at the lower layer of the panel. The ITO electrode of each pixel is connected to the TFT drain electrode, the grid is connected to the scanning bus, and the original power supply is connected to the signal bus. When the scanning signal voltage is applied, the original source electrode is turned on so that the signal voltage is applied to the storage capacitor and charged. The signal voltage of the storage capacitor is applied to the liquid crystal pixel at the frame rate so that the liquid crystal pixel is in a gated state.

At present, the grayscale has reached 256 levels; that is, 16.7 million colors can be obtained (almost full-color display). Since the industry came into being in the 1990s, the production line of thin film transistor (TFT) liquid crystal display has developed from the first generation to the 11th generation. For each renewal of generation, the area of substrate glass has been greatly increased, the output continuously improved, and the cost continuously reduced.

The insulating film, protective film, and semiconductor film are formed on Glass by the chemical PECVD (Plasma Enhanced Chemical Vapor Deposition) process. It is Plasma generated by injecting Gas between two electrodes and applying a high-frequency power supply.

For the assembly process of the TFT-LCD panel (screen), firstly, the cleaned color film substrate and TFT array substrate are coated with alignment film coating solution and are oriented by friction. Then the array substrate of the TFT is coated with sealing glue, and spacers with a size of 5-10 μ m are scattered on the array substrate as supporting points. Afterward, the array substrate and the color film substrate are assembled and sealed with sealing glue to form an empty box (Cell).

Response time is an important indicator to measure the quality of TFT-LCD, which refers to the response speed of TFT-LCD to input signals, that is, the response time of liquid crystal from dark to bright or from bright to dark. Generally speaking, it is divided into two parts: Tr (Rise Time) and Tf (Fall Time), and the response time is the sum of the two. The smaller the response time, the better. If it exceeds 40 milliseconds, the moving image will be hysteresis. At present, the standard response time of TFT-LCD is about 25 milliseconds, but a few models can reach 16 milliseconds. With 16ms ultra-fast response time, it can display more than 60 frames per second. It means it can completely solve the problems of ghost images and trailing smears existing in traditional LCD screens when playing games or watching DVDs.

Contrast refers to the brightness ratio between the bright area and the dark area of the display screen under the specified lighting conditions and observation conditions. Contrast is a parameter that directly reflects whether the TFT-LCD can present rich color levels. The higher the contrast, the better the layering of the restored picture. Presently, the nominal contrast of TFT-LCD is 250: 1 to 500: 1, and high-end products have a contrast of above 1000: 1. What should be explained here is that contrast must be matched with brightness to produce the best display effect. A high contrast ratio of 400: 1 or 500: 1 will make the display more colorful and softer, and the display effect of playing games or watching movies can be comparable to a CRT display.

The brightness of LCD screen is generally higher than that of traditional CRT display screen, and the brightness of TFT-LCD is generally in cd/m2 (lumens/square meter). The higher the brightness, the stronger the anti-interference ability of the display screen to the surrounding environment, and the brighter the display effect. This parameter should be at least 200cd/m2, preferably above 1000cd/m2 for industrial applications. The higher the brightness of the traditional CRT display screen, the greater its radiation. The luminance of TFT-LCD is obtained by the illumination of the LED (light-emitting diode) backlight, so there is no negative impact on the human body.

TFT-LCD is a backlight display device, and the light emitted by the backlight behind the LCD module inevitably leads to the only best viewing angle-facing up. When you look at TFT-LCD from other angles, color distortion will happen because the backlight can penetrate the next pixels and enter the human eye. The undistorted range is the visual angle of the LCD screen. The viewing angle of TFT-LCD is also divided into horizontal viewing angle and vertical viewing angle, and the horizontal viewing angle is generally larger than the vertical viewing angle. At present, as long as the horizontal viewing angle reaches 120 degrees and the vertical viewing angle reaches 140 degrees, the screen can meet the demands of most users. The latest TFT-LCD panel is produced with wide viewing angle technology, which can reach 140 degrees from top to bottom and 150 degrees from left to right, thus reducing the inconvenience caused by the small viewing angle. Of course, this performance can’t be compared with a CRT display with a viewing angle close to 180 degrees, but it is more than enough for most applications.

The pixel spacing of TFT-LCD refers to the interval between each pixel of the LCD screen. Currently, the standard pixel spacing of mainstream (16:9) 23.6-inch TFT-LCD products is generally 0.276 mm, and the corresponding resolution is 1920 × 1080.

The bandwidth of TFT-LCD is also an indicator to measure the LCD screen. Generally, the bandwidth of TFT-LCD is 80MHz. The large-screen TFT-LCD has the advantages of liquid crystal display and large-screen display, which makes the large-screen LCD products represented by 23.6-inch TFT-LCD favored by consumers. In addition, its visible area is larger than that of 24-inch color TV. Moreover, it has the advantage of no radiation, which can make users watch it at close range.

Since the panel thickness of TFT-LCD is the same, the main factors influencing the thickness of TFT-LCD will be the circuit control panel’s technology, the plastic shell’s design, and the compression of internal space. Of course, with the integration of a few cutting-edge liquid crystal technologies, the latest ultra-thin liquid crystal panels, thinner high-brightness LED technology, coupled with more integrated control IC design and more optimized heat dissipation treatment, the overall size of the product can be significantly reduced.

(5) Large-screen TFT-LCTV has begun to enter large-scale industrial production. The image quality of TFT-LCTV has reached or even exceeded CRT. For example, the resolution of the 86-inch TFT LCTV is 1920 × 1200, and its horizontal and vertical viewing angles are 170 degrees; The 100-inch TFT LC TV has been successfully developed and commercialized.

(6) Large-area low-temperature polysilicon TFT-LCD has been successfully developed and put into industrial production, and amorphous silicon TFT self-scanning LCD has been commercialized;

(7) Reflective TFT-LCD color display is beginning to be commercialized. For example, a 5.8-inch reflective display with a resolution of 400 × 234 and a picture ratio of 16: 9 has a reflectivity of 30%, a response speed of 30ms, and a power consumption of 0.15 watts.

(10) Backlight and inverter. Although reflective LCD is being actively developed, transmissive TFT-LCD with backlight will still be the mainstream product for a long time. The backlight is an essential accessory. Germany has developed a flat fluorescent lamp backlight for liquid crystal modules, with a brightness of 5000-7000cd/m2 and a life of 100,000 hours. Some new self-heating backlights can normally work in the range of-40 ℃ to 85 ℃. OEL backlight and high brightness LED backlight have been successfully developed and started to be used in TFT-LCD, Linfinity. Microelectronics invented a long-life inverter with cold cathode backlight, the modulation range of the light source of which reaches 500: 1.

TFT-LCD is mainly used in computers, video terminals, communication, instrumentation, and other industries. The main application fields are laptops, desktop computer monitors, workstations, industrial monitors, global positioning systems (GPS), personal data processing, game consoles, portable VCDs, DVDs, and other portable devices.

BOE was the leading manufacturer of large-area TFT LCD display units worldwide in 2020, accounting for approximately 27.7 percent of global unit shipments. LG Display and Innolux Corp. rounded out the top three manufacturing companies that year, with a shipment share of 14.1 and 13.7 percent, respectively.

Thin-film transistor (TFT) displays are flat-panel LCD displays in which each pixel on the screen is individually controlled by one or multiple transistors. These transistors act as individual electronic switches that allow pixels to change state more quickly, resulting in faster response rates, clear resolution, and easily controlled vibrant colors. Global shipments of TFT LCD displays have increased in recent years, reaching an all-time high of over 771 million units in 2019. However, recent data projects a growing oversupply in the years to come, as consumer demand for large TFT LCD TV and monitor devices is not expected to meet production capacity.

BOE Technology has shipped the largest quantities of large-area TFT LCD displays worldwide since 2018. The Chinese company provides interface devices, smart IoT systems and smart medicine technologies, but it is its work in the display industry that has helped the panel maker build a global reputation. With the commissioning of the world’s first gen 10.5 TFT LCD production line in 2018, BOE accelerated the mass production of large TFT LCD panels and surpassed its biggest competitor LG Display for the first time.Read moreShare of global large-area TFT LCD display unit shipments from 2016 to 2020, by manufacturerCharacteristicBOELG DisplayInnolux Corp.AUOSamsungChina StarOthers--------

IHS, & Website (Display Daily). (March 30, 2020). Share of global large-area TFT LCD display unit shipments from 2016 to 2020, by manufacturer [Graph]. In Statista. Retrieved February 21, 2023, from https://www.statista.com/statistics/612991/global-large-area-tft-lcd-display-share/

IHS, und Website (Display Daily). "Share of global large-area TFT LCD display unit shipments from 2016 to 2020, by manufacturer." Chart. March 30, 2020. Statista. Accessed February 21, 2023. https://www.statista.com/statistics/612991/global-large-area-tft-lcd-display-share/

IHS, Website (Display Daily). (2020). Share of global large-area TFT LCD display unit shipments from 2016 to 2020, by manufacturer. Statista. Statista Inc.. Accessed: February 21, 2023. https://www.statista.com/statistics/612991/global-large-area-tft-lcd-display-share/

IHS, and Website (Display Daily). "Share of Global Large-area Tft Lcd Display Unit Shipments from 2016 to 2020, by Manufacturer." Statista, Statista Inc., 30 Mar 2020, https://www.statista.com/statistics/612991/global-large-area-tft-lcd-display-share/

IHS & Website (Display Daily), Share of global large-area TFT LCD display unit shipments from 2016 to 2020, by manufacturer Statista, https://www.statista.com/statistics/612991/global-large-area-tft-lcd-display-share/ (last visited February 21, 2023)

Share of global large-area TFT LCD display unit shipments from 2016 to 2020, by manufacturer [Graph], IHS, & Website (Display Daily), March 30, 2020. [Online]. Available: https://www.statista.com/statistics/612991/global-large-area-tft-lcd-display-share/

Chen JC, Hu SJ, Huang PTB, Lin CJ, Chao KJ, Chen CC (2010) Finite capacity planning for multiple TFT-LCD color filter fabs. Key Eng Mater 419–420:637–640

Chen WL, Huang CY, Lai YC (2009) Multi-tier and multi-site collaborative production: illustrated by a case example of TFT-LCD manufacturing. Int J Comput & Ind Eng 57(1):61–72

Tsai KM, Wang SC (2009) Multi-site available-to-promise modeling for assemble-to-order manufacturing: an illustration on TFT-LCD manufacturing. Int J Prod Econ 117(1):174–184

Park BC, Park ES, Kim BH, Choi BK, Lee JH (2008) Simulation based planning and scheduling system for TFT-LCD fab. Proc 2008 Winter Simul Conf (WSC), pp. 2271–2276

Wu HH, Chen CP, Tsai CH, Yang CJ (2010) Simulation and scheduling implementation study of TFT-LCD Cell plants using Drum–Buffer–Rope system. Expert Syst Appl Vols 37:8127–8133

Lin JT, Chen YY (2007) A multi-site supply network planning problem considering variable time buckets—a TFT-LCD industry case. Int J Adv Manuf Technol 33:1031–1044

Sharp demonstrated a fourteen-inch TFT-LCD for TV in 1988 when the display size of the mass-produced TFT-LCD was three inches. The high display quality in Cathode Ray Tube size convinced other electronic companies to join the infant TFT-LCD industry aimed at emerging full-color portable PCs. Two decades later, TFT-LCDs replaced CRTs, making the vision of RCA"s LCD group in the 1960s a reality.

Describe briefly the intended site(s) of the milestone plaque(s). The intended site(s) must have a direct connection with the achievement (e.g. where developed, invented, tested, demonstrated, installed, or operated, etc.). A museum where a device or example of the technology is displayed, or the university where the inventor studied, are not, in themselves, sufficient connection for a milestone plaque.

Please give the address(es) of the plaque site(s) (GPS coordinates if you have them). Also please give the details of the mounting, i.e. on the outside of the building, in the ground floor entrance hall, on a plinth on the grounds, etc. If visitors to the plaque site will need to go through security, or make an appointment, please give the contact information visitors will need.

The milestone plaque is to be kept in Sharp Technology Innovation Museum, and shown to the public along with other milestones of Sharp business activities of a 100 year history.

Sharp Technology Innovation Museum is located in the premise of Sharp Technology Center where LCD research was started and culminated in mass-producing the world-first mini-calculator mounted with LCD and C-MOS logic : the calculator is displayed at the British Science Museum.

It showed that an ideal display, namely, a flat, low-power, light-weight, CRT-sized full-color video display ,which could be used also in high ambient light, is technologically feasible, and that is exactly what had been long waited for to be used in an emerging information age since LCD was press-released in 1968 by RCA.

3. A large mother glass scheme could work for a-Si-TFT-LCD, which was proved by the high display uniformity across the entire display area. The mother glass 300mm x 320mm was the very forerunner of the mother glass generation competition which started around 1990, 2 years after Sharp 14-in. full color TFT-LCD was demonstrated.

At the time when a mere small 3-in. a-Si-TFT-LCD production was just started with poor yield, unstable and far-from-being-matured production equipment, small output capacity drivers, engineers had to prepare line-defect free TFT-LCD panels with high display quality, meaning large contrast ratio, high color saturation with high uniformity, and they made a precise electrical and physical system analysis and designing and devised redundant pixel and bus line schemes, and employed normally-white LCD operation mode, which was first employed in 3-in. TFT-LCD panel, and developed the TFT-LCD panel and its driving scheme to achieve higher contrast ratio, better gray scale and full-color rendition, wider tolerance in temperature and cell-gap variations, leading higher display uniformity across the entire large display area, than normally-black mode could achieve in those days.

Sharp"s first application of TFT-LCD was television which is supposed to be exposed to "critical" consumers 3-5 hours everyday for more than 10 years.

So, from the very beginning of development project started in April 1984, TV business group, who understand the market, located in Yaita-shi, Tochigi-ken, and TFT-LCD research group located in Tenri-shi, Nara-ken, worked closely; even though, two places are about 600km apart.

TV group, headed by Magohiro ARAMOTO, whose leading member was Masakazu YAMAMOTO, joined by Shuhji KOHZAI later on, showed the clear target specifications and pointed out critical display quality factors to be improved, and also transferred TV evaluation methods to TFT-LCD research group; TFT-LCD research group, headed by Masataka MATUURA, whose leading members were Funada FUMIAKI, with Yutaka ISHII as sub-leader, for LC material and operation mode and acting deputy to Matsuura, Kohzo YANO for TFT process, Hiroshi TAKE for system designing of TFT, LCD panel and driving circuitry, and evaluation of TFT-LCD as an integrated system, achieved and acquired them.

In the production project started in November 1985, LCD business group, headed by Mitsuo ISHII, located in Yamato-Kohriyama-shi, Nara-ken, joined the project, bringing in panel production technology including large mother glass handling know-hows, and, the thin-film solar battery group, headed by Toshio TAKEMOTO, located in Shinjoh-shi, Nara-ken, was also incorporated into ISHII"s group,afterward, bringing in amorphous-Silicon(a-Si) thin-film solar-cell mass-production technology whose basics are similar to those of a-Si TFT.

In the Japanese Consumer Electronics Show, October 1986, the production project demonstrated 3-inch TFT-LCD TV which employed a normally-white LCD operation mode. The mechanical design of the 3-inch TFT-LCD module mounted on the demonstrated TV was done by Kenichi UKAI who joined the project June 1986 from Electronic Component Business Division, whose main products included miniaturized electronic TV tuners, located in Osaka-shi, Osaka-fu.

The world-first TFT-LCD factory with a large mother glass 300mmx320mm was build in the precinct of Research and Development Group, located in Tenri-shi, Nara-ken, toward the end of 1986, near the Central Reaearch Laboratories TFT-LCD research group belonged to.

April 1987, YANO and TAKE of TFT-LCD research group moved to LCD Business Division whose general manager was Isamu WASHIZUKA, to be the technology and engineering core members of the newly-created The 3rd Production Department which had all the essential functions to execute TFT-LCD business, such as TFT-LCD process engineering, electronics and mechanical engineerings, administration, and production, irregularly incorporated with Mitsuo ISHII as general manager.

The 1st Sharp LC-TV "3C-E1" with 3-inch TFT-LCD, display dot 384Hx240V in a triangle arrangement, was put on the martket June 1987, half a year later than originally scheduled; the TFT-LCD production yield was miserable, though.

In one of meetings held everyday in the evening to improve production yield of 3-inch TFT-LCD panel, Washizuka gave an additional mission to look into the future, and to search for TFT-LCD technology capability for TV, and instigated young engineers to study and propose larger display prototype development plans without giving any clear target size numbers and time frames.

Around middle of 1987, a voluntary project team was set up, headed by Mitsuo ISHII, whose leading members were Toshio AKAI for product planning, Kohzo YANO for TFT-LCD process and Hiroshi TAKE for electronics and system.

TAKE made a phone call to Magohiro ARAMOTO, general manager of TV Division, and had guided the TFT-LCD development project to improve display quality for TV, to try to understand the TV market, and asked ARAMOTO what would be the minimum size of TFT-LCD to be widely used by people.

TAKE, evaluation and characterization research engineer by background, knew the difficulty to prepare 14-in. panel using the same process and equipment used to mass-produce 3-in. panels with poor yield, but decided to accept ARAMOTO’s number 14-in., saying to himself the possible largest size on the mother glass would show up, more clearly than smaller sizes, problems and issues TFT-LCD had to solve and tackle with to be a viable technology in TV and other markets dominated by CRTs.

The target TFT-LCD panel specifications was accepted in the project team after YANO, with Hiroaki KATOH as his process designing section leader, made a thorough review of the TFT-LCD process and equipment in the 3-in.-mass-producing factory to make sure 14-in. was NOT impossible , and authorized by WASHIZUKA afterwards.

The 14-in. TFT-LCD panels were prepared by using the production line whose main product was 3-inch TFT-LCD panel, and 4-inch TFT-LCD production was just started.

At the very beginning of a-Si-TFT-LCD business startup, this work clearly showed a-Si-TFT-LCD have the potential to replace monster CRT in the coming information age by its superior characteristics: flatness, light-weight, small power consumption, high saturation full-color rendition, high readability in high ambient light, realized on the 14-in. display size, the most dominant size in the contemporary market by using the technology which was developed to mass-produce twenty 3-in. TFT-LCD TV panels laid out on the mother glass of 300mm x 320mm dimensions.

TV business group knew the market and joined the development project from the very beginning and gave a clear display quality target to TFT-LCD research group to achieve and make the TFT-LCD a viable display technology against CRT dominance.

[114] T. Nagayasu, T. Oketani, T. Hirobe, H. Kato, S. Mizushima, H. Take, K. Yano, M. Hijikigawa, and I. Washizuka, “A 14-in-diagonal full color a-Si TFT LCD,” in Proc. Int. Display Research Conf., San Diego, CA, Oct. 1988, pp. 56–58.

[2] B.J.Lechner, "History Crystallized_A First-Person Account of the Development of Matrix-Addressed LCDs for television at RCA in the 1960s",Information Display 1/08 p26-30

La pantalla LCD es una tecnología de visualización muy madura. Las pantallas OLED están surgiendo y se utilizan en muchos teléfonos móviles y televisores. Micro LED es una nueva generación de tecnología de visualización que proporcionará mejores efectos visuales.

LCDPantalla de cristal líquido, la pantalla de cristal líquido. La pantalla LED se refiere a un tipo de pantalla de cristal líquido (LCD), es decir, una pantalla de cristal líquido con LED (diodo emisor de luz) como fuente de luz de fondo. Aquí hay una explicación del principio de funcionamiento de TFT LCD.

Bajo costo y larga vida útil: la tecnología de pantalla LCD es relativamente madura. En comparación con OLED, LCD tiene menor dificultad y costo de fabricación, y tiene una vida útil más larga

Sin estroboscópico: la luz de fondo de la pantalla LCD es un panel de luz de fondo LED blanco independiente, por lo que básicamente no se puede lograr ningún parpadeo;

Contraste bajo: la pantalla LCD no puede apagar la luz de fondo cuando se muestra en negro, pero bloquea la luz mediante moléculas de cristal líquido, por lo que aparecerá en un color blanco grisáceo.

OLEDEl diodo emisor de luz orgánico (OLED) se refiere al fenómeno en el que los materiales semiconductores orgánicos y los materiales emisores de luz son impulsados por un campo eléctrico y conducen a la emisión de luz a través de la inyección y recombinación de portadores. Bajo la acción del campo eléctrico, los huecos generados por el ánodo y los electrones generados por el cátodo se moverán, se inyectarán en la capa de transporte de huecos y la capa de transporte de electrones, respectivamente, y migrarán a la capa emisora de luz. Cuando los dos se encuentran en la capa emisora de luz, se generan excitones de energía, excitando así las moléculas emisoras de luz y finalmente produciendo luz visible.

Bajo consumo de energía y flexibilidad: en comparación con LCD, OLED guarda la estructura de la retroiluminación, el cristal líquido y el filtro de color, reduce el consumo de energía y puede realizar una visualización flexible;

Alta relación de contraste, alto brillo, alta eficiencia luminosa y colores de imagen más vivos: OLED es autoluminoso, por lo que puede ser completamente no luminoso cuando sea necesario, y el negro de la pantalla es más puro;

El fenómeno estroboscópico es obvio, el color es brillante y hay un problema de tono de color, que causará daño a los ojos cuando se use durante mucho tiempo;

Micro LEDMicro LED (también conocido como μLed) se refiere a un chip con un tamaño inferior a 100 μm. Al igual que los LED ordinarios, también es autoiluminado. Los chips LED con tres colores luminosos RGB se utilizan para formar píxeles uno por uno para la visualización.

Comparado con LCD y OLED, La pantalla Micro LED tiene una velocidad de respuesta rápida, alto brillo, gran ángulo de visión, buen efecto de color y larga vida útil

Tiene las características de autoiluminación sin retroiluminación, tamaño pequeño, ligero y delgado, y también puede lograr el efecto de ahorro de energía.

Tecnología de chip: para los Micro LED que retienen el sustrato, el mayor desafío es cortar. A medida que el tamaño del chip se vuelve más pequeño, el rendimiento dividido también disminuye.

Conducción de la tecnología IC: cuando Micro LED está en uso, su corriente de conducción de energía es muy baja en comparación con un espacio pequeño. Bajo corriente baja, el estado de escala de grises bajo del IC tradicional no es bueno, lo que hará que Micro LED tenga la misma corriente pero el brillo La diferencia es grande o incluso algunas partes no son brillantes.

Inspección y mantenimiento: debido a que el tamaño de Micro LED es demasiado pequeño, el tamaño de su electrodo suele ser más pequeño que el de la aguja de la sonda, por lo que no se puede inspeccionar con la tecnología convencional de inspección puntual.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey